Patents

Literature

94results about How to "Insulation erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

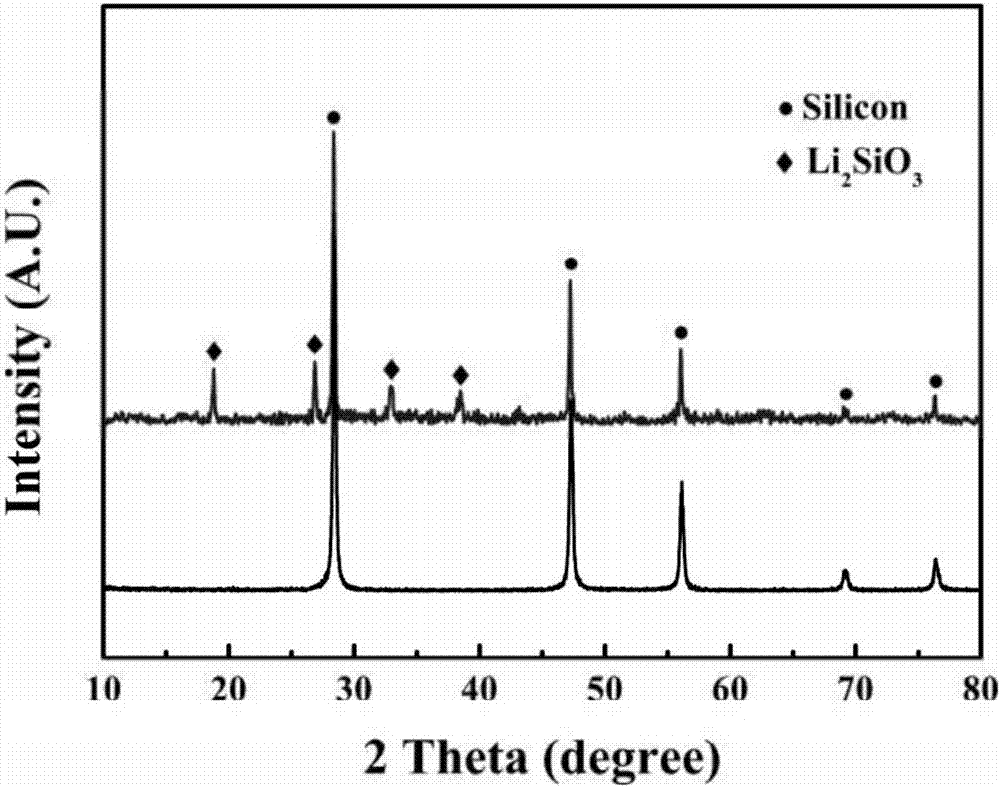

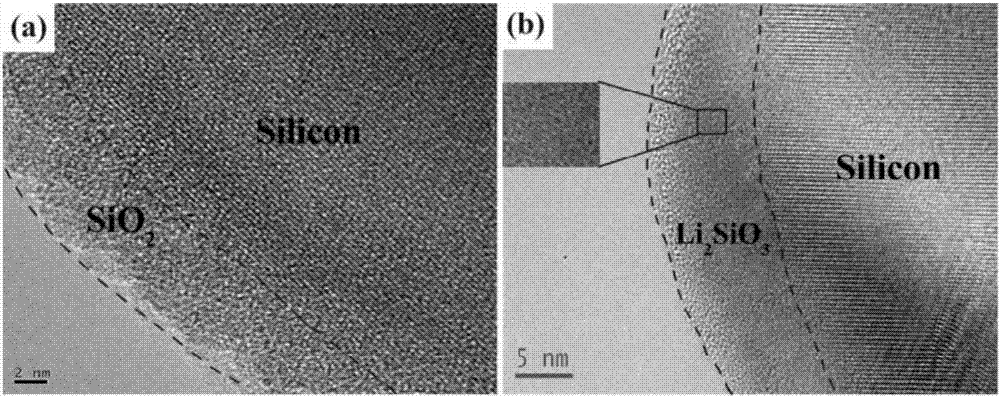

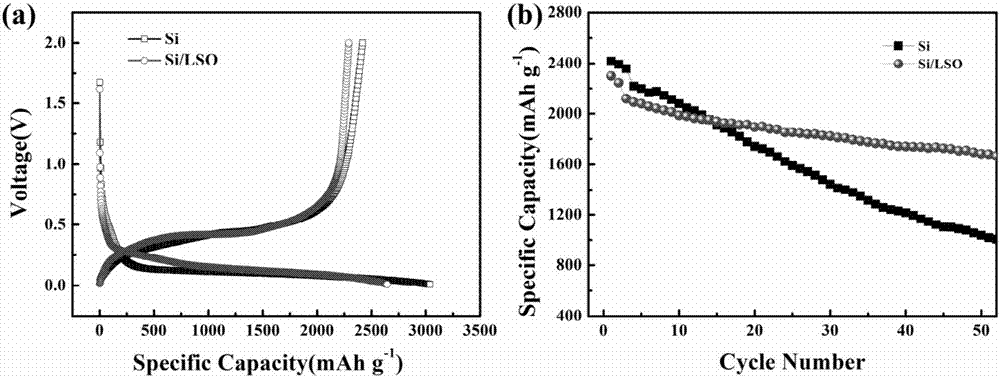

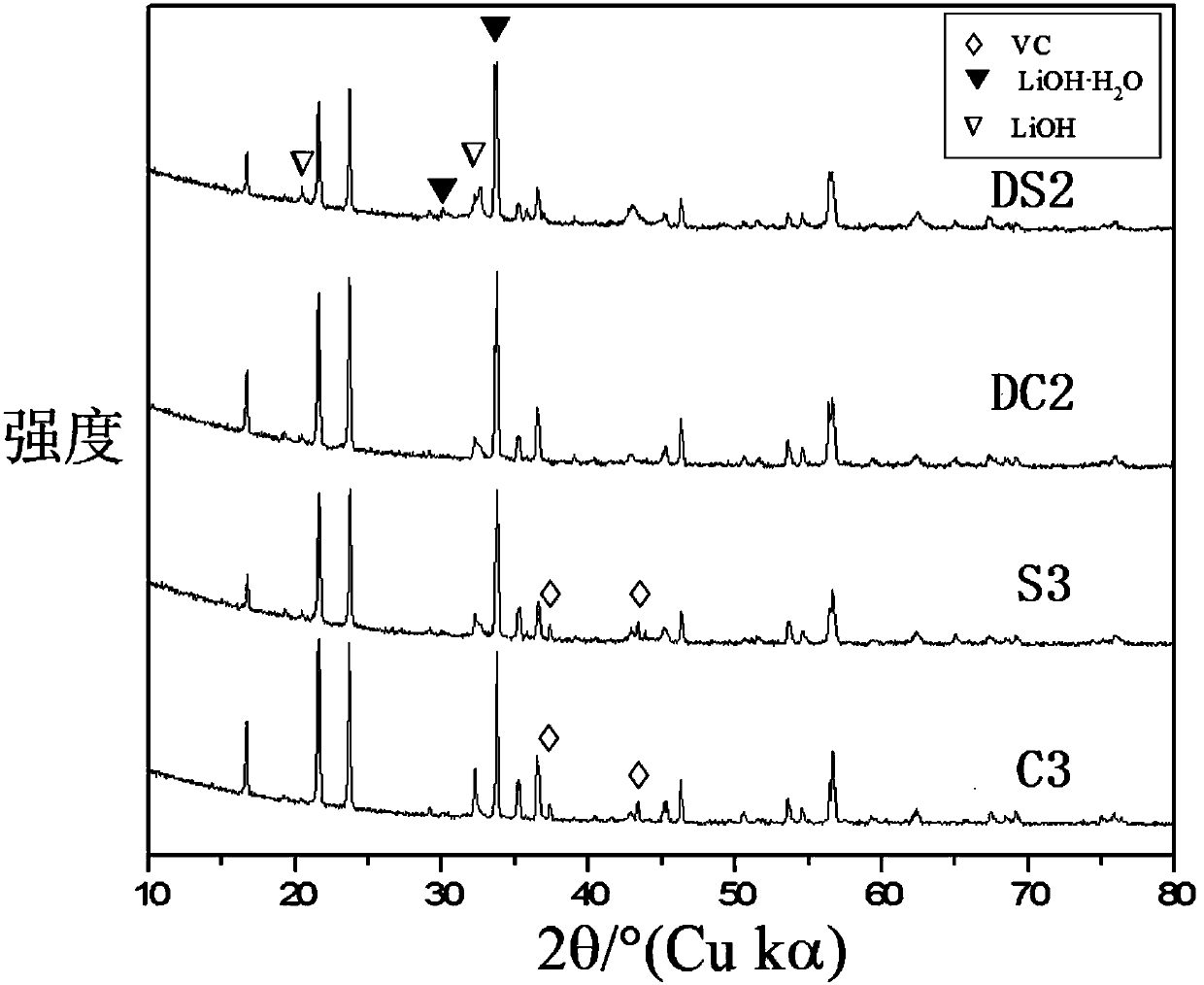

Lithium ion battery composite negative electrode material and preparation method thereof

InactiveCN107887587AImprove storage effectImprove Interface StabilityMaterial nanotechnologyCell electrodesChemical reactionSilicon dioxide

The invention discloses a lithium ion battery composite negative electrode material and a preparation method thereof. The surface of nanometer silicon is subjected to oxidization treatment to obtain nanometer silicon coated with silicon dioxide on the surface; the nanometer silicon coated with silicon dioxide on the surface is mixed with a lithium source uniformly to obtain a precursor; and the obtained precursor is placed into inert gas to be heated to obtain a nanometer silicon material coated with lithium silicate, and the product is subjected to washing, centrifugal separating and drying to obtain the lithium ion battery composite negative electrode material. By taking a uniform primary oxide layer on the surface of the nanometer silicon material as the substrate, an in-situ chemical reaction is performed to realize uniform coating of lithium silicate, so that stability between nanometer silicon and air or an electrolyte interface is improved effectively, thereby greatly improvingelectrochemical performance of the nanometer silicon material.

Owner:CENT SOUTH UNIV

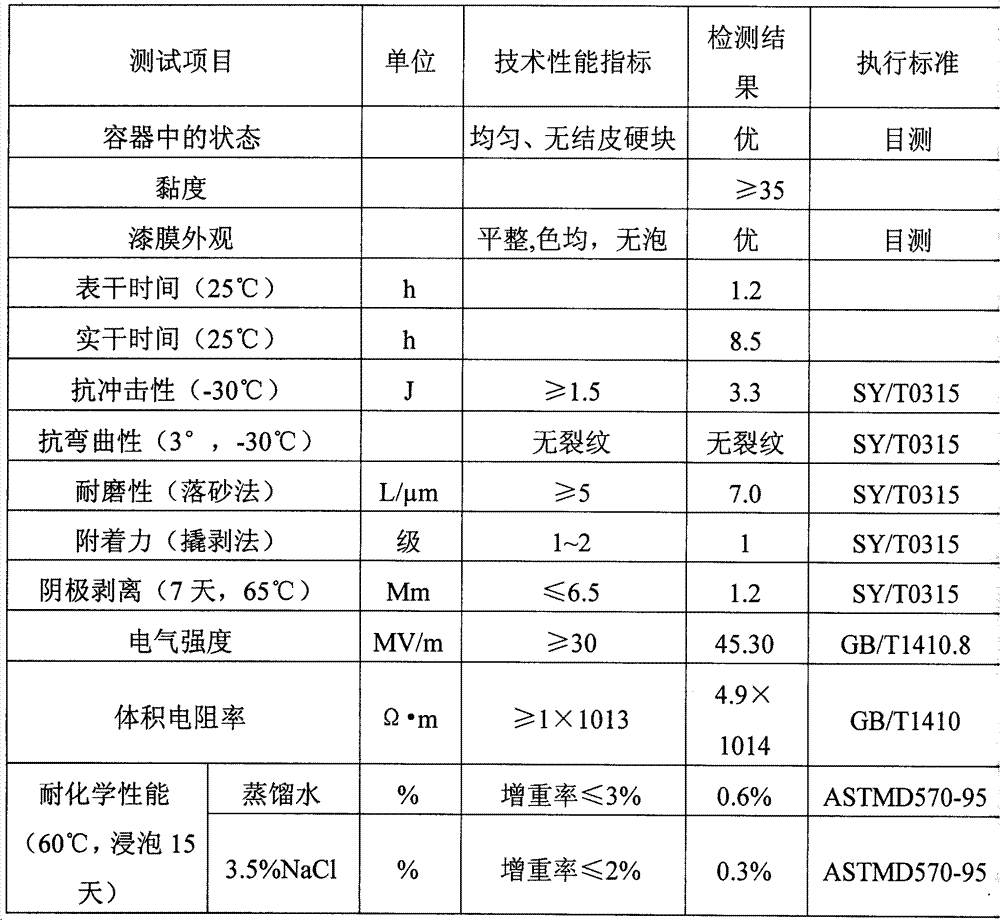

Environment-friendly nano-epoxy silicone heavy anti-corrosion coating and preparation method and using method thereof

ActiveCN102816495AImprove wear resistanceImprove corrosion resistanceAnti-corrosive paintsPolyamide coatingsWater basedEpoxy

An environment-friendly nano-epoxy silicone heavy anti-corrosion coating comprises a component A and a component B, wherein the component B is polyamide, and the component A is prepared by water-borne epoxy resin, a solvent, silicon carbide, aluminum oxide, nano-quartz powder, titanium dioxide power, zinc powder, aluminum powder, ceramic powder, cobalt-nickel ultrafine metal powder and graphite. A using method of the environment-friendly nano-epoxy silicone heavy anti-corrosion coating is that the component A and the component B are mixed evenly according to the weight ratio of 30-50:1 and then directly sprayed or brushed on the surface of an anti-corrosion object at the normal temperature. A coating layer formed by the coating has good abrasion resistance, corrosion resistance, impact resisting performance and flexibility and can effectively isolate corrosion of acid, alkali, salt and sea water. The surface of the coating layer is compact and smooth and has small resistance to a transmission medium. The coating can be widely applied to oil transportation pipelines, oil storage tanks, chemical equipment, ships, grinding wheel blades, pumps, dust removers, offshore steel structures and the like. In addition, the environment-friendly nano-epoxy silicone heavy anti-corrosion coating is water-based coating, does not contain harmful ingredients and is convenient and efficient in use.

Owner:SHANGHAI JIANYE TECH ENG

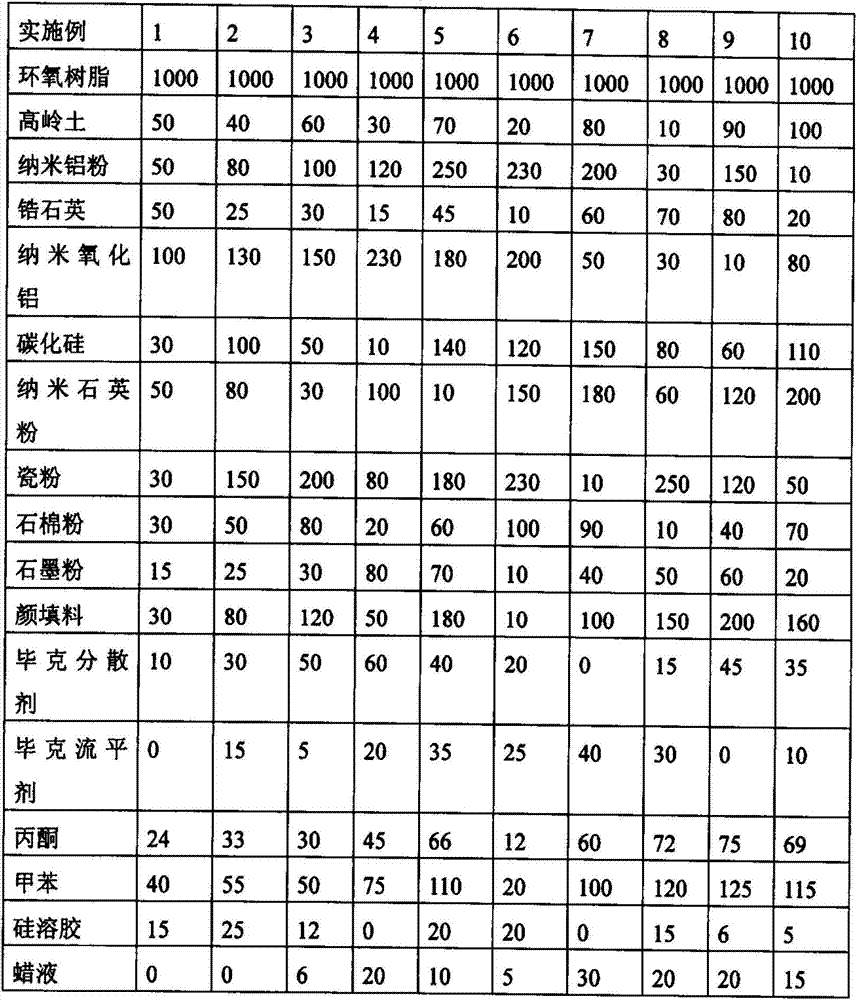

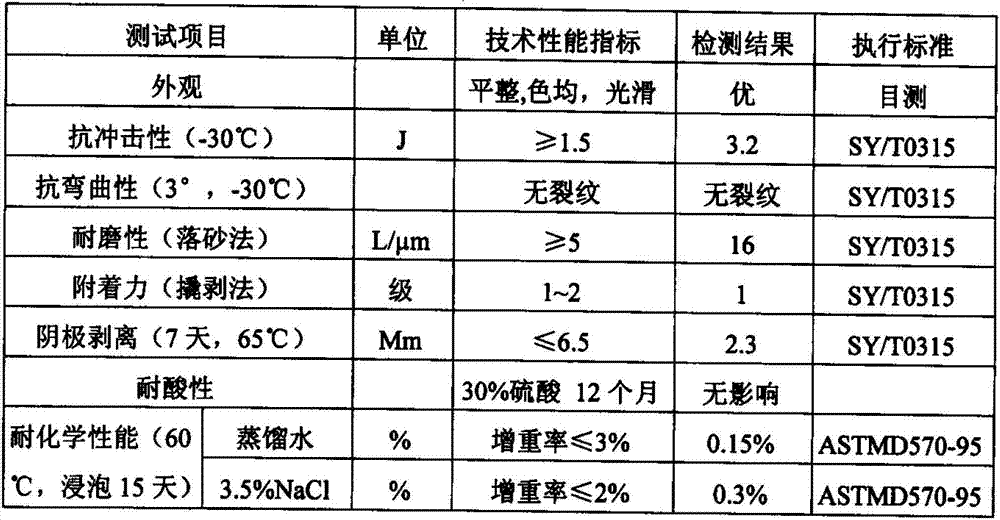

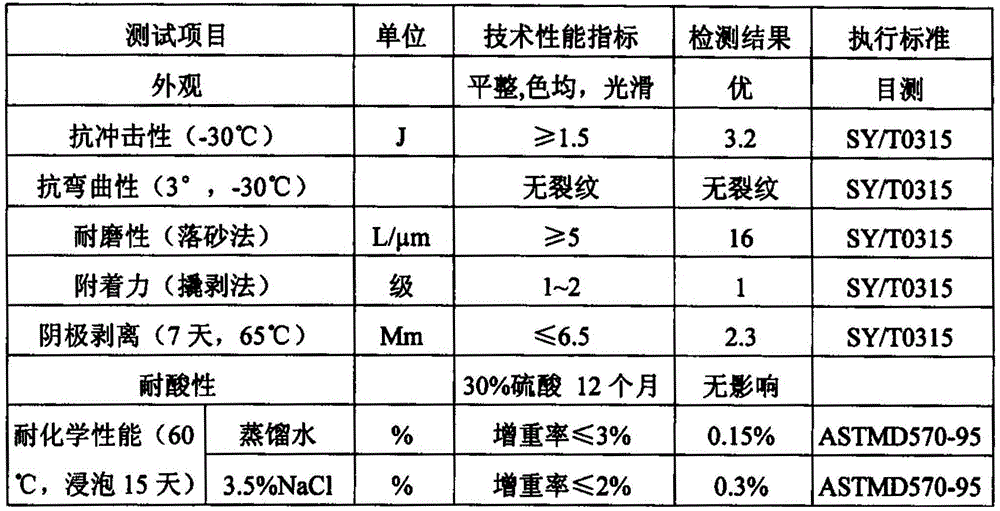

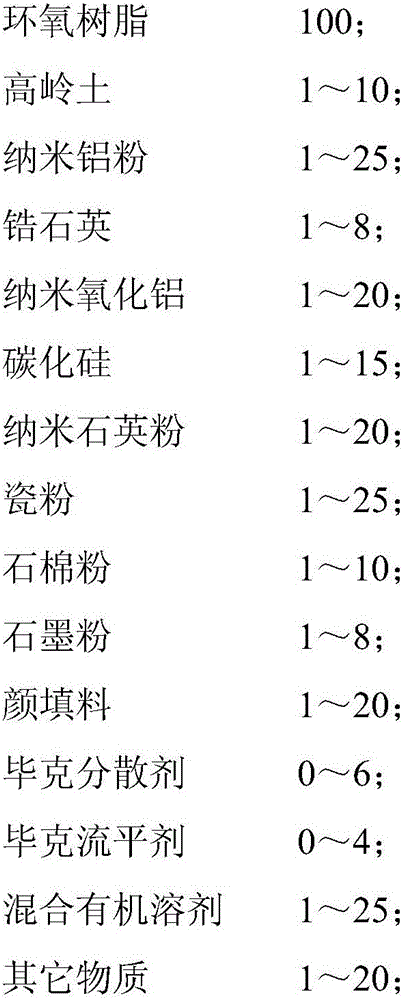

Manufacturing method of metal ceramic anticorrosive paint

ActiveCN103589273AImprove wear resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyNano al2o3

