Lithium ion battery composite negative electrode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve the problems of easy oxidation and abnormality of nano-silicon, and achieve high controllability, Improved storage performance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] After 0.8 g of nano-silicon particles were placed in humid air for one week, the nano-silicon was dissolved in 50 mL of deionized water at 10°C. Then add 0.05g of lithium carbonate, stir evenly, disperse ultrasonically, control the temperature to be constant during the process, and then freeze-dry the solution to obtain the precursor.

[0056] The obtained precursor was placed in an argon atmosphere tube furnace, heated to 900°C at 5°C / min, kept at a constant temperature for 2h, and cooled naturally to obtain a nano-silicon material coated with lithium silicate.

[0057] Subsequently, the nano-silicon material coated with lithium silicate is washed with deionized water, centrifuged at a high speed, and vacuum-dried to obtain a lithium-ion battery composite negative electrode material.

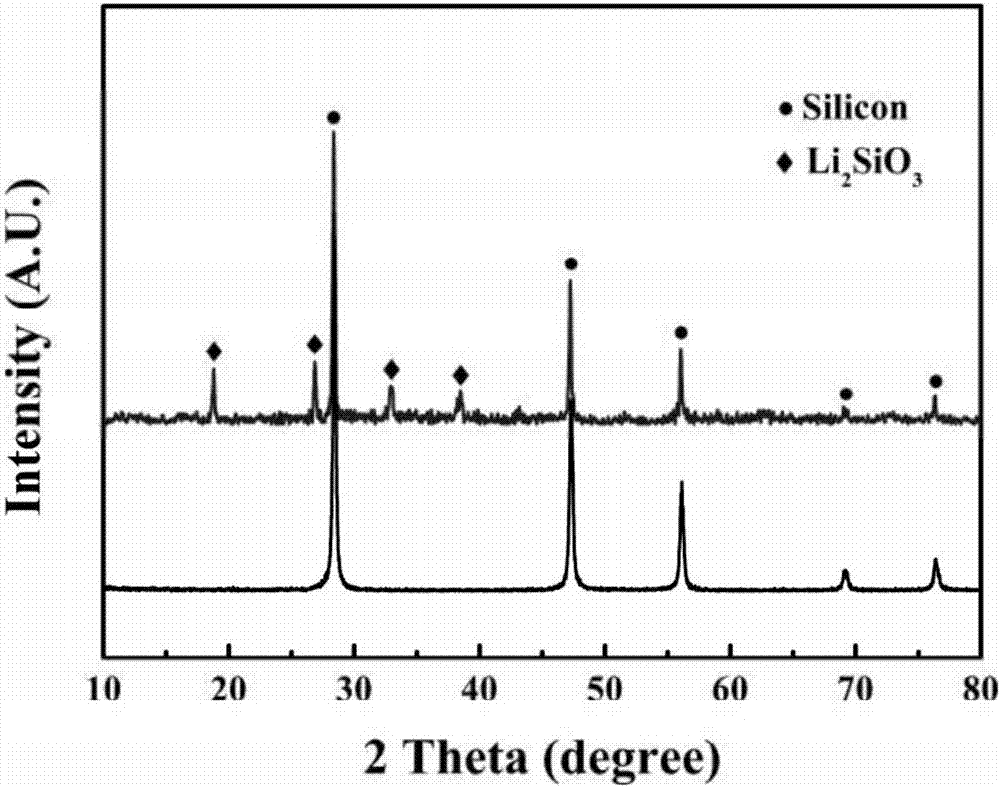

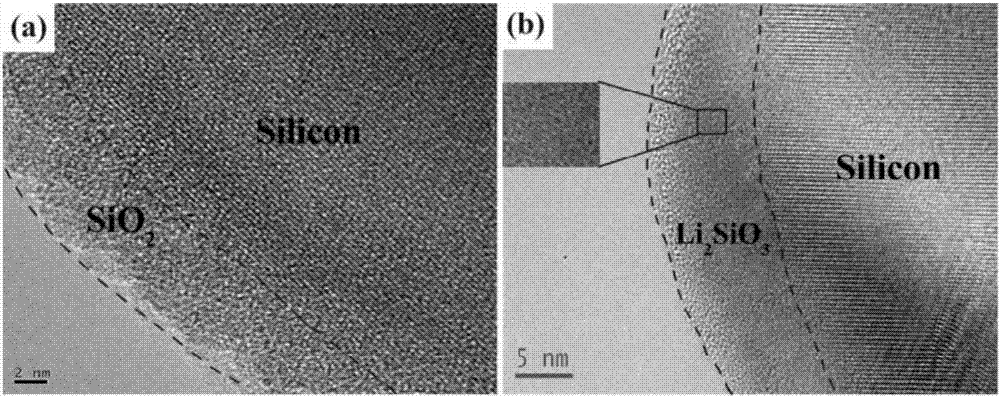

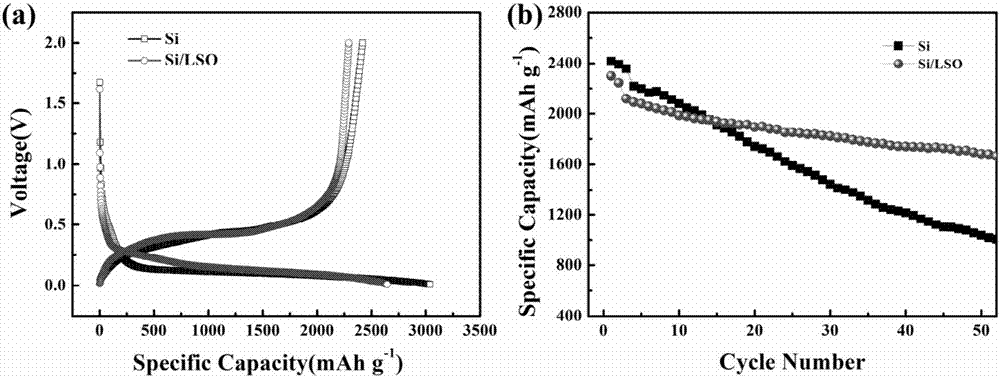

[0058] The physical and chemical performance characterization of the obtained lithium-ion battery composite negative electrode material is shown in figure 1 , figure 2 , image 3 . ...

Embodiment 2

[0060] Take 0.5g of nano-silicon and add 50ml of 10% hydrogen peroxide, stir and ultrasonically disperse, filter and dry in vacuum at 80°C. At room temperature, dissolve the treated nano-silicon in 50ml of ethanol, stir and ultrasonically disperse, add 0.5g of anhydrous lithium acetate, continue to stir and ultrasonically disperse uniformly for 1h. The solution was then freeze-dried to obtain the precursor.

