Metal-ceramic anticorrosion coating and preparation method thereof

A technology of anti-corrosion coatings and cermets, applied in the field of coatings, can solve the problems of inconvenient production and use, and inability to have corrosion resistance, stability, high temperature resistance, wear resistance and pressure resistance at the same time, and achieve good gas cutting and weldability, Good cathodic protection effect, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

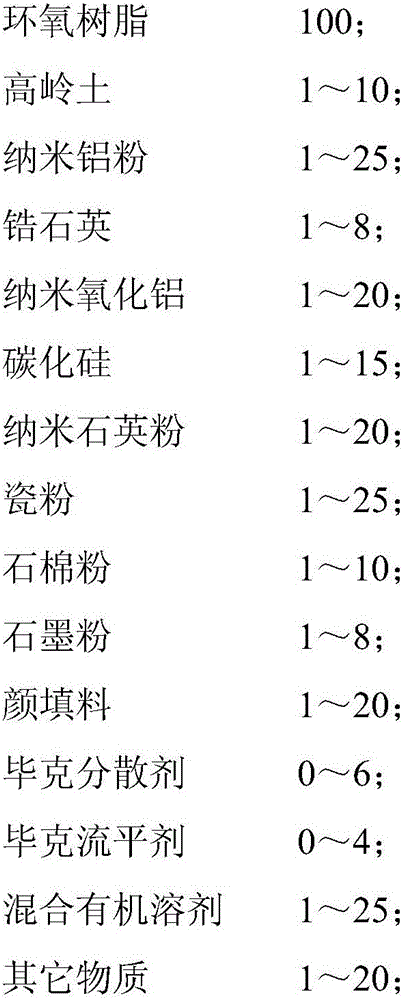

[0030] The formula (weight unit is gram) of 10 embodiments has been listed in table 1, and its preparation method is all: at normal temperature, kaolin, zircon quartz, silicon carbide, porcelain powder, asbestos powder, graphite powder of batching amount are first mixed Grind in a high-energy mill for 50-100 minutes, and then finely sieve the large-sized mixed powder for 50-80 minutes to make the particle size reach 20-200nm. Then mix the twice-ground powder and solid powder such as nano-aluminum powder, nano-alumina, nano-quartz powder, pigments and fillers with epoxy resin, BYK dispersant, BYK leveling agent, mixed organic solvents and other substances Mix the liquid components in the formula, fully disperse and stir evenly; then filter, pack and seal.

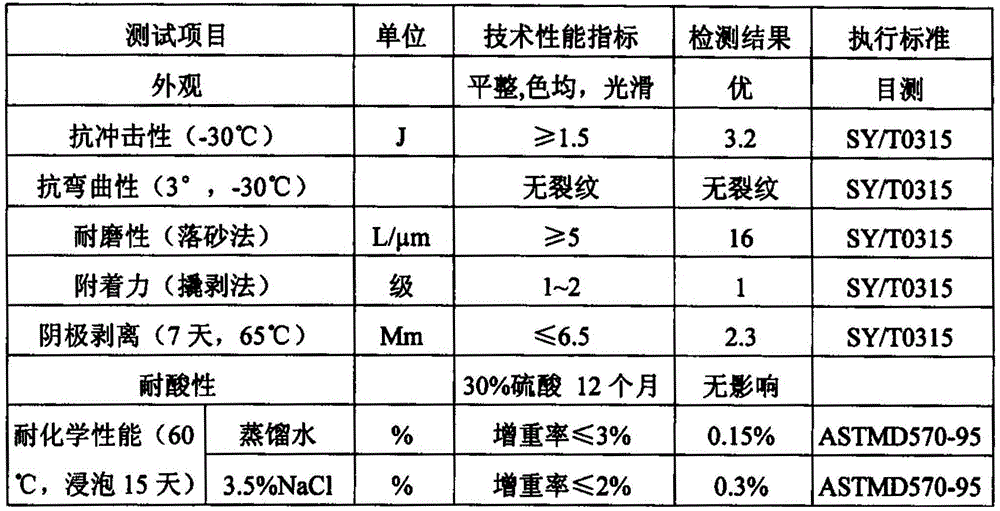

[0031] Table 1

[0032]

[0033] The cermet anticorrosion coating of the present invention does not need a primer, and can be used alone without a special topcoat. It can be directly sprayed or brushed on the metal surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com