A metal ceramic anticorrosive paint mainly includes kaolin, nanometer aluminium powder, nano alumina, silicon carbide, nano quartz powder, ceramic powder, asbestos powder, graphite powder, a pigment, a filler, epoxy resin, an additive and a mixed organic solvent. The solid powders are subjected to nano ultrafine treatment to reach a granularity of 20-200 nm. The paint provided by the invention is a single-component paint, which is simple in manufacturing process, economical and environment-friendly. The coating of the paint does not require a primer and can be used alone without adding special finish. The coating has excellent wear resistance, corrosion resistance, impact resistance, stability, strong adhesion, compactness and stability, and can effectively prevent erosion by acid, alkali, salt and seawater. In addition, the paint can be widely applied to oil pipeline, oil storage tank, chemical equipment, ships, bridges, offshore platforms and other steel structure buildings.

Owner:SHANGHAI JIANYE TECH ENG

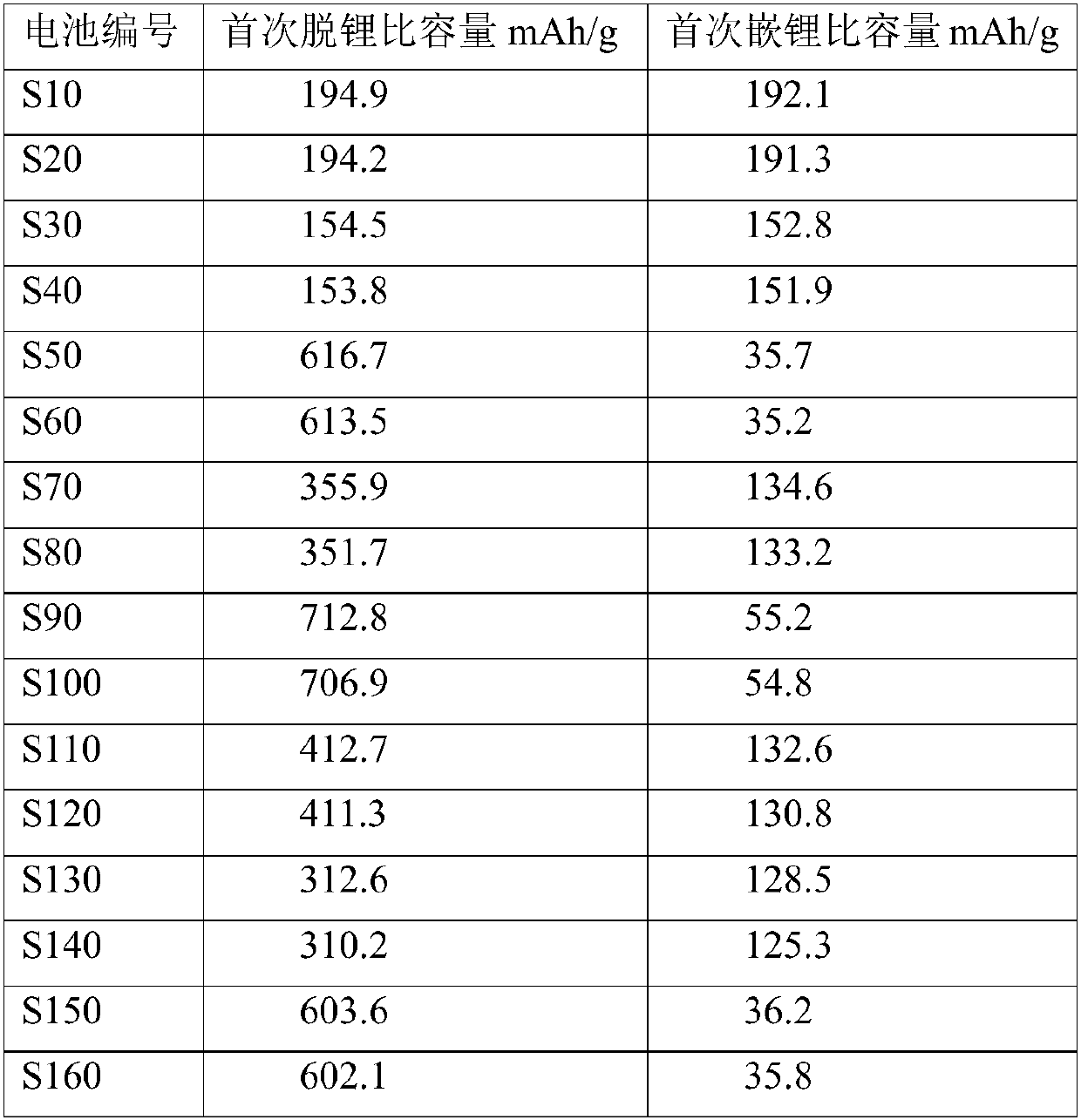

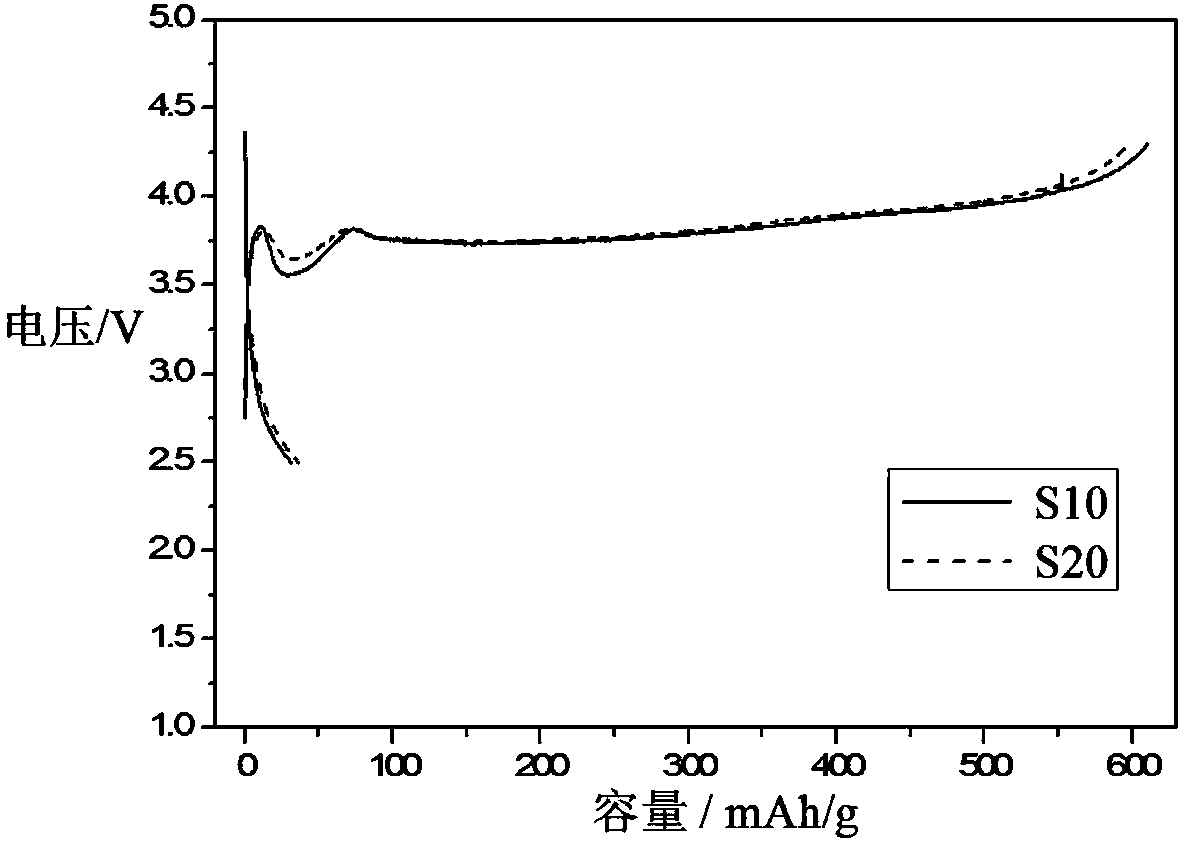

Positive active material, preparation method thereof, positive electrode and battery

PendingCN110299515AImprove stabilityInsulation erosionCell electrodesSecondary cellsCarbideLithium-ion battery

The present invention provides a positive active material comprising a core material and a coating layer. The core material comprises a lithium salt which is one or more selected from the group consisting of LiFeBO3, Li2FeSiO4, Li5FeO4, Li6CoO4, Li6MnO4, Li2NiO2 and Li2CuO2. The coating layer coats the core material and comprises carbon and metal carbide. The invention also provides a positive electrode containing the positive active material and a lithium-ion battery, the coating layer of the positive active material can isolate the influence of water in the air on the core material, the stability and conductivity of the material are improved, and the electrical conductivity and stability of the battery are improved.

Owner:BYD CO LTD

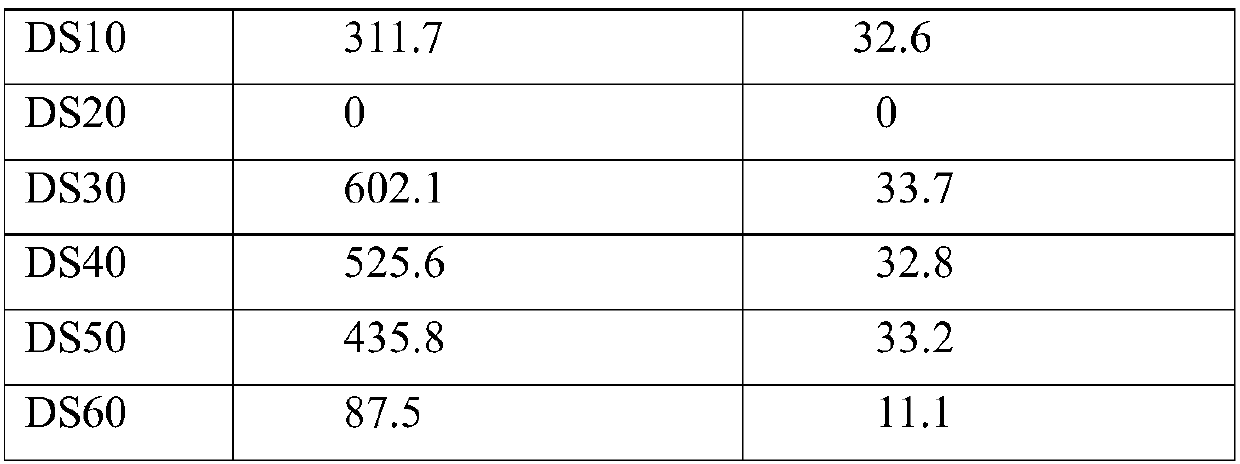

Graphite electrode nanometer antioxidant and preparation method thereof

The invention belongs to the technical field of graphite electrodes, and provides a graphite electrode nanometer antioxidant and a preparation method thereof. The graphite electrode nanometer antioxidant is prepared from the following components in parts by weight: 20 to 30 parts of water, 20 to 30 parts of nano-oxide ceramic powder, 15 to 20 parts of graphene, 10 to 20 parts of dispersant, 10 to15 parts of film-forming additive, 6 to 12 parts of stabilizer and 5 to 10 parts of polyhedral oligomeric silsesquioxane, wherein the dispersant is polyethylene glycol; the film-forming additive is thiol-based chitosan; the stabilizer is a mixture of zinc borate and polyetherimide in the mass ratio of 2 to 1. By adopting the graphite electrode nanometer antioxidant, the problem of conductivity decrease of a graphite electrode after introduction of the graphite electrode under the risks of peeling and falling off due to cracks generated in the heating process of a generated antioxidation layersince the antioxidation temperature is not high during use of the graphite electrode nanometer antioxidant in the prior art is solved.

