Spherical 5-V spinel lithium nickel manganese oxide material and preparation method thereof

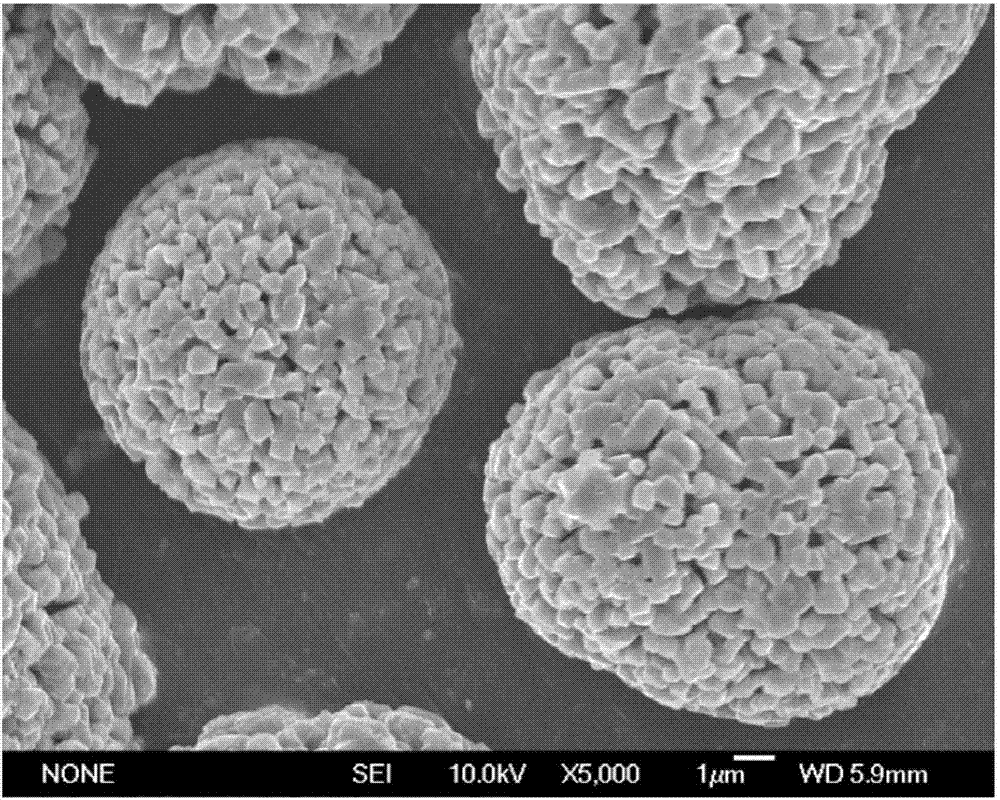

A technology of lithium nickel manganate and spinel is applied in the field of spherical 5V spinel lithium nickel manganate material and its preparation, which can solve the problem of uneven mixing of elements in the solid phase method, and achieve the effects of inhibiting dissolution and improving cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

