Water-phase quantum dot microcrystal preparation method

A technology of quantum dots and quantum dot solutions, applied in the field of surface chemistry, can solve the problems of difficult purification, loss of luminescence properties, unstable light intensity and light effect of quantum dot crystals, etc., and achieve the effect of improving luminescence stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a water-phase quantum dot microcrystal, the steps are as follows:

[0040] 1) Preparation of type A stabilizer: 10 g of anhydrous zinc chloride dissolved in 100 mL of deionized water; preparation of type B stabilizer: 5 g of sodium carbonate and 5 g of sodium silicate dissolved in 100 mL of water.

[0041] 2) In the 100mL CdSe water phase quantum dot aqueous solution, first add 20mL of the type A stabilizer described in the previous item, stir well, then add 20mL of the type B stabilizer, and finally add 1M dilute hydrochloric acid to the mixture, and adjust the pH to 9.5. The above mixture needs to be stirred for more than 15min to 60min.

[0042] 3) drying and dehydrating the activated water-phase quantum dots to prepare quantum dot microcrystalline powder;

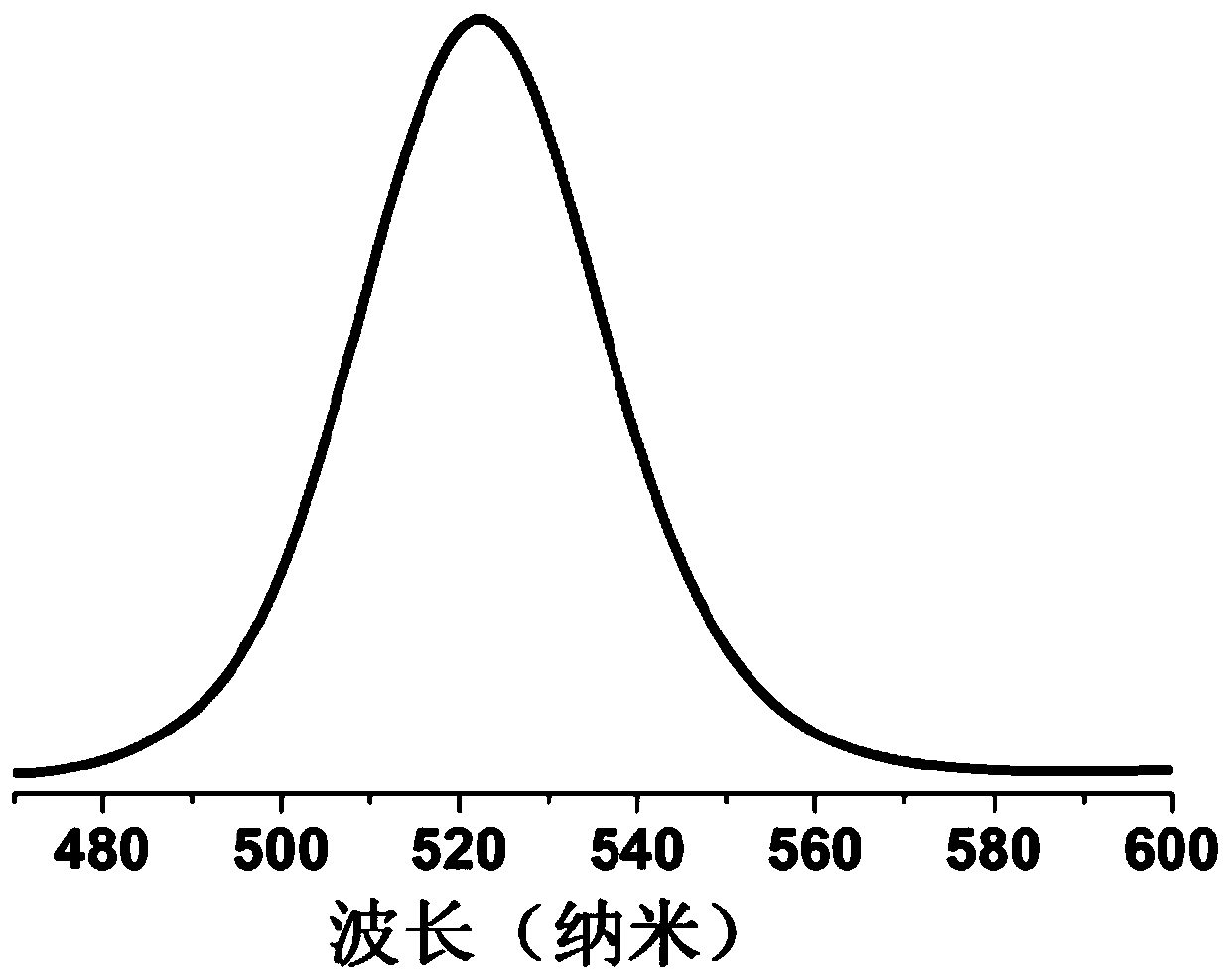

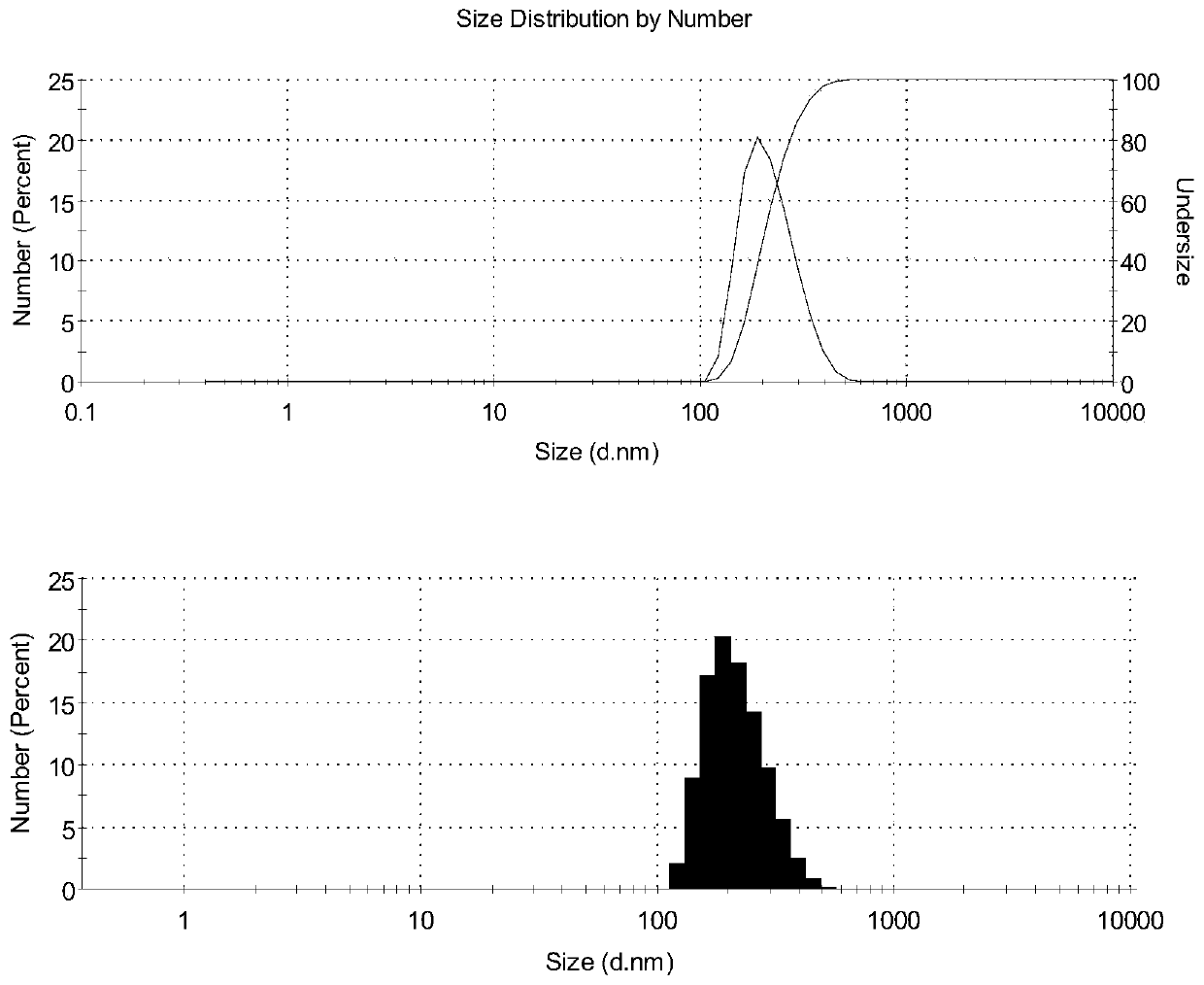

[0043] 4) Data: Fluorescence emission spectra, micrographs, and particle size distribution of typical aqueous quantum dots and quantum dot crystallites obtained after using stabilizers. ...

Embodiment 2

[0050] A method for preparing a water-phase quantum dot microcrystal, the steps are as follows:

[0051] 1) Prepare type A stabilizer: dissolve 5g of anhydrous calcium chloride in 100mL of deionized water; prepare type B stabilizer: dissolve 5g of sodium molybdate and 5g of sodium tungstate in 100mL of water.