Owner:河北弘华节能科技有限公司

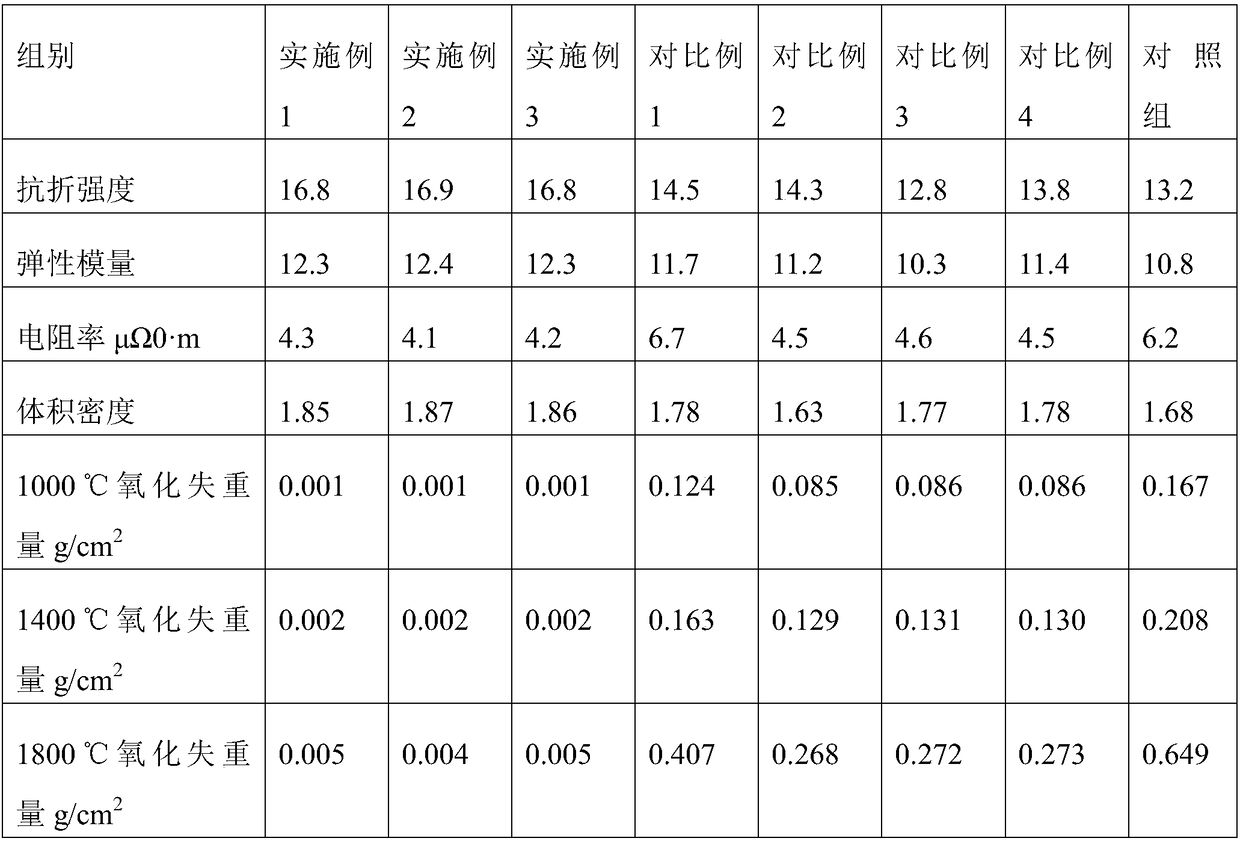

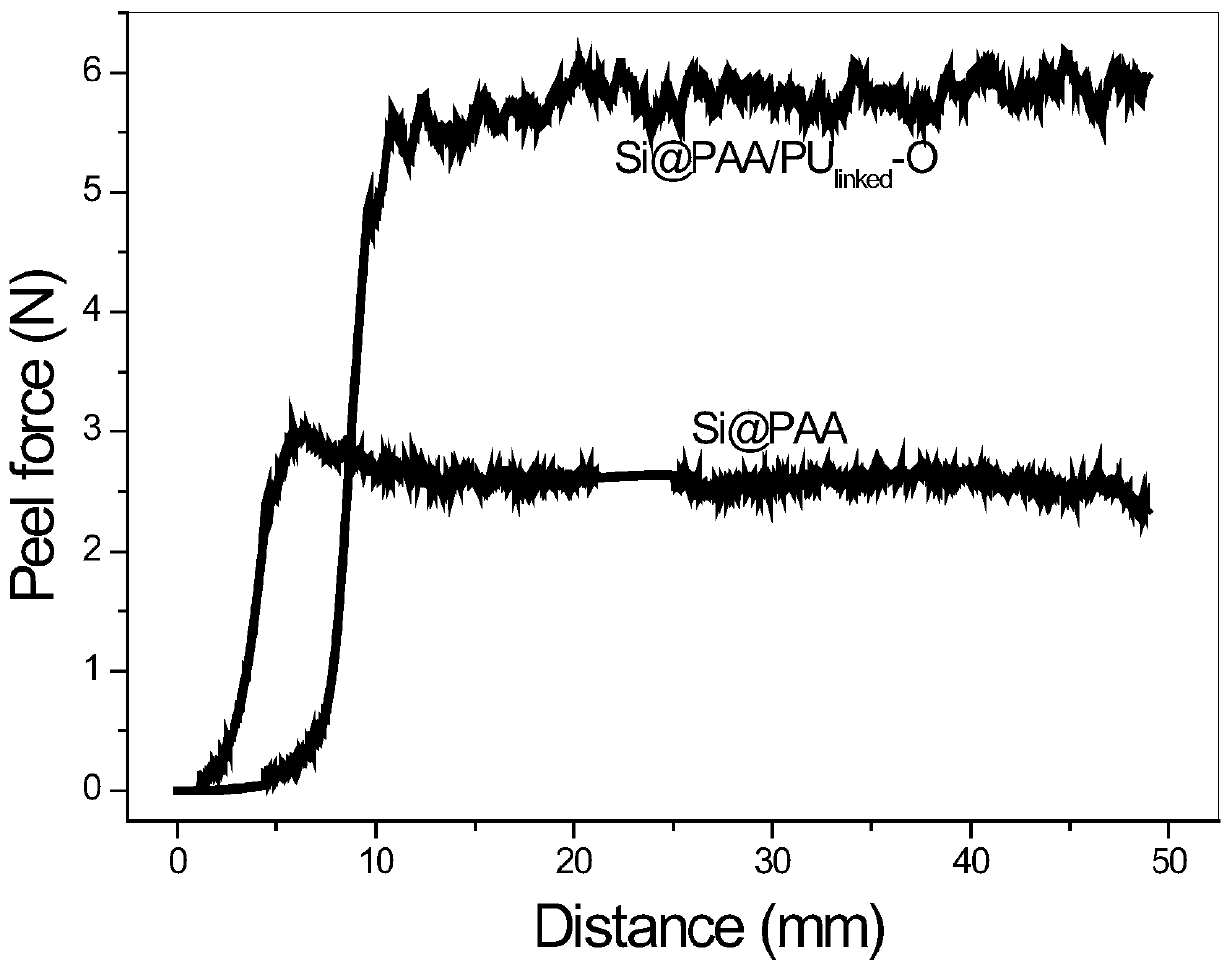

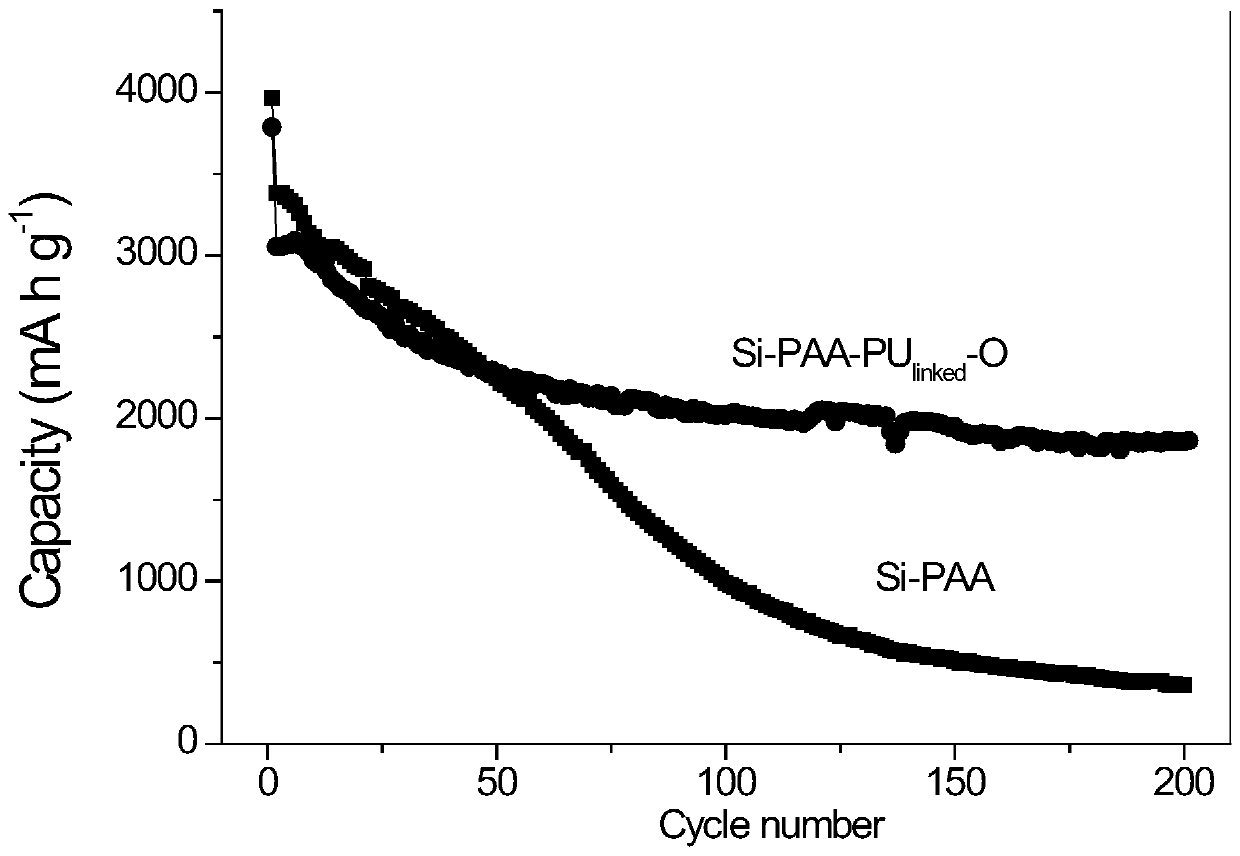

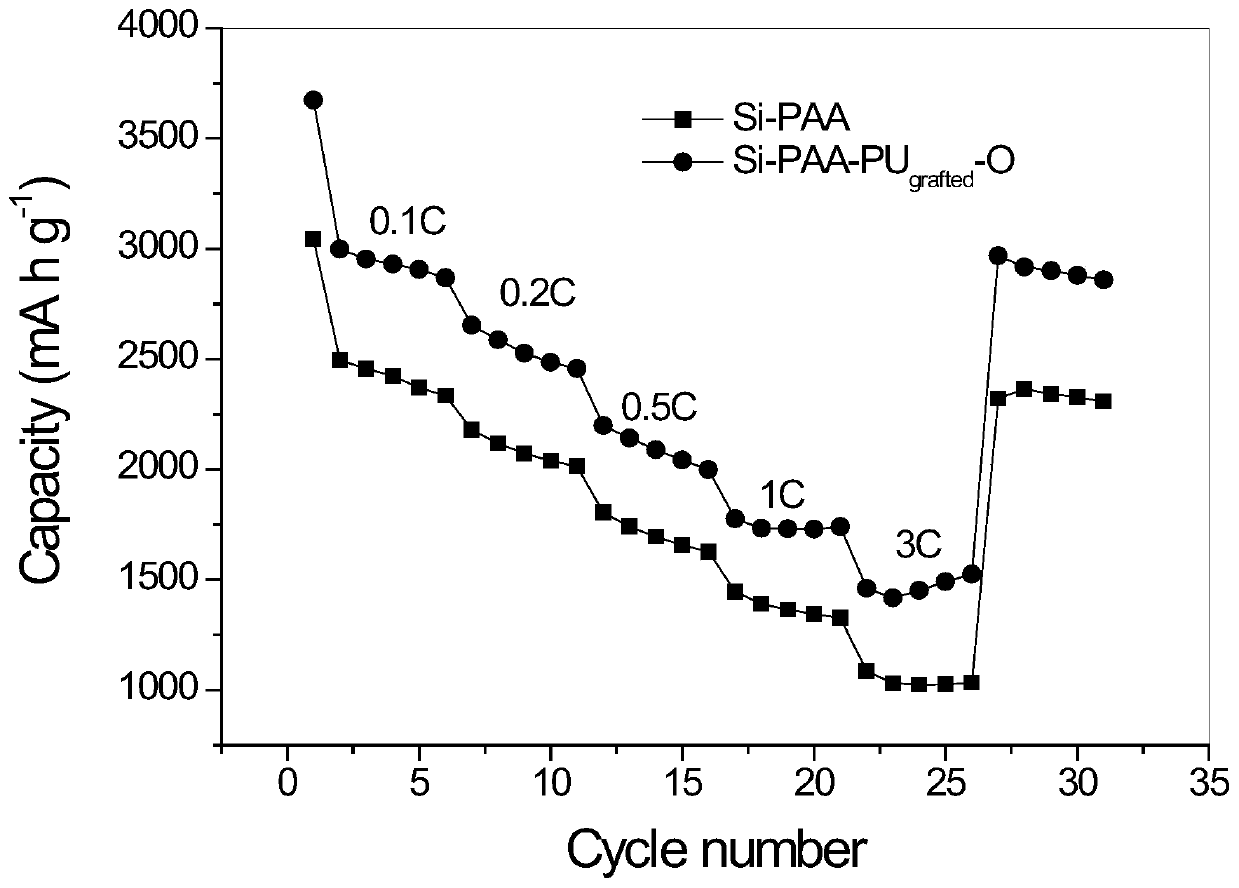

Binder with three-dimensional network structure and preparation method and application thereof

ActiveCN110676456AEnsure structural stabilityImprove cycle stabilityCell electrodesSecondary cellsPolymer scienceALLYL SUCROSE

The invention relates to a binder with a three-dimensional network structure and a preparation method and an application thereof. The binder is formed by cross-linking a low-molecular-weight polyurethane prepolymer by taking high-molecular-weight polyacrylic acid and high-molecular-weight polyurethane as chain-shaped brackets. The binder has the cohesiveness of polyacrylic acid and the high elasticity of polyurethane, and can firmly bind an active material and a conductive agent together. In the charging and discharging process, the active material expands and contracts, and the binder can expand and contract along with the expansion and contraction of the active material. Thus, the structural stability of an electrode material can be well maintained, the electrode does not come off in thecharging and discharging process, and the cycling stability and the rate capability can be improved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

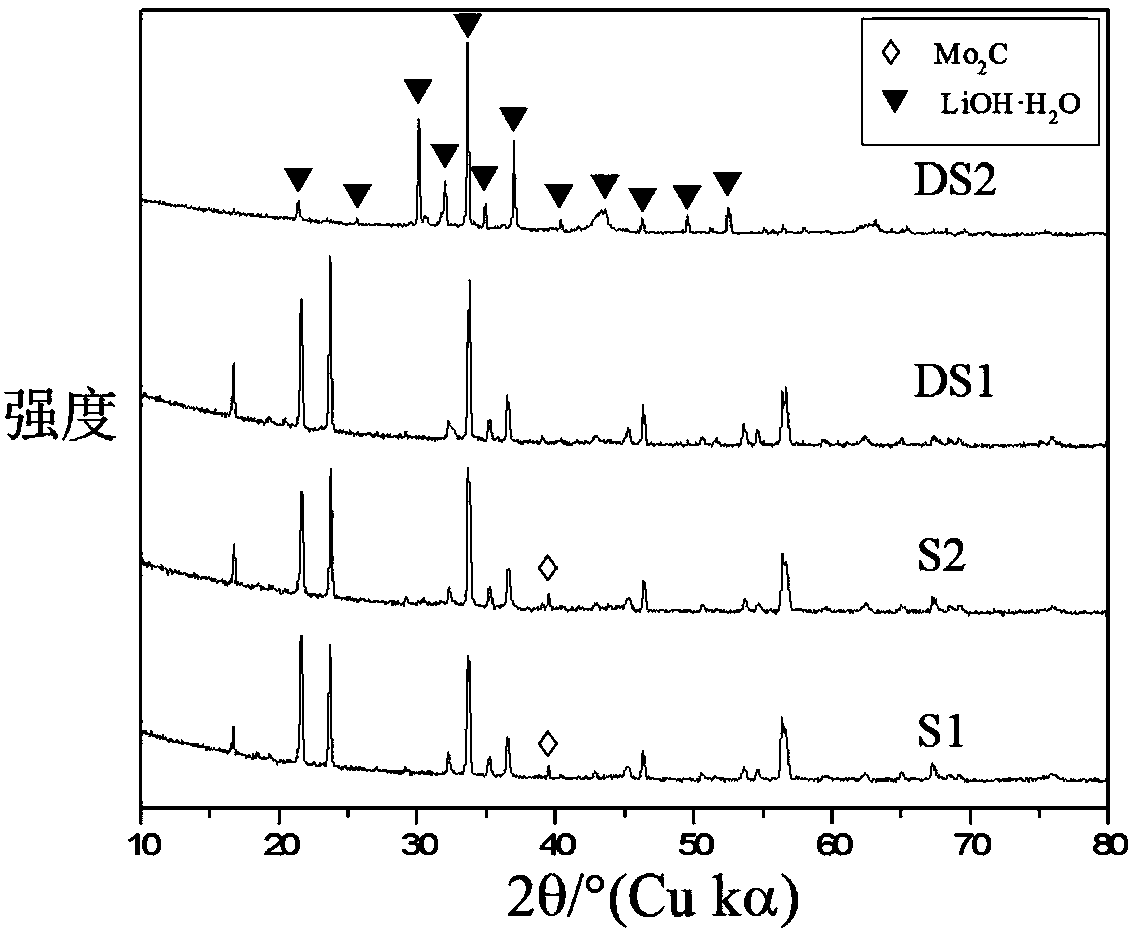

Positive active material, preparation method thereof, positive electrode and high-specific energy power battery

The invention provides a positive active material. The positive active material comprises a core and a coating layer, wherein the coating layer is arranged on a surface of the core, the material of the core comprises Li5FeO4, and the material of the coating layer comprise Mo2C and carbon. A preparation method of the positive active material, a positive electrode comprising the positive active material and the high-specific energy power battery are also provided. With the positive active material provided by the invention, the influence of water in air on the core layer Li5FeO4 can be isolated,the material stability is improved, and the conductivity and the stability of the battery are improved.

Owner:SHENZHEN BYD LITHIUM BATTERY

Pipeline under-pressure leakage stoppage repairing and multiple-layer long-acting anti-corrosion device and construction method thereof

ActiveCN111520570AFree from corrosion damageDoes not affect bindingAntifouling/underwater paintsPaints with biocidesSurface engineeringInsulation layer

The invention discloses a pipeline under-pressure leakage stoppage repairing and multi-layer long-acting anti-corrosion device and a construction method thereof and belongs to the technical field of surface engineering. A six-layer protection system including a leakage stoppage and strengthening layer, anticorrosive paste, an inflaming retarding anti-corrosion belt, an oily blocking layer, an anti-corrosion protection cover and a contamination-preventing and weather-proof face coating is adopted, due to the extremely good tracing ability of the six-layer protection system, the six-layer protection system can be tightly combined with a base material, a protection film composed of the anticorrosive paste and the inflaming retarding anti-corrosion belt and surface oxide of the base material can be subjected to complexation so as to prevent secondary corrosion, meanwhile, the erosion of a corrosive medium on the base material is isolated, sealing protection on anti-corrosion components isachieved through an external oily material insulation layer and the nonmetal protection cover, it is ensured that the anti-corrosion components are not lost, the contamination-preventing face coatingof the inflaming retarding nonmetal protection cover has prominent dirt-preventing performance and good weather-resisting performance, and a permanent outer protection function is provided for the protection cover.

