Nanometer TiC modified graphene reinforced titanium-matrix composite material, and preparation method and application thereof

A technology of titanium-based composite materials and graphene, which is applied in the field of metal-based composite materials, can solve the problem of less titanium-based composite materials, and achieve the effects of reduced ground reaction and excellent dispersion and coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

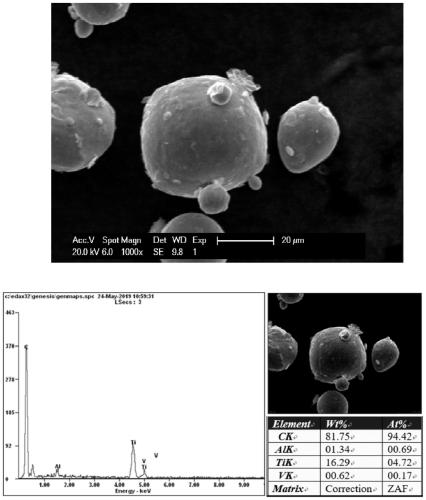

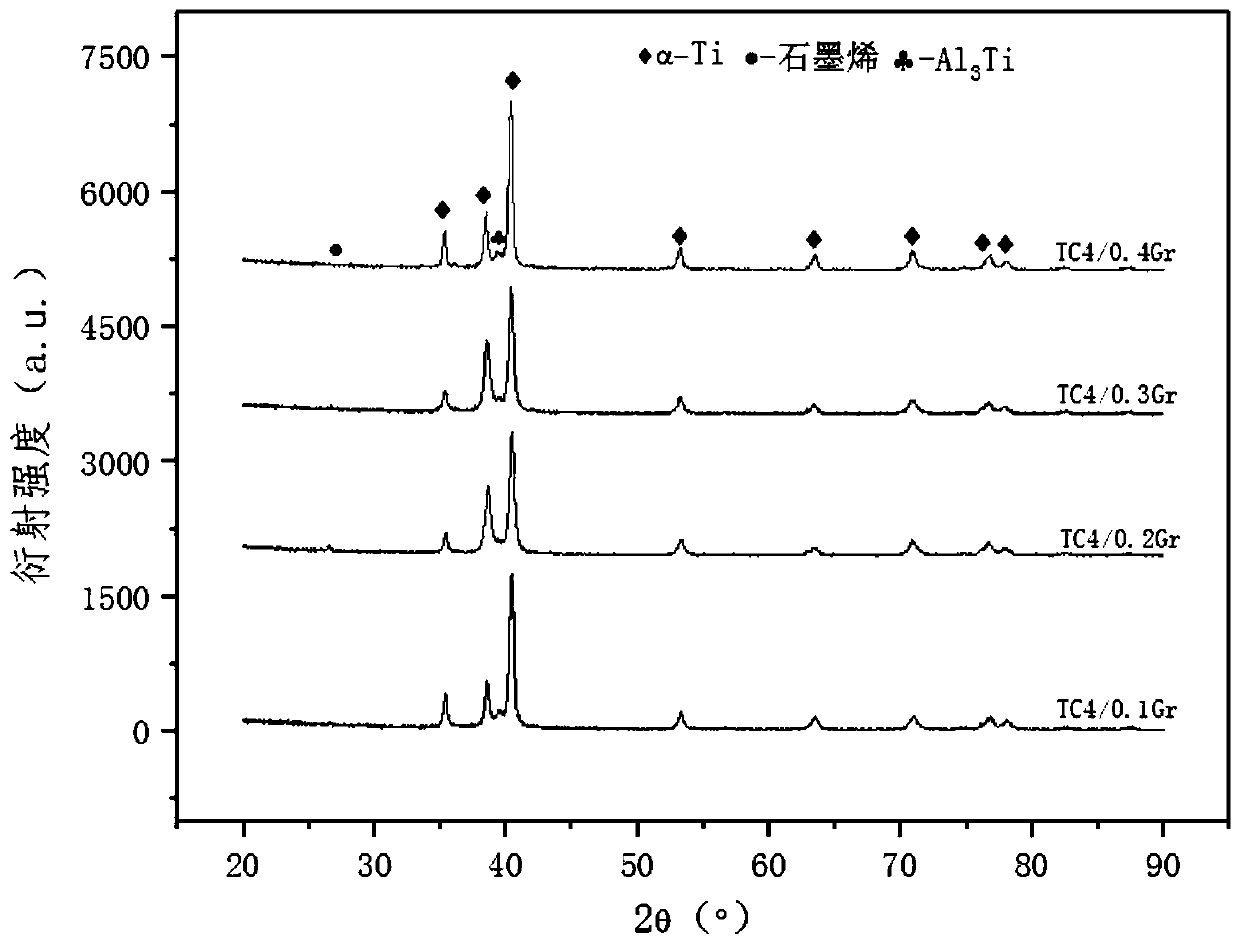

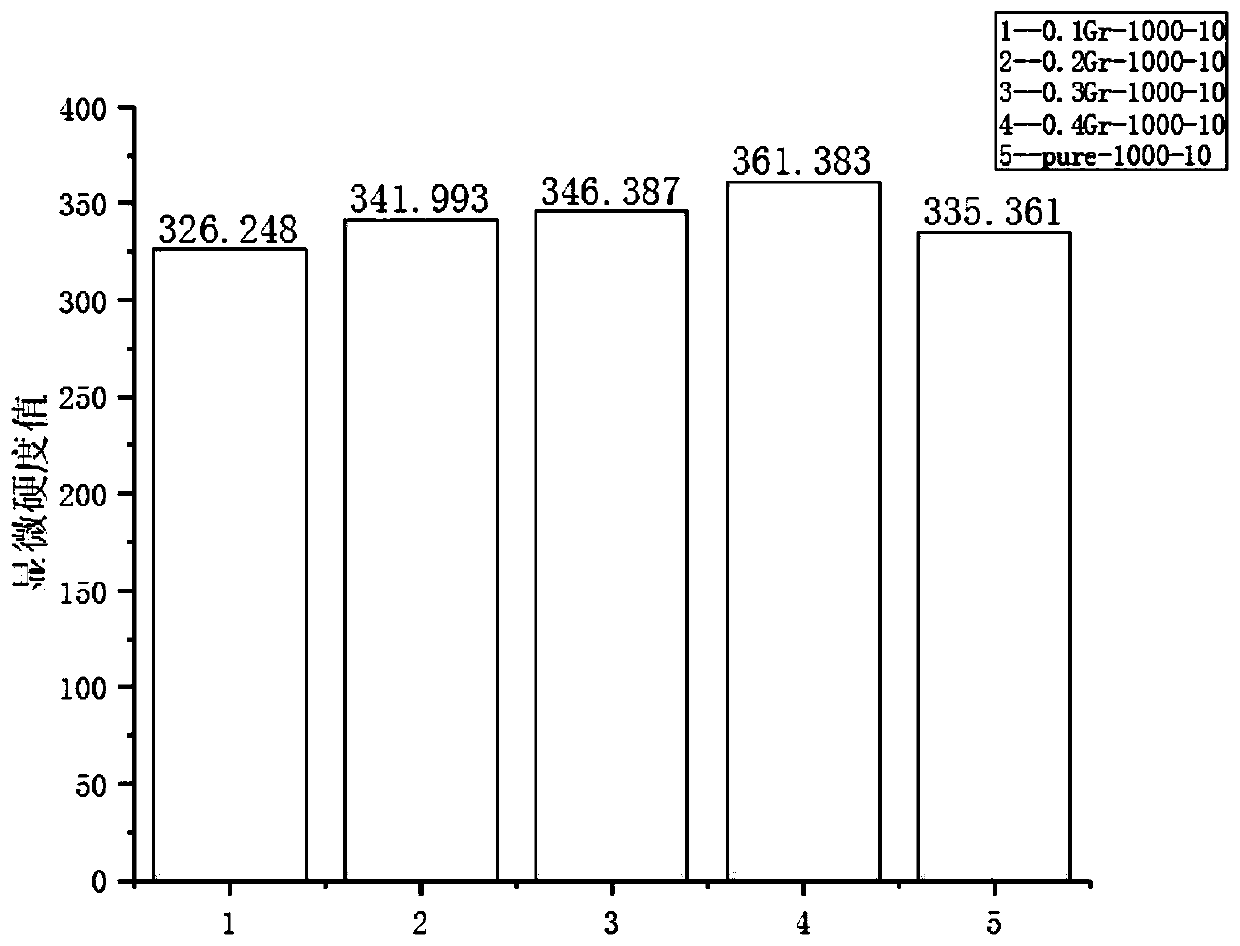

[0043] Spark plasma technology sinters to produce nano-TiC modified graphene-reinforced titanium-based composite materials, using nano-TiC powder, graphene powder and spherical Ti-6Al-4V (TC4) powder as raw materials, of which nano-TiC powder has a particle size of 40nm and a graphene sheet thickness 1-5nm, diameter 0.1-6μm, particle size of titanium powder is 50μm (300 mesh), and a cylindrical composite material sintered body with a diameter of 20mm and a height of 10mm is produced.

[0044] Specific steps are as follows:

[0045] (1) Weigh 20g of TC4 powder and place it in a plastic tank, add nano-TiC powder with a mass fraction of 0.05wt.% (relative to the mass fraction of the titanium matrix), and add a certain amount of stainless steel grinding balls. The ball-to-material ratio is 1: 1. Mix continuously at a speed of 60r / min for 16h on the mixer.

[0046] (2) Continue to add the graphene powder that mass fraction is 0.2wt.% (relative to the mass fraction of titanium mat...

Embodiment 2

[0052] Spark plasma technology sinters to produce nano-TiC modified graphene-reinforced titanium-based composite materials. Nano-TiC powder, graphene powder and spherical pure Ti powder are used as raw materials. The particle size of nano-TiC powder is 40nm, and the thickness of graphene sheets is 1-5nm. The diameter is 0.1-6 μm, the particle size of the titanium powder is 80 μm (200 mesh), and a cylindrical composite material sintered body with a diameter of 20 mm and a height of 8 mm is produced.

[0053] Specific steps are as follows:

[0054] (1) Weigh 20g of pure Ti powder (purity is 99.5%) and place it in a plastic tank, add nano-TiC powder with a mass fraction of 0.05wt.% (relative to the mass fraction of the titanium matrix), add a certain amount of stainless steel mill The ratio of ball to material is 2:1. Mix continuously at a speed of 60r / min for 20h on the mixer.

[0055] (2) Continue to add the graphene powder that mass fraction is 0.4wt.% (relative to the mass ...

Embodiment 3

[0061] Nano-TiC modified graphene-reinforced titanium-based composite materials are produced by hot-pressing sintering. Nano-TiC powder, graphene powder and spherical Ti-12Nb-12Zr powder are used as raw materials. The particle size of nano-TiC powder is 40nm, and the thickness of graphene sheet is 1-5nm. The diameter is 0.1-6 μm, the particle size of the titanium powder is 80 μm (200 mesh), and a cylindrical composite material sintered body with a diameter of 20 mm and a height of 10 mm is produced.

[0062] Specific steps are as follows:

[0063] (1) Weighing 20g of Ti-12Nb-12Zr powder is placed in a plastic tank, adding a mass fraction of 0.05wt.% (relative to the mass fraction of the titanium matrix) nano-TiC powder, adding a certain amount of stainless steel grinding balls, balls Material ratio 5:1. Mix continuously at a speed of 60r / min for 10h on the mixer.

[0064] (2) Continue to add the graphene powder that mass fraction is 0.4wt.% (relative to the mass fraction of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com