Patents

Literature

49results about How to "Reduce grinding allowance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

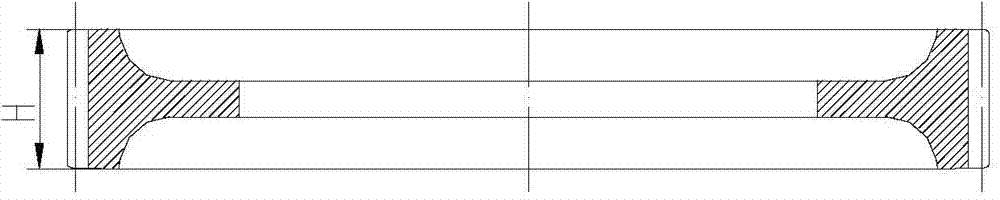

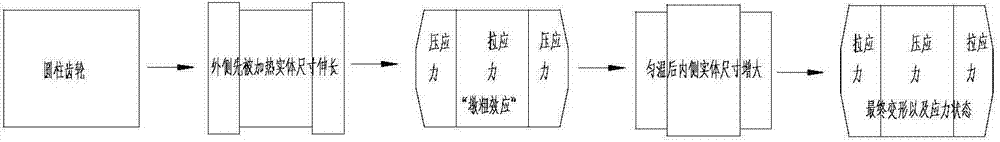

Carburizing and quenching method for cylindrical gear

InactiveCN104498965ACompensation corrects cone distortionEliminate internal stressSolid state diffusion coatingFurnace typesGear grindingElastic plastic

The invention relates to a carburizing and quenching method for a cylindrical gear, and belongs to the technical field of heat treatment. The method comprises the following steps: heating until the temperature exceeds elastic-plastic transformation temperature of low-carbon steel for primary preheating; heating until the temperature is less than the phase-transition temperature Ac1 of the low-carbon steel for preheating again; performing carburizing, high-temperature tempering, quenching, and low-temperature tempering. According to the carburizing and quenching method for the cylindrical gear, effective measures for inhibiting or removing deformation are respectively performed for a plurality of process stages and supplement each other and are organically combined, so that the deformation of the cylindrical gear carburizing and quenching thermal treatment can be obviously reduced, the preset grinding allowance of the gear can be properly decreased, and as a result, the gear grinding time is reduced, and conditions are created for lowering the gear manufacturing cost.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

