Slag ladle lining heat insulation coating system and construction technology

A technology of thermal insulation coating and construction technology, applied in the field of metallurgical materials, can solve the problems of reduced anti-stick performance, unmentioned service life, reduced effective components of spray paint, etc., to achieve the effect of isolating erosion and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

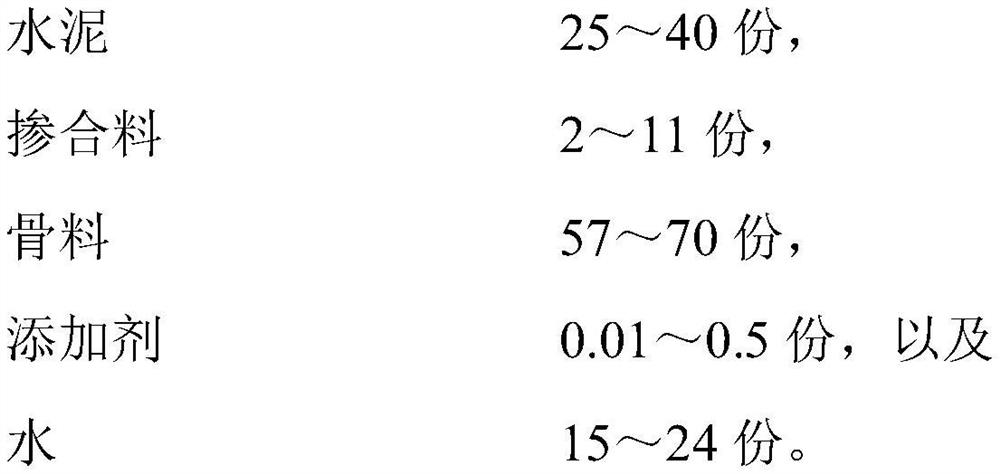

[0051] (1) Modeling material layer: 33 parts of P·O 42.5R ordinary Portland cement, 1.92 parts of bentonite, 1 part of silica fume, 64 parts of 40-140 mesh quartz sand, 0.03 parts of polycarboxylate superplasticizer, polyether 0.01 part of antifoaming agent, 0.02 part of hydroxyethyl cellulose ether, and 0.02 part of saponin air-entraining agent. Mix the above materials evenly, add 17 parts of water in total, mix evenly in a blender, and then apply it directly to the innermost layer of the slag tank lining.

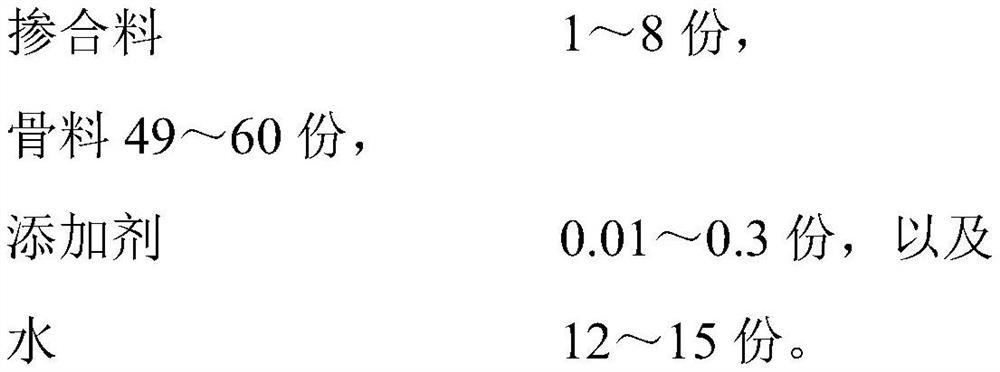

[0052](2) Wear-resistant material layer: 14 parts of CA50-Ⅲ aluminate cement, 28 parts of ordinary Portland cement with P·O 52.5, 2 parts of slag powder, 2.87 parts of micro silica fume, the continuous distribution range of particle size is 0.1-2mm 33 parts of quartz sand, 20 parts of coke gemstone with a continuous particle size distribution range of 0.1-2 mm, 0.05 part of naphthalene superplasticizer, 0.03 part of silicone defoamer, 0.03 part of saponin air-entraining a...

Embodiment 2

[0056] (1) Modeling material layer: 29 parts of P·Ⅱ42.5R Portland cement, 2 parts of bentonite, 1.96 parts of nano-silica, 67 parts of 40-140 mesh quartz sand, 0.02 parts of polycarboxylate superplasticizer, saponins Air-entraining agent 0.02 parts. Mix the above materials evenly, add 15 parts of water in total, mix evenly in a blender, and then apply it directly to the innermost layer of the slag tank lining.

[0057] (2) Wear-resistant material layer: 15 parts of CA50-Ⅲ aluminate cement, 26 parts of P·Ⅱ52.5 ordinary Portland cement, 2.91 parts of slag powder, 2 parts of micro silica fume, 2 parts of nano silicon dioxide, granular 26 parts of quartz sand with a continuous diameter distribution range of 0.1-2 mm, 26 parts of coke gemstones with a continuous particle size distribution range of 0.1-2 mm, 0.06 part of naphthalene-based superplasticizer, and 0.03 part of hydroxyethyl cellulose ether. After mixing the above materials evenly, add 14 parts of water with a total mass...

Embodiment 3

[0061] (1) Modeling material layer: 30 parts of P·O 42.5R ordinary Portland cement, 1 part of bentonite, 1.94 parts of microsilica, 1 part of nano-silica, 66 parts of 40-140 mesh quartz sand, polycarboxylate 0.03 part of water agent, 0.02 part of hydroxyethyl cellulose ether, and 0.01 part of saponin air-entraining agent. After mixing the above materials evenly, add 18 parts of water with a total mass, mix evenly in a mixer, and then apply it directly to the innermost layer of the slag tank lining.

[0062] (2) Wear-resistant material layer: 10 parts of CA50-Ⅲ aluminate cement, 32 parts of P·Ⅱ52.5 ordinary Portland cement, 2.92 parts of micro silica fume, 3 parts of nano silicon dioxide, the continuous distribution range of particle size is 24 parts of quartz sand with a particle size of 0.1-2 mm, 28 parts of coke gemstones with a continuous particle size distribution range of 0.1-2 mm, 0.05 parts of naphthalene-based superplasticizer, 0.01 part of saponin air-entraining agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com