Owner:青岛海弗莱安全科技有限公司

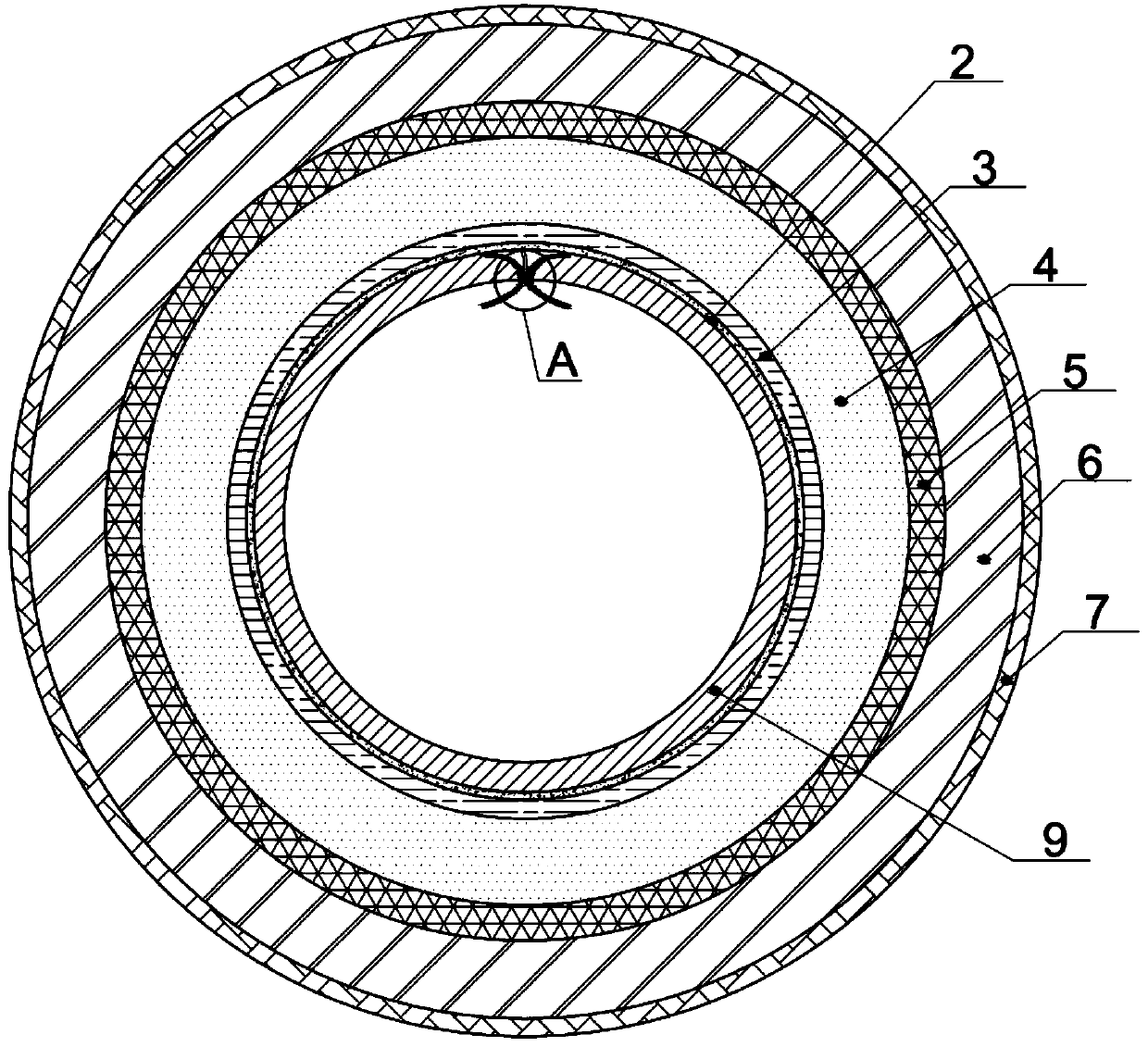

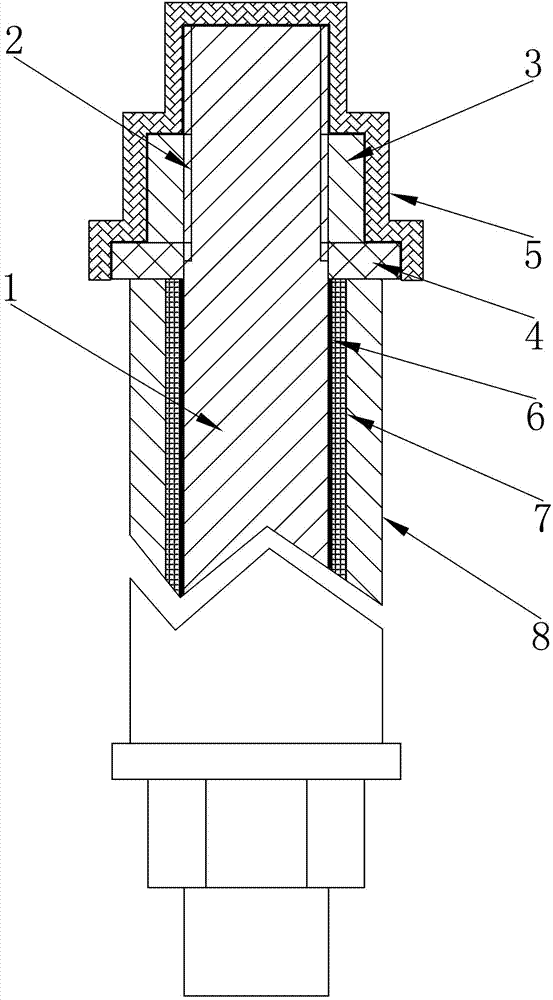

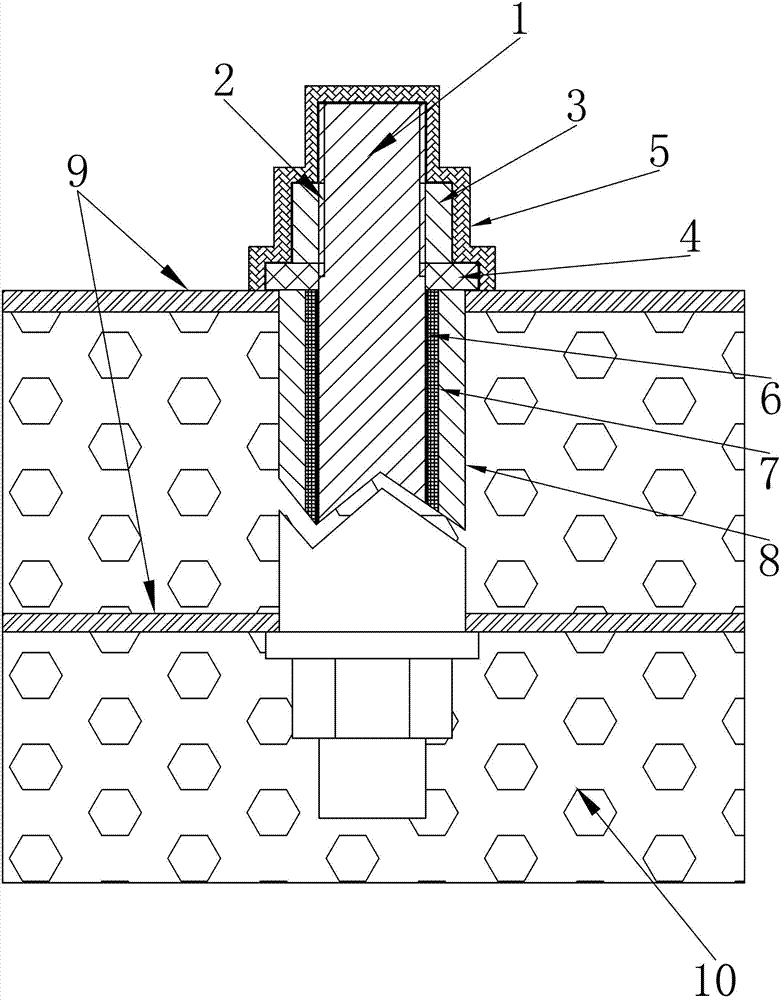

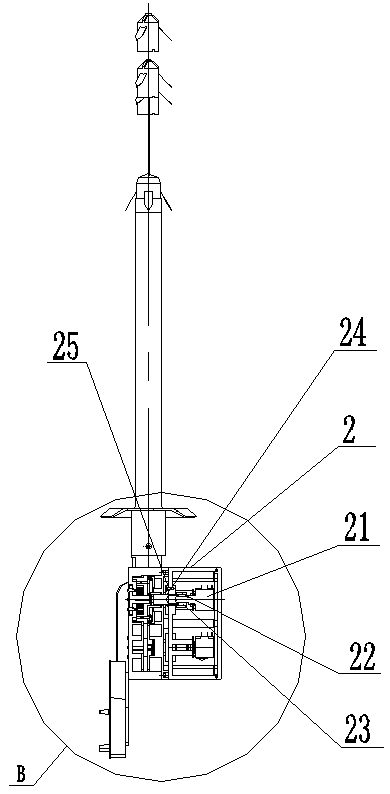

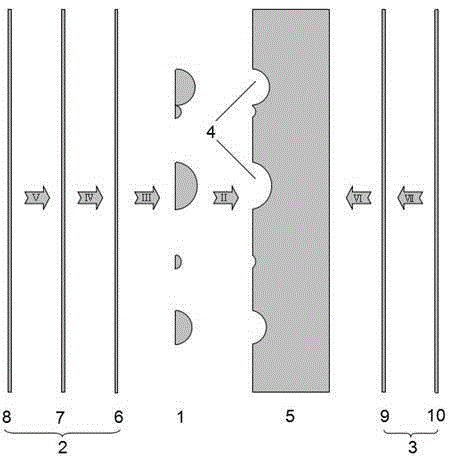

Anchor bolt for marine wind power base

The invention discloses an anchor bolt for a marine wind power base, which comprises a screw rod (1), wherein both ends of the screw rod (1) are respectively provided with a thread section (2); at least one end of the screw rod (1) is provided with a protective nut (3), a gasket (4) and an antirust cover (5) capable of covering the exposed thread section (2); the surfaces of the screw rod (1), the nut (3) and the gasket (4) are respectively provided with a chromium-free Dacromet coating (6); an epoxy glass lamella coating (7) is arranged on the chromium-free Dacromet coating (6) of the screw rod (1); and an anticorrosion sleeve (8) matched with the outer diameter of the screw rod (1) is also sheathed on the screw rod (1). The thread section (2), the gasket (4) and the nut (3) at the end provided with the antirust cover are respectively coated with an epoxy zinc-rich primer which performs the functions of shielding and cathodic protection. The thickness of the chromium-free Dacromet coating (6) is 10.0-11.9 micrometers, and the thickness of the dry film of the epoxy glass lamella coating (7) is 50-80 micrometers.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

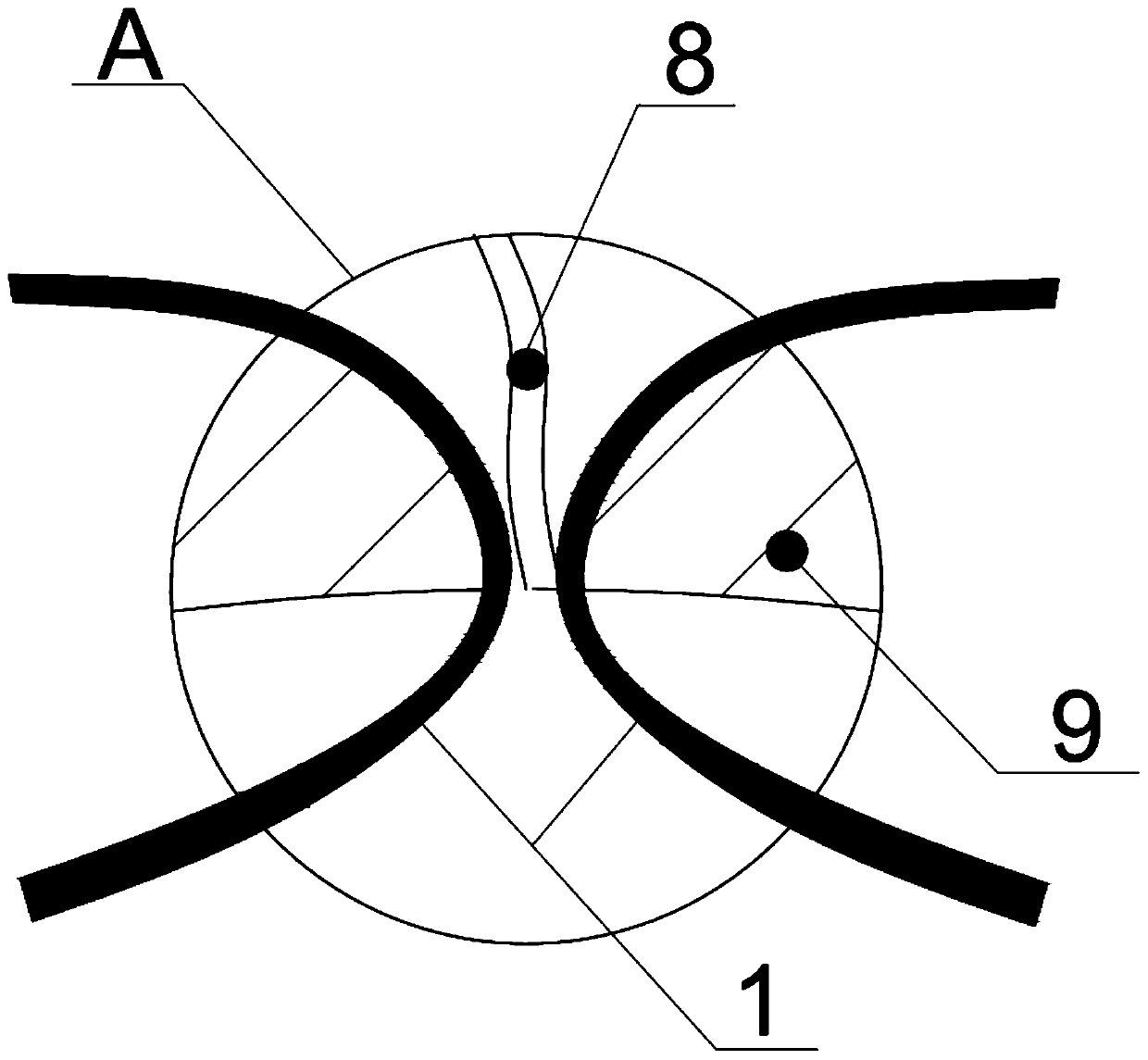

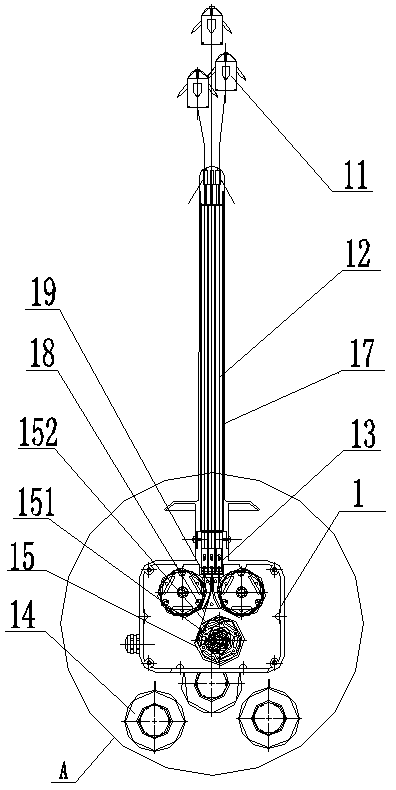

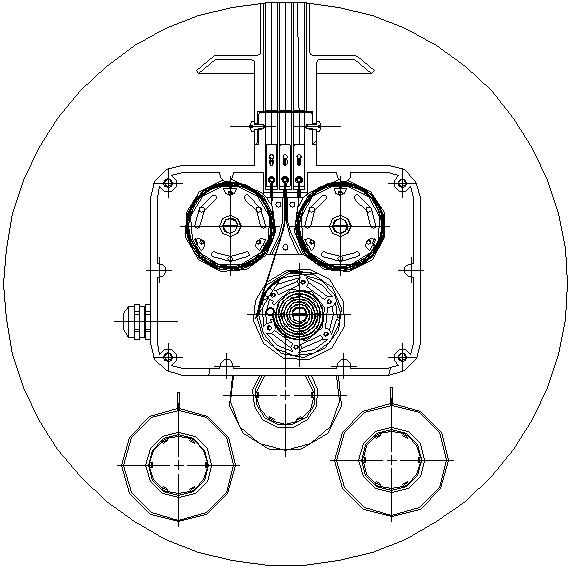

Three-base-point roof separation layer monitor

PendingCN109163688AInsulation erosionGuaranteed accuracyMeasurement devicesEngineeringField monitoring

The invention discloses a three-base-point roof separation layer monitor, and relates to a coal mine production field monitoring instrument. The three-base-point roof separation layer monitor comprises a guide pipe, a mechanical shell, an electrical shell and three sets of independent separation layer monitoring mechanisms same in structure, and is used for respectively monitoring a shallow base point A and a deep base point B of a separation layer and a deep base point C in a steady rock layer, which is 8-14 meters from a tunnel roof. A mechanical and electrical combined monitoring device isdesigned in the invention; displacement between an anchor fluke and the top of a device due to the separation layer is converted into an electrical signal of a potentiometer; displacement of the separation layer is displayed after processing; the measurement effectiveness and accuracy can be improved; the three sets of mutually independent separation layer monitoring mechanisms are designed; the deep base point in the steady rock layer, which is 8-14 meters from the tunnel roof, is increased in the monitoring base points; the base point is used as the stationary reference point, and used as amovement reference of the roof separation layer; and thus, the accuracy and the reliability of the measured separation layer data are ensured.

Owner:TAIAN SUCCEED ELECTRONICS SCI & TECH

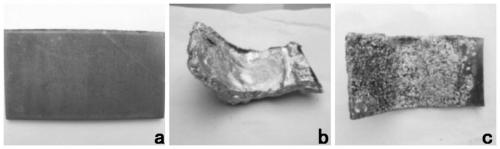

Repair method for steel storage tank corrosion pit

InactiveCN105345388AReduce the difficulty of repairReduce the possibility of using open flamesMolten spray coatingFiberCarbon fibers

The invention relates to a repair method for a steel storage tank corrosion pit and belongs to the technical field of welding. A pit after repair comprises three parts, including aluminum for filling up the pit, an aluminum-sprayed erosion resistant coating on the inner surface and a carbon fiber sheet back-up coat on the outer surface. In the repair method, the aluminum for filling up the pit plays the roles of smoothing tank wall and facilitating construction of the erosion resistant coating in later period and delaying of tank wall corrosion because the erosion resistant coating is used as a positive pole after corrosion perforation; the aluminum-sprayed erosion resistant coating on the inner surface can isolate direct contact between stored matter and steel of the tank wall and play the roles of delaying or even stopping further erosion and protecting the tank wall; the carbon fiber sheet back-up coat on the outer surface plays the roles of solidifying the tank body and shearing internal pressure so as to prevent discarding of the storage tank caused by the fact that the tank wall is thinned and cannot bear internal pressure. The combined use of the three parts can lastingly and effectively protect and solidify the storage tank.

Owner:WUHAN UNIV

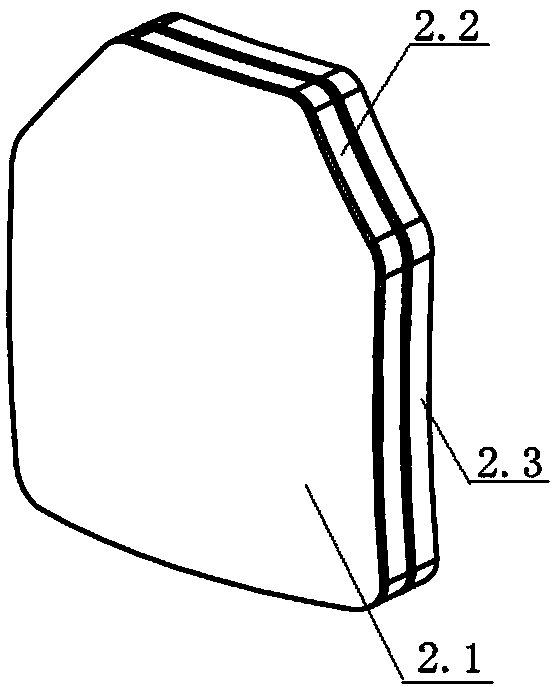

Vacuum composite bulletproof plug board and manufacturing method thereof

The invention discloses a bulletproof plug board and further discloses a manufacturing method of the bulletproof plug board. The plug board comprises a shell. The shell is further provided with a sealed cavity. The sealed cavity is internally provided with an inner core structure, and the inner core structure is matched with the sealed cavity in shape and size; the inner core structure comprises acrack arresting layer, a bullet breaking layer and a reinforcing layer which are arranged sequentially; and the crack arresting layer comprises an aramid fiber crack arresting layer body, the bulletbreaking layer comprises a boron carbide bullet breaking layer body, and the reinforcing layer comprises a polyethylene reinforcing layer body. The bulletproof plug board can effectively isolate erosion of severe environments such as ultraviolet rays and air to a bulletproof inner core, the stability of the bulletproof plug board is improved greatly, and the service life of the bulletproof plug board is prolonged greatly. In addition, the outer surface of the bulletproof plug board is completely and closely welded through a titanium alloy, and thus the waterproof, dampproof and abrasion-resistant effects can be achieved. The bullet facing surface adopts a titanium alloy bulletproof armor board so that when the bulletproof plug board is subjected to bullet striking, the situation that ceramic splutters and hurt people can be effectively prevented.