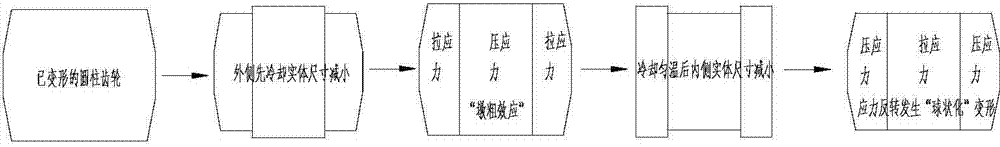

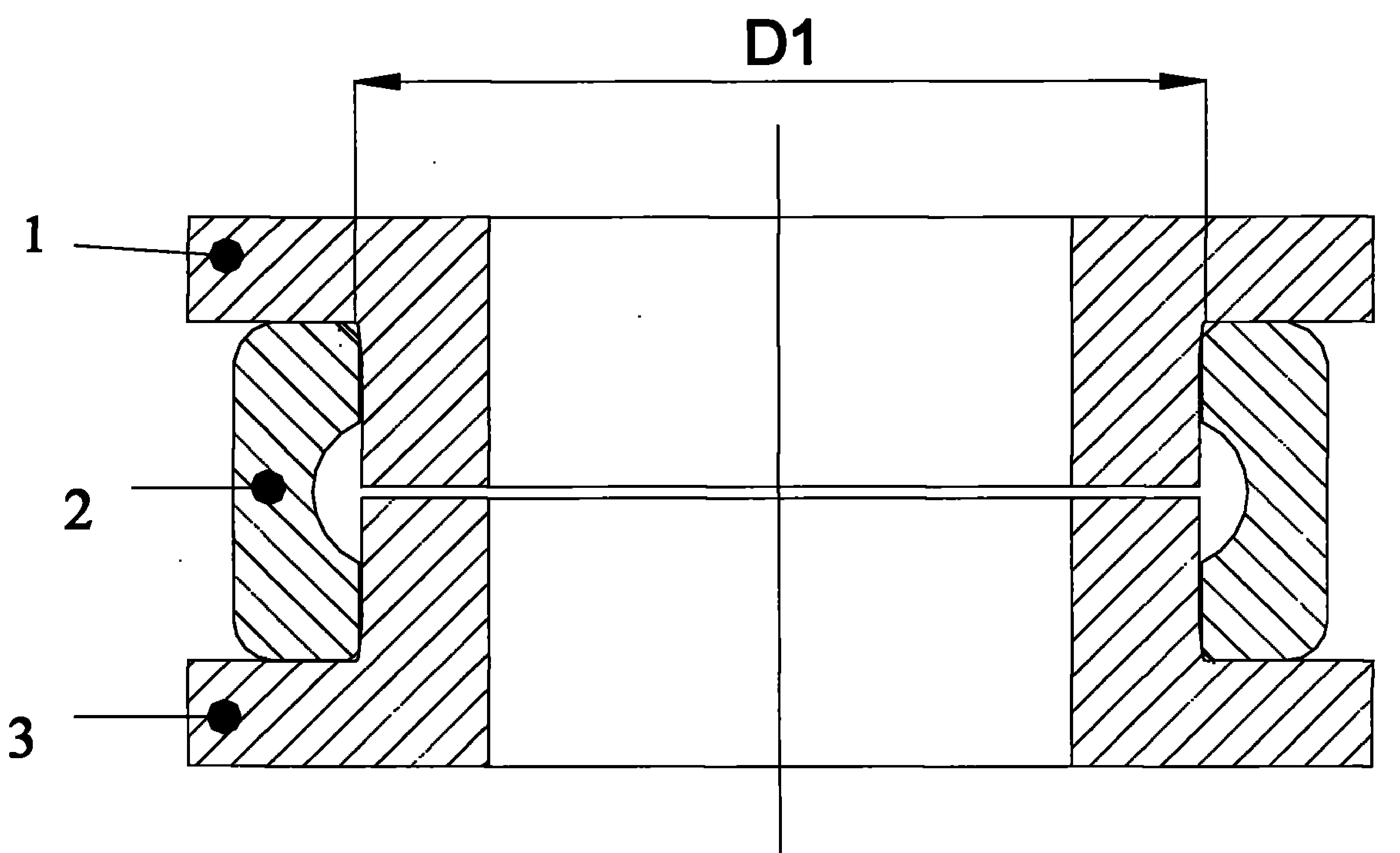

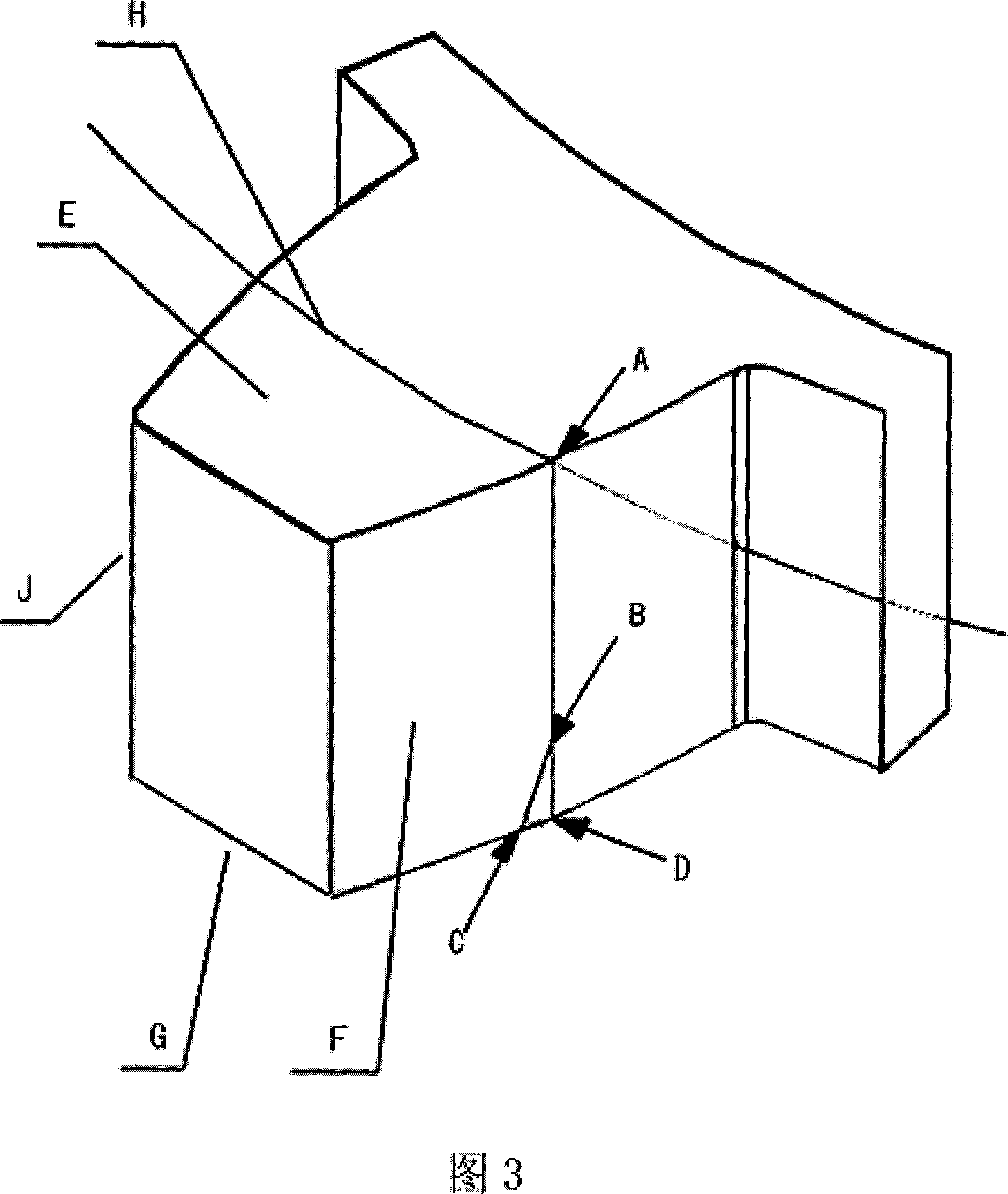

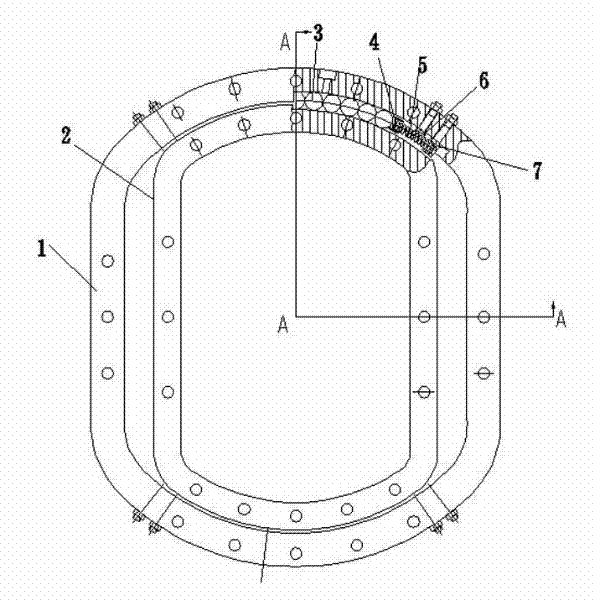

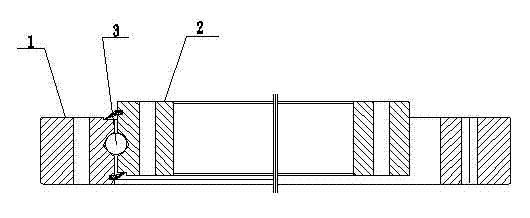

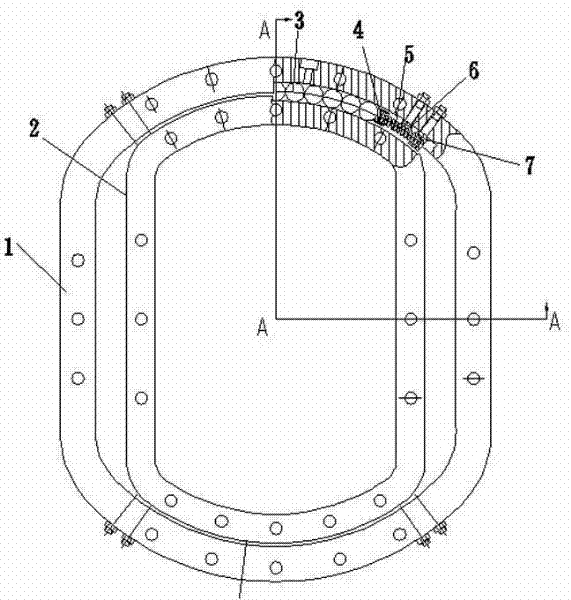

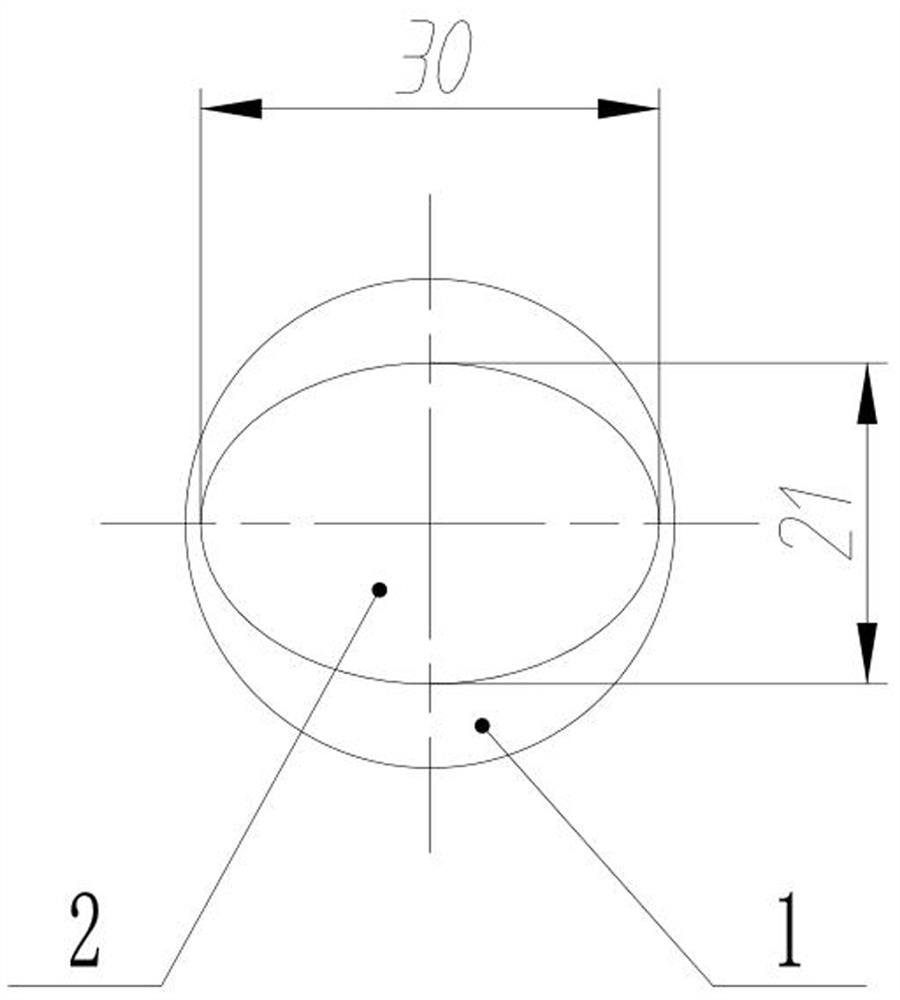

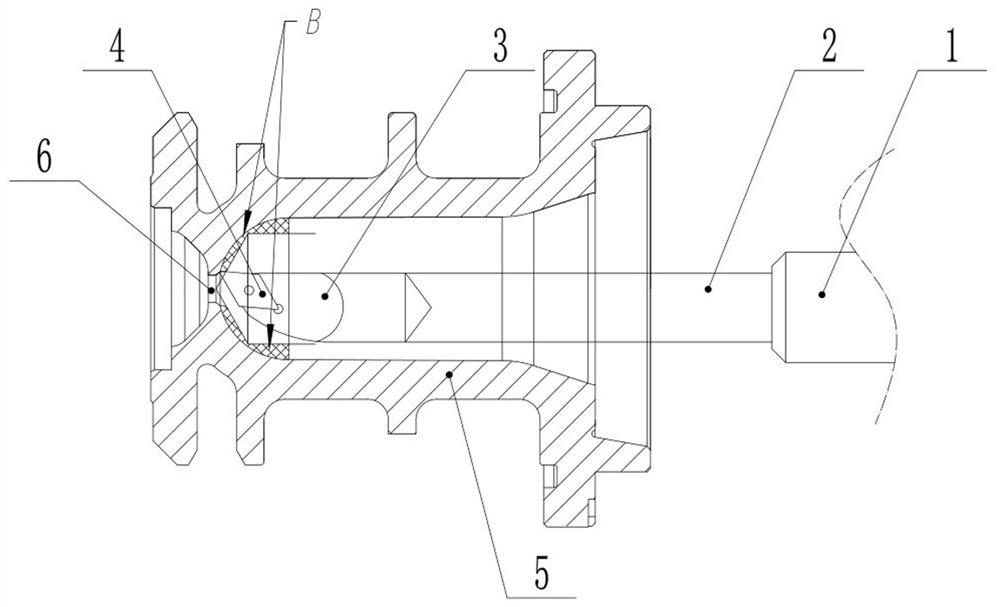

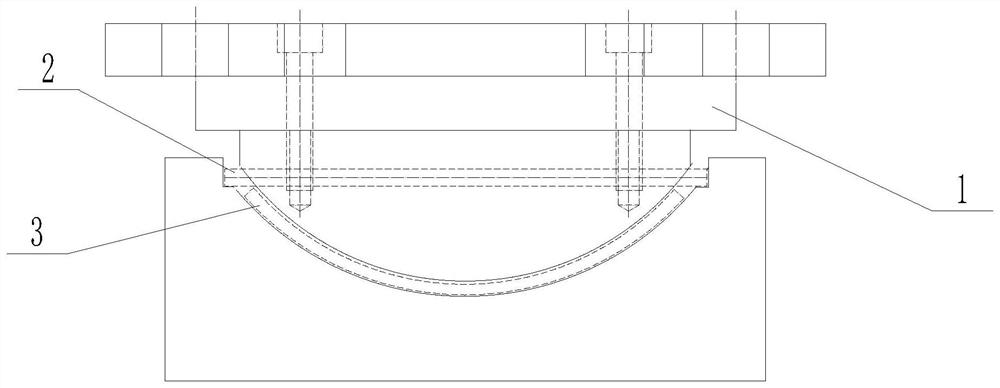

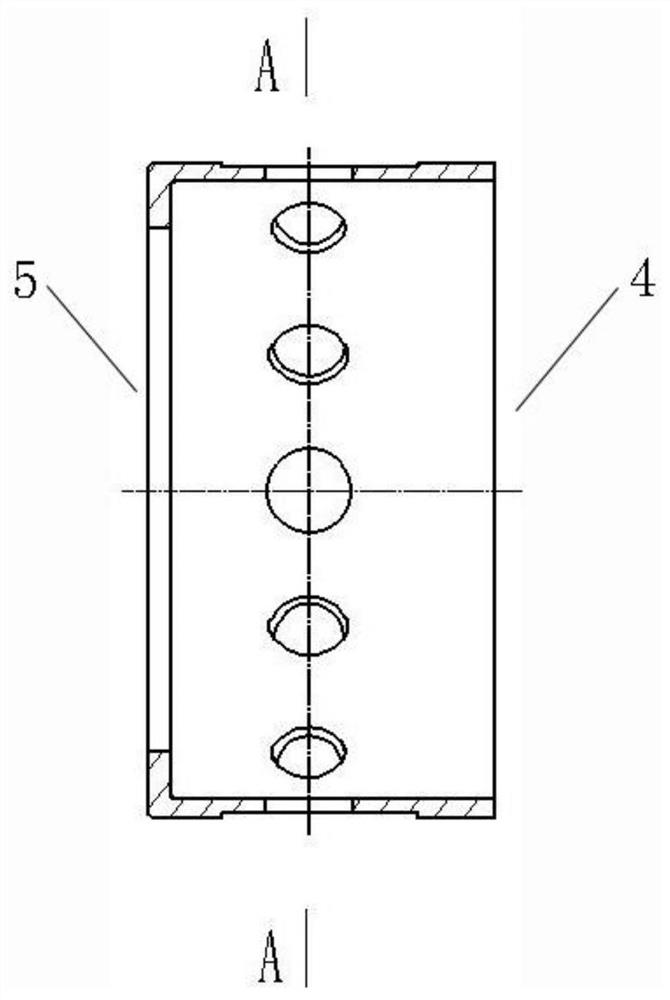

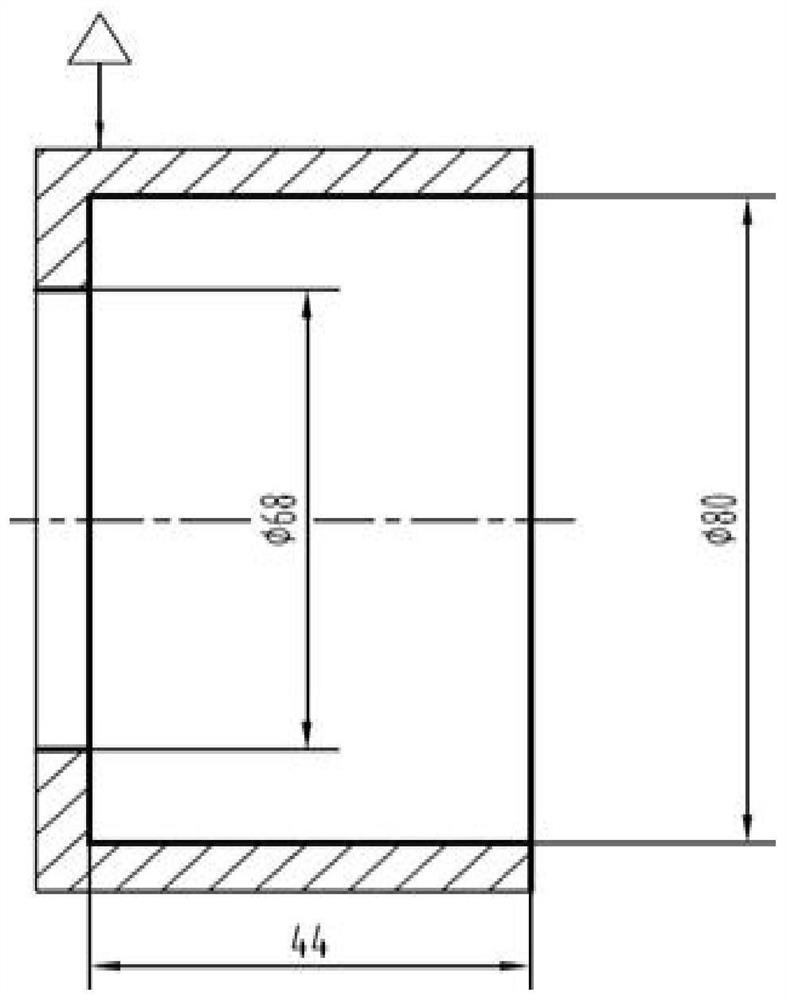

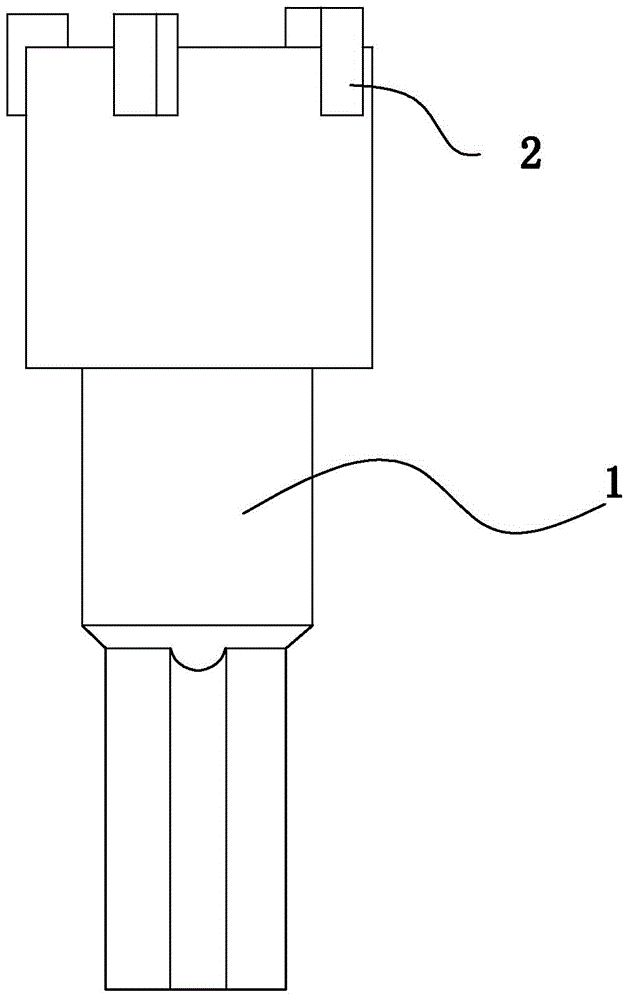

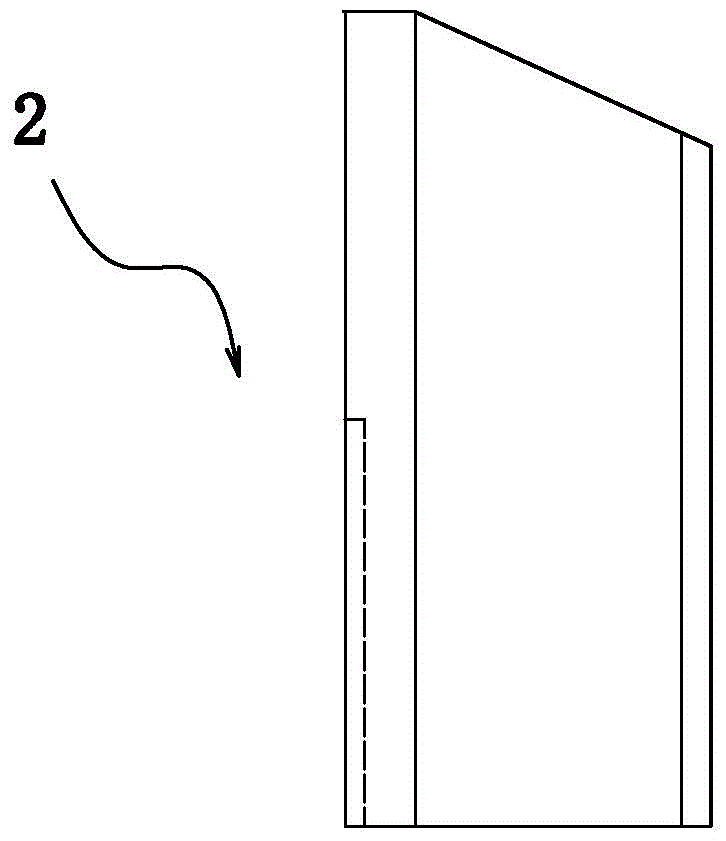

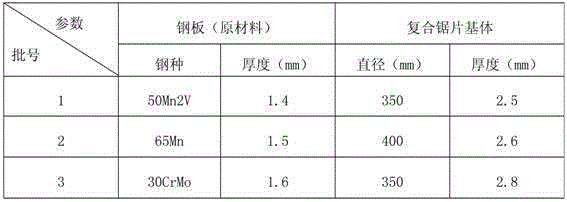

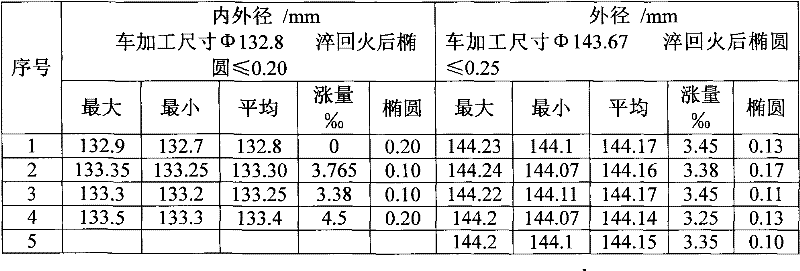

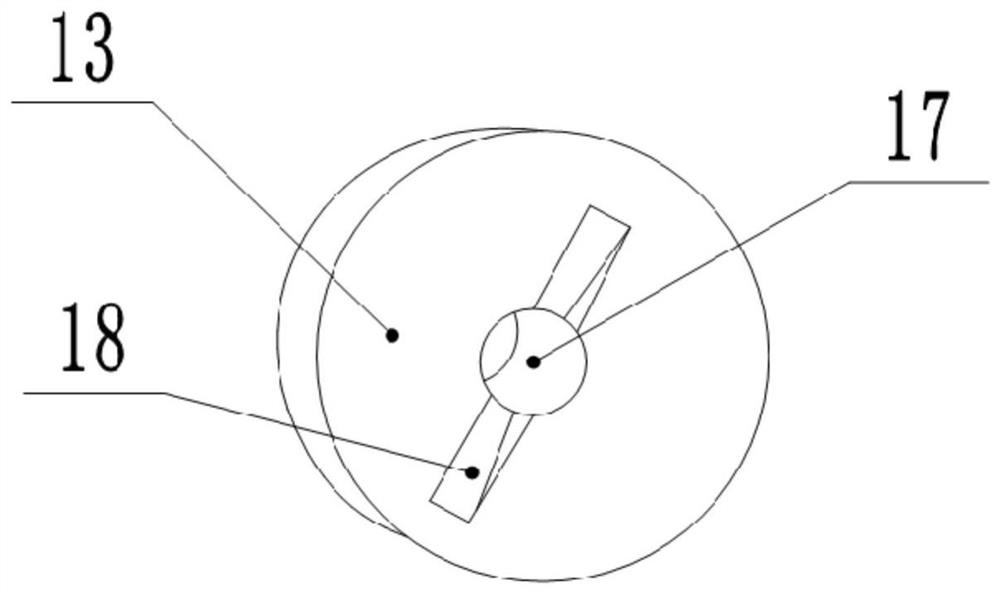

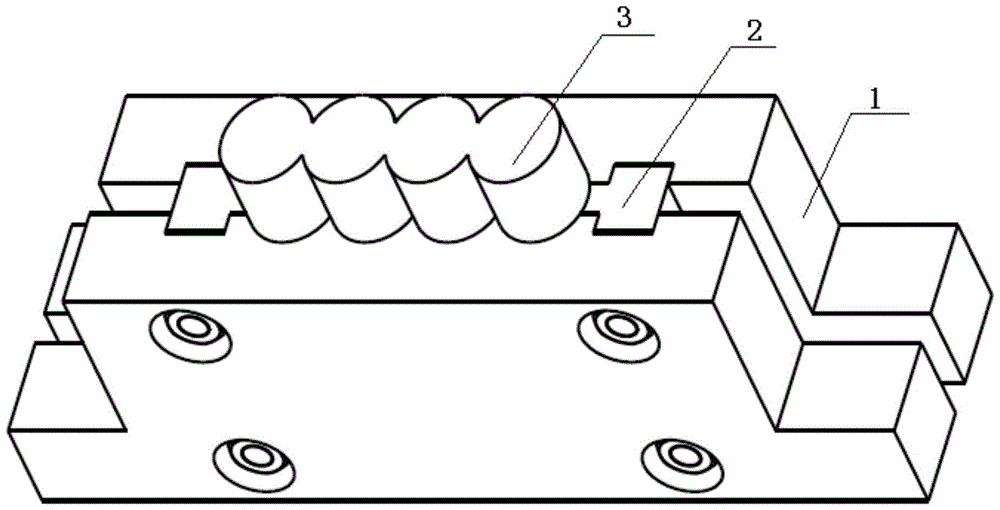

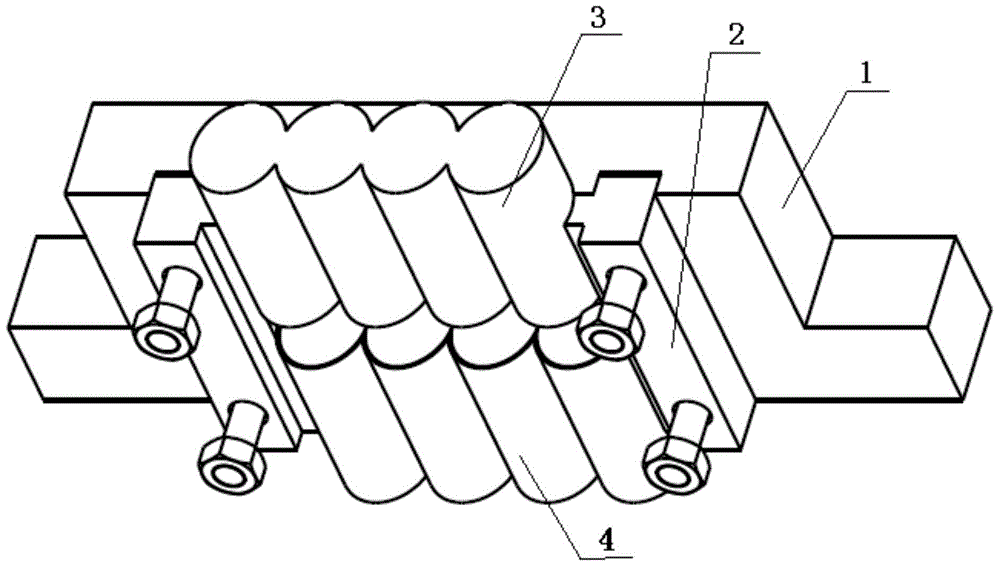

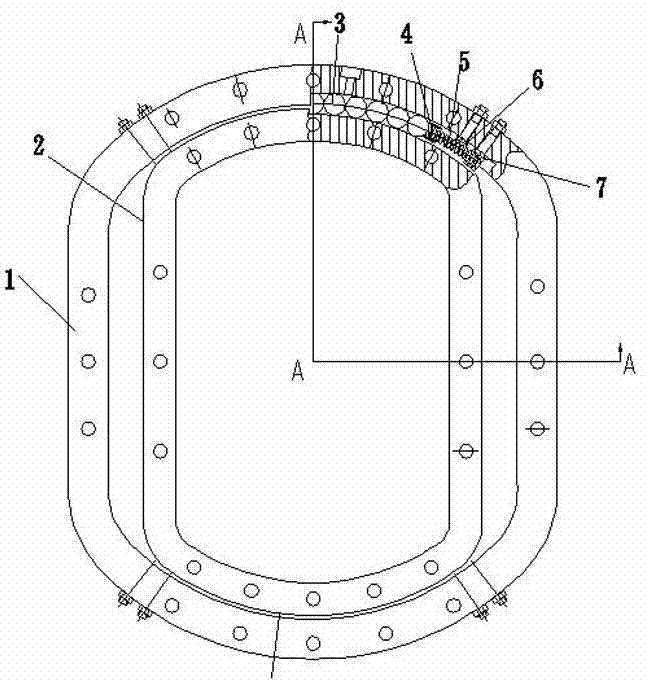

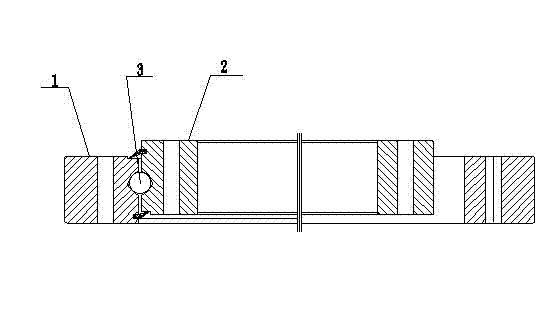

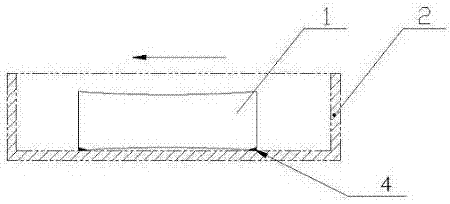

Control method for preventing deformation in quenching process of 9Cr18 thin-wall bearing ring

ActiveCN101775480AAvoid quenching deformationImprove ergonomicsFurnace typesHeat treatment furnacesEconomic benefitsHeating furnace

The invention relates to a control method for preventing deformation in the quenching process of a 9Cr18 thin-wall bearing ring. The method comprises the following steps of: firstly designing an upper die (1) and a lower die (3) which have symmetrical structures; before quenching, loading the 9Cr18 thin-wall bearing ring (2) into a 45KW box-type heating furnace for preheating, wherein the preheating temperature is 850 DEG C, and the preheating time is 30 min; shifting the 9Cr18 thin-wall bearing ring into a 50KW high-temperature box-type heating furnace for heating, wherein