Preparation method of high temperature-resisting mullite fiber porous heat insulation tile

A technology of mullite fiber and heat-insulating tile is applied in the field of preparation of high-temperature resistant mullite fiber porous heat-insulating tile, which can solve the problems of not high temperature resistance, inability to coat fibers well, and the like. Uniform distribution, good coating, good fiber coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

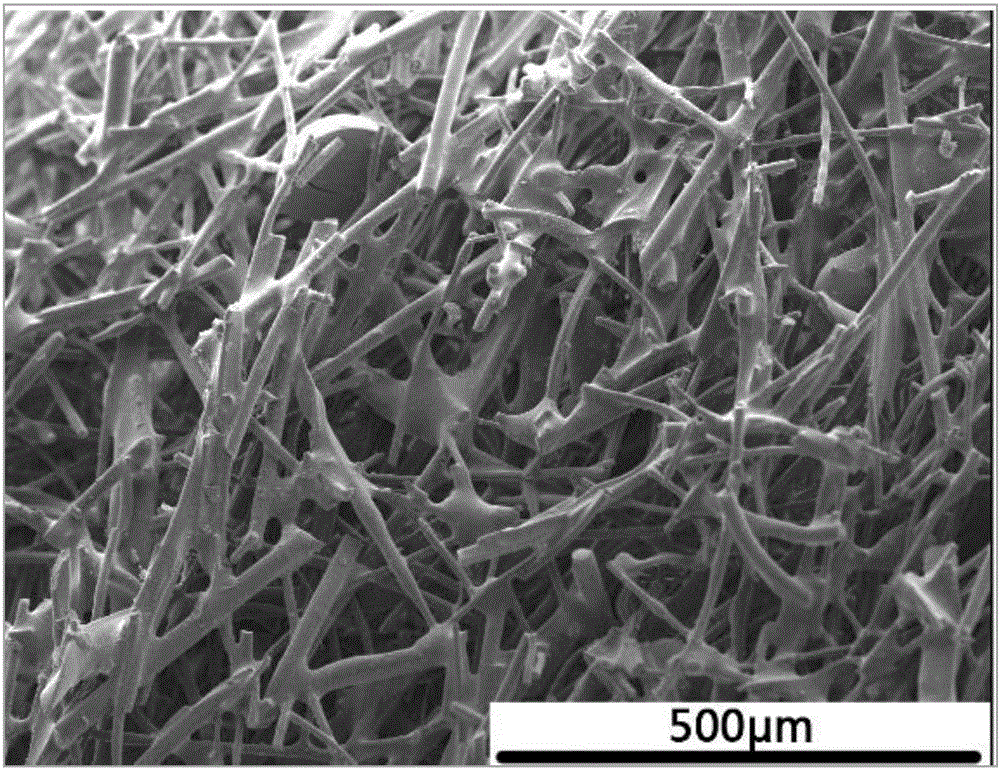

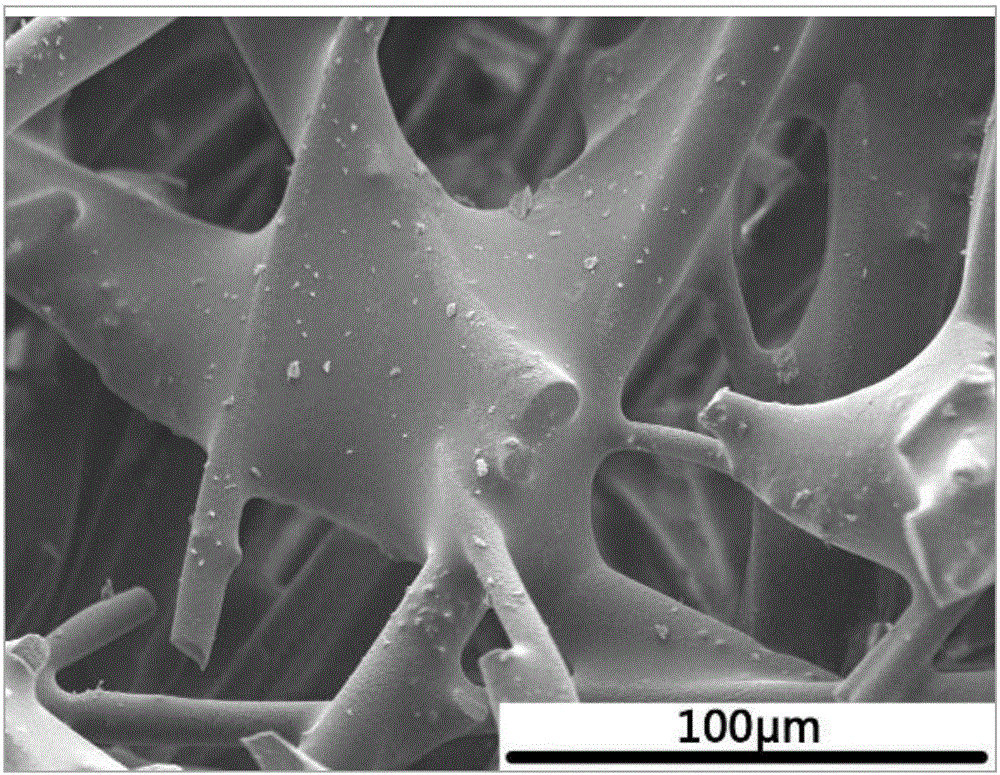

[0037] In this embodiment, a method for preparing a mullite fiber porous heat-insulating tile is specifically carried out according to the following steps:

[0038] (1) The polycrystalline mullite fiber is sheared by a fiber pulverizer, and the shearing time is 2 minutes to obtain a chopped mullite fiber with a length of 600 μm;

[0039] (2) Mix 20g of acrylamide (AM), 100g of tert-butanol (TBA) and 2g of methylenebisacrylamide (MBAM) evenly to obtain a premixed solution;

[0040] (3) Weigh 100g of the premixed solution obtained in step (2), add 2g of Si powder, and stir with an electromagnetic stirrer until the silicon powder is completely dispersed in the premixed solution to obtain a premixed slurry;

[0041] (4) Put the slurry obtained in the step (3) into a ball mill and carry out ball milling for 6h to obtain a more evenly dispersed ceramic slurry;

[0042] (5) Weigh 15g of the polycrystalline mullite fiber obtained in step (1), and slowly add the fiber into the slurry ...

Embodiment 2

[0048] In this embodiment, a method for preparing a mullite fiber porous heat-insulating tile is specifically carried out according to the following steps:

