High temperature aluminium liquid corrosion resistant paint, and preparation method thereof

A technology of high temperature resistance and aluminum liquid, applied in the field of materials, can solve the problems of pollution, land occupation, large red mud discharge, etc., and achieve the effects of good chemical stability, uniform spreading, and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

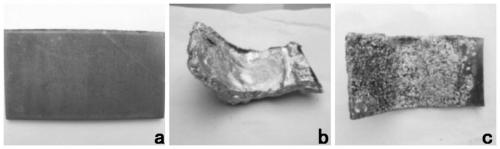

Embodiment 1

[0036] The invention provides a high-temperature resistant aluminum liquid corrosion coating, which is made of the following raw materials in weight percentage: 50% of glass powder, 10% of red mud, 25% of borax, 5% of boric acid, 5% of carbonate, 3% of zirconia and oxide Titanium 2%, the total of the above raw materials is 100%; the carbonate is potassium carbonate.

[0037] The preparation method of the high-temperature resistant molten aluminum corrosion coating is characterized in that it comprises the following steps:

[0038] (1) Dry the red mud, mix it with other raw materials and crush it into a powder with a particle size of less than 200 mesh, add a binder and water to make a slurry;

[0039] (2) coating the slurry on the workpiece to form a coating with a thickness of 0.4mm, and drying;

[0040] (3) After the drying is completed, high-temperature sintering is carried out at a temperature of 900° C. and kept for 40 minutes, and cooled with the furnace to complete the...

Embodiment 2

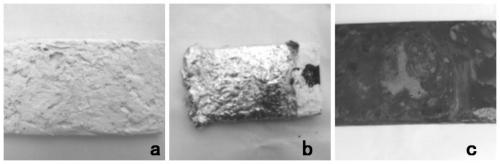

[0042] The invention provides a high temperature resistant molten aluminum corrosion coating, which is made of the following raw materials in weight percentage: 30% of glass powder, 25% of red mud, 20% of borax, 5% of boric acid, 10% of carbonate, 3% of zirconia and oxide Titanium 8%, the total of the above raw materials is 100%;

[0043] Also include the binder of 25% of the total weight of raw materials, the binder is water glass;

[0044] Described carbonate is sodium carbonate.

[0045] The preparation method of the high-temperature resistant molten aluminum corrosion coating is characterized in that it comprises the following steps:

[0046] (1) Dry the red mud, mix it with other raw materials and crush it into a powder with a particle size of less than 200 mesh, add a binder and water to make a slurry;

[0047] (2) coating the slurry on the workpiece to form a coating with a thickness of 0.3 mm, and drying;

[0048] (3) After the drying is completed, high-temperature si...

Embodiment 3

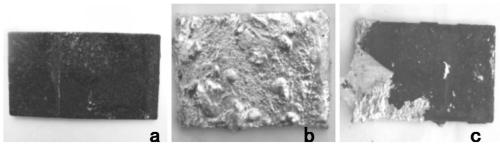

[0050] The invention provides a high-temperature resistant aluminum liquid corrosion coating, which is made of the following raw materials in weight percentage: 30% of glass powder, 10% of red mud, 30% of borax, 6% of boric acid, 6% of carbonate, 10% of zirconia and oxide Titanium 8%, the total of the above raw materials is 100%;

[0051] It also includes an adhesive of 30% of the total weight of raw materials, and the adhesive is water glass;

[0052] Described carbonate is sodium carbonate and potassium carbonate with a weight ratio of 2:1.

[0053] The preparation method of the high-temperature resistant molten aluminum corrosion coating is characterized in that it comprises the following steps:

[0054] (1) Dry the red mud, mix it with other raw materials and crush it into a powder with a particle size of less than 200 mesh, add a binder and water to make a slurry;

[0055] (2) coating the slurry on the workpiece to form a coating with a thickness of 0.3 mm, and drying; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com