Environment-friendly nano-epoxy silicone heavy anti-corrosion coating and preparation method and using method thereof

A nano-ring, heavy-duty anti-corrosion technology, applied in the field of coatings, can solve the problems that the comprehensive performance cannot meet the harsh marine environment, it is difficult to form a surface protection structure, and the construction environment requirements are high. dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

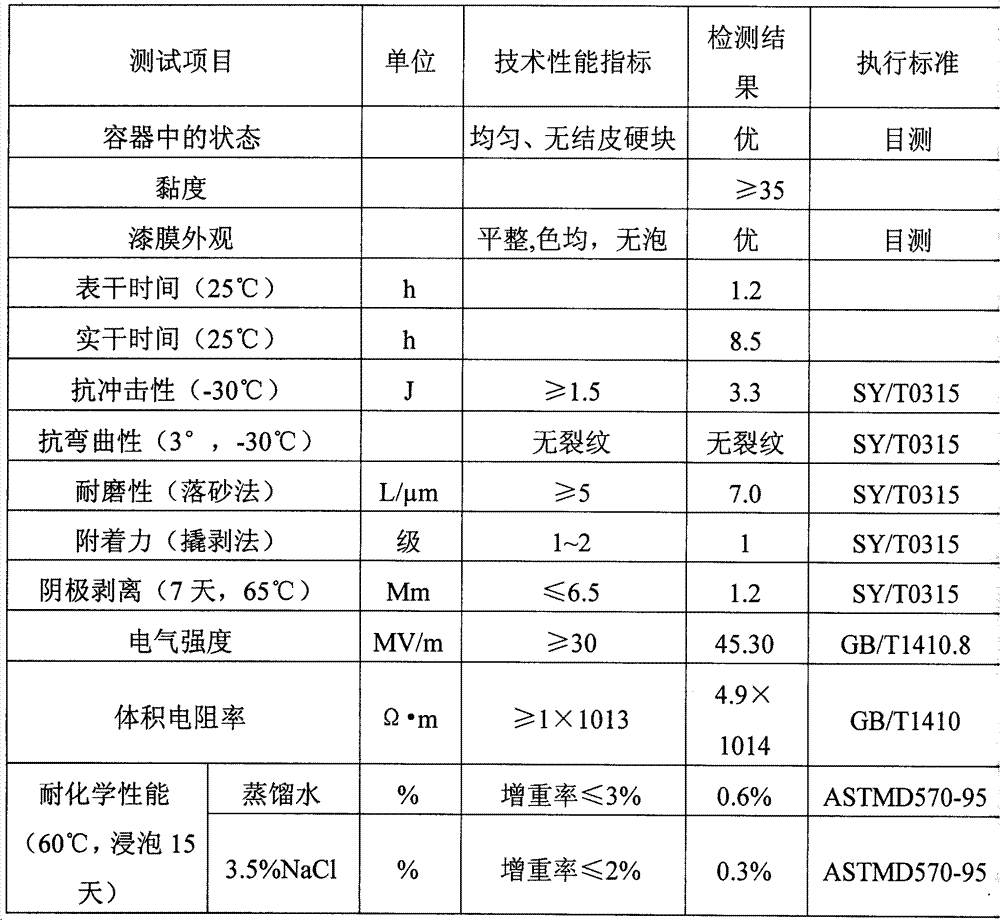

Examples

Embodiment 1

[0027] Silicon carbide, alumina, nano-quartz powder, titanium dioxide, zinc powder, aluminum powder, ceramic powder, cobalt-nickel ultra-fine metal powder and graphite are respectively subjected to nano-ultrafine treatment, so that the particle size reaches 15-700nm;

[0028] Accurately weigh 1 kg of silicon carbide, 1 kg of alumina, 10 kg of nano-quartz powder, 10 kg of titanium dioxide, 2 kg of zinc powder, 5 kg of aluminum powder, 10 kg of ceramic powder, and superfine Put 1 kg of metal powder into the sand mill and mix evenly to form the mixed filler;

[0029] Transfer the above-mentioned mixed filler into a high-speed disperser, add 20 kg of water-based epoxy resin and 40 kg of water, and stir evenly to obtain a semi-finished product;

[0030] After the semi-finished product is filtered, inspected and loaded into barrels, the finished product of component A of an environment-friendly nano epoxy silicon heavy-duty anti-corrosion coating of the present invention can be obta...

Embodiment 2

[0032] Silicon carbide, alumina, nano-quartz powder, titanium dioxide, zinc powder, aluminum powder, ceramic powder, cobalt-nickel ultra-fine metal powder and graphite are respectively subjected to nano-ultrafine treatment, so that the particle size reaches 15-700nm;

[0033] Accurately weigh 2 kg of silicon carbide, 2 kg of alumina, 5 kg of nano-quartz powder, 5 kg of titanium dioxide, 8 kg of zinc powder, 2 kg of aluminum powder, 5 kg of ceramic powder and 1 kg of graphite after nano-ultrafine treatment Mix evenly in the sand mill to form a mixed filler;

[0034] Transfer the above-mentioned mixed filler into a high-speed disperser, add 40 kg of water-based epoxy resin and 30 kg of styrene-acrylic emulsion, stir evenly, and obtain a semi-finished product;

[0035] After the semi-finished product is filtered, inspected and loaded into barrels, the finished product of component A of an environment-friendly nano epoxy silicon heavy-duty anti-corrosion coating of the present inv...

Embodiment 3

[0037] Silicon carbide, alumina, nano-quartz powder, titanium dioxide, zinc powder, aluminum powder, ceramic powder, cobalt-nickel ultra-fine metal powder and graphite are respectively subjected to nano-ultrafine treatment, so that the particle size reaches 15-700nm;

[0038] Accurately weigh 5 kg of silicon carbide, 5 kg of alumina, 8 kg of nano-quartz powder, 7 kg of titanium dioxide, 3 kg of zinc powder, 4 kg of aluminum powder and 6 kg of ceramic powder after nano-ultrafine treatment, and put them into the sand mill Internal mixing is evenly mixed filler;

[0039] Transfer the above-mentioned mixed filler into a high-speed disperser, add 10 kg of water-based epoxy resin and 50 kg of water, and stir evenly to obtain a semi-finished product;

[0040] After the semi-finished product is filtered, inspected and loaded into barrels, the finished product of component A of an environment-friendly nano epoxy silicon heavy-duty anti-corrosion coating of the present invention can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com