the heating temperature is 1070 DEG C, and the time for keeping the temperature is 5 min; taking the 9Cr18 thin-wall bearing ring out, and placing the 9Cr18 thin-wall bearing ring on the lower die of the quenching die; covering the upper die of the quenching die, and fixing the upper die, the 9Cr18 thin-wall bearing ring and the lower die as a whole to be placed in quenching oil for quenching; separating the upper die and the lower die 3 min after quenching, and taking out the 9Cr18 thin-wall bearing ring. The qualification rate of the bearing ring quenched by adopting the invention reaches 98 percent, and the economic benefit is remarkable.

Owner:LUOYANG BEARING RES INST CO LTD

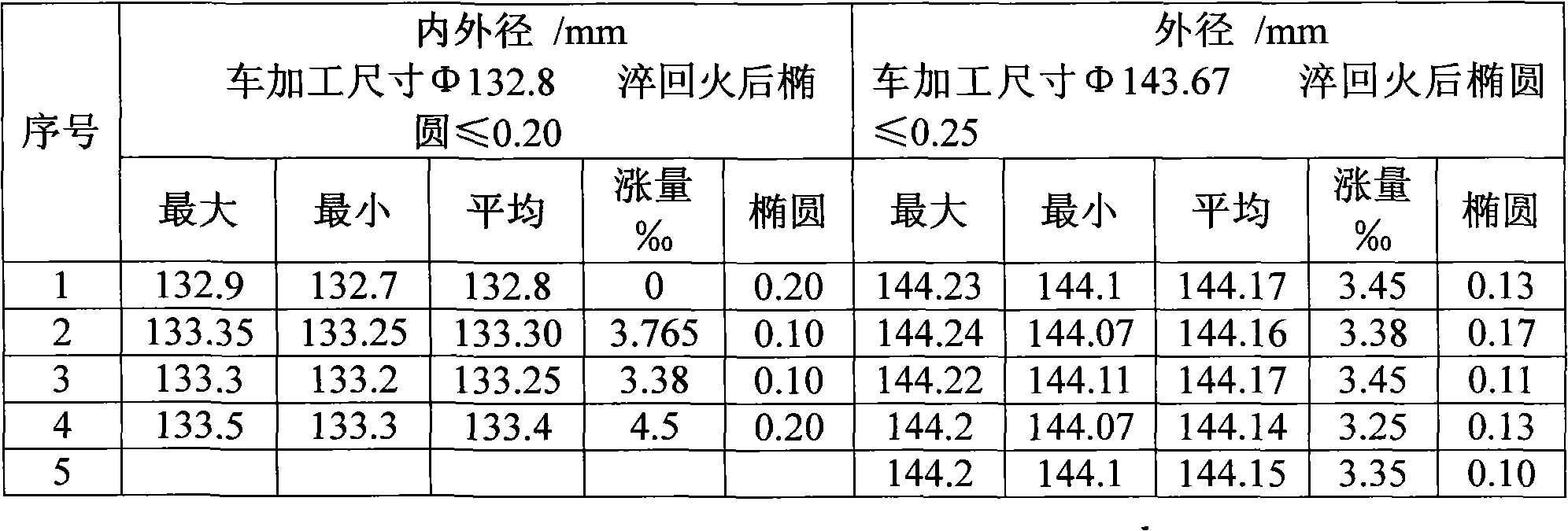

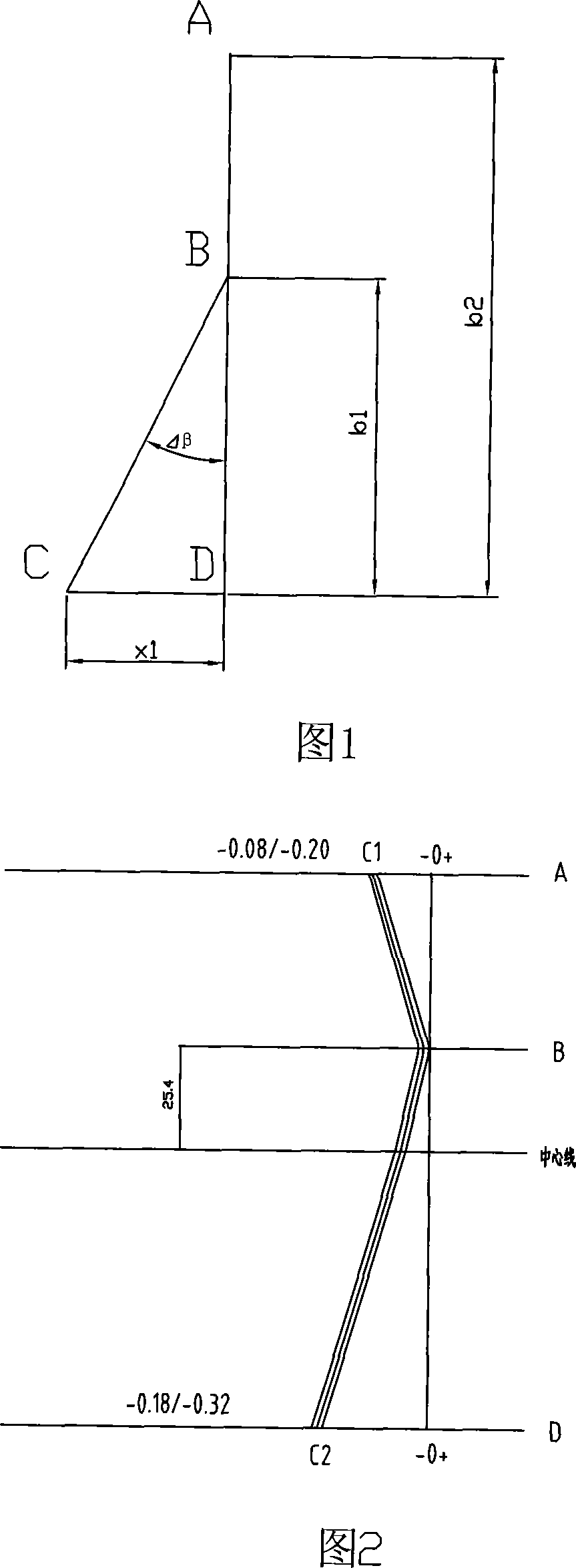

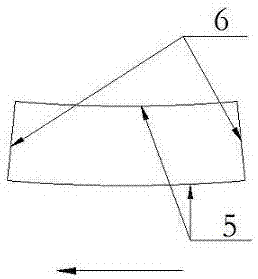

Tooth direction shaping gear hobbing processing technique

ActiveCN101085480AUniform tooth surface hardness differenceMeet the design requirementsGear teethEngineeringMachining process

The invention relates to the machining of gear teeth. The machining process comprises: Based on the drawing, it uses the hobber machining the gear to the inspection point A or D, computing the differential change wheel angle t based on the hobber differential mechanism with CB line actual spiral angle and gear and hobber parameter, loosening the differential change wheel, holding the change angle t, imitating the difference of machining small spiral gears, forming fixing point from the end surface fixing theoretical point C. It can get rid of the deficiencies of step, insufficient effective hardening and teeth surface hardness.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