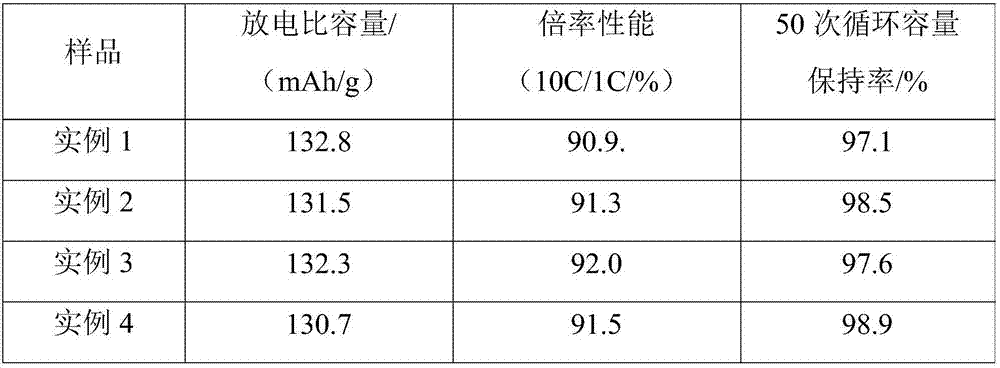

Examples

Embodiment 1

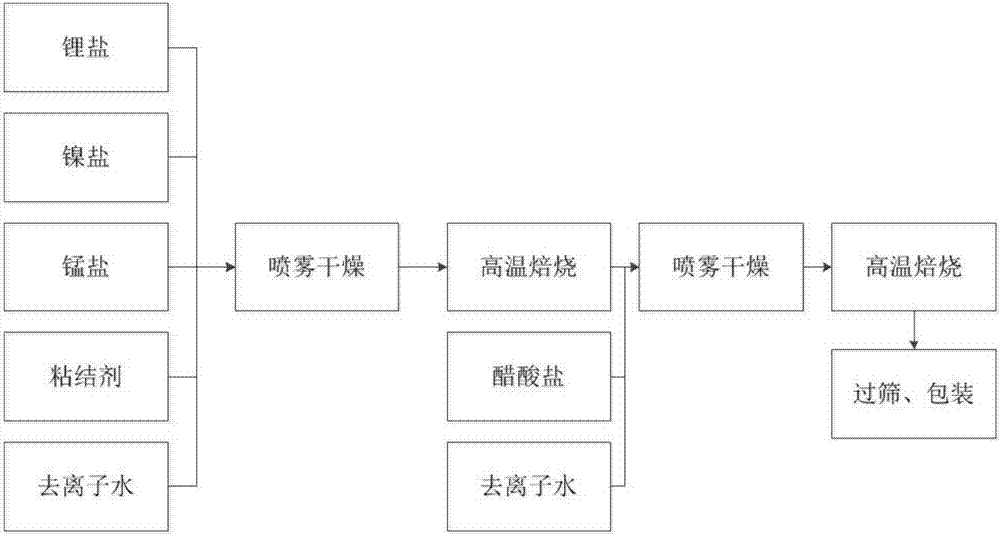

[0026] A preparation method of a spherical 5V spinel lithium nickel manganese oxide material, comprising the steps of:

[0027] 1) Dissolve 1mol lithium nitrate, 0.5mol nickel nitrate, 1.5mol manganese nitrate and polyethylene glycol with the quality of the above three substances and 5% in deionized water to obtain material I;

[0028] 2) Spray drying the material I at a drying temperature of 240° C. to obtain material II;

[0029] 3) Roasting the material II once in a roasting kiln and air atmosphere, the roasting temperature is 800°C, and the roasting time is 12 hours, to obtain the material III;

[0030] 4) Add material III and copper acetate whose mass is 2% of the mass of material III into deionized water, stir and mix evenly at high speed to obtain material IV;

[0031] 5) Spray drying material IV at a drying temperature of 240° C. to obtain material V;

[0032] 6) Carry out secondary roasting of material V in a roasting kiln in an air atmosphere at a roasting temperat...

Embodiment 2

[0035] A preparation method of a spherical 5V spinel lithium nickel manganese oxide material, comprising the steps of:

[0036] 1) Dissolve 1mol lithium nitrate, 0.5mol nickel nitrate, 1.5mol manganese nitrate and polyethylene glycol with the quality of the above three substances and 10% in deionized water to obtain material I;

[0037] 2) Spray drying the material I at a drying temperature of 280° C. to obtain material II;

[0038] 3) Roasting the material II once in a roasting kiln in an air atmosphere, the roasting temperature is 900° C., and the roasting time is 4 hours, to obtain the material III;

[0039] 4) adding material III and magnesium acetate whose mass is 5% of material III to deionized water, and stirring at high speed to mix evenly to obtain material IV;

[0040] 5) Spray drying material IV at a drying temperature of 240° C. to obtain material V;

[0041] 6) Carry out secondary roasting of material V in a roasting kiln in an air atmosphere at a roasting tempe...

Embodiment 3

[0043] A preparation method of a spherical 5V spinel lithium nickel manganese oxide material, comprising the steps of:

[0044] 1) 1.05mol lithium nitrate, 0.5mol nickel nitrate, 1.5mol manganese nitrate and polyvinylpyrrolidone whose quality is the above three substances and 10% are dissolved in deionized water to obtain material I;

[0045] 2) Spray drying the material I at a drying temperature of 240° C. to obtain material II;

[0046] 3) Roasting the material II once in a roasting kiln and air atmosphere, the roasting temperature is 800°C, and the roasting time is 12 hours, to obtain the material III;

[0047] 4) Add material III and zinc acetate whose mass is 2% of the mass of material III into deionized water, stir and mix evenly at high speed to obtain material IV;

[0048] 5) Spray drying material IV at a drying temperature of 240° C. to obtain material V;

[0049] 6) Carry out secondary roasting of material V in a roasting kiln in an air atmosphere at a roasting tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com