Starch adhesive and preparation method thereof

A starch adhesive, starch technology, applied in the directions of starch-derived adhesives, adhesives, adhesive types, etc., can solve the problems of poor water resistance, poor storage stability, etc., and achieve good fluidity and antifreeze. Large, good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The application discloses a preparation method of starch adhesive, comprising the following steps:

[0028] (1) Preparation of the nanocellulose suspension: immerse the paper product in a sulfuric acid solution, heat, shear and stir for a certain period of time, wash and dialyze;

[0029] (2) Preparation of polyvinyl alcohol solution: the polyvinyl alcohol is dissolved in water, hydrochloric acid is added dropwise, a surfactant is added and dissolved;

[0030] (3) Preparation of dialdehyde starch solution: the starch and water are formulated into starch emulsion, the oxidant and hydrochloric acid are added, and the reaction solution is obtained by heating for a certain period of time, and the reaction solution is subjected to suction filtration, washing, and hot water dissolution;

[0031] (4) Add the nanocellulose suspension, the polyvinyl alcohol solution and the crosslinking agent into the dialdehyde starch solution, heat and stir for a certain period of time, adjust...

Embodiment 1

[0039] A starch adhesive, in parts by weight, comprising: 50 parts of nanocellulose suspension, 50 parts of starch, 1 part of oxidizing agent, 20 parts of polyvinyl alcohol, 0.05 part of surfactant and 0.25 part of crosslinking agent.

[0040] The starch is a mixed starch of corn starch, tapioca starch and potato starch, the oxidizing agent is potassium permanganate, the surfactant is a mixture of alkyl sodium sulfate and sodium pyrophosphate, and the crosslinking agent is a silane coupling agent containing epoxy groups.

[0041] The preparation method of starch adhesive, comprises the following steps:

[0042] (1) Preparation of nanocellulose suspension: immerse the paper product in a sulfuric acid solution with a mass fraction of 50%, heat, shear and stir for 2.5 hours, wash and dialyze;

[0043] (2) Preparation of polyvinyl alcohol solution: dissolve polyvinyl alcohol with water, add dropwise a mass fraction of 35% hydrochloric acid, add surfactant and dissolve;

[0044] (...