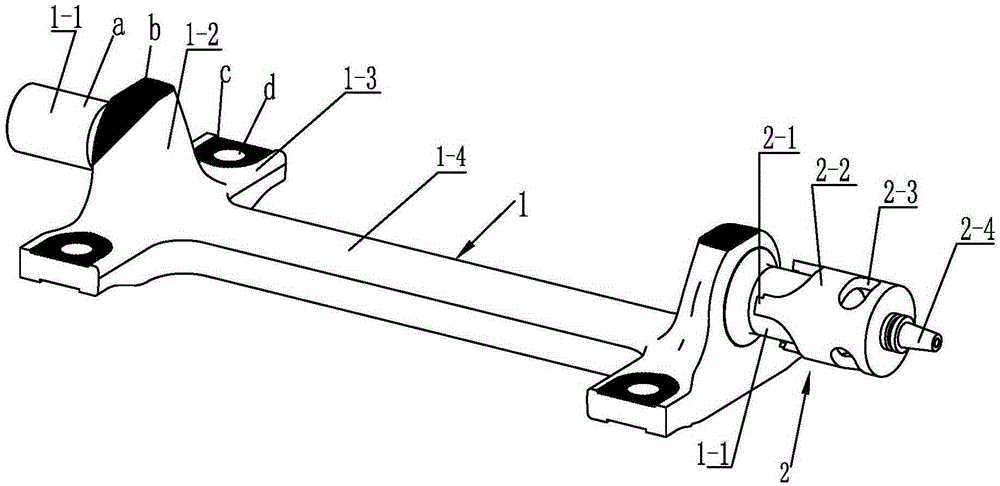

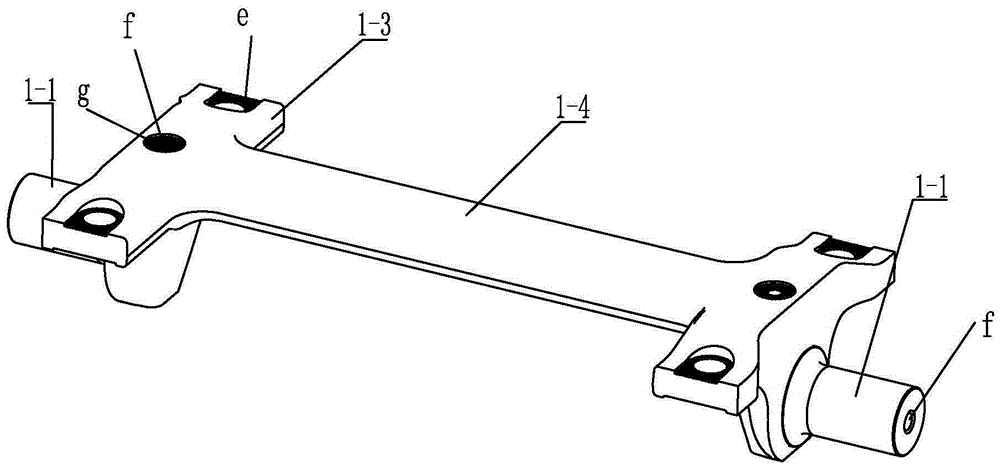

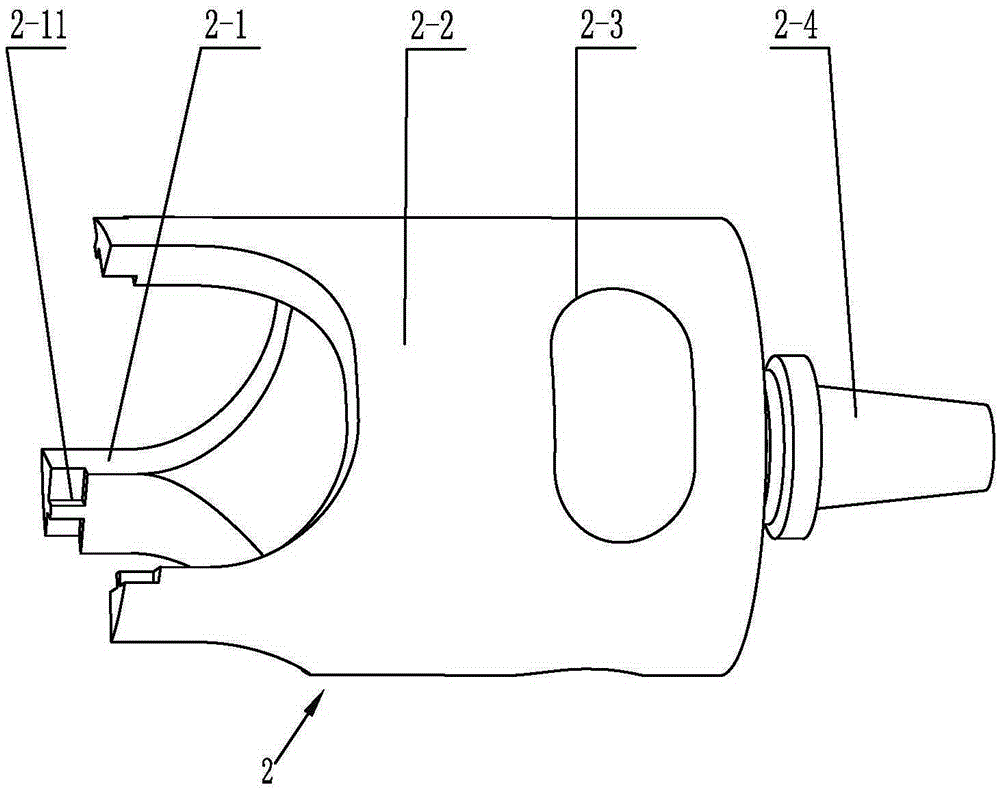

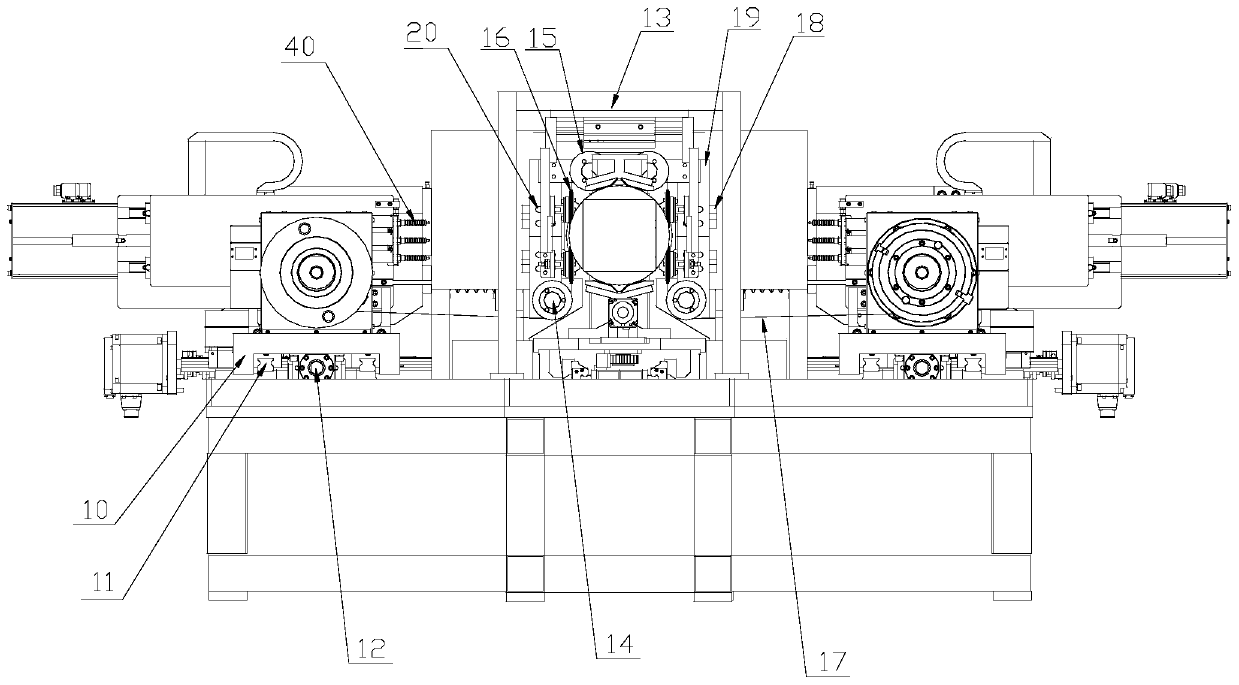

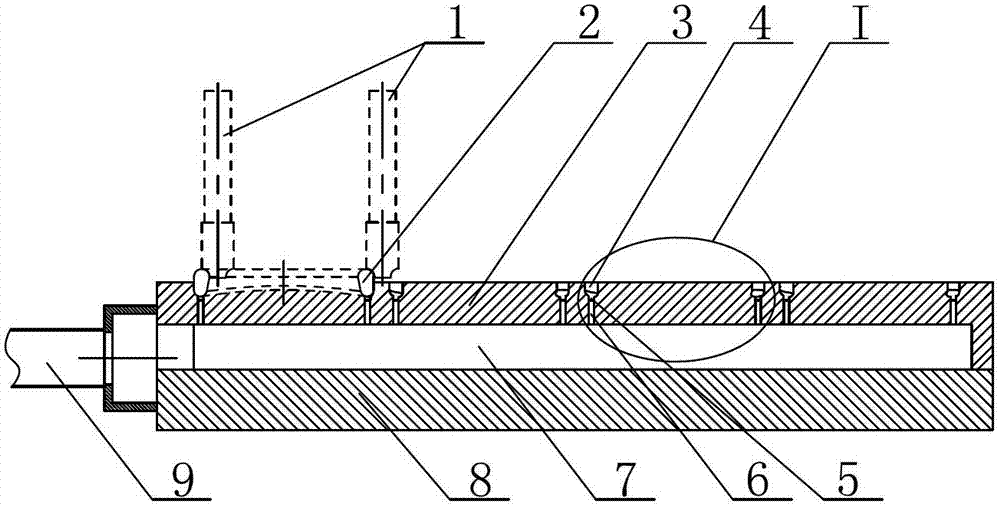

Mechanical processing method of axle bridge for rail vehicle

ActiveCN105397429AHigh strengthReduce the number of positioning and clampingBogiesStress relievingWork in process

The invention relates to a mechanical processing method of an axle bridge for a rail vehicle. The method comprises the following steps: (1) treating the bottom surface of an axle bridge blank as a positioning surface, and clamping; drilling central holes in the end surfaces of two shaft necks; (2) ejecting ejector pins into the central holes in the shaft necks; roughly turning the outer circumferences of the rotating shaft necks; roughly milling the bottom surface of each mounting seat and the bottom surface of each shaft head, and drilling holes in the bottom surfaces; roughly milling the top parts of the shaft heads and the upper end of each mounting seat; (3) modifying the central holes in the two ends of the shaft necks after stress-relieving treatment; (4) positioning and clamping in central holes in the two ends of a semi-finished axle bridge through the ejector pins on a machine tool; performing fine turning for outer circles of the shaft necks; performing fine milling for the planes of the bottom parts of the mounting seats, and reaming; (5) clamping the semi-finished axle bridge on the mounting seats of the machine tool; driving two coaxial grinding cutting tools to rotate through an output shaft of the machine tool so as to enable an empty chamber of a forward-moving barrel-shaped tool body to gradually sleeve the corresponding shaft neck; cutting the outer circle of each shaft neck through a blade until the specified size is reached, so as to obtain the finished axle bridge. With the adoption of the method, the axle bridge processing precision can be improved, and the processing efficiency and product qualification ratio can be improved.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

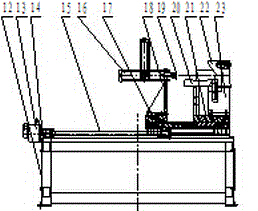

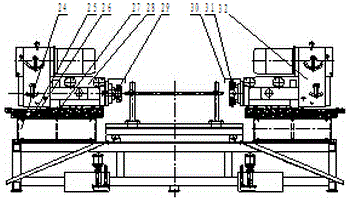

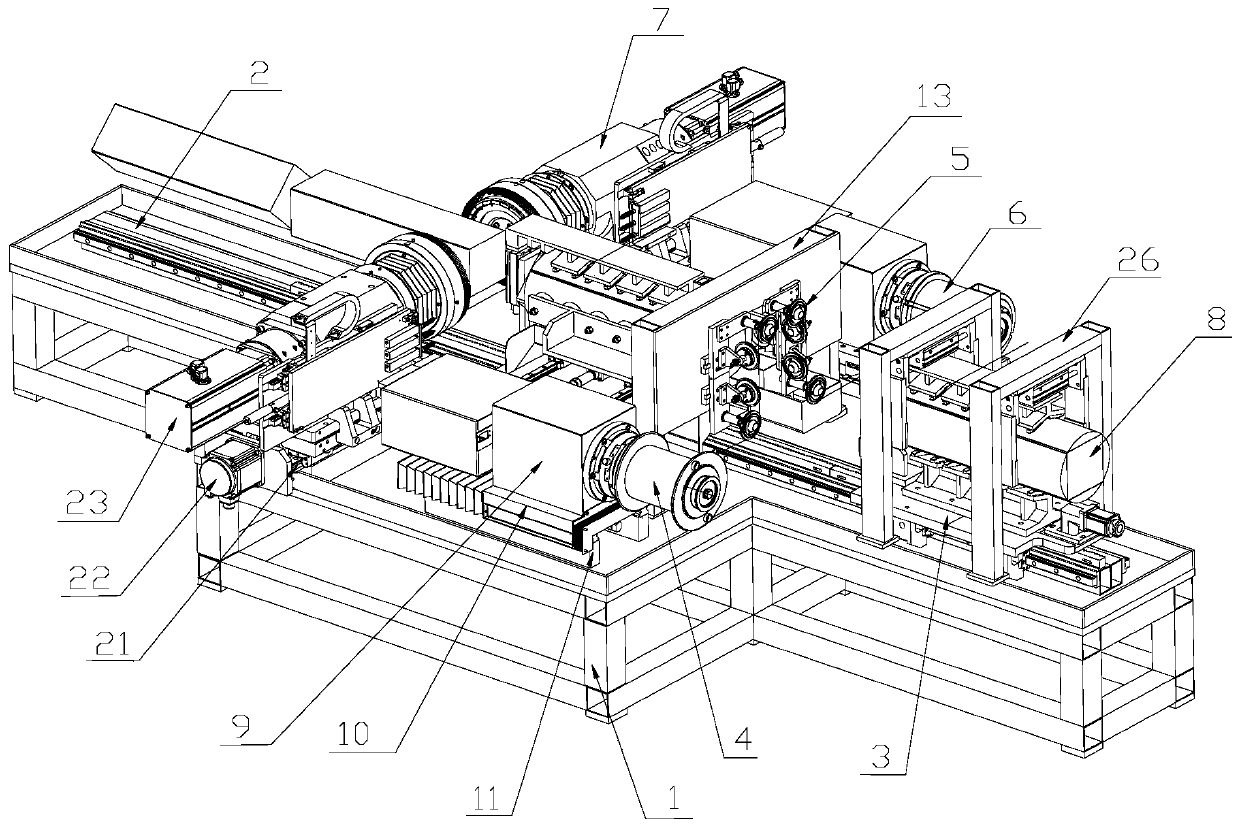

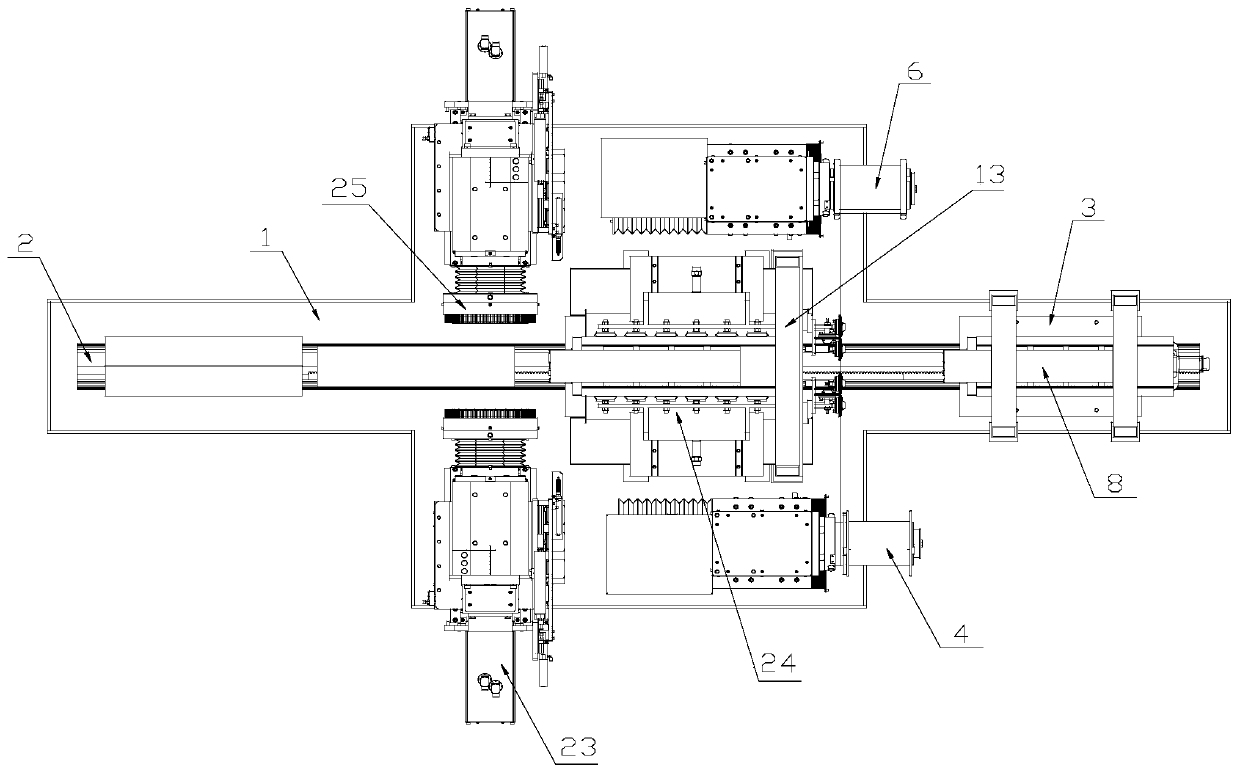

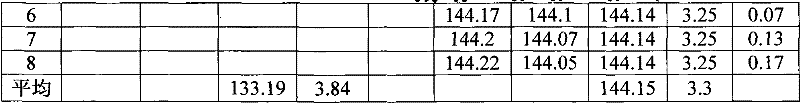

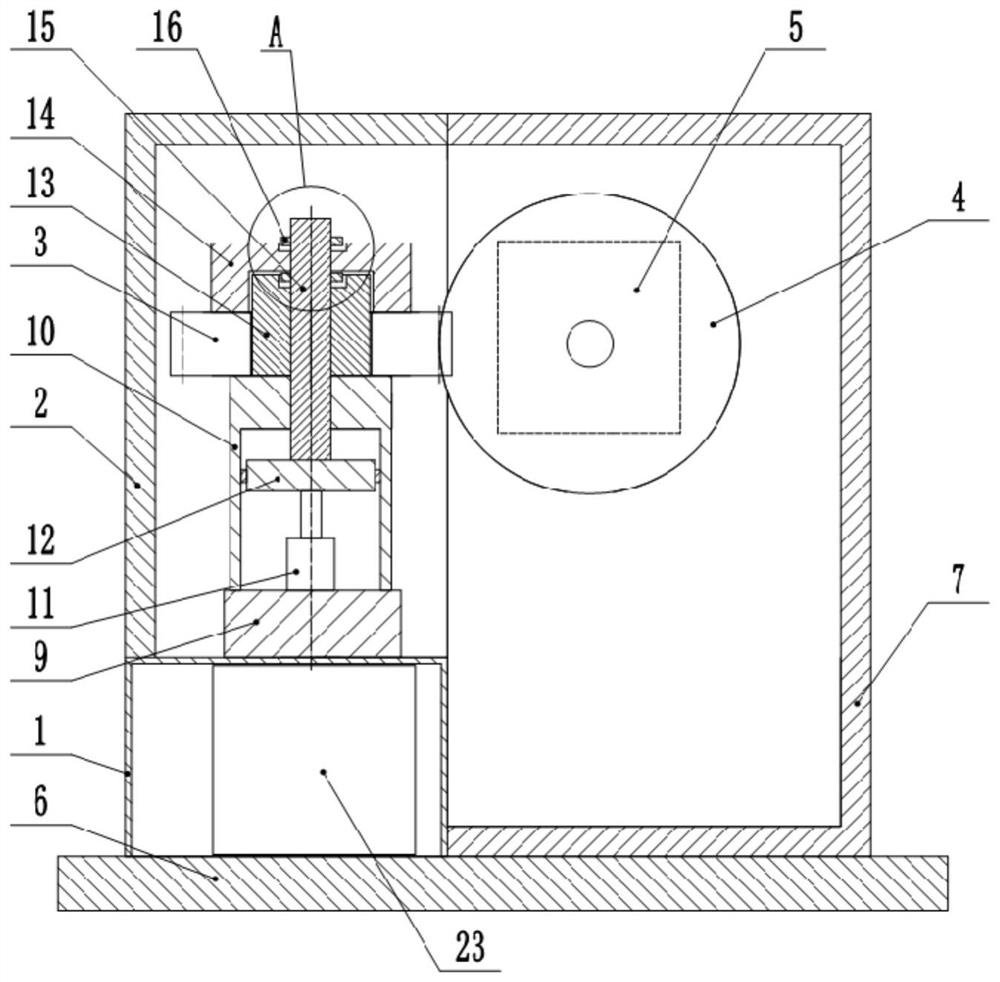

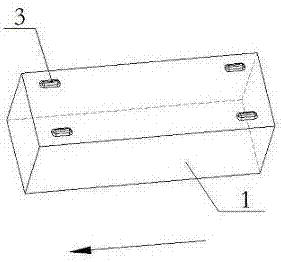

Machine tool for automatically milling two end faces and drilling central holes of pin shaft

InactiveCN105436893AHigh concentricityReasonable and practical designOther manufacturing equipments/toolsHigh volume manufacturingEconomic benefits

The invention provides a machine tool for automatically milling two end faces and drilling central holes of a pin shaft. According to the machine tool, central hole drilling and one-outer-circle sleeving and turning are combined into one working procedure, automatic feeding and automatic discharging are carried out, and the production efficiency is greatly improved. The machine tool is mainly composed of a tool frame assembly, an automatic positioning device, an automatic clamping device, an automatic feeding device, an automatic double-face milling device, an automatic central hole drilling and sleeving-turning device and an automatic discharging device. The machine tool is reasonable and practical in design, two-end-face milling, central hole drilling and one-outer-circle sleeving and turning are combined into one working procedure, automatic feeding and automatic discharging are achieved, the speed is high, labor and time are saved, the concentricity of the central holes of the two ends is high, the grinding allowance is small, the production efficiency and the economic benefits of an enterprise are improved, the quality of a machined product is excellent, and the machine tool particularly meets the large-scale production requirement.