Owner:湖北贵族真空科技股份有限公司

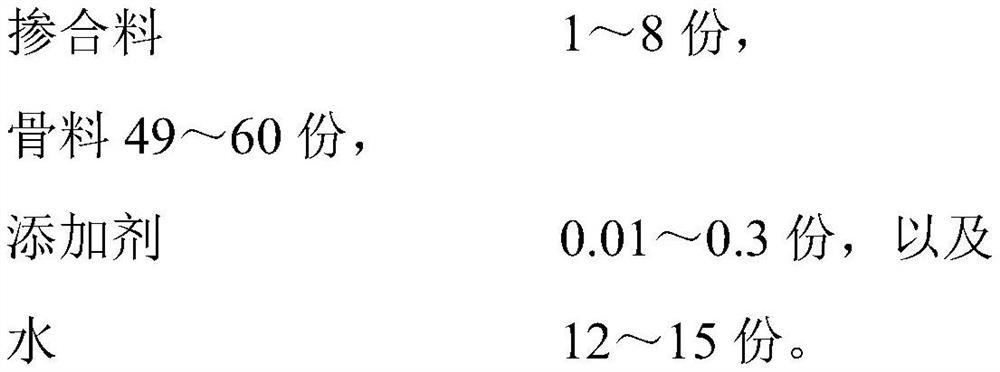

Medicament composition for preventing relapse and for treating gastric ulcer

InactiveCN101347463AGuaranteed stabilityInsulation erosionOrganic active ingredientsDigestive systemSide effectOligosaccharide

The invention discloses a medicine composition for preventing recurrence and curing gastric ulcer. The active components contain the raw materials with the following parts by weight: 10 to 85 portions of chito-oligosaccharide, 5 to 90 portions of algae colloid and 0 to 25 portions of dietary fiber. The medicine composition, with definite efficacy, naturalness and no toxicity and side effect, can form highly mucous gel similar to biological gastric mucus of human body with high antibacterial effect and viscosity in stomach body. When adverse factors reduce the secretion and synthesis of gastric mucus, the composition can timely supplement the biological gastric mucus of human body so as to ensure an important protection barrier for gastric mucosa is obtained and the composition effectively prevent recurrence and cure gastric ulcer, which is different from the conventional curing method of using antacid agent and anti-secretion agent to inhibit excessive secretion of gastric acid.

Owner:阎玲

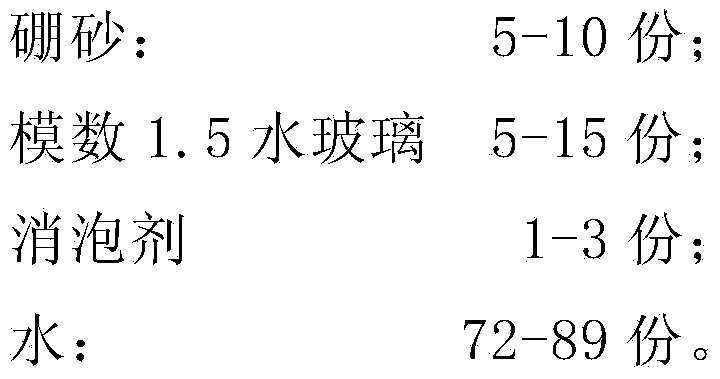

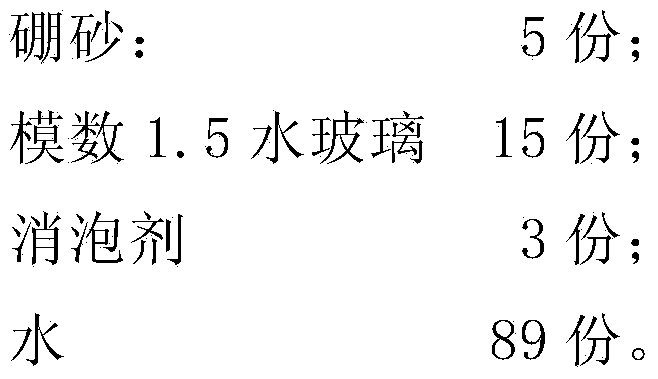

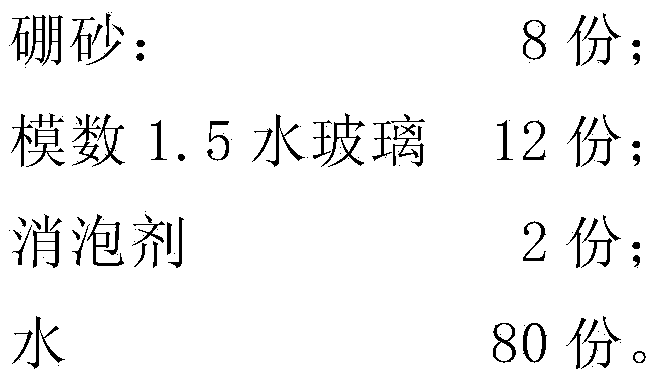

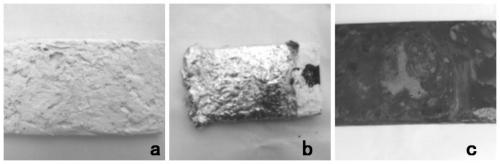

Anti-decarbonizing agent for bearing steel thermal treatment for preparing bearing and preparation method thereof

The invention discloses an anti-decarbonizing agent for bearing steel thermal treatment for preparing a bearing. The anti-decarbonizing agent is prepared from the following raw materials in parts by weight: 5-10 parts of borax, 5-15 parts of water glass with modulus of 1.5, 1-3 parts of defoamer and 72-89 parts of water. The preparation method comprises the following steps: first, heating water to 60-70 DEG C; adding borax to stir and dissolve; adding the defoamer till borax is fully dissolved; and uniformly stirring and gradually adding water glass with modulus of 1.5 to obtain the anti-decarbonizing agent. The anti-decarbonizing agent disclosed by the invention can form a compact chemical protective film on the surface of bearing steel to prevent a decarbonizing layer from being formed on the surface of the bearing steel due to thermal treatment, so that the grinding allowance can be reduced by 20-30%, thereby improving the processing efficiency. As the compact chemical protective film on the surface of a steel product can isolate corrosion of oxygen and water vapor in a put process after thermal treatment, anti-rust treatment is reduced or avoided. The anti-decarbonizing agent disclosed by the invention is particularly suitable for thermal treatment of a mesh belt furnace.

Owner:广德中隆轴承有限公司

Efficient silicon solar module

InactiveCN105140323AReduce the chance of occurrenceDelay agingPhotovoltaic energy generationSemiconductor devicesHigh transmittanceEthylene-vinyl acetate

The invention discloses an efficient silicon solar module, which comprises a tempered glass layer, an ethylene-vinyl-acetate (EVA) layer I, a silicon layer, an EVA layer II and a back plate, wherein at least one antireflection film also coats the outer surface of the tempered glass layer; the thickness of each antireflection film is d; d=(n+0.25)lambda; lambda is 400-760nm; the exposed surface of the EVA layer I is a high-transmittance modified EVA plastic layer coated with an oxygen barrier layer; the exposed surface of the EVA layer II is a thermally stably modified high-heat dissipation EVA plastic layer coated with the oxygen barrier layer; and the back plate is in a multi-layer structure. The efficient silicon solar module has the advantages of stable structure, high solar utilization efficiency and high generation efficiency, and simultaneously has good heat dissipation property.

Owner:宁波贝达新能源科技有限公司

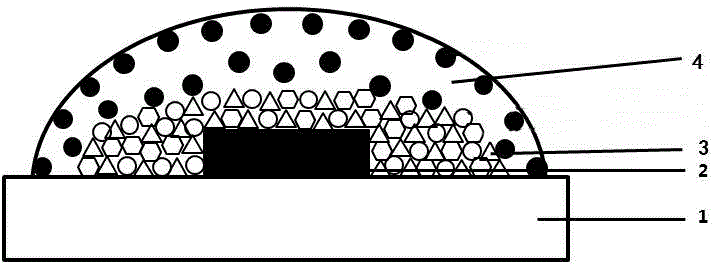

Ultraviolet light-emitting diode promoting growth of plants

InactiveCN103560201AHigh luminous intensityImprove luminous efficiencySemiconductor devicesRare earthUltraviolet lights

An ultraviolet light-emitting diode promoting growth of plants comprises a base, an ultraviolet light-emitting diode chip, a light-emitting layer and a packaging layer, wherein the light-emitting layer and the packaging layer are arranged on the ultraviolet light-emitting diode chip. The light-emitting layer on the ultraviolet light-emitting diode chip is formed by mixing high-purity inorganic nano light-emitting materials, rare earth blue fluorescent powder and rare earth red fluorescent powder. The packaging layer is formed by mixing packaging glue and inorganic nano powder and applied to the light-emitting layer of the ultraviolet light-emitting diode chip. Because an ultraviolet light source serves as an exciting source body of the light-emitting layer on the ultraviolet light-emitting diode chip, light emitting strength can be effectively improved, light emitting efficiency can be improved, the high-purity inorganic nano light-emitting materials, the rare earth blue fluorescent powder and the rare earth red fluorescent powder can be excited, and light can be more sufficiently and evenly emitted. Because the inorganic nano powder with the ultraviolet shielding ability is mixed in the packaging layer, redundant ultraviolet can be absorbed, large-wavelength blue light can be emitted, and the ultraviolet is effectively shielded and the plants are less damaged on the premise that red light and blue light pass.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Coating for garbage cremator inner wall

InactiveCN101323720AExtended service lifeInsulation erosionCoatingsIncinerator apparatusTalcIncineration

The invention relates to a paint, in particular to a corrosion-inhibiting and crust-promoting paint of the internal wall of a garbage incinerator. Talcum powder with the proportion of 5 percent to 20 percent, aluminous powder with the proportion of 50 percent to 80 percent, silica powder with the proportion of 1 percent to 5 percent, bentonite with the proportion of 1 percent to 10 percent and fluorite powder with the proportion of 1 percent to 10 percent are taken as raw materials, borax with the proportion of 1 percent to 10 percent and sodium tripolyphosphate with the proportion of 1 percent to 5 percent are taken as bonding agents, tartaric acid conservant occupies the proportion of 5 percent to 10 percent, a proper amount of water is added, and a paste paint is formed after mixing, grinding and stirring. The paint has the advantages of being capable of preventing the castable of the internal wall of the garbage incinerator from corrosion and prolonging the service life of the internal wall of the garbage incinerator, and the paint is simple to be prepared and easy to be applied.

Owner:韩亚伟

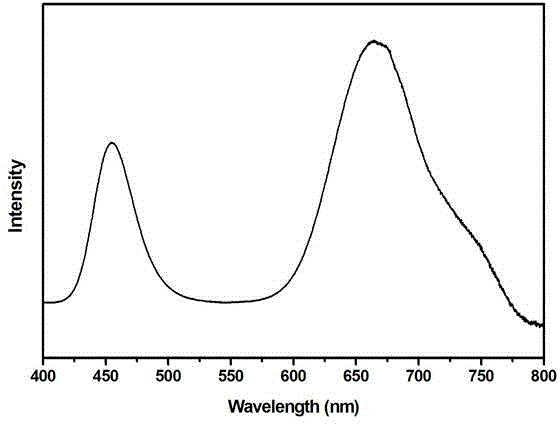

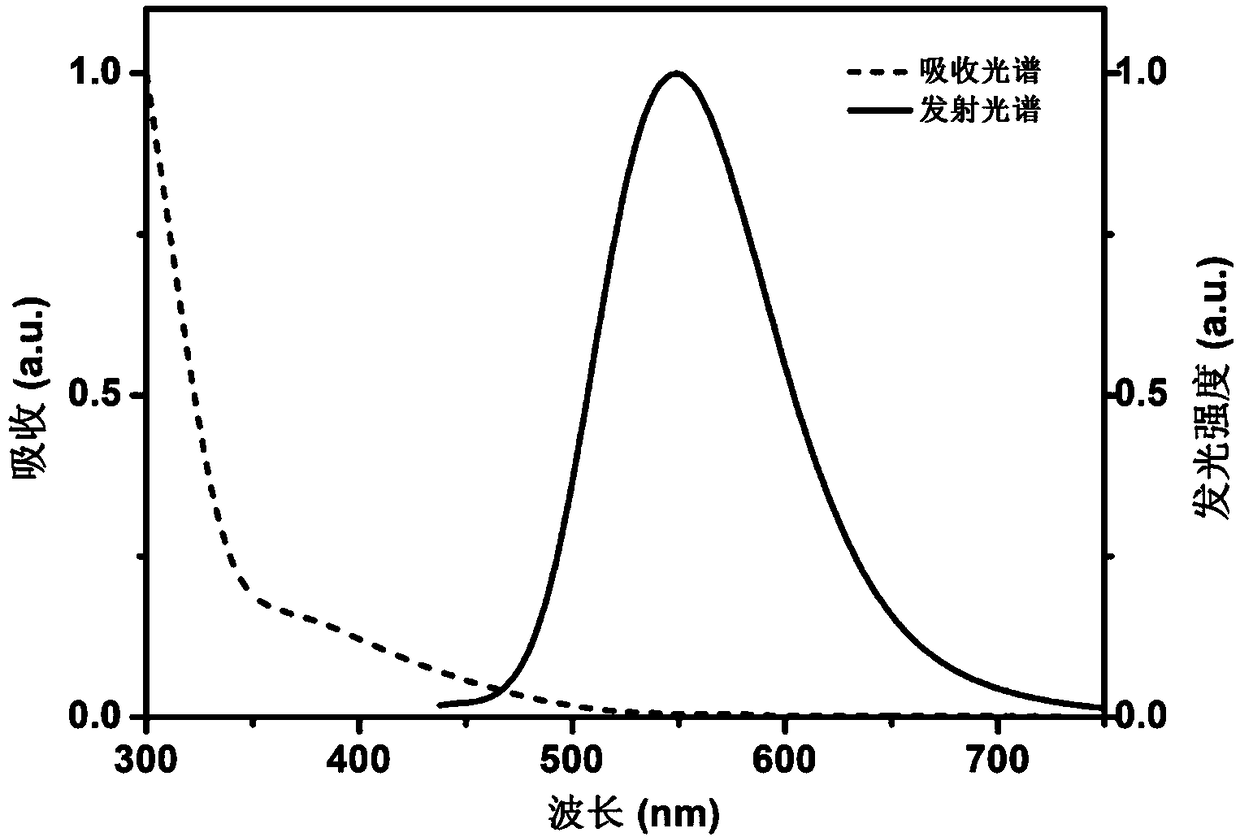

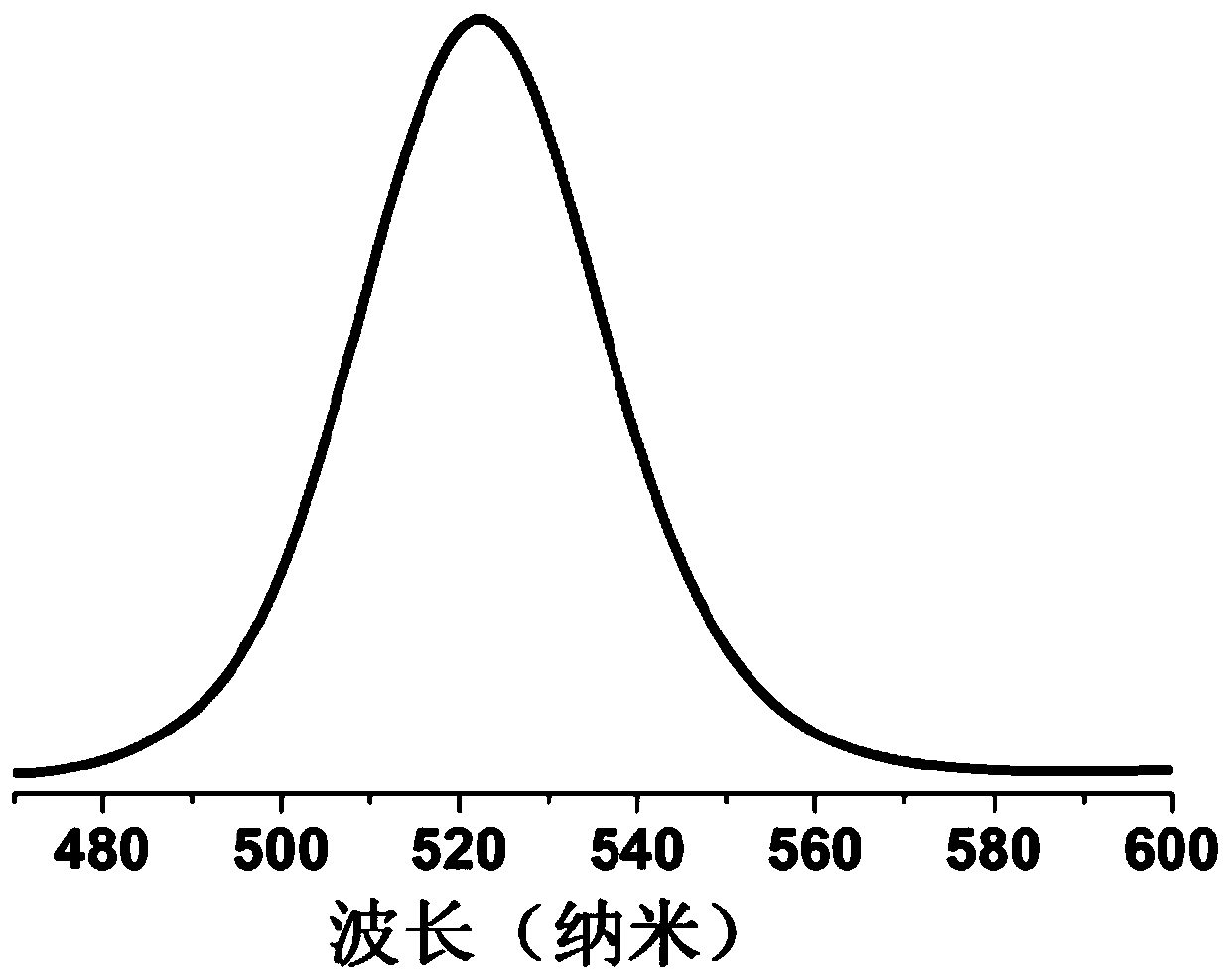

High-performance quantum dot white light LED and preparing method thereof

ActiveCN108110123AImprove luminous efficiencyGood colorSemiconductor devicesLattice mismatchRe absorption

A high-performance quantum dot white light LED and a preparing method thereof belong to the field of semiconductor illumination. The high-performance quantum dot white light LED is based on an electroluminescent blue light LED chip. The high-performance quantum dot white light LED is obtained through successively coating a CdSe / CdS / ZnS quantum dot thin-film layer which emits red light and a Cu:ZnInS / ZnS / ZnS:Al quantum dot thin-film layer that emits green light. According to Cu:ZnInS / ZnS / ZnS:Al quantum dot which emits green light, Al3<+> can be packaged through kernel doped Cu2<+> and an external ZnS housing layer, thereby improving light / thermal stability. The CdSe / CdS / ZnS gradient alloy quantum dot which emits red light supply multiple-housing-layer protection, thereby reducing defects caused by surface crystal lattice mismatch and preventing light degeneration. The coating manner of layered structure can remarkably suppress energy transmission and re-absorption between quantum dots and furthermore improves light emitting efficiency. The prepared quantum dot white light LED is suitable for an occasion wherein low color temperature, high color rendering index and high light emitting efficiency are required, and is particularly suitable for the displaying and illuminating field with relatively high requirement for light emitting stability.

