Self-elevating novel latticed pile leg for ocean platform

A technology of offshore platform and lattice structure, which is applied to underwater structures, infrastructure engineering, buildings, etc., can solve the problems of construction difficulties of built-in stiffeners and the difficulty of fully exerting the mechanical properties of materials, so as to improve the overall stability and local Stability, convenient construction, and the effect of improving fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

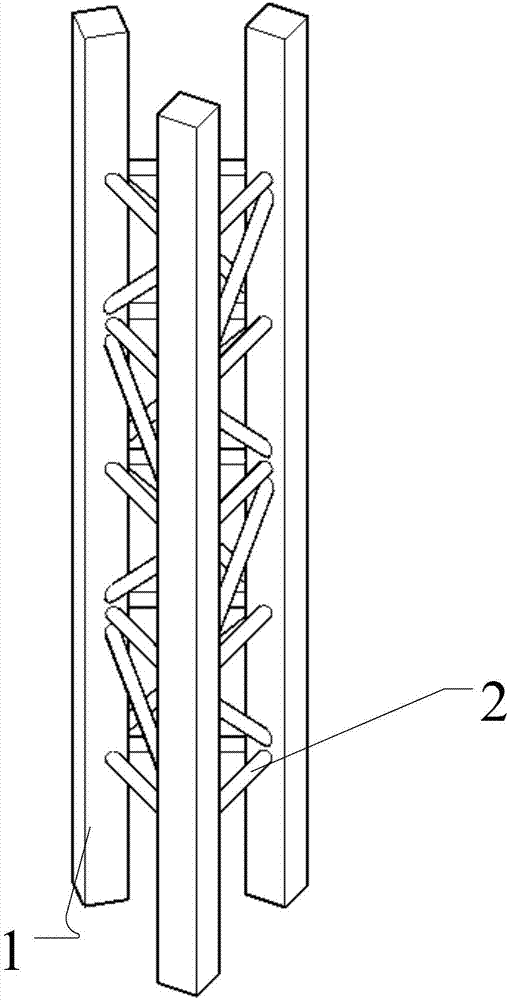

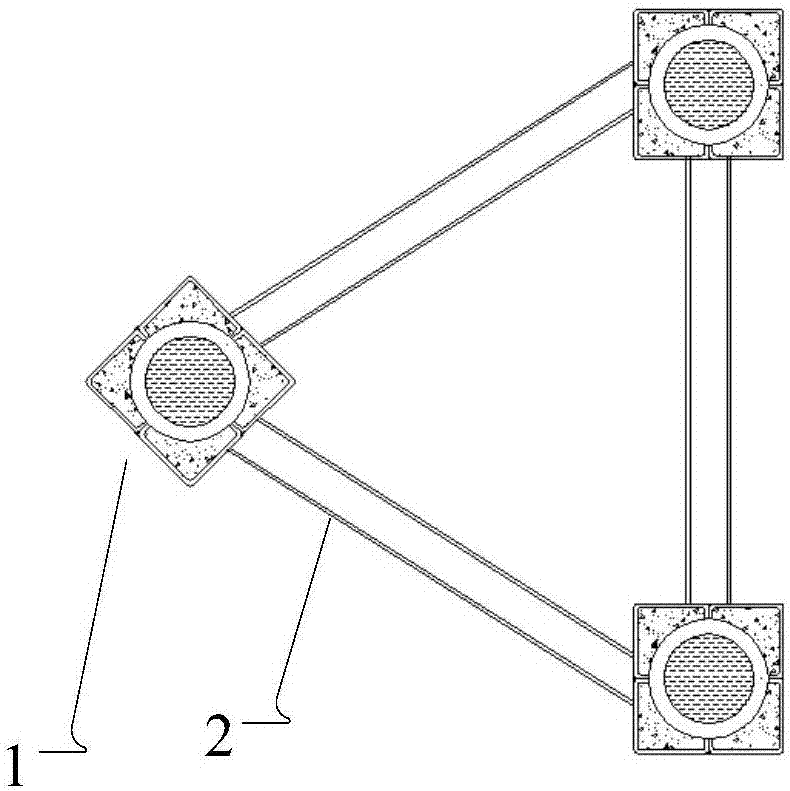

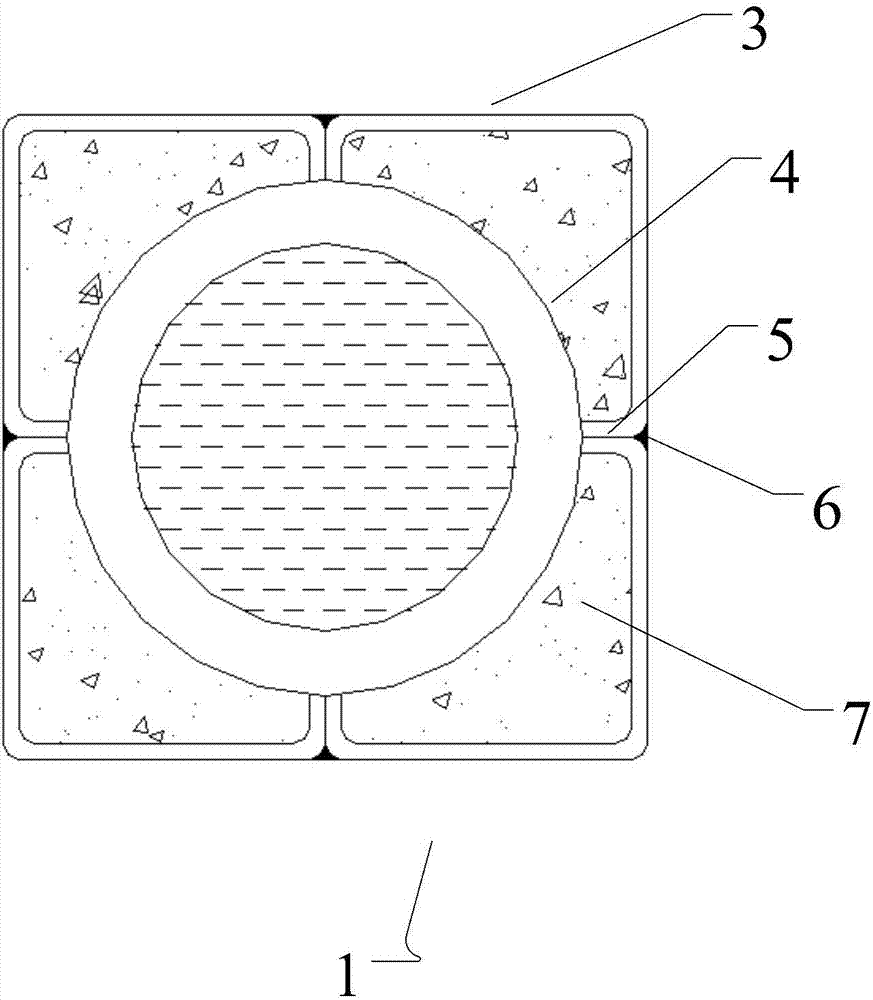

[0023] Such as Figure 1~3 As shown, the present invention discloses a new lattice-type leg of a self-elevating offshore platform, which includes a triangular leg body 1 arranged in parallel, the leg body 1 includes a square steel pipe 3, and the inside of the square steel pipe 3 The stiffeners 5 arranged in the length direction are welded with circular steel pipes 4 , and the interior of the circular steel pipes 4 is filled with water, and the space between the square steel pipes 3 and the circular steel pipes 4 is filled with concrete 7 . The square steel pipe 3 has a square shape, and the stiffeners 5 are arranged in the middle of the four sides inside the square steel pipe 3 . The stiffener 5 is a double-rib par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com