Owner:DONGYING XINSHENG MACHINERY

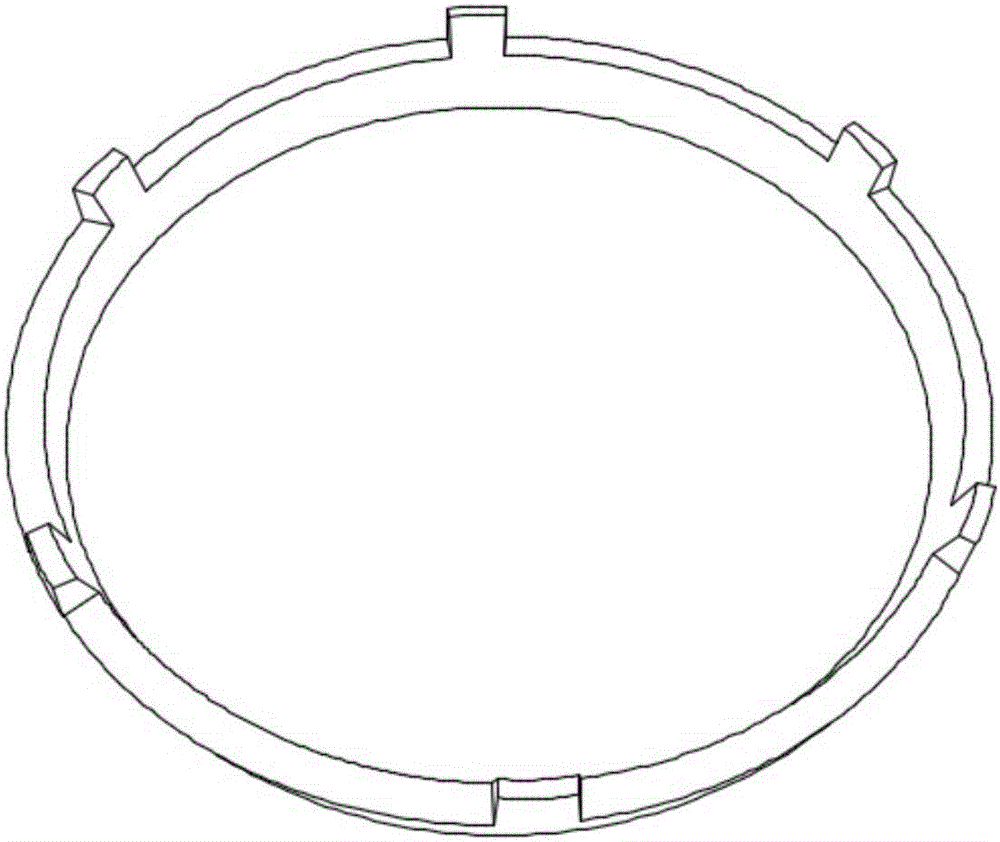

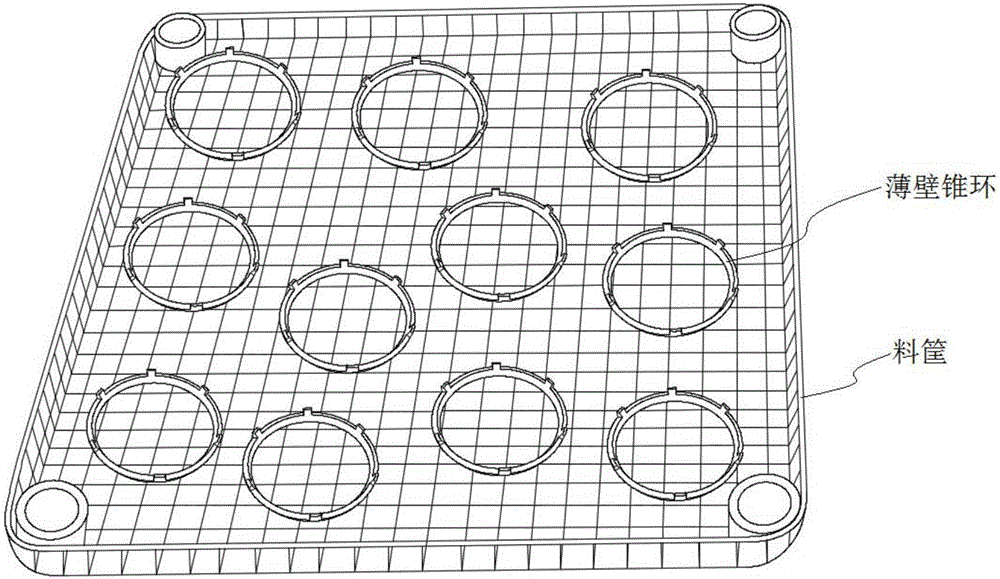

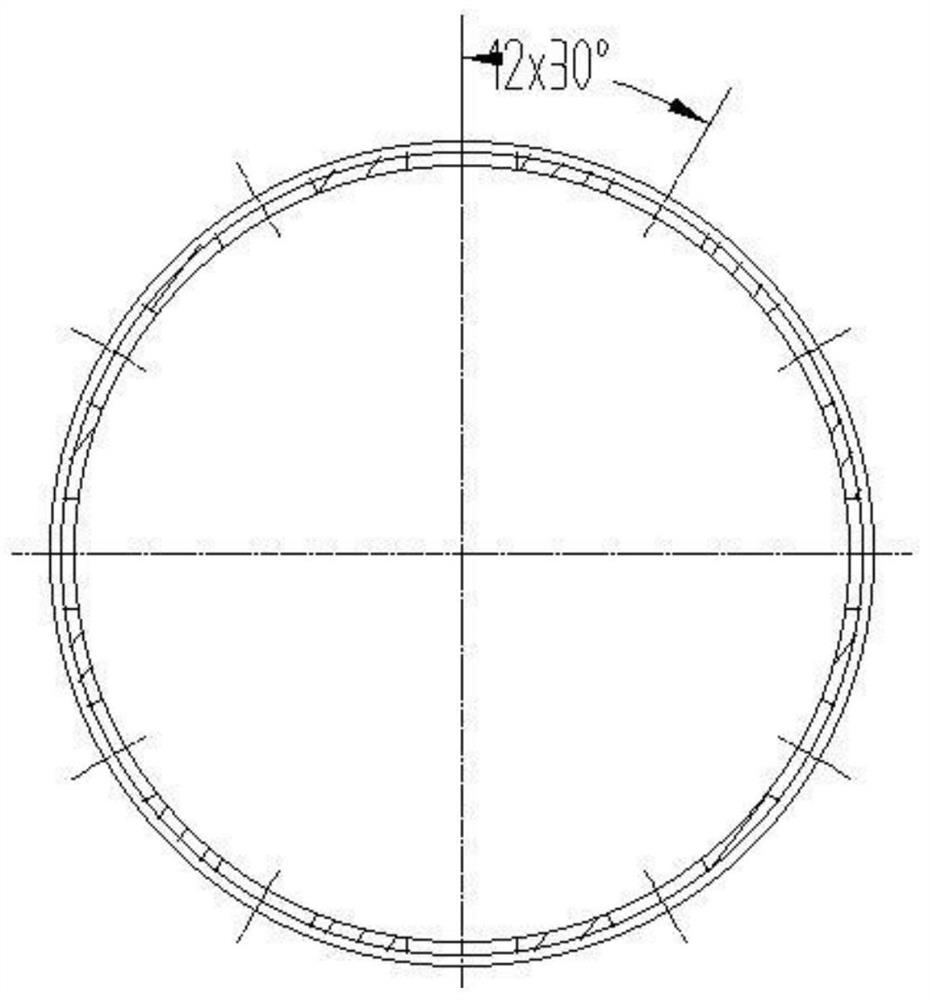

Heat treatment technology for reducing deformation of GCr15 thin-wall conical ring

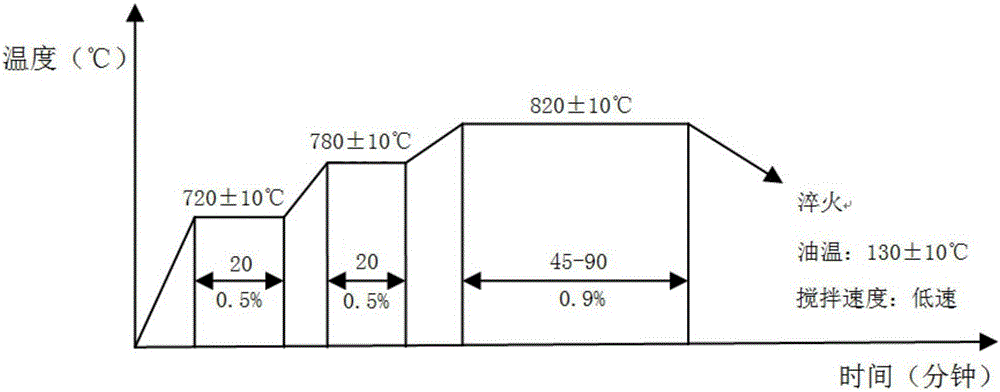

ActiveCN106048195ASmall amount of deformationReduce grinding allowanceFurnace typesProcess efficiency improvementCarbon potentialThermal insulation

The invention discloses a heat treatment technology for reducing deformation of a GCr15 thin-wall conical ring and belongs to the field of heat treatment technology. The technology comprises the following steps: 1) machining of a spheroidized annealed blank into a thin-wall conical ring part; 2) crating; 3) front cleaning; 4) quenching: thermal insulation at 720 + / - 10 DEG C for 20 + / - 1 min, and carbon potential is 0.5 + / - 0.025%; thermal insulation at 780 + / - 10 DEG C for 20 + / - 1 min, and carbon potential is 0.5 + / - 0.025%; thermal insulation at 820 + / - 10 DEG C for 45-90 min, and carbon potential is 0.9 + / - 0.025%; and cooling in 130 + / - 10 DEG C of quenching oil; 5) post cleaning; and 6) tempering: tempering temperature is 185 + / - 5 DEG C, and time is 150 + / - 10 min. According to the invention, deformation of the thin-wall conical ring part after heat treatment is reduced, grinding allowance after heat treatment is decreased, grinding cost after heat treatment is lowered, and first pass yield for heat treatment reaches 100%.

Owner:常州新区河海热处理工程有限公司

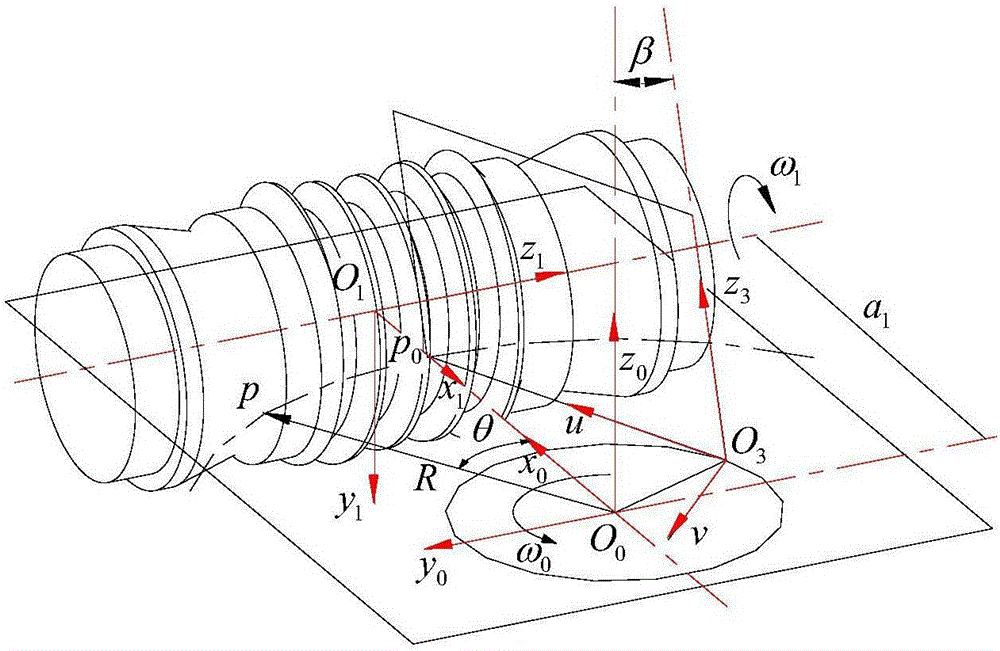

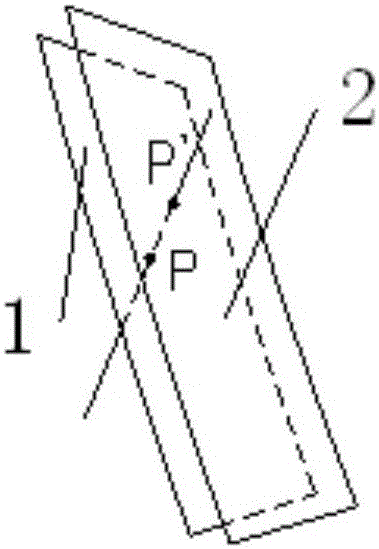

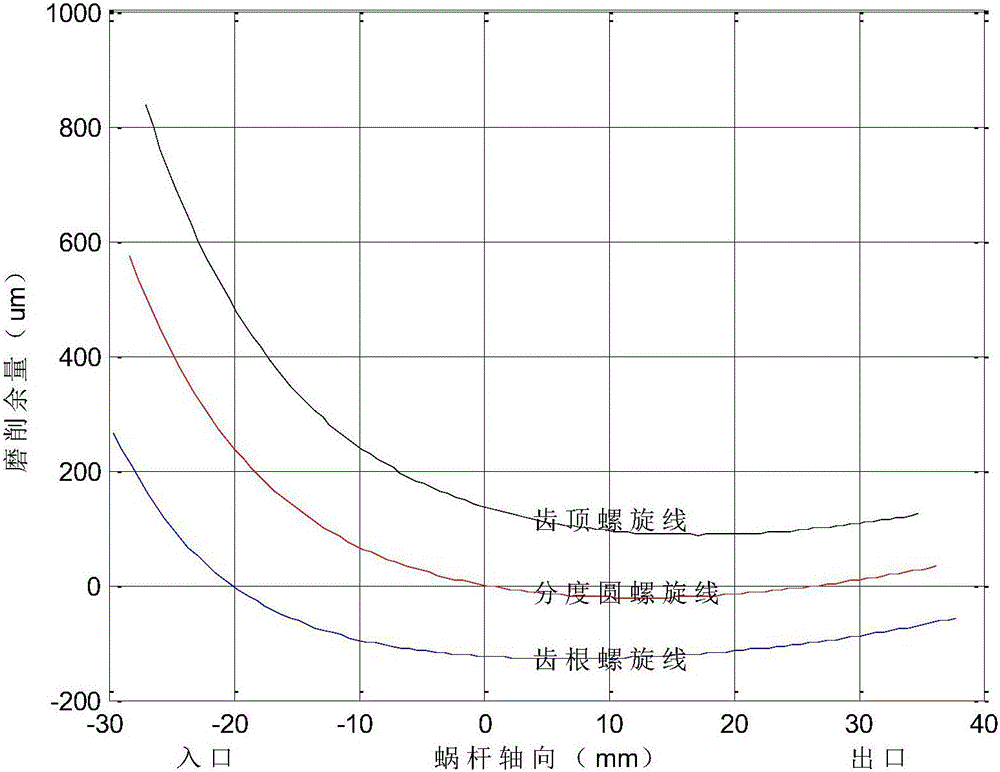

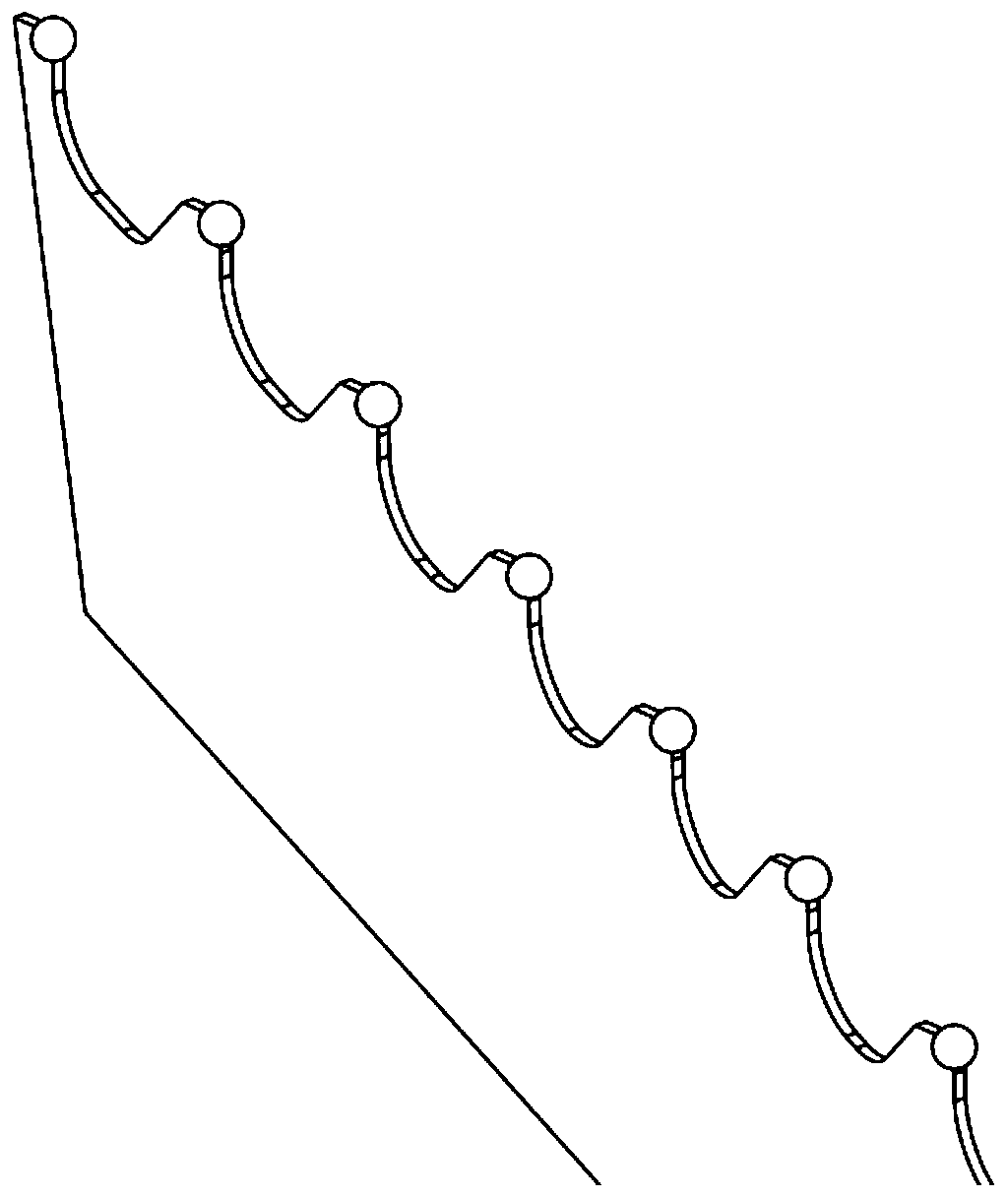

Method for homogenizing gear tooth surface grinding allowance of planar enveloping hourglass worm

