Production method of squeezing type rubber roller

A production method and technology of rubber rollers, applied in the field of rubber roller processing, can solve the problems of high energy consumption and high cost of vulcanization process, and achieve the effects of short processing cycle, cost reduction and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

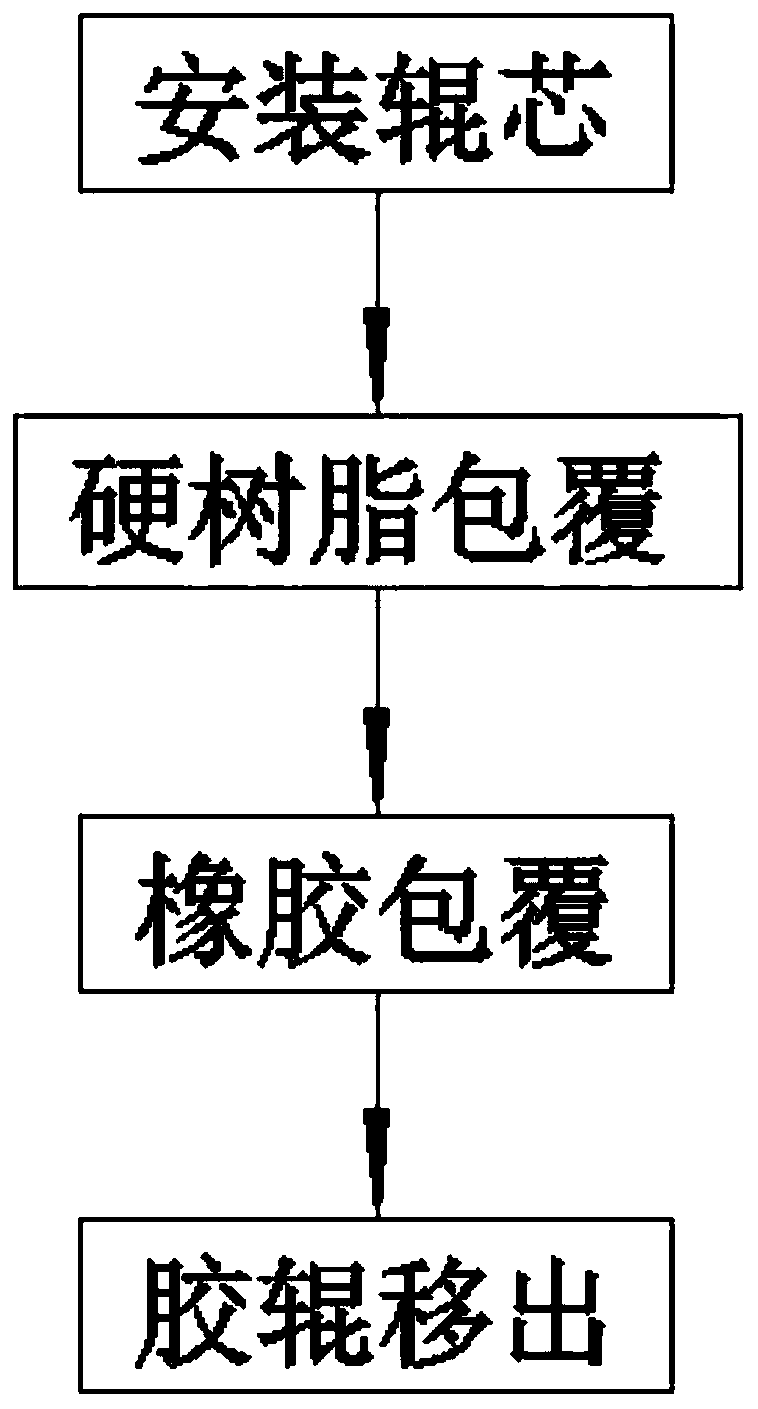

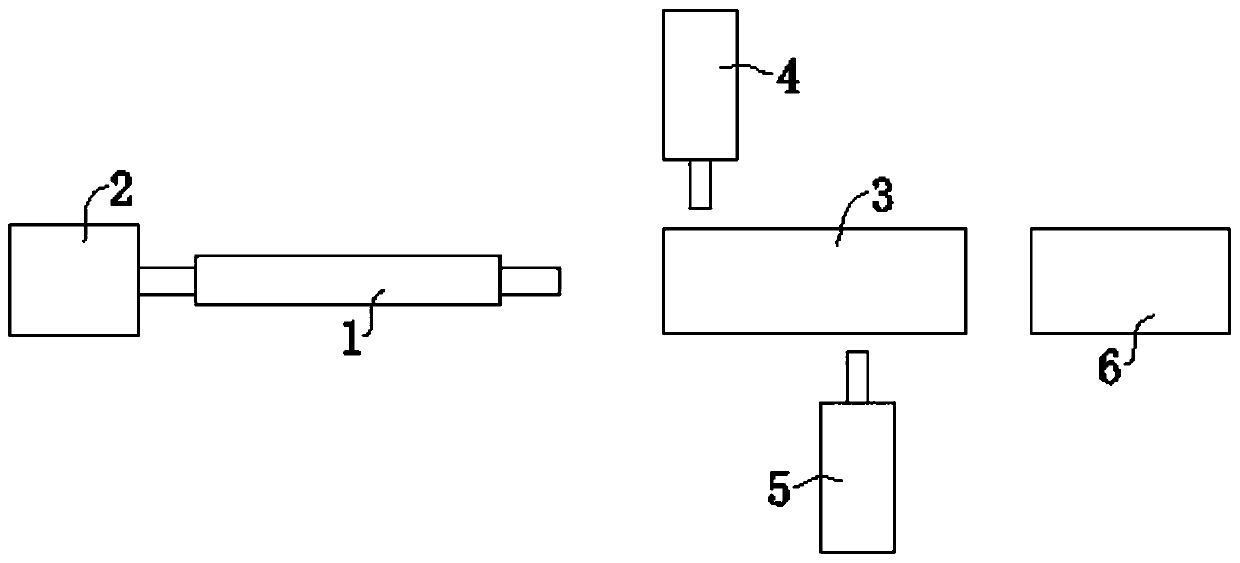

[0023] Embodiment 1: a kind of production method of extruded rubber roller, as figure 1 , 2 shown, including the following steps:

[0024] S1, install roller core 1

[0025] The roller core 1 is pushed by the tractor 2, so that the roller core 1 enters the mold 3, and under the traction of the tractor 2, the roller core 1 advances in parallel in the mold 3. The roller core 1 should be placed horizontally in the mold 3, the interior of the mold 3 is hollow, and the inner wall of the mold 3 is 10 cm away from the peripheral surface of the roller core 1, so as to be extruded and coated.

[0026] S2, hard resin coating

[0027] While the roller core 1 advances in parallel, the 1# extruder 4 extrudes the hard resin so that the hard resin is completely and stably coated on the peripheral surface of the roller core 1 .

[0028] S3, rubber covering

[0029] After the hard resin is coated, 2# extruder 5 extrudes the rubber so that the rubber is completely and stably fused and coat...

