Three-base-point roof separation layer monitor

A roof separation and monitoring device technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of easy oxidation, corrosion, difficult reference points, shallow depth of measurement reference points, etc., to ensure accuracy and reliability, and improve effectiveness. And the effect of accuracy, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

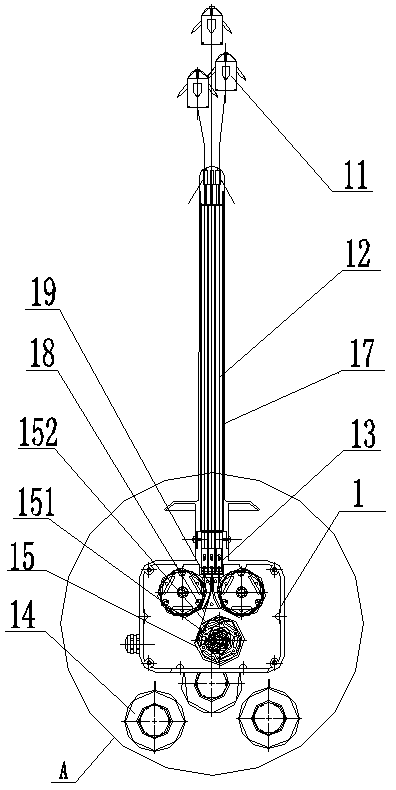

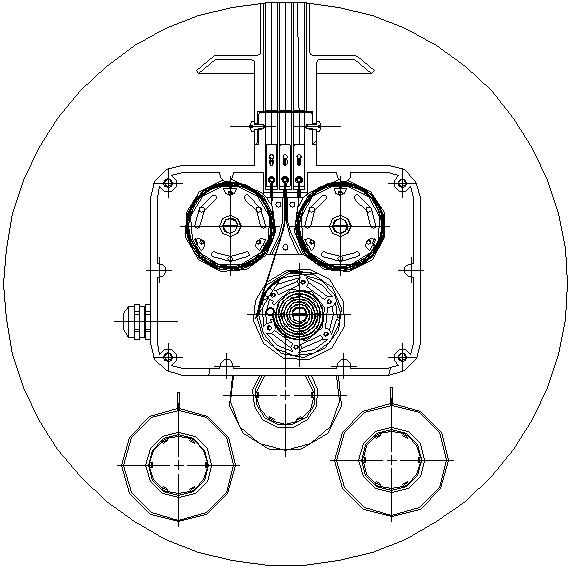

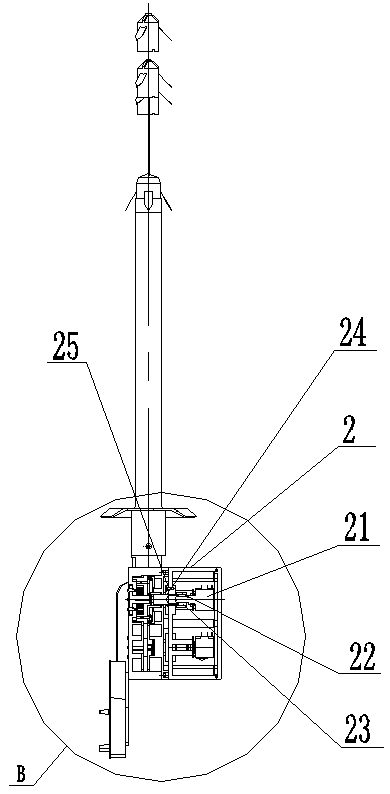

[0023] Such as Figure 1-5 As shown, a three-base-point roof detachment monitor includes a guide tube 17, a mechanical housing 1, an electrical housing 2, and three sets of independent detachment monitoring mechanisms with the same structure, which are respectively used to monitor the shallow detachment of the detachment layer. The base point A, the deep base point B, and the deep base point C in the stable rock stratum 8-14 meters above the top of the roadway roof. Wheel 16 and potentiometer 21, one end of the steel wire 12 is connected to the anchor fluke 11, the other end passes through the connecting slider 13 and is fixed, and three mutually independent slideways are arranged in the guide tube 17, and the three groups of the separation layer monitoring The initial positions of the connection sliders 13 of the mechanism are respectively set at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com