Positive active material, preparation method thereof, positive electrode and high-specific energy power battery

A positive electrode active material and positive electrode technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of inability to isolate materials, erosion, and inability to play a coating role, and achieve excellent electrical conductivity, reduce side reactions, and improve electrical conductivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present application also provides a method for preparing a positive electrode active material, wherein the method includes:

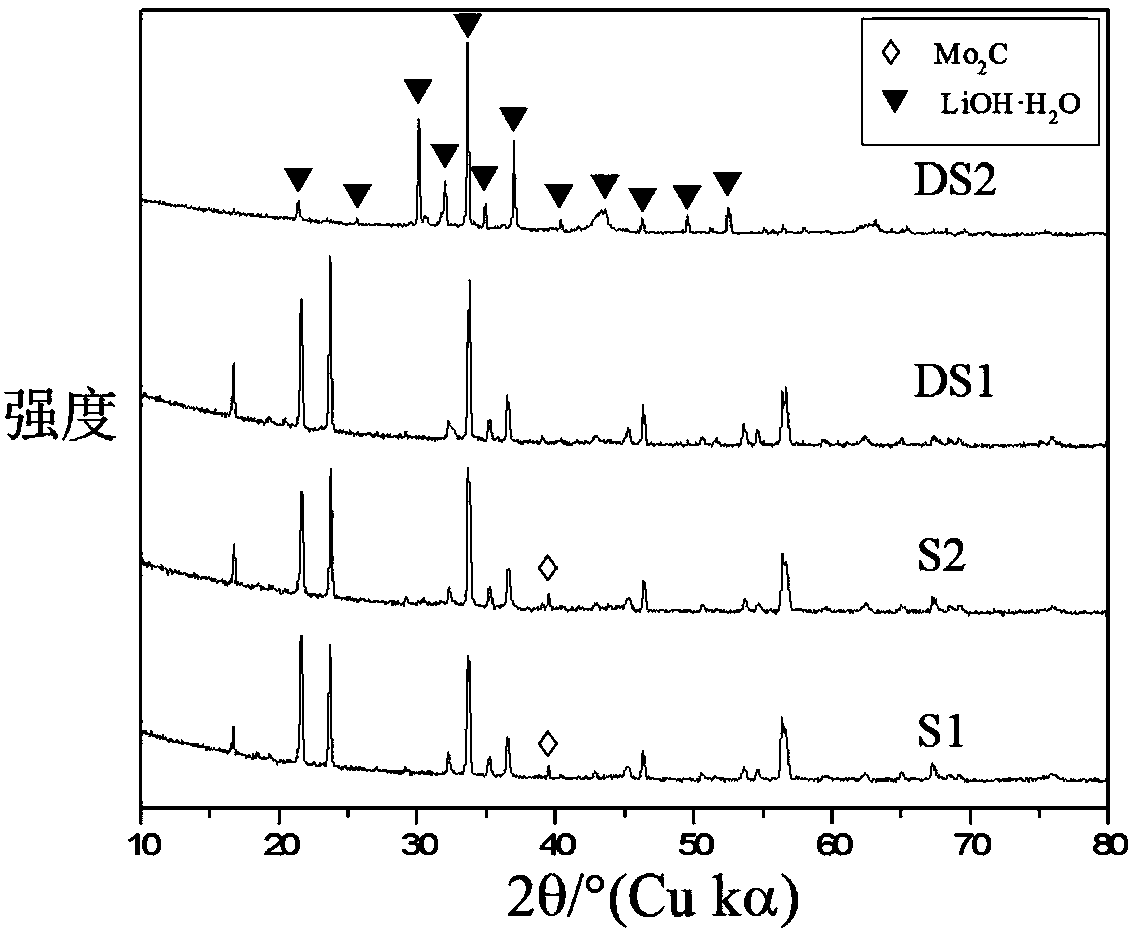

[0029] S1, will Li 5 FeO 4 , carbon source and molybdenum source are mixed according to the mass ratio of 80-94: 6.5-51.5: 4.7-26, and sintered under an inert atmosphere to obtain Li 5 FeO 4 / C+Mo 2 C cathode active material.

[0030] Preferably, the high temperature sintering temperature is 700~900°C, and the sintering time is 2~48h; the inert atmosphere is one of helium, neon or argon; the carbon source is selected from sucrose, glucose, epoxy resin One or more of polyvinyl alcohol and phenolic resin.

[0031] In the above preparation method, the intermediate material Li 5 FeO 4 Mixed with molybdenum source and carbon source and then sintered to generate carbon and Mo 2 In the process of C coating layer, the carbon source is first carbonized to form and Li 5 FeO 4 The elemental carbon in close contact with the molybdenum source, t...

Embodiment approach

[0055] Among them, the separator can be selected from various separators used in high specific energy power batteries known to those skilled in the art, such as polyolefin microporous membrane (PP), polyethylene felt (PE), glass fiber felt or ultrafine glass fiber paper Or PP / PE / PP. As a preferred embodiment, the separator is PP / PE / PP.