The invention relates to the technical field of grinding allowance homogenizing, in particular to a method for homogenizing gear tooth surface grinding allowance of a planar enveloping hourglass worm. The method is characterized by specifically comprising the following steps: a, establishing a mathematical model of the gear tooth surface grinding allowance of the planar enveloping hourglass worm; b, constructing an equation for enabling grinding allowance at an inlet and grinding allowance at an outlet in a helical line of a reference toroidal surface to be consistent by taking a tooth-punching center distance FORMULA and a radius of a tooth-punching base circle FORMULA as parameters; and enabling grinding allowance at a tooth-top helical line at the inlet and grinding allowance at a tooth-root helical line at the outlet to be consistent; c, solving the equation, regulating parameters of a machine tool to carry out tooth punching according to the tooth-punching center distance and the base circle radius; and d, obtaining smallest grinding allowance according to a difference value at a maximum point and a minimum point of the grinding allowance on a tooth surface. Compared with the prior art, the method has the advantages of being capable of reducing integral grinding allowance, homogenizing grinding allowance at the inlet and the outlet, and homogenizing the grinding allowance at the tooth root and the tooth top.

Owner:上海合纵重工机械有限公司

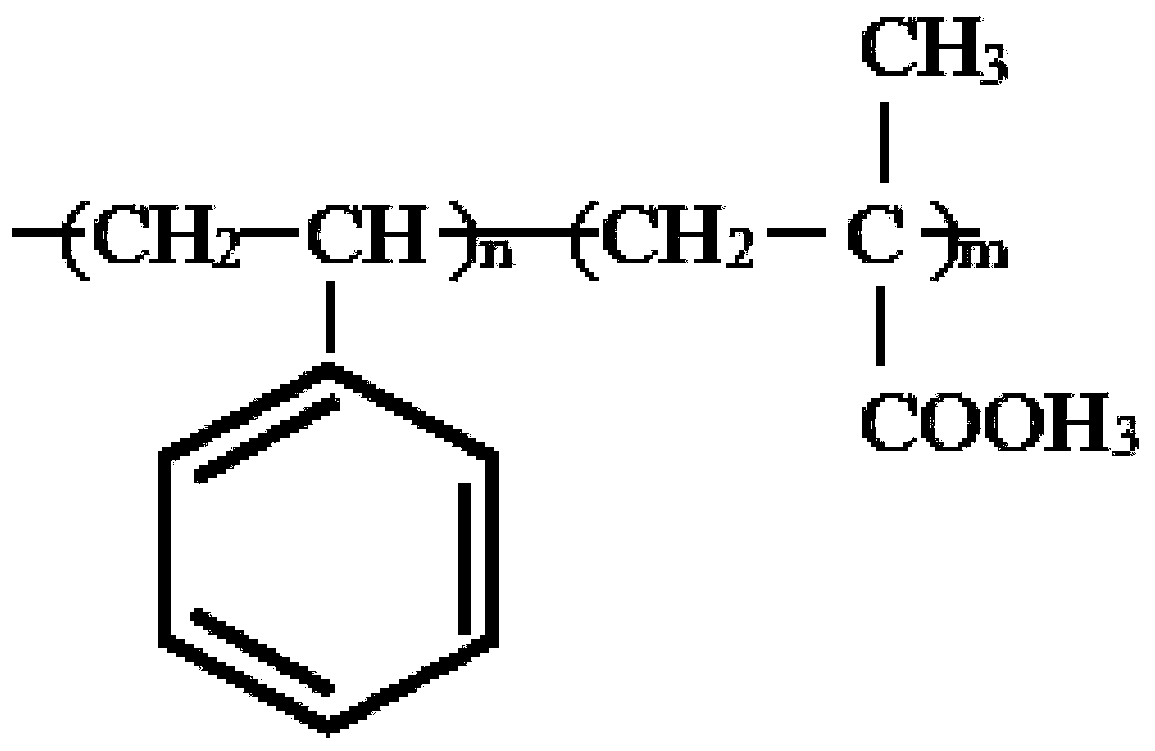

Anti-decarbonizing agent for bearing steel thermal treatment for preparing bearing and preparation method thereof

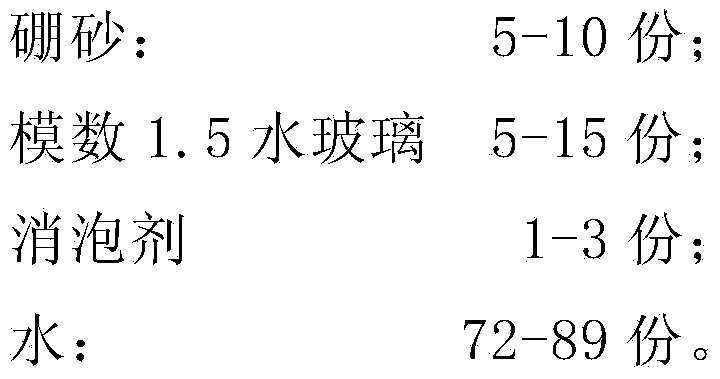

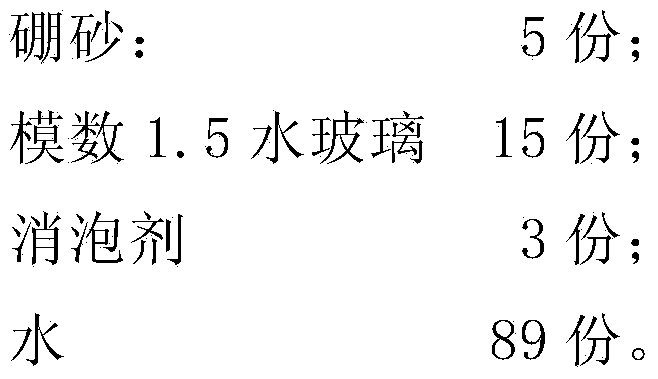

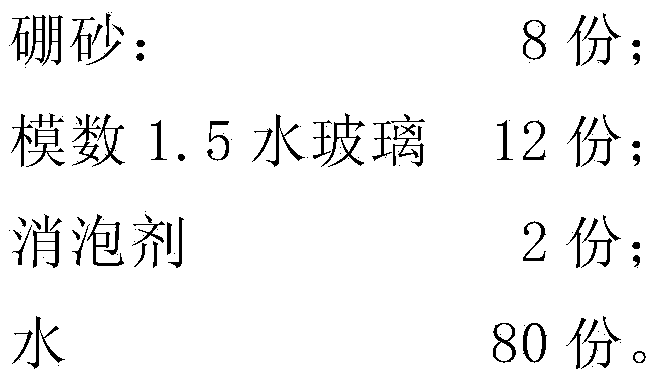

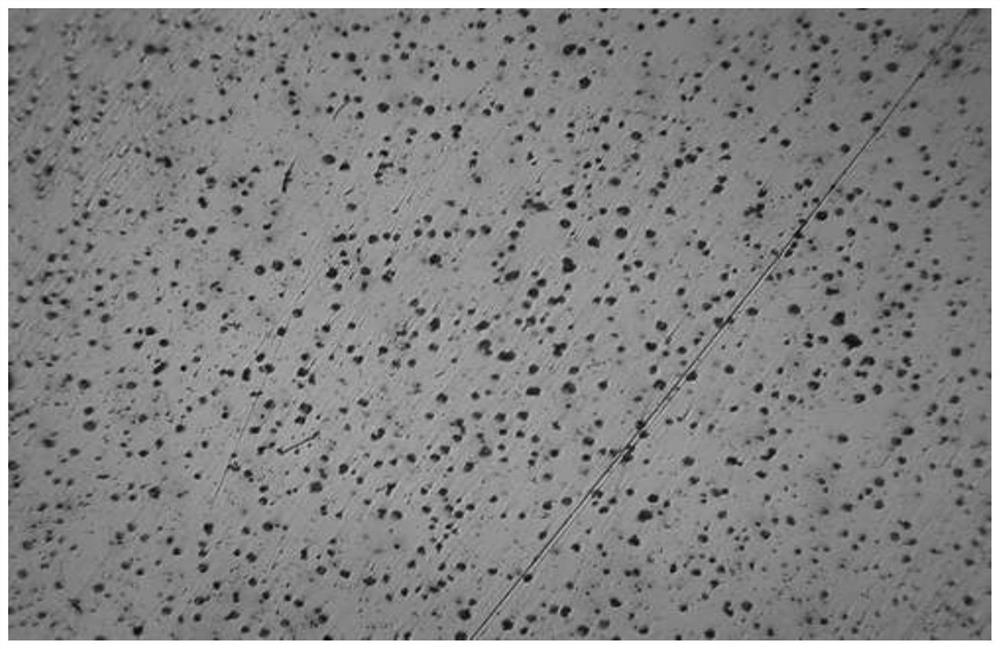

The invention discloses an anti-decarbonizing agent for bearing steel thermal treatment for preparing a bearing. The anti-decarbonizing agent is prepared from the following raw materials in parts by weight: 5-10 parts of borax, 5-15 parts of water glass with modulus of 1.5, 1-3 parts of defoamer and 72-89 parts of water. The preparation method comprises the following steps: first, heating water to 60-70 DEG C; adding borax to stir and dissolve; adding the defoamer till borax is fully dissolved; and uniformly stirring and gradually adding water glass with modulus of 1.5 to obtain the anti-decarbonizing agent. The anti-decarbonizing agent disclosed by the invention can form a compact chemical protective film on the surface of bearing steel to prevent a decarbonizing layer from being formed on the surface of the bearing steel due to thermal treatment, so that the grinding allowance can be reduced by 20-30%, thereby improving the processing efficiency. As the compact chemical protective film on the surface of a steel product can isolate corrosion of oxygen and water vapor in a put process after thermal treatment, anti-rust treatment is reduced or avoided. The anti-decarbonizing agent disclosed by the invention is particularly suitable for thermal treatment of a mesh belt furnace.

Owner:广德中隆轴承有限公司

Index plate machining gear shaving cutter gear grinding machine tooth grinding method

InactiveCN104959681AWill not increase the cumulative total deviation of the tooth pitchReduce processing stepsGear-cutting machinesGear teethGear grindingMachining

The invention discloses an index plate machining gear shaving cutter gear grinding machine tooth grinding method. The index plate machining gear shaving cutter gear grinding machine tooth grinding method comprises the following steps that a large plane grinding wheel gear grinding machine is used for machining a gear blank with the number z of teeth of a ground gear two times of the number Z of working grooves of an adopted index plate; an odd number or even number of same-name tooth faces of the gear blank are subjected to fine machining to serve as standard tooth faces, and one set of tooth faces to be machined in different-name tooth faces is judged according to the parity of the tooth crossing number K measured according to a common normal line; the working allowance of the tooth faces on the same side is determined according to the average deviation of an algebraic sum of the single pitch deviation of an even number of teeth and an odd number of teeth, and fine machining of the left tooth faces is finished. The index plate machining gear shaving cutter gear grinding machine tooth grinding method has the advantages that the number of machining steps is small, the grinding allowance is small, and the product precision is high.

Owner:黄乐

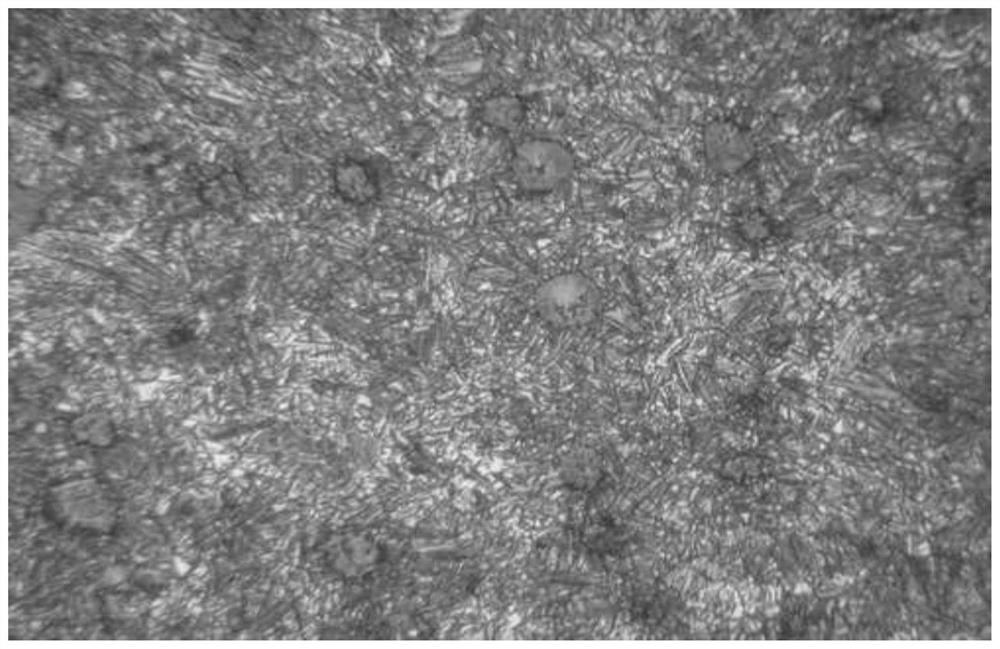

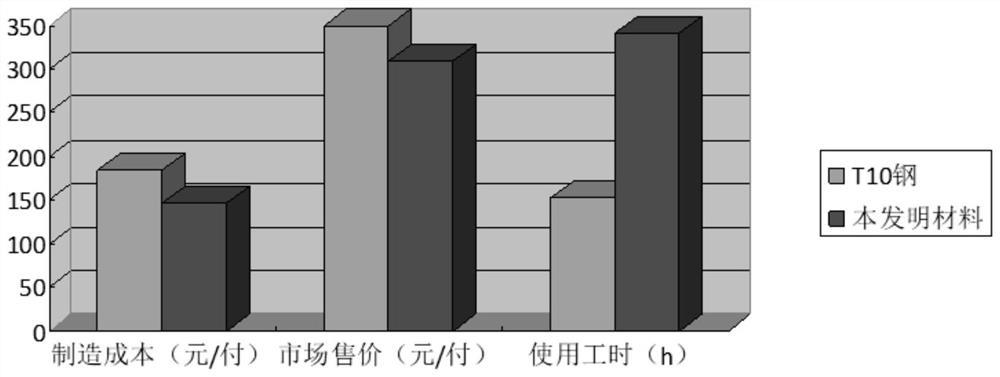

Self-hardening iron-based material for shear blade and preparation method of shear blade

InactiveCN112210715AImprove impact toughnessHigh impact strengthFurnace typesHeat treatment furnacesCarbon layerWear resistance

The invention discloses a self-hardening iron-based material for a shear blade. The self-hardening iron-based material is prepared from the following raw material components in percentage by mass: 3.0%-4.0% of C, 2.0%-3.5% of Si, 0.1%-0.6% of Mn, not more than 0.06% of P, not more than 0.02% of S, not more than 0.05% of Re, not more than 0.04% of Mg and the balance of Fe. The self-hardening iron-based material solves the problem that the prior carbon steel and alloy steel blade loses wear resistance and fatigue resistance due to movement or loss of the carbon layer and the hardening layer. Thepreparation method of the shear blade is simple in process, the manufacturing and processing cost of the material is greatly reduced, and the preparation method has good practical value.