[0061] The obtained precursor was placed in an argon atmosphere tube furnace, heated to 700°C at 5°C / min, kept at a constant temperature for 5h, and cooled naturally to obtain nano-silicon materials coated with lithium silicate and carbon layers.

[0062] Subsequently, the nano-silicon material coated with lithium silicate and carbon layer is washed with deionized water, centrifuged at a high speed, and vacuum-dried to obtain a lithium-ion battery composite negative electrode material.

[0063] The microstructure characterization of the obtained lithium-ion battery compo...

Embodiment 3

[0065] Take nano-silicon and add 50ml of 10% hydrogen peroxide, stir and ultrasonically disperse, filter and dry in vacuum at 80°C. At room temperature, the treated nano-silicon and lithium oxalate were mixed in a mass ratio of 2:1. The mixture was milled in a high-speed vibrating ball mill at 1200 rpm for 3 h to obtain a precursor.

[0066] The obtained precursor was placed in an argon atmosphere tube furnace, heated to 900°C at 5°C / min, kept at a constant temperature for 5h, and cooled naturally to obtain a nano-silicon material coated with lithium silicate.

[0067] Subsequently, the nano-silicon material coated with lithium silicate is washed with deionized water, and vacuum-dried after high-speed centrifugation to obtain a lithium-ion battery composite negative electrode material.

[0068] Figure 6 It is the XRD spectrum of the obtained lithium-ion battery composite negative electrode material. The results show that the lithium-ion battery composite negative electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com