[0056] The preparation method of the high specific energy power battery provided by the present invention can be a method known to those skilled in the art. Generally speaking, the method includes sequentially winding the positive electrode, the negative electrode and the separator between the positive electrode and the negative electrode to form a pole core , put the pole core into the battery case, add electrolyte, and then seal, wherein, the methods of winding and sealing are well known to those skilled in the art. The amount of electrolyte used is conventional. The electrolyte can also be replaced by one of all solid electrolytes, solid ...

Embodiment 1

[0060] Preparation of positive electrode active material:

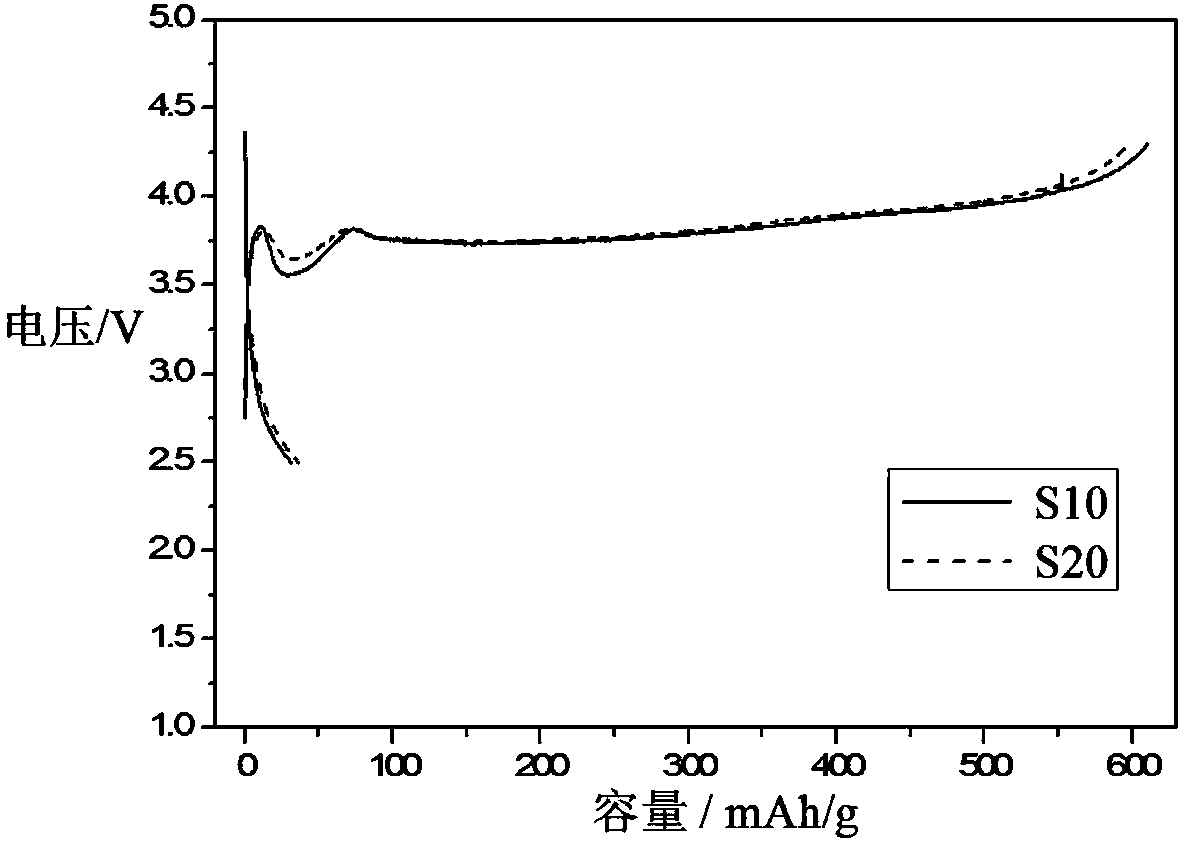

[0061] LiOH·H 2 O and Fe 2 o 3 Mix according to the molar ratio of 10:1, place in a stirring ball mill and mix and grind for 8 hours; place the precursor prepared by fully mixing and grinding in a corundum crucible; put the crucible in a tube furnace, blow in nitrogen, and start heating from room temperature, The heating rate was 5 °C / min, the temperature was raised to 850 °C for 20 h, and then naturally cooled to room temperature to obtain Li 5 FeO 4 Material. Will Li 5 FeO 4 、MoO 3 Mix with glucose at a mass ratio of 100:7.7:25.9, place in a stirring ball mill, add ethanol, and wet mix and grind for 6 hours; dry the precursor prepared by fully mixing and grinding, and place it in a corundum crucible; put the crucible into a tubular In the furnace, Ar gas was introduced and heated from room temperature with a heating rate of 5 °C / min, and the temperature was raised to 800 °C for 10 h, and then naturally coole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com