Owner:XIAN UNIV OF TECH

Square cutting, edge cutting and polishing all-in-one machine

PendingCN110154256AAchieve excisionReduce grinding allowanceWorking accessoriesGrinding machinesEngineeringCrystalline silicon

The invention relates to a square cutting, edge cutting and polishing all-in-one machine, and belongs to the technical field of crystalline silicon machining equipment. The all-in-one machine comprises a base, wherein a sliding rail is arranged on the base, a feeding workbench mechanism, a centering mechanism, a squaring mechanism, a scrap edge falling mechanism and at least two polishing mechanisms are sequentially arranged on the sliding rail along the conveying direction of crystalline silicon, the feeding workbench mechanism is used for bearing the crystalline silicon and driving the crystalline silicon to move along the sliding rail, cutting lines bypass a squaring net of the squaring mechanism and form parallel lines, the scrap edge falling mechanism is used for sucking scrap edges generated under the cutting of the squaring mechanism, and the at least two polishing mechanisms are symmetrically arranged along the sliding rail. According to the all-in-one machine, the squaring mechanism and the polishing mechanism are integrated into one, and the crystal silicon can directly enter the slicing process after being machined at one time; the squaring mechanism adopts a form of two-wire squaring, so that cutting the crystal silicon into square bars and removing edges and corners are realized, the grinding allowance of the grinding procedure is reduced, and the rough grinding procedure is omitted; and a crystal bar is subjected to edge and corner machining immediately following one-time polishing after cut into the square bars, so that the grinding efficiency is remarkably improved.

Owner:QINGDAO GAOCE TECH CO LTD

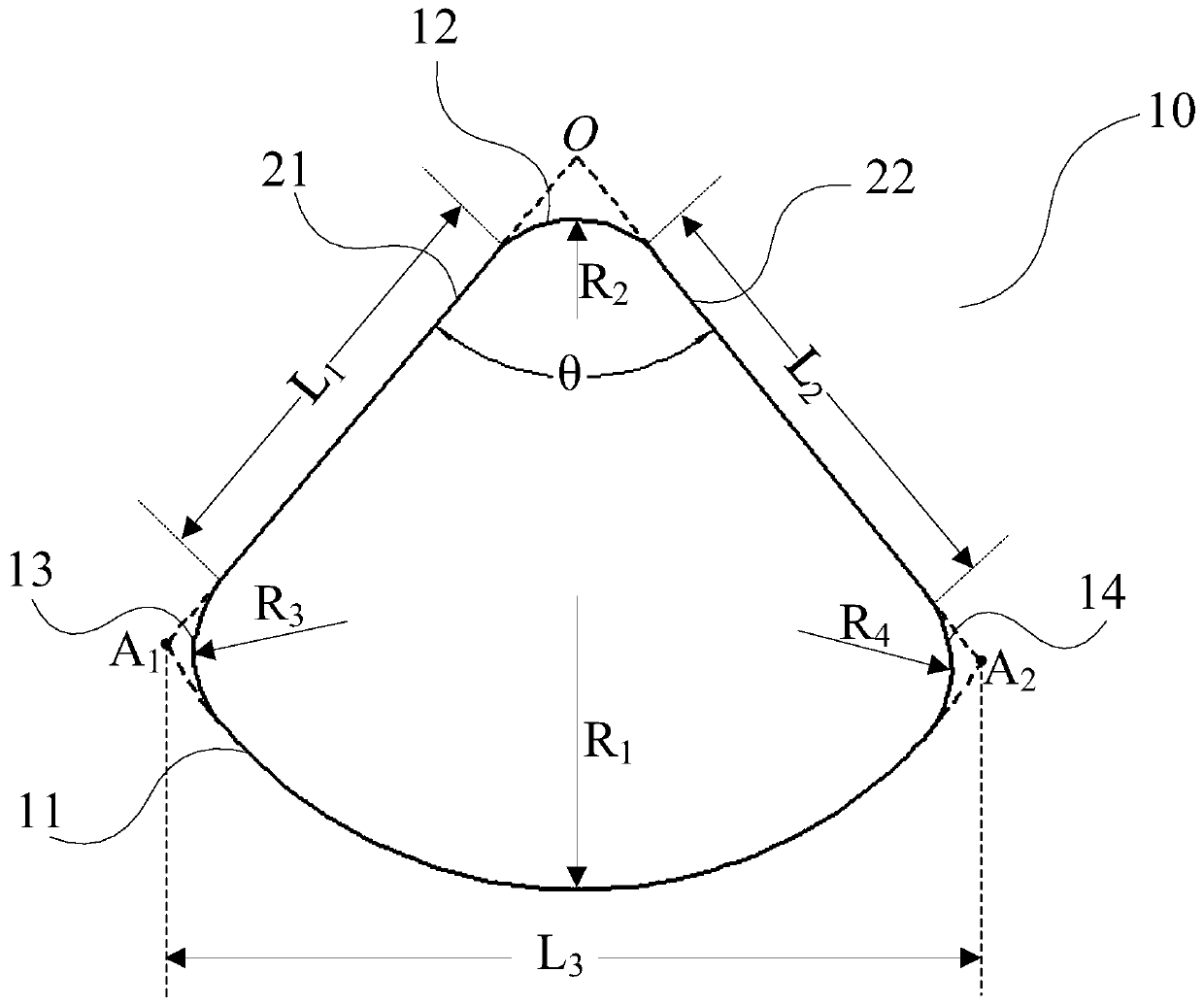

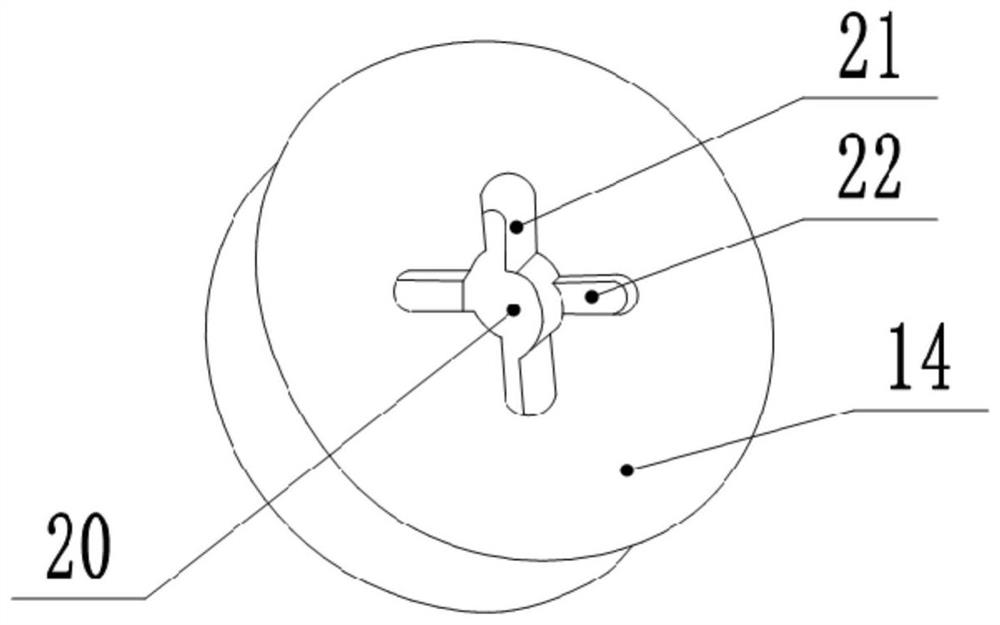

Reciprocating swing type four point contact ball rotating disk bearing

InactiveCN102364134AReduce grinding allowanceUniform processing depthBall bearingsBearing componentsLine segmentAmygdalus persica

The invention relates to a reciprocating swing type four point contact ball rotating disk bearing. The rotating disk bearing which comprises an outer ring, an inner ring and steel balls is characterized in that: the outer ring and the inner ring are respectively formed by connecting two parallel line segments and two arc segments, two arc segments are respectively positioned on and connected withtwo ends of each line segment, joints are smooth arc transitions, the curvature of the arc segments of the outer ring is equal to the curvature of the arc segments of the inner ring, and the angle ofthe arc segments of the inner ring is less than the angle of the arc segments of the outer ring; the arc segments of the outer ring and the arc segments of the inner ring are provided with a peach-shaped raceway, steel ball socket blocks, a spring, a limiting block, and a spring containing block are arranged in the raceway, and the steel balls on the raceway are arranged on the arc segment between the steel ball socket blocks on two ends. The rotating disk bearing which has the advantages of simple structure and novel conception allows the rotating movement angle of the steel balls to be limited after that a work system moves, so the limiting block allows the limiting angle position of the steel ball movement to be guaranteed; and the angle of the arc segments of the outer ring is greaterthan the angle of the arc segments of the inner ring, so the low angle range swinging of the inner ring does not allow the movement interference to appear.