Owner:JILIN UNIV

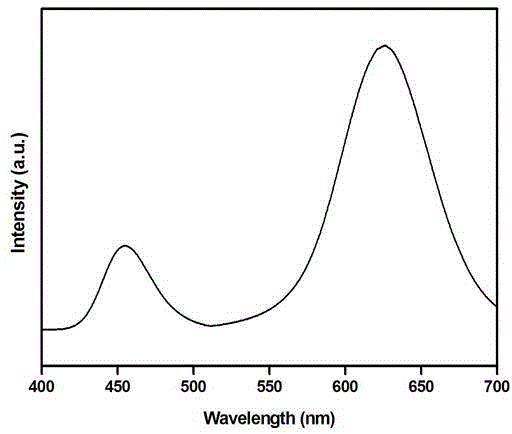

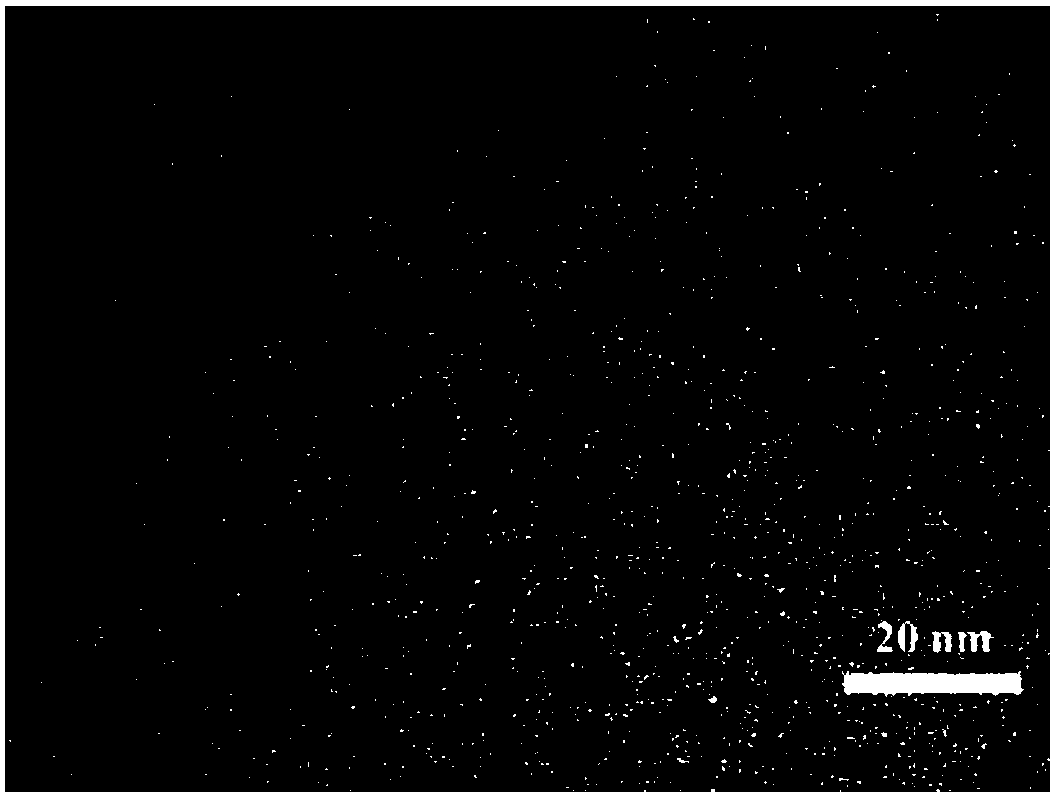

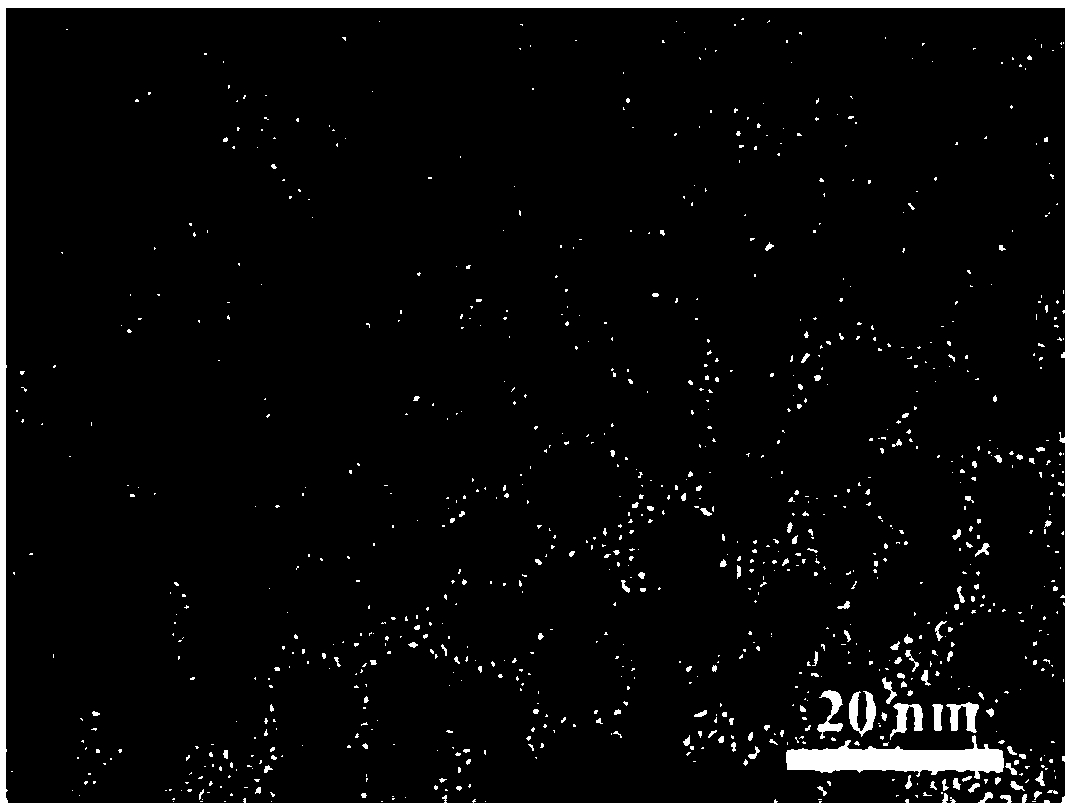

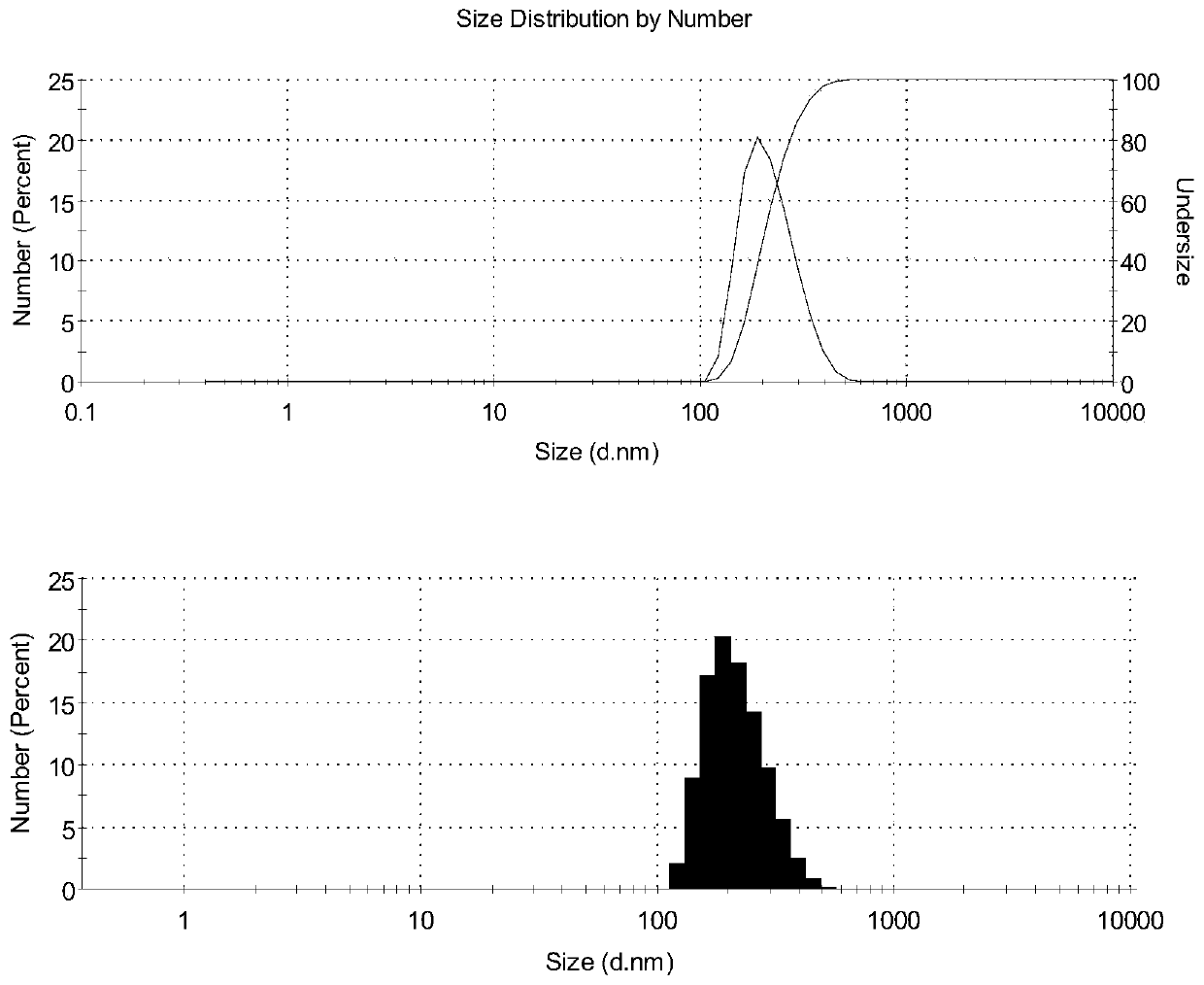

Water-phase quantum dot microcrystal preparation method

InactiveCN110699083AInsulation erosionImprove luminescence stabilityMaterial nanotechnologyNanoopticsChemical physicsPhoto stability

The invention belongs to the field of surface chemistry, and relates to a water-phase quantum dot microcrystal preparation method, which comprises: adding a stabilizer into a water-phase quantum dot solution, and drying and dehydrating to prepare a quantum dot microcrystal, wherein the stabilizer comprises a stabilizer A and a stabilizer B, the two stabilizers are matched, the stabilizer A is a salt solution containing divalent or trivalent cations, and the stabilizer B comprises a salt solution containing at least one monovalent cation. According to the prepared quantum dot microcrystal of the invention, by modifying and coating the water-phase quantum dots, the erosion of factors such as oxygen and the like to the quantum dots is isolated, and the light-emitting stability of the quantumdots is improved; and compared with the quantum dots dispersed in an aqueous solution, the water-phase quantum dot microcrystal of the invention has the following characteristics that the light emitting stability of the quantum dots is greatly improved, and the quantum dots can be stored for more than 6 months at a high temperature of 180 DEG C and a low temperature of minus 40 DEG C without luminous decay.

Owner:MA ANSHAN MICROCRYSTALLINE PHOTOELECTRIC MATERIAL CO LTD

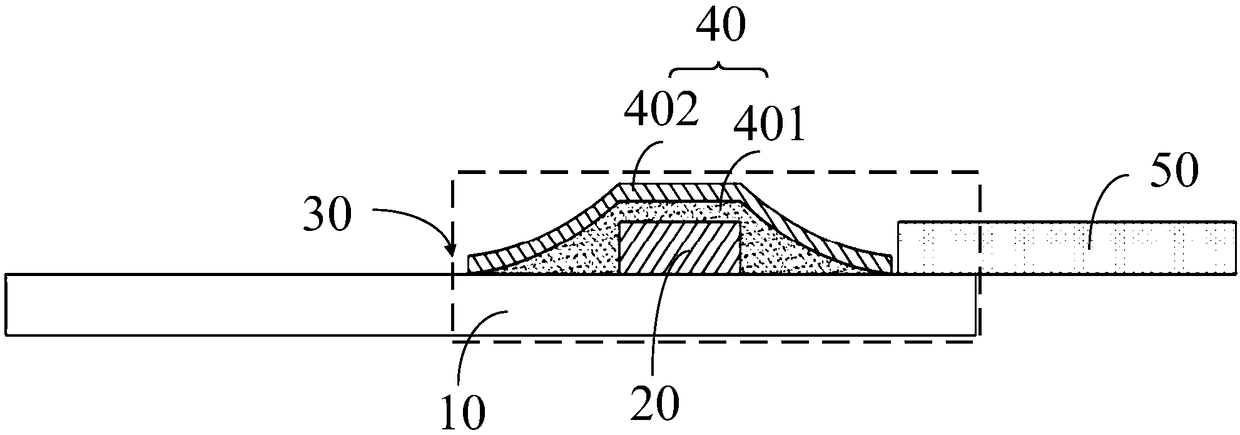

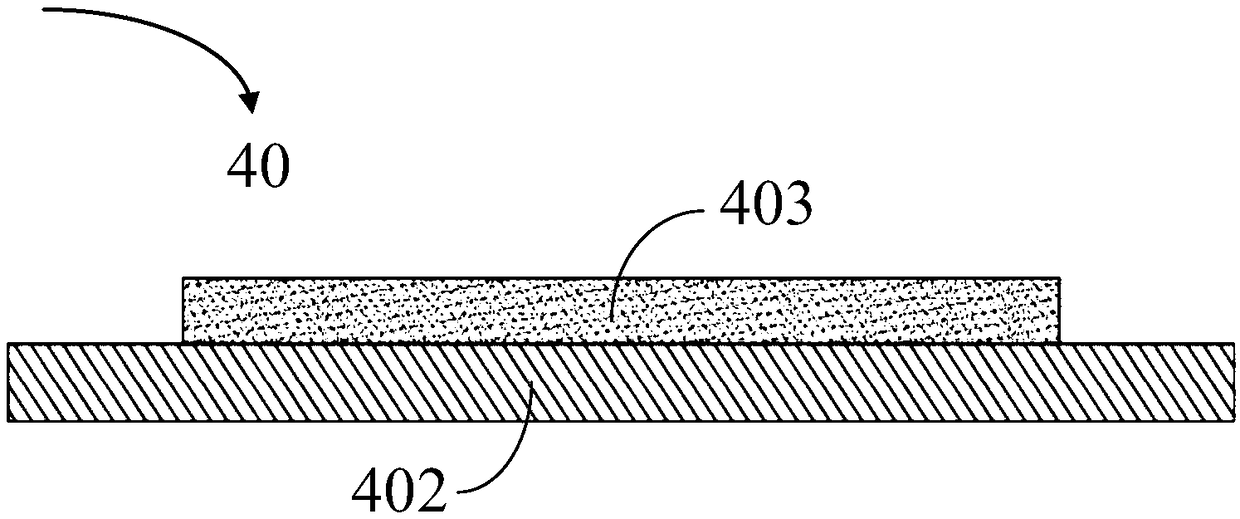

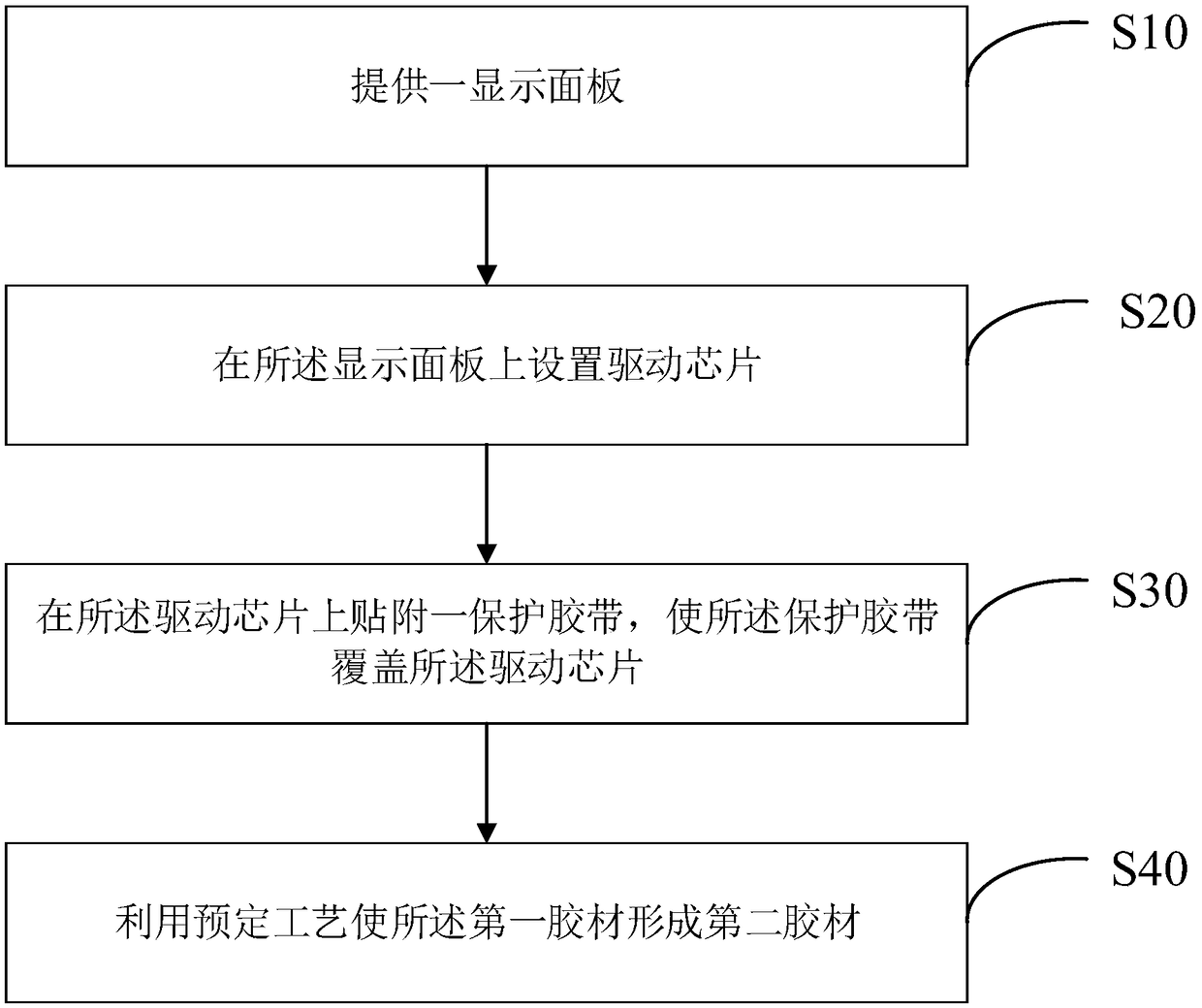

Display module, manufacturing method thereof, and electronic device

ActiveCN108983477AInsulation erosionImprove qualitySemiconductor/solid-state device detailsSolid-state devicesAdhesiveElectrical and Electronics engineering

The invention provides a display module, a manufacturing method thereof, and an electronic device. The display module includes a display panel, a driving chip located on the display panel, and a protective tape which is on the driving chip and comprises a second adhesive on the driving chip and a tape on the second adhesive, wherein the second adhesive fills a region between the tape and the display panel. According to the invention, by setting the protective tape on the driving chip, the second adhesive in the protective tape fills the region between the tape and the display panel, the tape is connected to the display panel such that a driving IC is completely covered by the protective tape, external water and oxygen are isolated from eroding the driving IC, and the quality of a display screen is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

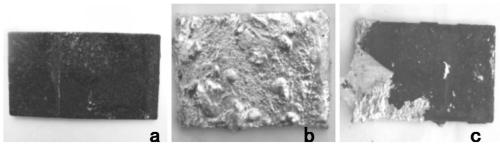

High temperature aluminium liquid corrosion resistant paint, and preparation method thereof