[0049] (1) The polycrystalline mullite fiber is sheared by a fiber pulverizer, and the shearing time is 6 minutes to obtain a chopped mullite fiber with a length of 500 μm;

[0050] (2) acrylamide (AM), tert-butanol (TBA) and methylenebisacrylamide (MBAM) according to acrylamide (AM): tert-butanol (TBA): methylenebisacrylamide (MBAM) = The mass ratio of 20:80:2 is mixed evenly to obtain a premixed solution;

[0051] (3) Weigh 80g of the premixed solution obtained in step (2), add 3.2g of Si powder, and stir with an electromagnetic stirrer until the silicon powder is completely dispersed in the premixed solution to obtain a premixed slurry;

[0052] (4) Put the slurry obtained in the step (3) into a ball mill and carry out ball milling for 8h to obtain a more evenly dispersed ceramic slurry;

[0053] (5) Weigh 16g of the...

Embodiment 3

[0057] In this embodiment, a method for preparing a mullite fiber porous heat-insulating tile is specifically carried out according to the following steps:

[0058] (1) The polycrystalline mullite fiber is sheared by a fiber pulverizer, and the shearing time is 10 minutes to obtain a chopped mullite fiber with a length of 400 μm;

[0059] (2) acrylamide (AM), tert-butanol (TBA) and methylenebisacrylamide (MBAM) according to acrylamide (AM): tert-butanol (TBA): methylenebisacrylamide (MBAM) = The mass ratio of 20:60:2 is mixed evenly to obtain a premixed solution;

[0060] (3) Take 90g of the premixed solution obtained in step (2), add 5.4g of Si powder, and stir with an electromagnetic stirrer until the silicon powder is completely dispersed in the premixed solution to obtain a premixed slurry;

[0061] (4) Put the slurry obtained in the step (3) into a ball mill and carry out ball milling for 8h to obtain a more evenly dispersed ceramic slurry;

[0062] (5) Weigh 27g of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com