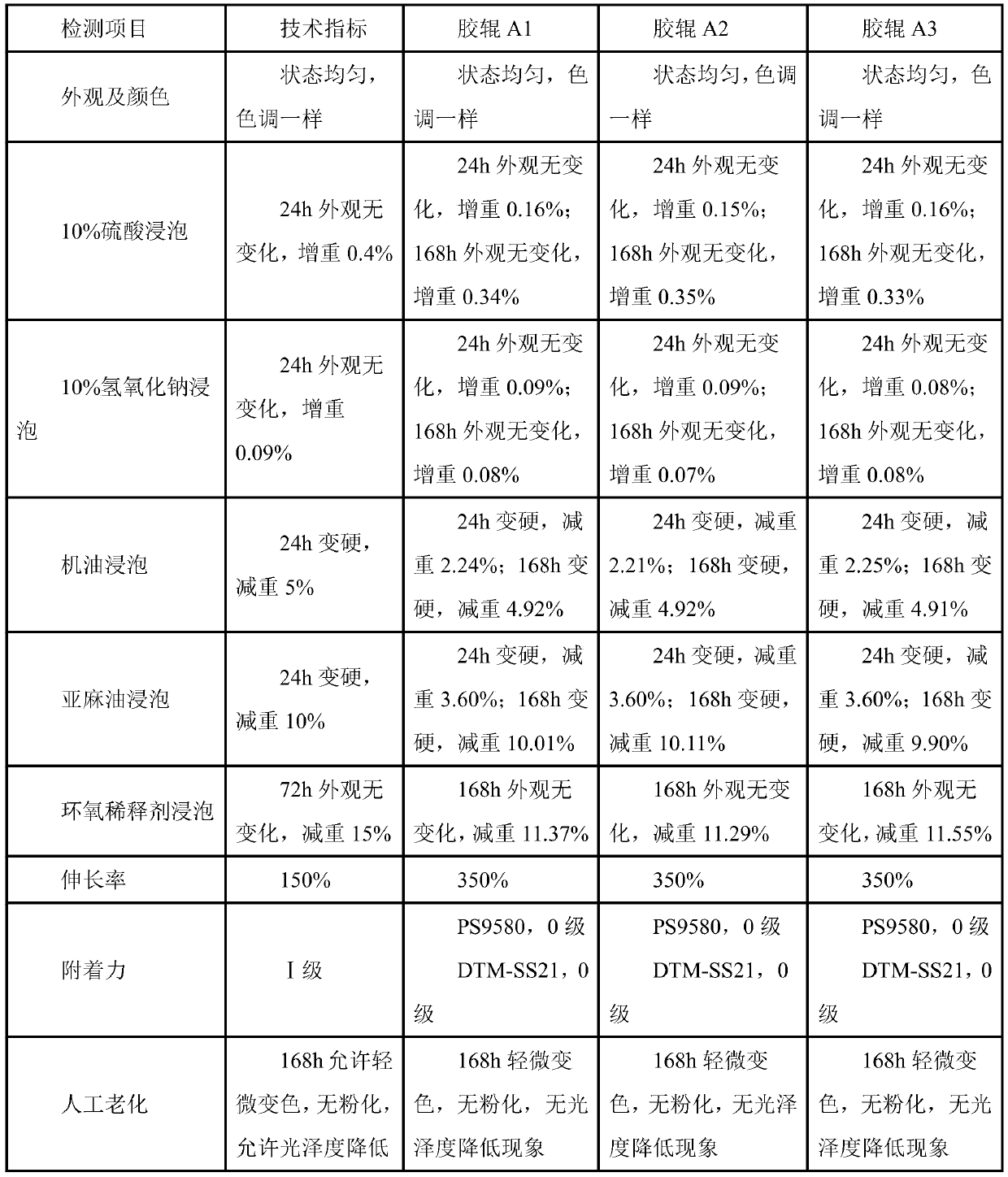

Embodiment 2

[0032] Embodiment 2: A kind of production method of extruded rubber roller, the difference with embodiment 1 is that the temperature of feeding section of 1# extruder 4 and 2# extruder 5 is 160 ℃, and the temperature of compression section is 170 ℃. °C and the temperature of the melting section are both 190 °C, and the temperature of the metering section is both 205 °C. Cot A2 was prepared.

Embodiment 3

[0033] Embodiment 3: A production method of extruded rubber rollers, the difference from Example 1 is that the temperature of the feeding section of 1# extruder 4 and 2# extruder 5 is 190°C, and the temperature of the compression section is 220°C. °C, the melting section temperature is 210 °C, and the metering section temperature is 205 °C. Cot A3 was produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com