The invention belongs to the technical field of material, and more specifically relates to a high temperature aluminium liquid corrosion resistant paint, and a preparation method thereof. According tothe preparation method, raw materials are combined, glass powder and red mud are taken as the main components, borax, boric acid, and a carbonate are added as fluxing agents to reduce paint melting point, and improve the spreadability and fluidity on workpieces; zirconium oxide and titanium oxide are added to reduce paint layer thermal expansion coefficient, increase paint layer chemical stability and mechanical strength; isolating of contact and erosion of high temperature aluminium liquid on workpieces is realized, and excellent corrosion resistance is achieved. According to the preparationmethod of the high temperature aluminium liquid corrosion resistant paint, a bonding agent and water are added into the raw material components, an obtained mixture is used for uniform coating of workpieces, and high temperature sintering is carried out, and finally, a compact protective coating layer is formed on workpiece, combination of the coating layer with the workpiece is firm, hardness ishigh, chemical stability is high, and excellent washing-out resistance and corrosion resistance on high temperature aluminium liquid are achieved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

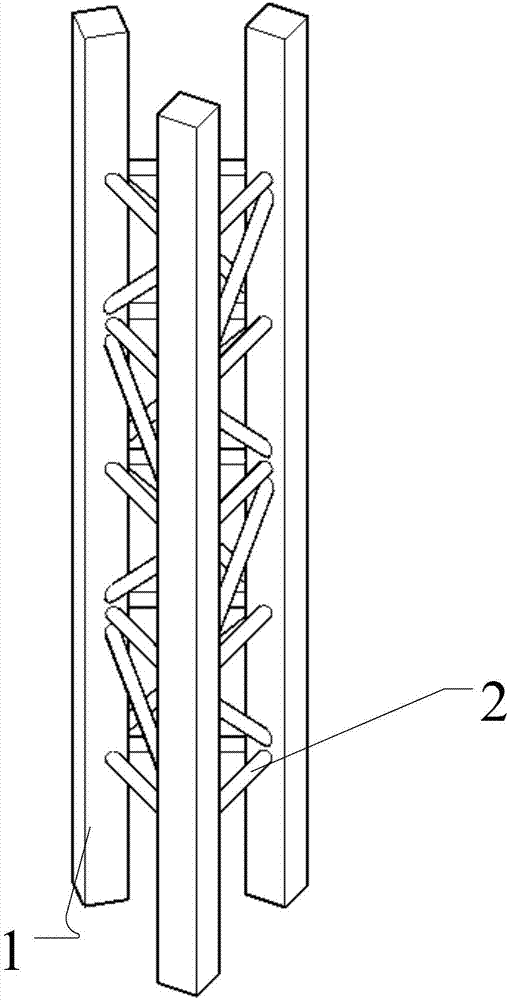

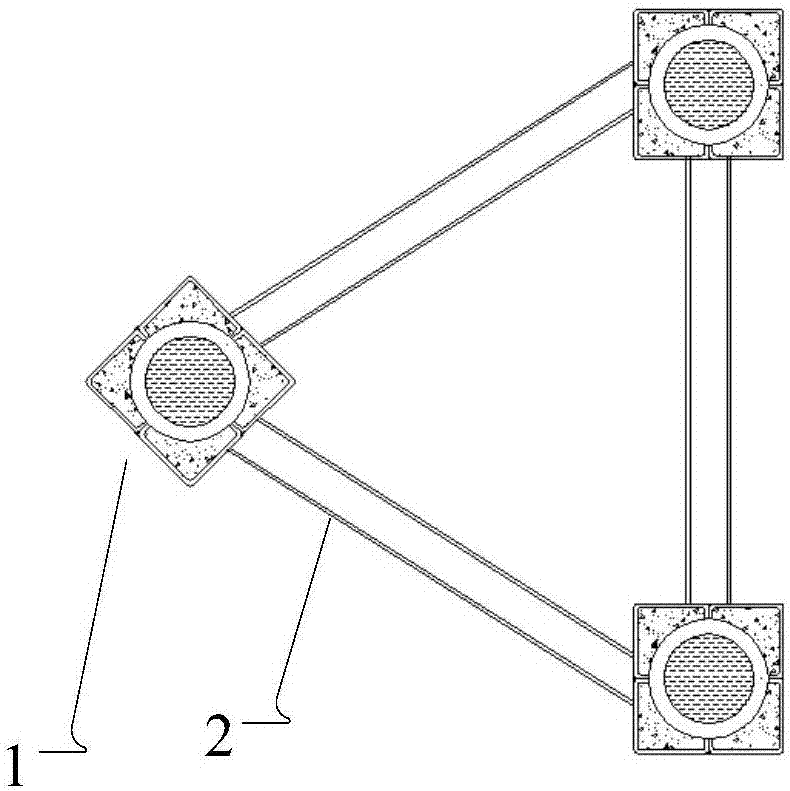

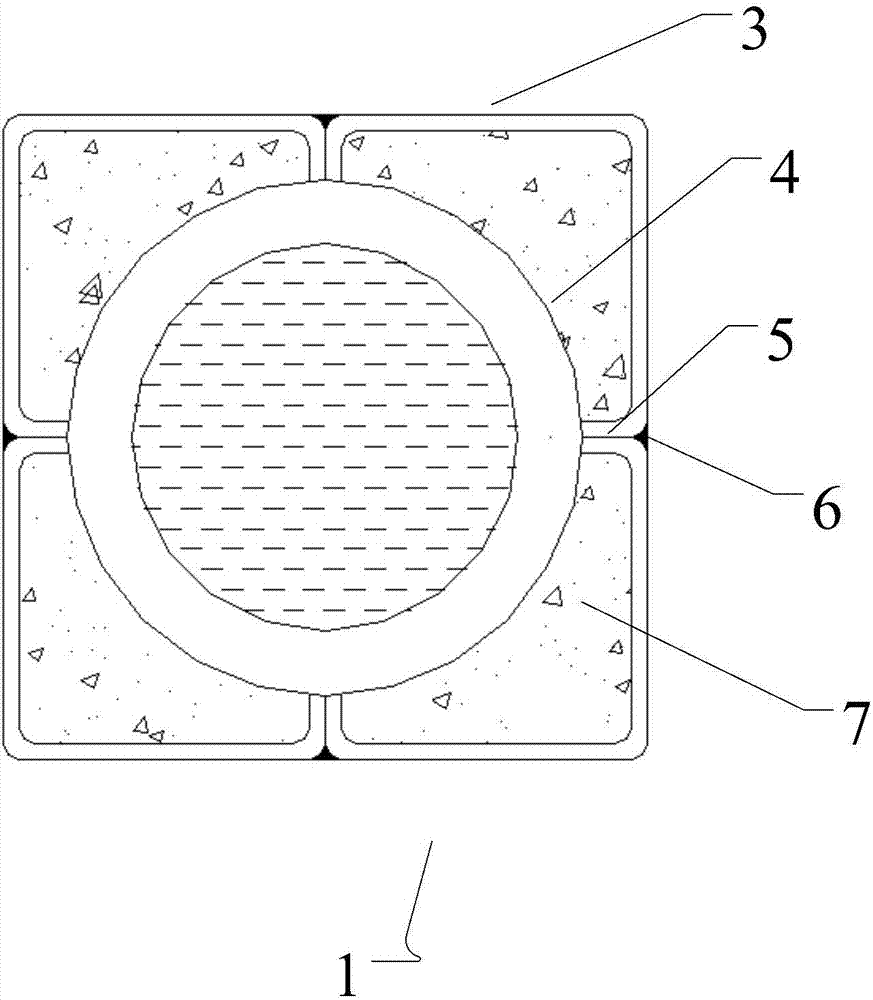

Self-elevating novel latticed pile leg for ocean platform

InactiveCN107165147AIncrease section sizeEasy to installArtificial islandsUnderwater structuresShock resistanceEngineering

The invention discloses a new lattice type pile leg of a self-elevating offshore platform, comprising a pile leg body arranged in parallel with a triangle, and is characterized in that: the pile leg body comprises a square steel pipe, and the inside of the square steel pipe is arranged along the length direction The stiffening rib is welded with a circular steel pipe, the interior of the circular steel pipe is hollow with water, and the space between the square steel pipe and the circular steel pipe is filled with concrete. The novel lattice type pile legs of the self-elevating offshore platform of the invention have the characteristics of high stability, strong bearing capacity, low cost, strong corrosion resistance, excellent seismic resistance, convenient maintenance and long service life.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

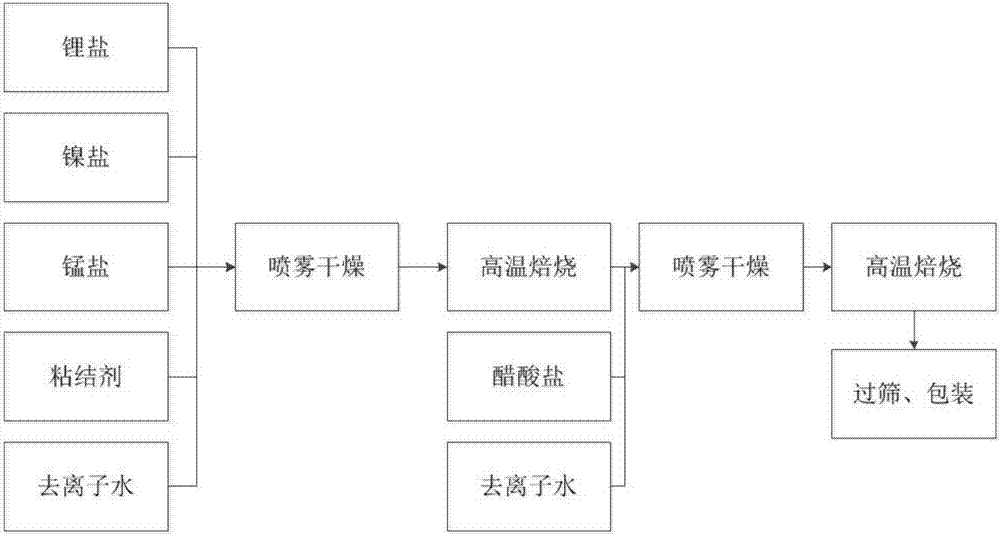

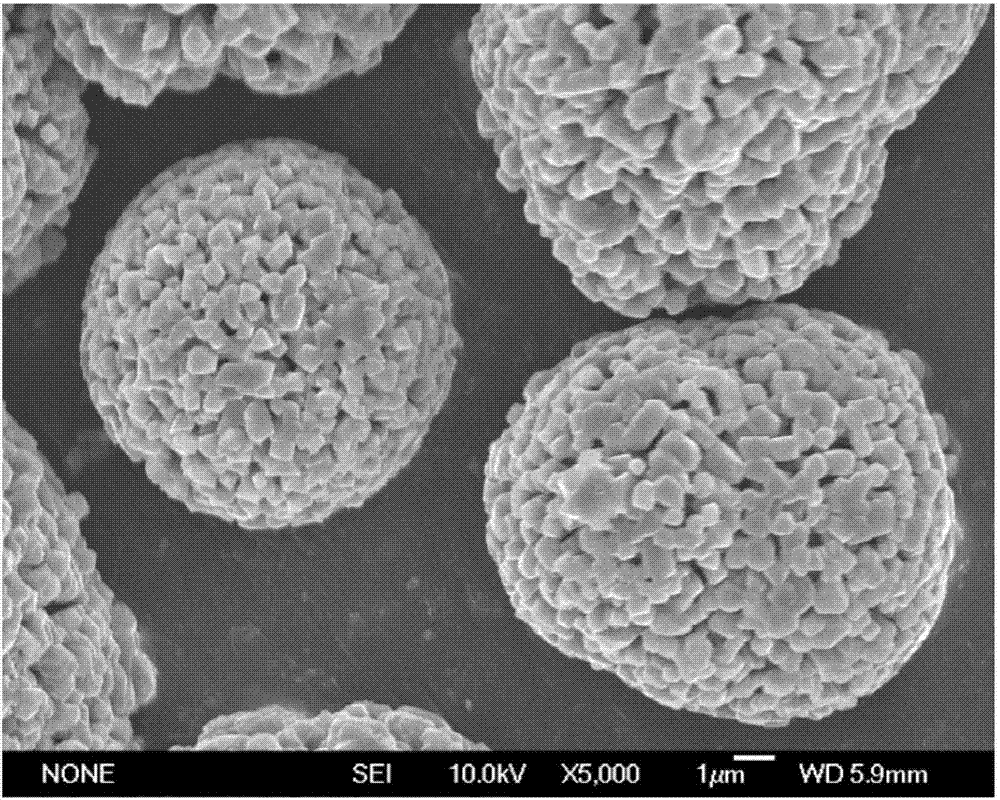

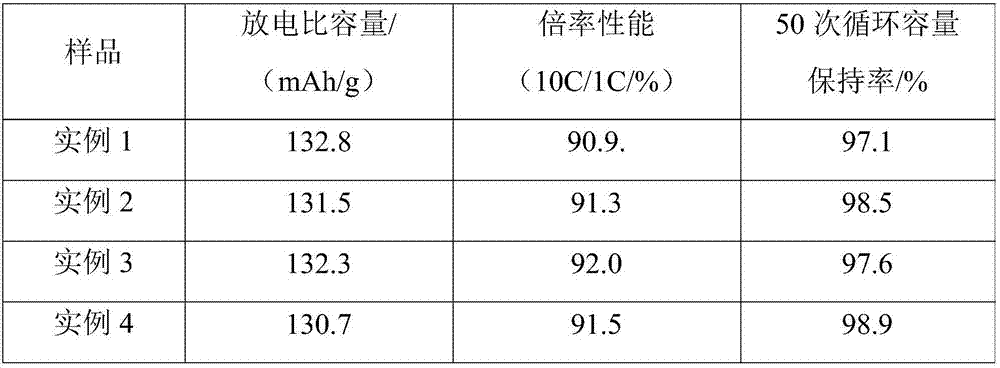

Spherical 5-V spinel lithium nickel manganese oxide material and preparation method thereof

InactiveCN106910878AInhibition of dissolutionWell mixedCell electrodesSecondary cellsAir atmosphereNickel salt

The invention discloses a preparation method for a spherical 5-V spinel lithium nickel manganese oxide material. The preparation method comprises the following steps: dissolving a lithium salt, a nickel salt, a manganese salt and a binder in deionized water so as to obtain a material I, wherein a mol ratio of Li to Ni to Mn is (1-1.05): 0.5: 1.5, and the mass of the binder accounts for 5 to 10% of the total mass of a lithium salt, a nickel salt and a manganese salt; subjecting the material I to spray drying and then to primary roasting at 800 to 900 DEG C in an air atmosphere for 4 to 12 h; uniform mixing a product obtained in the previous step with acetate in ionized water under stirring; and carrying out spray drying and carrying out secondary roasting at 450 to 550 DEG C for 6 to 12 h so as to obtain the spherical 5-V spinel lithium nickel manganese oxide material. The preparation method provided by the invention integrates the advantages of a conventional liquid-phase method and a conventional solid-phase method, omits the necessary step of precipitation of a lithium source, a nickel source and a manganese source in the liquid-phase method and overcomes the defect of non-uniform mixing of elements in the solid-phase method.

