PEDOT-coated lithium titanate nano particles preparation method and application thereof

A nanoparticle, lithium titanate technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high cost and complex application process, and achieve the effects of high rate performance, easy collection, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

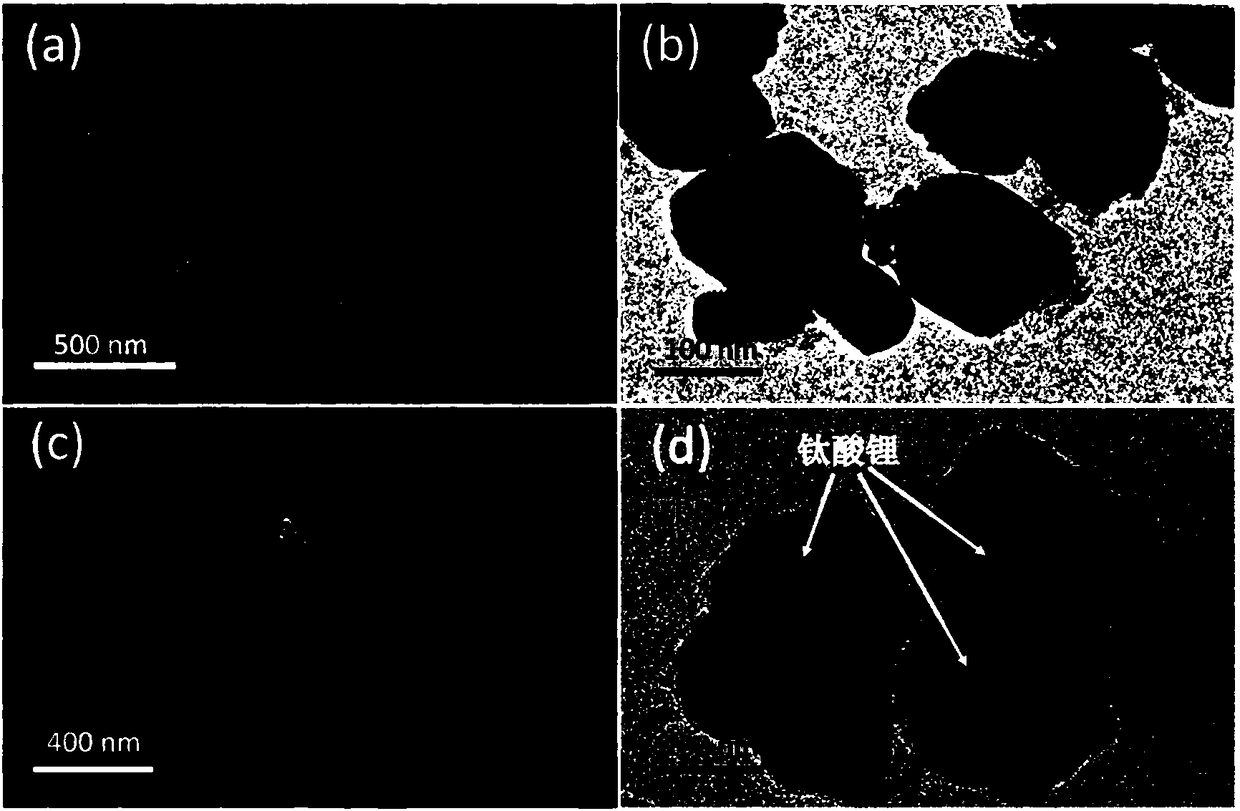

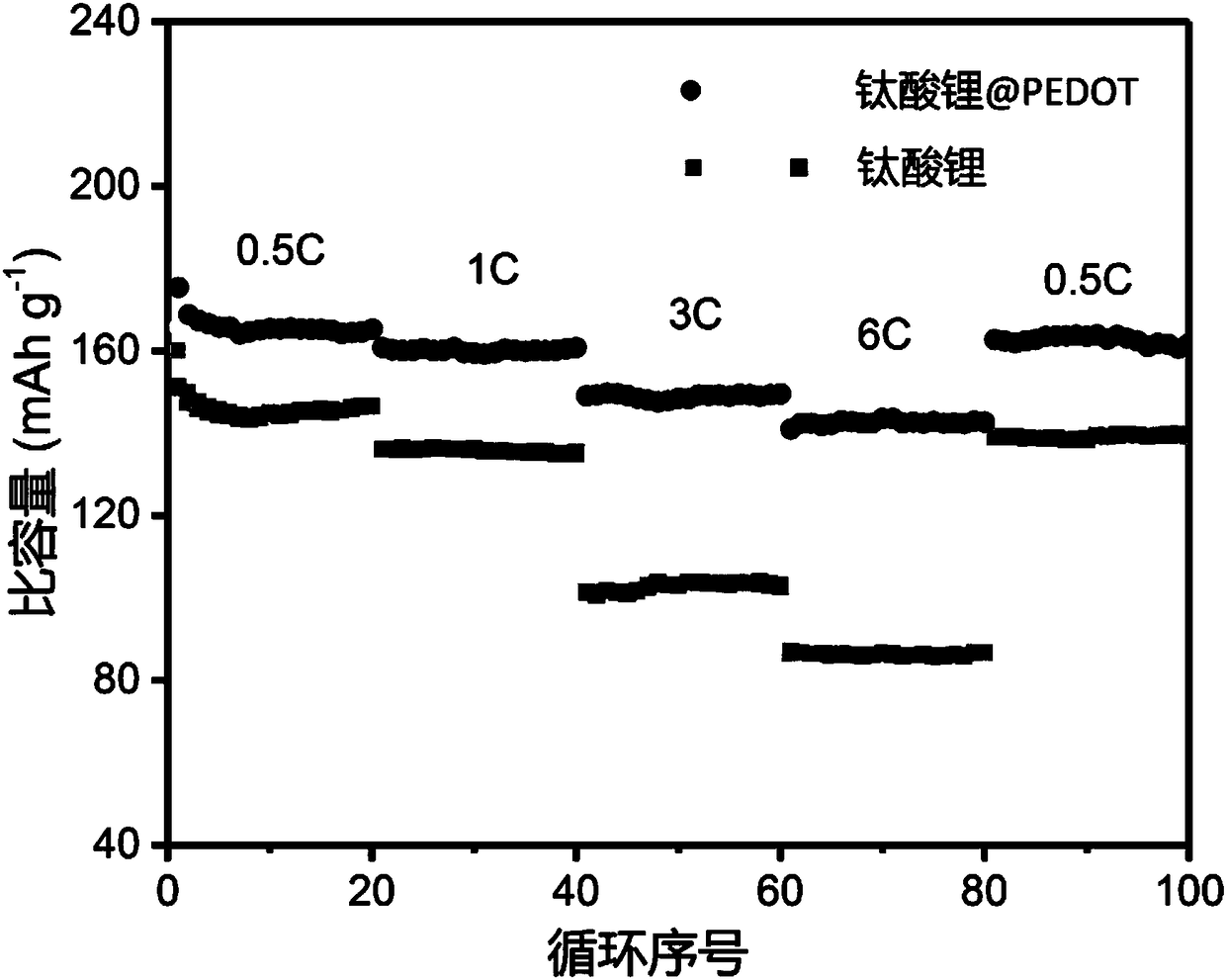

[0022] Example 1: Accurately weigh 1.35g of titanium dioxide nanoparticles and 0.32g of lithium hydroxide and place them in a planetary ball mill, and ball mill them at a speed of 1500 rpm for 18 hours; the obtained mixture is placed in a tube furnace, and the heating rate of calcination is 1 ℃ / min, calcined at 500℃ for 36h under air condition, cooled to room temperature to obtain lithium titanate nanoparticles; accurately weigh 0.10g of 3,4-ethylenedioxythiophene monomer (EDOT), add 24mL of deionized Water, sonicated at a frequency of 20KHz for 30 minutes; accurately weighed 0.60g of lithium titanate nanoparticles obtained, added to the EDOT dispersion, ultrasonicated at a frequency of 60KHz for 1h, and then continuously stirred at a speed of 1000rpm for 2h to obtain a mixed solution The ammonium persulfate (APS) of 0.24g and the hydrochloric acid (HCl) that 35mg mass fraction are 37wt.% are dissolved in the deionized water of 35mL, stir well, add in the above-mentioned mixed ...

Embodiment 2

[0023] Example 2: Accurately weigh 3.99g of titanium dioxide nanoparticles and 1.66g of lithium carbonate, place them in a planetary ball mill, and ball mill them at a speed of 3000 rpm for 6 hours; place the obtained mixture in a tube furnace, and calcinate at a heating rate of 5°C / min, calcined at 800°C