[0052]2) In the 100mL CdSe quantum dot aqueous solution, first add 10mL of the type A stabilizer described in the previous article, stir evenly, then add 10mL of the type B stabilizer, and react for 1 hour under stirring; then add 5mL of the type A stabilizer, Stir evenly, then add 5 mL of Type B stabilizer, and finally adjust the pH of the mixture to 12.5 with solid sodium hydroxide. The above mixture needs to be stirred for 4 hours.

[0053] 3) drying and dehydrating the activated water-phase quantum dots to prepare quantum dot microcrystalline powder;

[0054] 4) Data: the fluorescence emission spectrum, micrograph and particle size distribution of the quantum dot ...

Embodiment 3

[0060] A method for preparing a water-phase quantum dot microcrystal, the steps are as follows:

[0061] 1) Preparation of type A stabilizer: 5 g of magnesium chloride hexahydrate dissolved in 100 mL of deionized water; preparation of type B stabilizer: 4 g of sodium silicate dissolved in 100 mL of water.

[0062] 2) In the 100mL CdTe quantum dot aqueous solution, first add 5mL of the B-type stabilizer described in the previous item, stir evenly, then add 5mL of the A-type stabilizer, stir for 1 hour, and stir for 4 hours.

[0063] 3) drying and dehydrating the activated water-phase quantum dots to prepare quantum dot microcrystalline powder;

[0064] 4) Data: the fluorescence emission spectrum, micrograph and particle size distribution of the quantum dot microcrystal obtained after using the stabilizer are as follows: Figure 10-12 shown.

[0065] Emission peak of quantum dot aqueous solution: 595nm

[0066] Half width of quantum dot aqueous solution: 32.8nm

[0067] Quan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com