Owner:TIANJIN B&M SCI & TECH

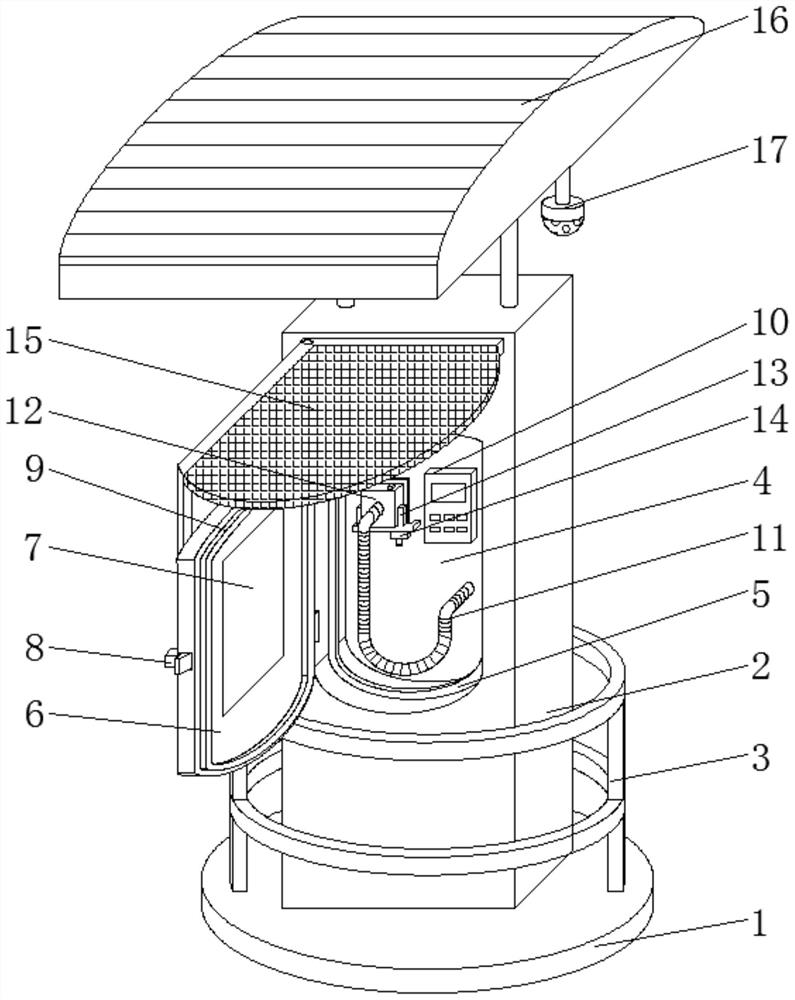

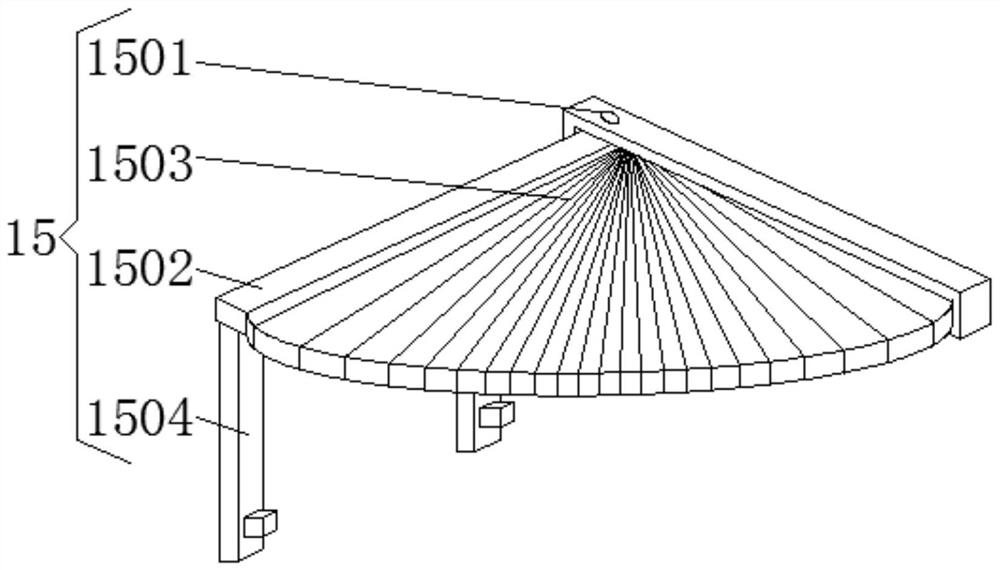

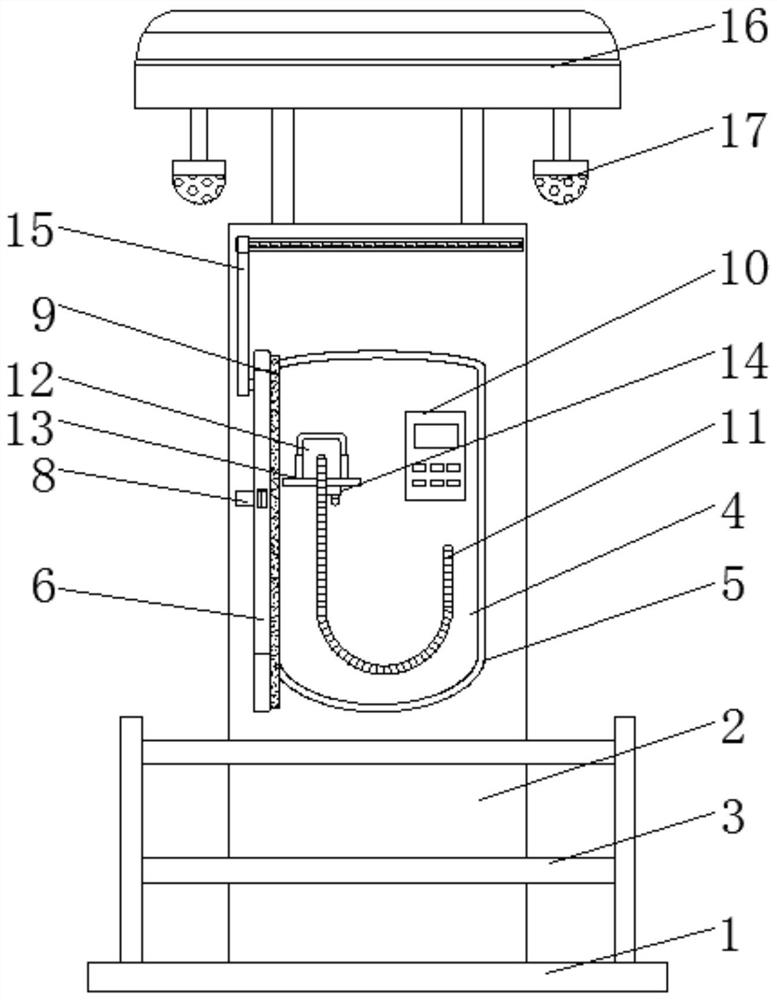

Matched protection device for new energy charging facility

InactiveCN112046315APrevent leakageAvoid damageCharging stationsElectric vehicle charging technologyRainy weatherSight line

The invention discloses a matched protection device for a new energy charging facility. The device comprises a bottom supporting seat, the upper surface of the bottom supporting seat is fixedly connected with a charging box, the upper surface of the bottom supporting seat is fixedly connected with an anti-collision fence, the front surface of the charging box is provided with a sealing groove, a sealing partition plate is arranged in the sealing groove, and one side of the sealing groove is hinged with a sealing door. An observation window is arranged on the sealing door, a convenient lockingmechanism is arranged on the sealing door and located on one side of the observation window, a sealing ring is fixedly connected to the back face of the sealing door, a man-machine exchange module isfixedly connected to the side face of the sealing groove, and a charging connecting wire is arranged on the side face of the sealing groove and located below the man-machine exchange module. Accordingto the matched protection device for the new energy charging facility, through cooperative arrangement of the sealing groove, the sealing door and the sealing ring, rainwater erosion can be more properly isolated when the device is in cloudy and rainy weather in the using process, and through arrangement of the anti-collision fence, a driver can be reminded when the sight line effect is poor in the using process.

Owner:郑州三骏能源科技有限公司

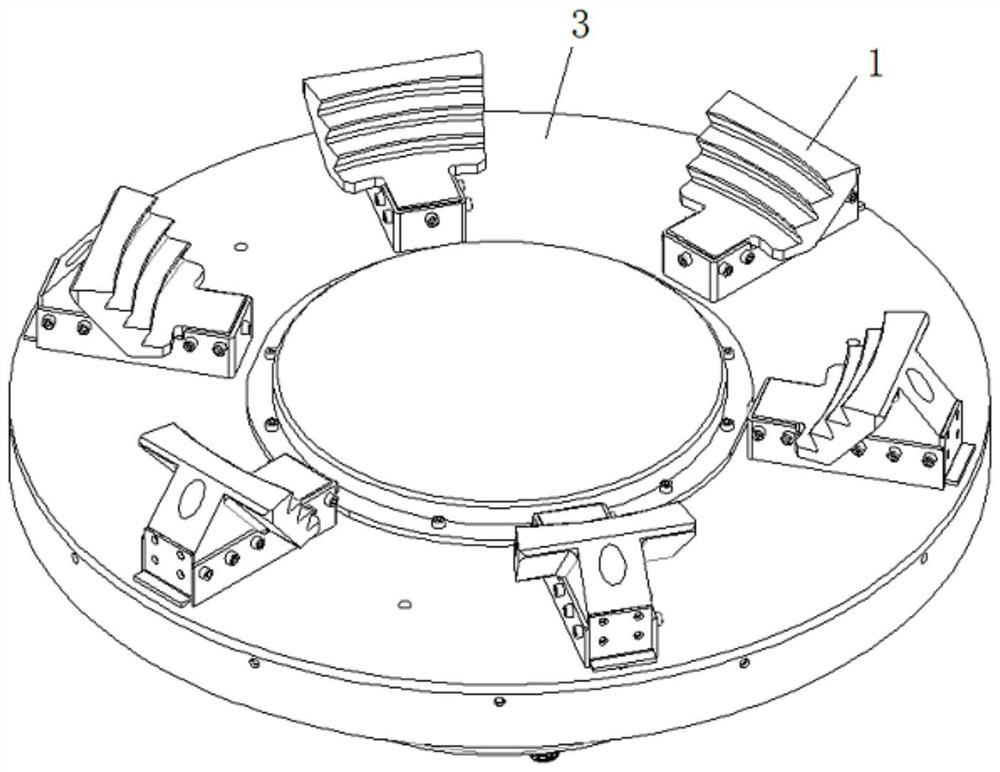

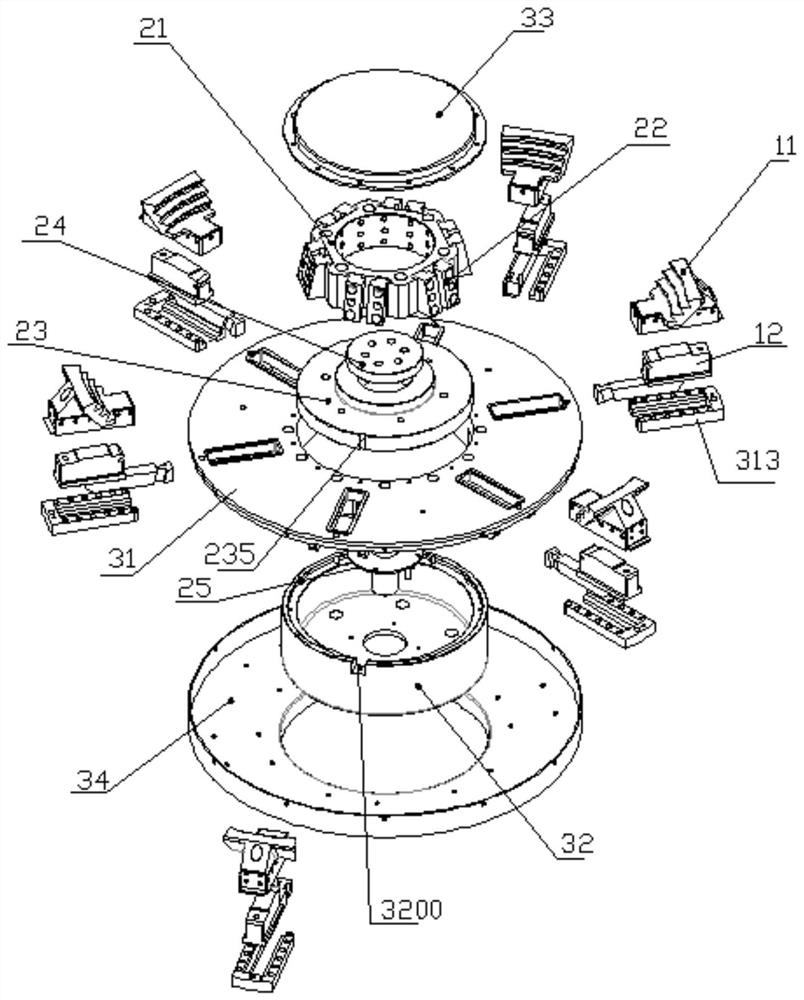

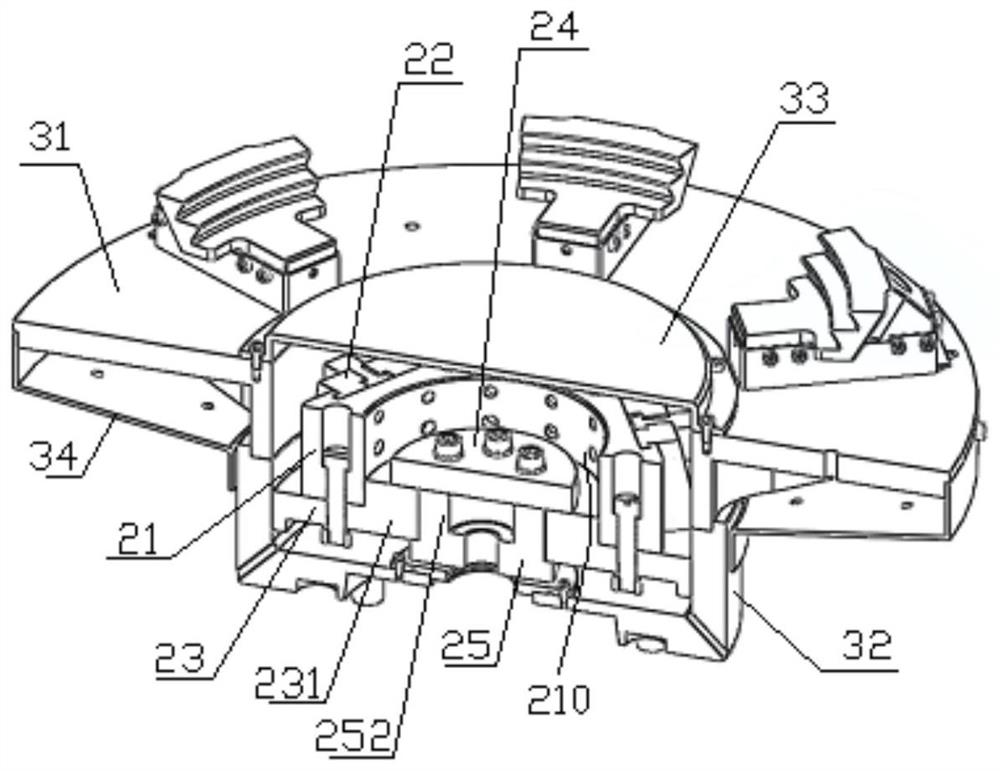

Flexible machining clamp for automobile hub

PendingCN112692622AImprove processing efficiencyReduce use costWork clamping meansPositioning apparatusStructural engineeringMechanical engineering

The invention discloses a flexible machining clamp for an automobile hub. The clamp comprises a clamping jaw, a clamping jaw driving seat and a clamping jaw disc, the clamping jaw driving seat is movably arranged in the hollow position of the middle of the clamping jaw disc, and a plurality of driving grooves which are obliquely formed in the axial direction of the clamping jaw disc are evenly distributed in the outer wall of the clamping jaw driving seat. The clamping jaws are connected to the clamping jaw disc in a sliding mode in the radial direction of the clamping jaw disc, a sliding arm is arranged on each clamping jaw, each clamping jaw is connected with the corresponding driving groove in a sliding fit mode through the corresponding sliding arm, and arc clamping jaw grooves distributed in a multi-step mode are formed in each clamping jaw and used for being matched with hubs of various sizes. Each clamping jaw is provided with a plurality of arc clamping jaw grooves distributed in a step shape, hubs of different sizes can be clamped without disassembly, the machining efficiency is improved, and the use cost is reduced. The designed clamping jaw driving seat structure adopts a hexahedron structure, so that the indexing is more accurate.

Owner:JIANGSU SLD PRECISION TECH

Metal-ceramic anticorrosion coating and preparation method thereof

ActiveCN103589273BImprove wear resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyNano al2o3

A cermet anti-corrosion coating, its formula mainly includes: kaolin, nano-aluminum powder, nano-alumina, silicon carbide, nano-quartz powder, porcelain powder, asbestos powder, graphite powder, pigments and fillers, epoxy resin, additives, mixed organic Solvents, etc., the solid powder is treated by nanometer ultra-fine processing, so that the particle size can reach 20-200nm. The paint of the invention is a one-component paint, and the manufacturing process is simple, economical and environmentally friendly. The paint coating does not need a primer, and can be used alone without a special topcoat. The coating has excellent wear resistance, corrosion resistance, impact resistance and stability. The coating has strong adhesion, dense and stable, and can effectively insulate Acid, alkali, salt, seawater erosion. It can be widely used in oil pipelines, oil storage tanks and chemical equipment, ships, bridges, offshore platforms and other steel structures.

Owner:SHANGHAI JIANYE TECH ENG

Environmental-friendly aqueous dust-removing and dust-preventing paint for steel structure

InactiveCN104673018AEasy constructionImprove compactnessFireproof paintsAnti-corrosive paintsAcrylic resinPolishing

The invention relates to an environmental-friendly aqueous dust-removing and dust-preventing paint for a steel structure. The paint is mainly prepared from the following components in percentage by mass: 15-60% of a silicone-contained acrylic resin solution, 1-40% of a rust-converting and rust-preventing agent, 5-30% of a rust-preventing flame retardant, 3-10% of pigments and filler and the balance of water. According to the dust-removing and dust-preventing paint provided by the invention, only loose rust scales on the surface and crusty old paints and oil strains need to be removed without complete polishing; the paint does not need to be diluted or is diluted with a small amount of water and can be used directly after being opened; the paint is commonly smeared once or twice, the surface dry time is 30-60 minutes, and the paint is convenient to construct. The paint is aqueous and environmental-friendly, non-toxic, harmless and odorless, free of damages to the environment and a human body, incombustible and inexplosive and convenient to convey; the paint is good in compatibility with other marketed intermediate paints and finishing paints. The dust-removing and dust-preventing paint provided by the invention is small in specific gravity and great in coating rate, and 8-12 square meters can be coated by using one kilogram of the paint; the use of the paint has the advantages of high efficiency and small labor intensity; the construction period can be shortened by 40%, and the unit manual cost can be lowered by 60%. The tools used are washed by water and therefore the consumption is less.

Owner:SHANGHAI JINTIAN RUST REMOVAL & RUST PROOF CO LTD

Making method of nutritional rice cake for infants

ActiveCN106614905ASmall particle sizeEasy to absorbDough treatmentBakery productsRice flourAir drying

The invention discloses a making method of a nutritional rice cake for infants. The making method comprises the following steps that 1, sardine powder is prepared; 2, the rice cake is prepared, wherein the sardine powder is processed with moderate flame microwaves for 10-15 seconds, glutinous rice flour, ginger juice, ground seaweed, Chinese olive powder, walnut powder, wheat meal, sesame powder, spinach juice, crude salt and pickled cabbage juice are added and mixed, rolling and forming are formed to obtain a cake blank, the surface of the cake blank is coated with a layer of rice cake protective agent and then is brushed with a layer of plant oil mixed liquid after air-drying, the cake blank is put in a baking oven, baking is performed under the conditions of the upper flame temperature of 130-150 DEG C and the lower flame temperature of 145-157 DEG C for 40-48 minutes, cooling is performed for 6-10 hours, then ultraviolet sterilization is performed for 15-20 minutes, and a rice cake finished product is obtained after sealing and package. The made nutritional rice cake for infants has the advantages of being attractive in appearance, good in taste and rich in nutrition, promotes infant growth and has a wide market popularization value.

Owner:杨凌诚智食品科技有限公司

Anti-aging rubber material and preparation method thereof

The invention belongs to the technical field of rubber composite materials, and particularly relates to an anti-aging rubber material and a preparation method thereof. The anti-aging rubber material is prepared from the following components in parts by weight through high-temperature vulcanization: butadiene styrene rubber, butadiene rubber, chlorinated polyethylene, zinc oxide, stearic acid, a flame retardant, a modified reinforcing anti-aging agent, a vulcanizing agent sulfur, an accelerant and a softening agent. The preparation method comprises the following steps: sequentially adding the styrene-butadiene rubber, the butadiene rubber and the chlorinated polyethylene for plastifying and uniform mixing; and sequentially adding the other raw materials, carrying out uniform mixing, and carrying out high-temperature vulcanization. According to the invention, a silane coupling agent is subjected to grafting reaction with an antioxidant and white carbon black at the same time, the micromolecular antioxidant is chemically grafted to the white carbon black through the silane coupling agent, and the silane coupling agent and a rubber chain are cross-linked through high-temperature vulcanization to form a net structure; and thus, the dispersing performance of the white carbon black is improved, and meanwhile, the migration of the anti-aging agent in the rubber is avoided, so the anti-aging performance of the rubber is enhanced.

Owner:XUZHOU COLLEGE OF INDAL TECH

Slag ladle lining heat insulation coating system and construction technology

The invention discloses a slag ladle lining heat-insulation coating system and a construction process, the heat-insulation coating system structurally comprises a modeling material layer, a wear-resistant material layer and a heat-resistant coating layer, the modeling material layer is directly coated on a slag ladle lining to serve as a bottom layer of the coating system; the wear-resistant material layer is coated on the modeling material layer to serve as a middle layer of the coating system; the heat-resistant coating layer is coated on the wear-resistant material layer and is used as a surface layer of the coating system. High-quality raw materials are adopted, the proportion is optimized, meanwhile, through material structure design, the heat-resistant coating layer, the wear-resistant material layer and the modeling material layer adopt material systems with different temperature bearing properties according to different positions of the heat-resistant coating layer, the wear-resistant material layer and the modeling material layer, and a gradient heat-conducting material system is formed; a slag ladle lining heat insulation coating system with hierarchical optimization heat insulation, high strength, high corrosion resistance and ultra-long service life is formed, the one-time ladle overturning rate can be increased to 99% or above, and the service life of the slag ladle lining heat insulation coating system is almost the same as that of a slag ladle body.

Owner:BEIJING NEW VISION BUILDING CONSTR TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com