for 10h under air conditions, cooled to room temperature, and obtained lithium titanate nanoparticles; accurately weighed 0.10g of EDOT, added 20mL of deionized water, and ultrasonicated at a frequency of 60KHz for 1h; accurately weighed to obtain 1.00g of lithium titanate nanoparticles was added to the EDOT dispersion liquid, ultrasonicated at a frequency of 40KHz for 1h, and then continuously stirred at a speed of 800 rpm for 3h to obtain a mixed solution; % HCl was dissolved in 44 mL of deionized water, stirred evenly, added to the mixed solution obtained above, stirred at room temperature at a speed of 700 rpm for 6 hours, and the obtained mixed solution was centrifuged a...

Embodiment 3

[0024]Example 3: Accurately weigh 3.99g of titanium dioxide nanoparticles and 2.93g of lithium nitrate, place them in a planetary ball mill, and ball mill them at a speed of 2000 rpm for 24 hours; place the obtained mixture in a tube furnace, and calcinate at a heating rate of 3°C / min, calcined at 1000°C for 48h under air conditions, cooled to room temperature, and obtained lithium titanate nanoparticles; accurately weighed 0.11g of EDOT, added 20mL of deionized water, and ultrasonicated at a frequency of 40KHz for 0.8h; accurately weighed 0.25 g of the obtained lithium titanate nanoparticles was added to the EDOT dispersion liquid, and after ultrasonication at a frequency of 20 KHz for 30 minutes, stirring was continued at a speed of 500 rpm for 4 h to obtain a mixed solution; 0.18 g of APS and 29 mg of mass fraction were 37wt.% HCl was dissolved in 20 mL of deionized water, stirred evenly, added to the mixed solution obtained above, stirred at 800 rpm for 18 hours at room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com