Embodiment 2

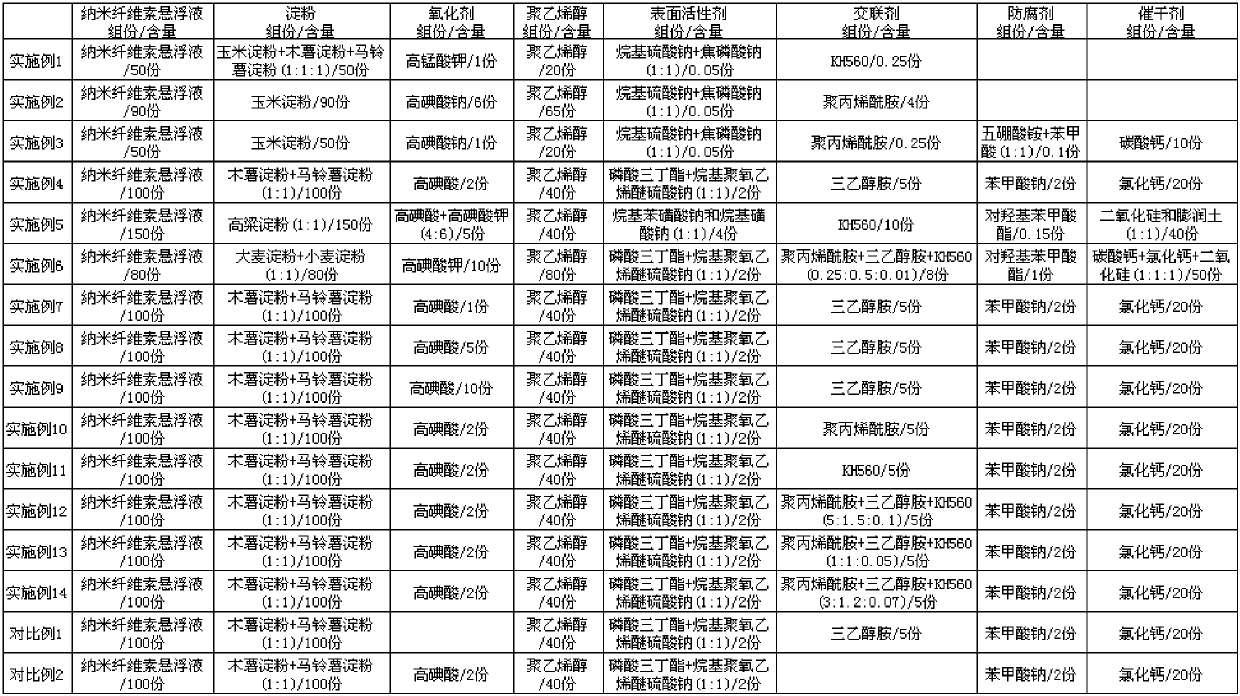

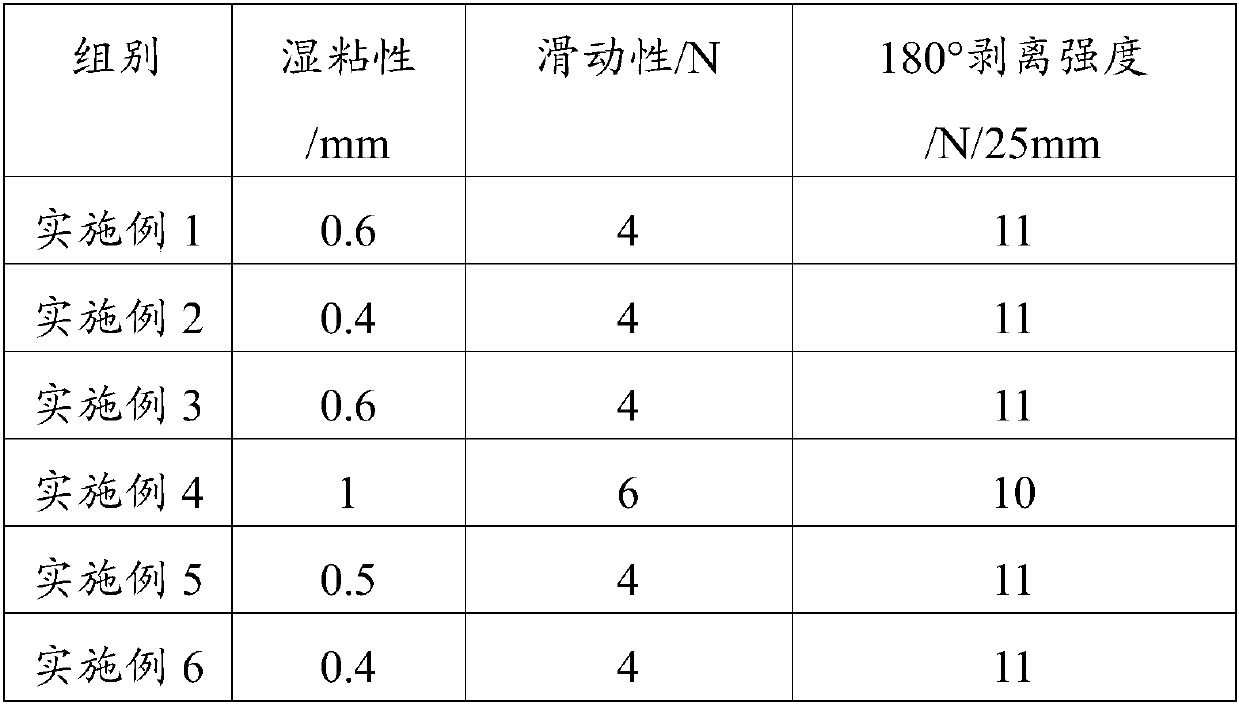

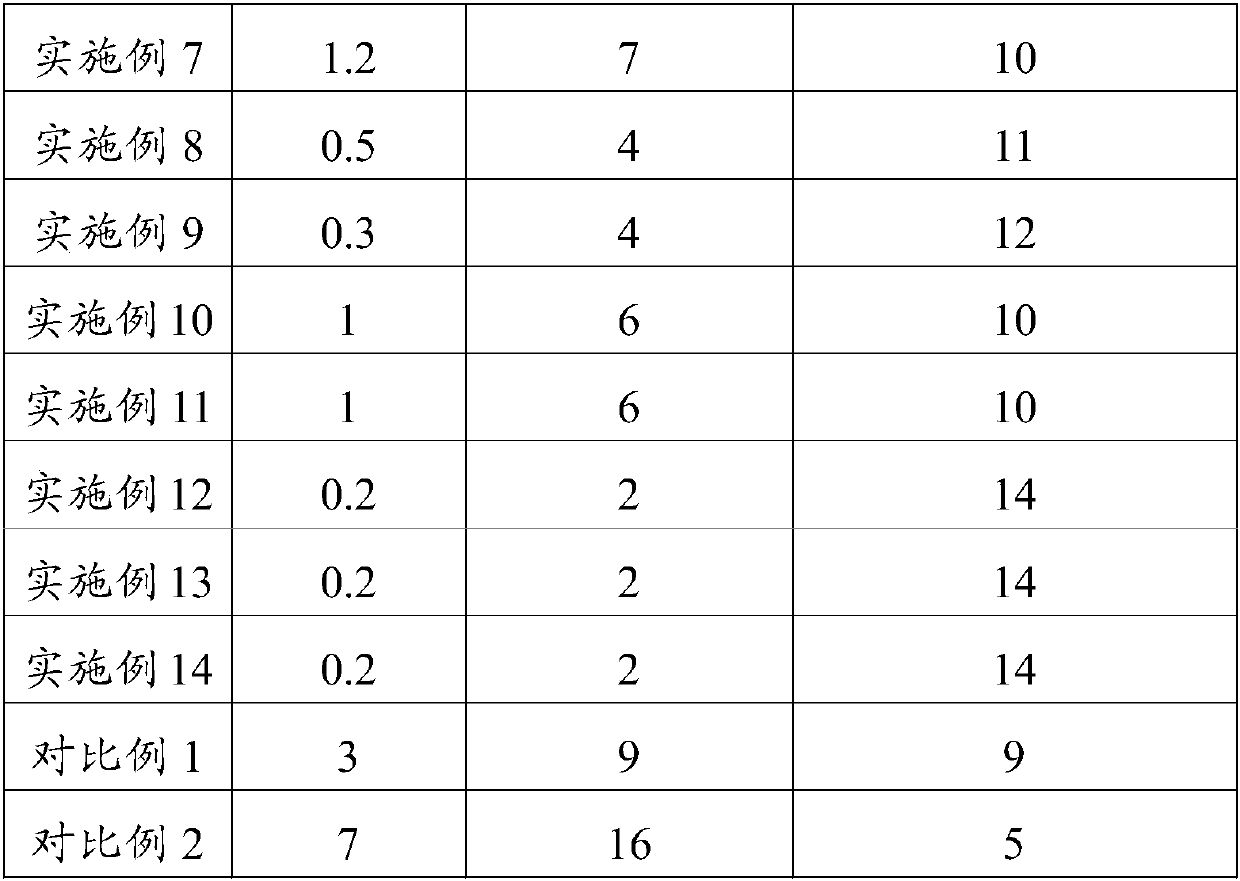

[0046] The specific components and contents of the starch adhesives in Examples 2-14 and Comparative Examples 1-2 are different from those in Example 1, as shown in Table 1. In Table 1, starch, oxidant, surfactant, crosslinking agent, and drier are mixtures, and the proportions of each component are weight ratios. The preparation method of Example 2 is the same as that of Example 1. The preparation methods of Examples 3-14 and Comparative Example 1-2 are added after heating and stirring and before adjusting the pH. With embodiment 1.

[0047] Table 1:

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com