Owner:HENAN UNIV OF SCI & TECH

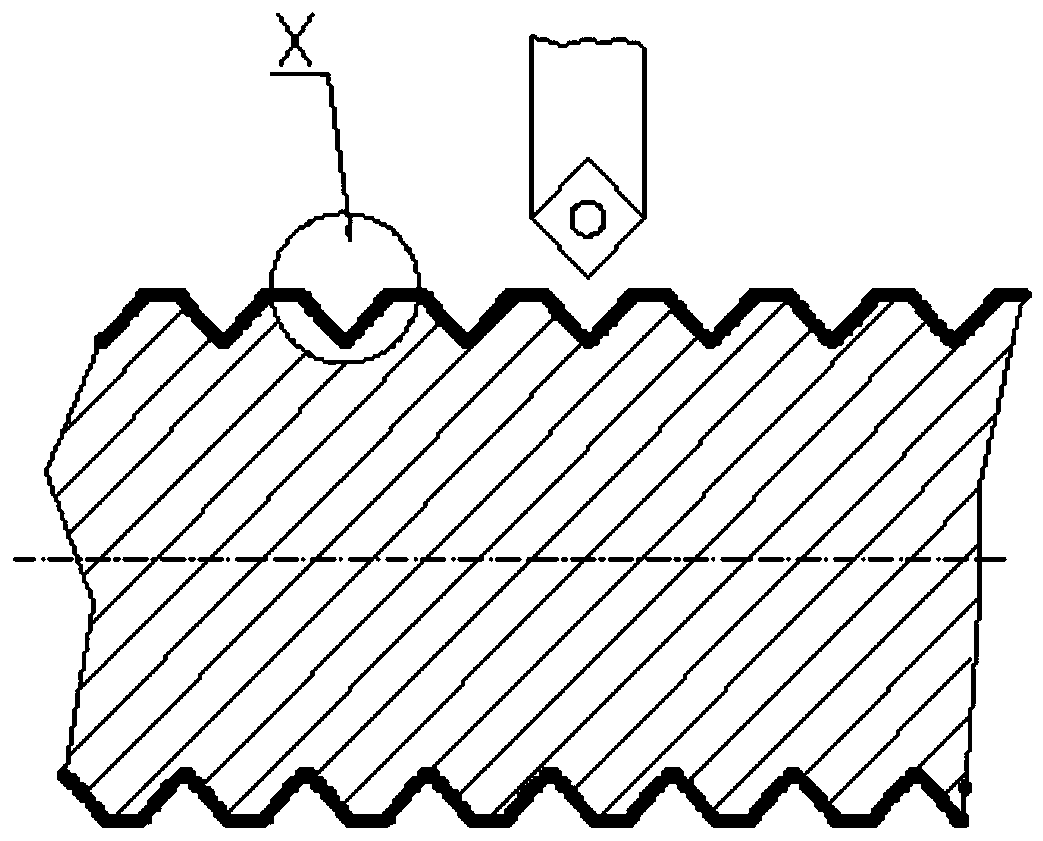

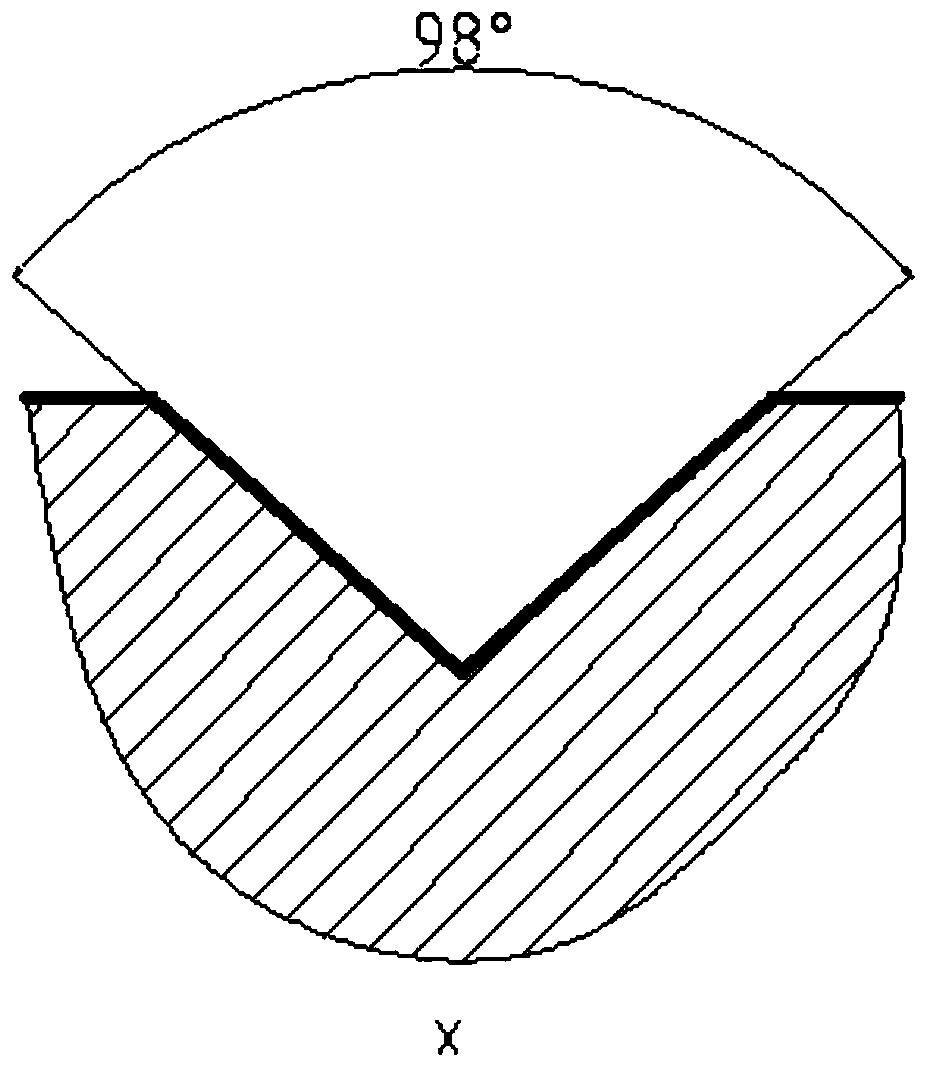

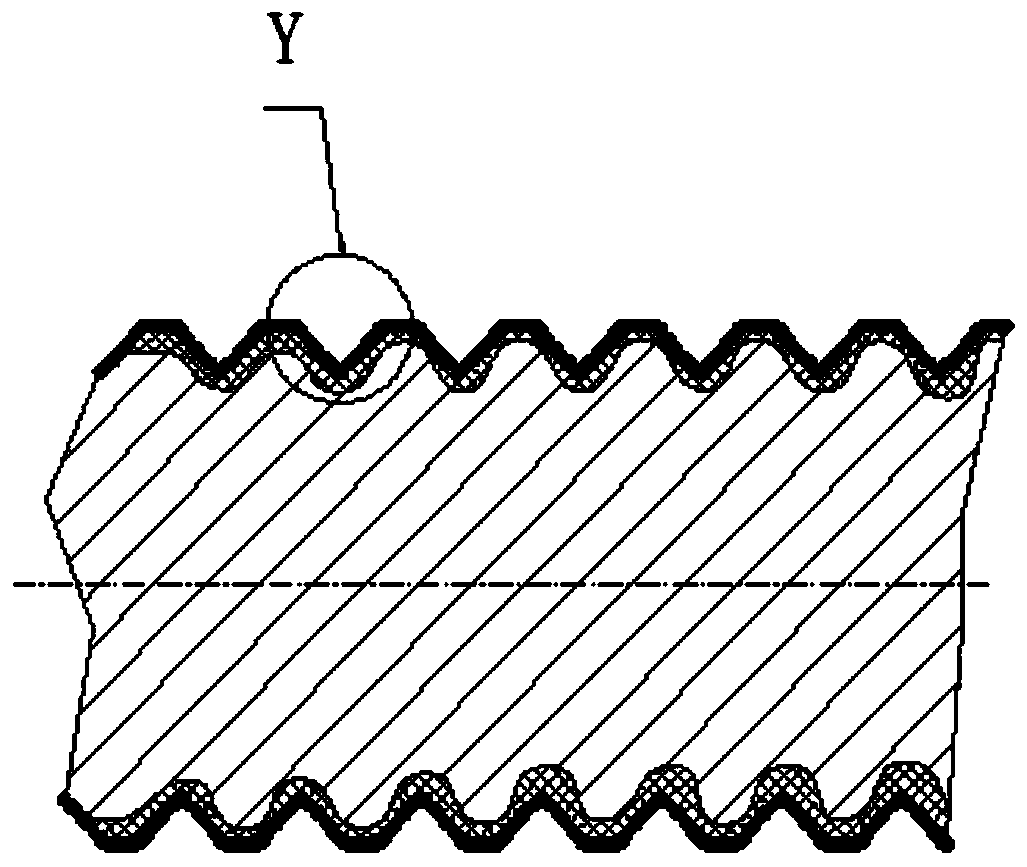

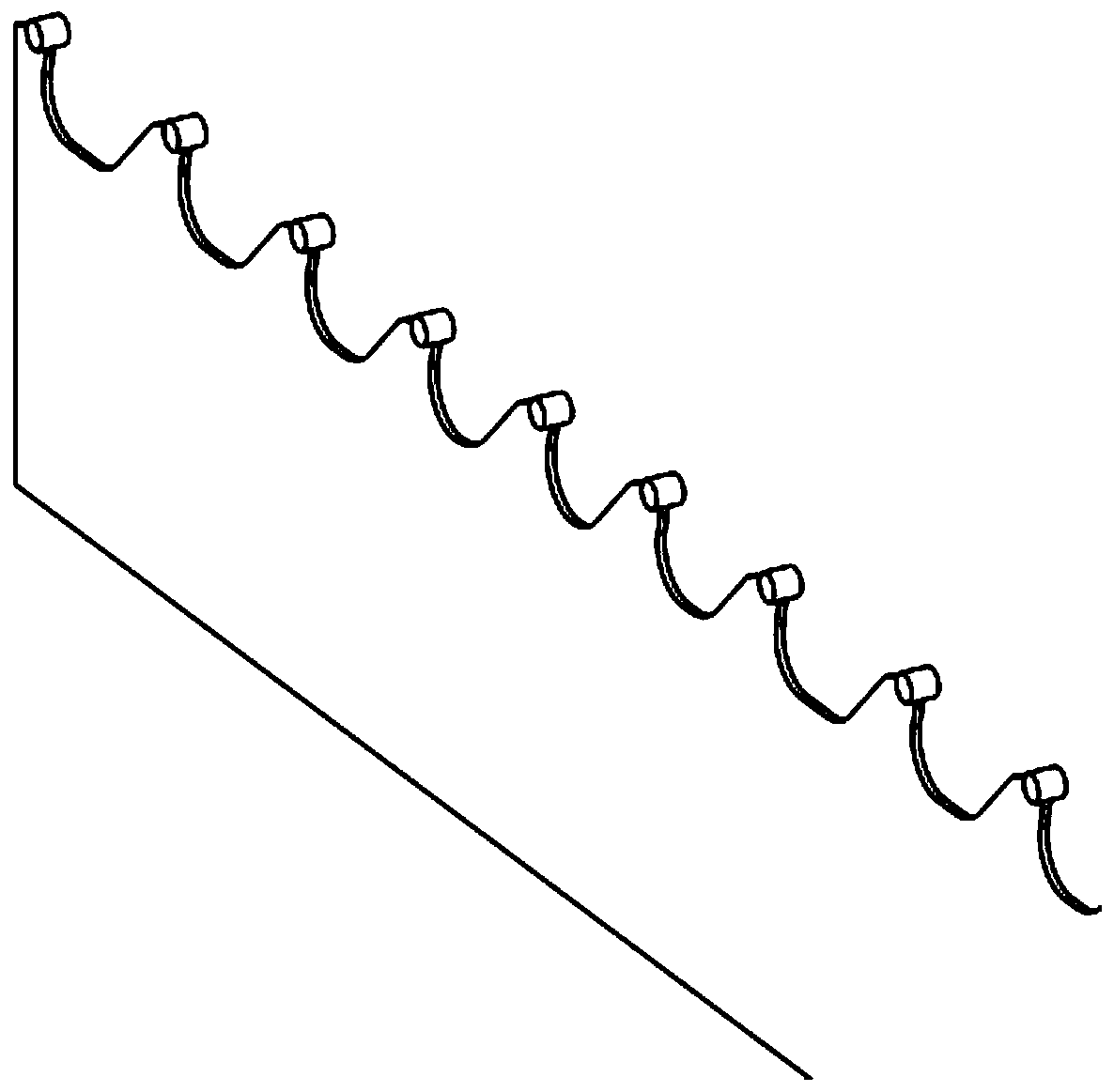

Method for machining ball screw electric power steering machine rack

The invention relates to a method for machining a ball screw electric power steering machine rack. The method includes the following steps that (1) a V-shaped spiral channel is cut in the surface of acylindrical screw rod; (2) the screw rod with the V-shaped spiral channel being cut is subjected to quenching treatment; and (3) the V-shaped spiral channel subjected to quenching treatment is accurately ground, a circular ball channel is ground in the inner side surface of the V-shaped spiral channel, and accordingly the ball screw electric power steering machine rack can be obtained. Compared with the prior art, machining difficulties are reduced, dependence on single procedures is distributed into other procedures, equipment utilization efficiency is improved and the utilization rate is increased; and the service life of cutters is prolonged and cost is reduced. In addition, by adoption of the machining method disclosed in the invention, the period cycle is greatly shortened, production efficiency is improved and the yield is increased.

Owner:上海格尔汽车科技发展有限公司

Cutter head for being welded to tooth support of band saw blade, band saw blade and electrode

The invention provides a cutter head for being welded to a tooth support of a band saw blade. The cross section of the cutter head is surrounded by a first straight line segment, a second straight line segment, a first arc segment which is in contact with the tooth support and a second arc segment which is arranged relative to the first arc segment; one end of the first arc segment is connected with one end of the first straight line segment, and the other end of the first arc segment is connected with one end of the second straight line segment; one end of the second arc segment is connectedwith the other end of the first straight line segment, and the other end of the second arc segment is connected with the other end of the second straight line segment; and the second arc segment is protruded to one side away from the first arc segment. According to the cutter head disclosed by the invention, the shape of the cutter head for welding is changed, so that the grinding allowance of a hard alloy cutter head is reduced, the welding strength is improved, the grinding efficiency is improved, the durability of a diamond grinding wheel for grinding hard alloy is strengthened, and the purpose of reducing cost is achieved.

Owner:BICHAMP CUTTING TECH (HUNAN) CO LTD

Bottle preform injection molding model machining tool and method for machining model

The invention relates to a bottle preform injection molding model machining tool. The bottle preform injection molding model machining tool comprises a clamping part, an overhanging part, a tool bit and a blade which are sequentially connected, wherein the section of the clamping part is a circle, the diameter of the clamping part is 16 mm, the length of the clamping part is 70 mm, the section ofthe overhanging part is an oval with the long axis being 15 mm and the short axis being 10.5 mm, the maximum length of the overhanging part is 55 mm, and the distance from the tail end of the overhanging part to the front end of the blade is 80 mm; and the tool bit is welded to the front end of the overhanging part, the blade is installed at the front end of the tool bit, and the distance betweena tool nose of the blade and the axis of the tool is 5.25 mm. By using the machining tool, a ball head part of a whole cavity can be completely turned by using a turning tool, so that the machining procedure of a machining center is omitted, and the machining time is greatly saved. Meanwhile, the coaxiality error (the precision is 0.005mm) generated by two times of clamping can be reduced, the grinding allowance of an universal grinder during finish machining is further reduced, the machining time is saved while the working procedures are reduced, the cost consumed by the tool is reduced, andtherefore the efficiency of the whole technological process is improved.

Owner:SONGYUAN MACHINERY MFG

Preparation method of brake friction plate processed by flat plate mold

ActiveCN112727966AAvoid uniformityAvoid looseFriction liningActuatorsCylinder moldManufactured material

The invention provides a preparation method of a brake friction plate processed by a flat plate mold, which comprises the following steps: S1, preheating and pressing a flat plate: horizontally paving a prepared friction plate raw material in the flat plate mold, and closing and hot-pressing an upper mold and a lower mold of the flat plate mold to form a flat plate blank of the friction plate; S2, hot-pressing bending: directly placing the flat plate blank of the friction plate prepared in the step S1 into a bending mold while being hot to be pressed into a blank shape of a long bent plate friction plate, and the blank is an arc-shaped friction plate blank; and S3, batch bending, hot-pressing, curing and forming: placing multiple arc-shaped friction plate blanks into a row mold at the same time to be hot-pressed, cured and formed into the long bent plate friction plate. The invention provides the novel preparation method of the brake friction plate processed by the flat plate mold, which has the advantages of uniform product thickness, intact corners, high forming precision and high qualification rate, particularly high qualification rate of long bent plates, and is different from a cylinder mold and row mold processing mode.

Owner:HUBEI FEILONG FRICTION & SEALING MATERIALS

Machining method of guide sleeve type thin-wall part

The invention discloses a machining method of a guide sleeve type thin-wall part. The machining method comprises the following steps that 1, allowance of the end face of an open end of the thin-wall part and allowance of an inner hole are removed; 2, the end surface allowance and the outer circle allowance of a reference surface end of the thin-wall part are removed; 3, carburizing treatment is performed on the reference surface end; 4, semi-finish turning is conducted on the end face of the open end and the inner hole of the thin-wall part; 5, semi-finish turning is conducted on the inner hole and an outer circle of the reference surface end and chamfers of the inner hole and the outer circle; 6, a circumferential hole is drilled in the outer circle of the thin-wall part; 7, reference surface end heat treatment is performed; 8, the end face of the open end is ground; 9, the end face of the reference surface end is ground; 10, fine turning is conducted on the inner hole and an outer circle notch of the open end; 11, a reference surface end positioning hole is finely ground; 12, a grinding tool is matched, and redundant grinding allowance of the outer circle is removed through turning; 13, the grinding tool is matched, and the outer circle is accurately ground to the final size; and 14, burrs are removed by a bench worker. According to the machining method, through reasonable process route arrangement and design of a special tool, the dimensional tolerance requirement of the outer circle and the bounce requirement of the outer circle relative to a reference surface are guaranteed under the condition that deformation is controlled.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

A kind of lost foam of stmma large-size solid casting plate and its preparation method

InactiveCN107552725BHigh bonding strengthFully integratedFoundry moulding apparatusCompression moldingEvanescent mode

The invention discloses an STMMA large-size solid casting plate lost mold and a preparation method thereof. Including the process steps of bead selection, pre-foaming, drying and aging, molding, cooling, demoulding and plate drying, the invention can solve defects such as carbon black on the surface of ductile iron parts after casting, and can effectively reduce the amount of gas generated to avoid Back spraying occurs during pouring to prevent the deformation of the STMMA lost pattern produced, improve the bonding strength between beads, ensure the full fusion of beads, improve the structural strength of castings, and achieve the goal of saving raw materials, reducing costs and environmental protection The effect, and the yield of castings is greatly improved; the comprehensive production cost of castings is further reduced.

Owner:ANHUI POLYTECHNIC UNIV +2

Cylindrical cutter upset-extruding molding method

The invention relates to a cylindrical cutter upset-extruding molding method. Extruding is utilized to replace brazing, or a cemented cutter is adopted. A press machine is adopted to compress a cutter body to enable the cutter body to have radial and axial plastic deformation. Mechanical biting force is utilized to achieve connection of the cutter body and a hard alloy cutter bit to achieve the advantages of simple process method, high accuracy, high production speed, low labor intensity, no pollution in the manufacturing process and the like.

Owner:许自清

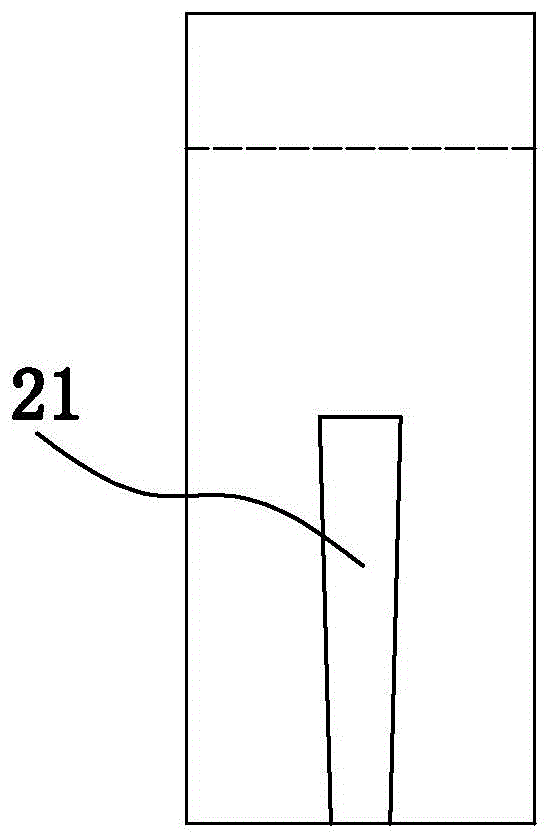

A method for manufacturing a composite sound-absorbing diamond saw blade matrix

ActiveCN102756177BLow costShorten the processing cycleMetal sawing tool makingFurnace typesPerformance indexQuenching

The invention provides a manufacturing method of a composite noise-reducing diamond saw blade base body. The manufacturing method comprises the process steps of: preparing a single-sheet saw blade base bodies, carrying out combined rolling welding, quenching and annealing, and carrying out finish machining. The manufacturing method is characterized in that after two single-sheet saw blade base bodies are wholly punched and baited and burrs are removed, a damping material is clamped between the two single-sheet saw blade base bodies; a composite noise-reducing diamond saw blade base body blank is formed by rolling welding and the composite noise-reducing diamond saw blade base body blank is subjected to continuous pressurizing, oil spraying and quenching, controllable temperature pressurizing, cooling and finish machining to form a composite noise-reducing diamond saw blade base body finished product. The manufacturing method disclosed by the invention has the advantages that the single work procedure efficiency in a product manufacturing process is improved and the secondary annealing do not need to be carried out, so that the machining cost of the product is effectively reduced and various performance indexes of the product are improved.

Owner:HEIXUANFENG SAW IND

Control method for preventing deformation in quenching process of 9Cr18 thin-wall bearing ring

ActiveCN101775480BAvoid quenching deformationImprove ergonomicsFurnace typesHeat treatment furnacesEconomic benefitsEngineering

The invention relates to a control method for preventing deformation in the quenching process of a 9Cr18 thin-wall bearing ring. The method comprises the following steps of: firstly designing an upper die (1) and a lower die (3) which have symmetrical structures; before quenching, loading the 9Cr18 thin-wall bearing ring (2) into a 45KW box-type heating furnace for preheating, wherein the preheating temperature is 850 DEG C, and the preheating time is 30 min; shifting the 9Cr18 thin-wall bearing ring into a 50KW high-temperature box-type heating furnace for heating, wherein the heating temperature is 1070 DEG C, and the time for keeping the temperature is 5 min; taking the 9Cr18 thin-wall bearing ring out, and placing the 9Cr18 thin-wall bearing ring on the lower die of the quenching die;covering the upper die of the quenching die, and fixing the upper die, the 9Cr18 thin-wall bearing ring and the lower die as a whole to be placed in quenching oil for quenching; separating the upper die and the lower die 3 min after quenching, and taking out the 9Cr18 thin-wall bearing ring. The qualification rate of the bearing ring quenched by adopting the invention reaches 98 percent, and the economic benefit is remarkable.

Owner:LUOYANG BEARING RES INST CO LTD

A method of improving the service life and performance of the roller body by using high-energy supersonic spraying technology

ActiveCN111363997BHigh hardnessImprove wear resistanceMolten spray coatingSurface engineeringThermal spraying

The invention belongs to the technical field of high-energy supersonic thermal spraying of surface engineering, and in particular relates to a method for improving the service life and performance of a roller body by utilizing the high-energy supersonic thermal spraying technology. The invention adopts high-energy supersonic spraying technology, inserts inert gas into the supersonic powder feeding system, and uses the high-pressure inert gas flowing in with the powder to heat and expand in the combustion chamber of the supersonic spraying system to directly drive tungsten carbide powder particles into high-speed and high-energy Particles, high-speed and high-energy particles are directly embedded in the roller base, and the roller body does not need to be sandblasted before spraying. The high-energy powder particles form a tungsten carbide coating on the surface of the roller body. The tungsten carbide coating has high hardness, ultra-low porosity, and low surface area. With the characteristics of roughness and low grinding allowance, the precipitates of the film are not easy to adhere during the casting and cooling process of the roll surface, and the friction coefficient of the working surface of the roll body remains constant during long-term use, which can significantly improve the wear resistance of the roll surface and roll life.

Owner:GUANGDONG YUEKE NEW MATERIALS TECH CO LTD

Gear finish machining device and method

InactiveCN112475477AEasy to installSimple and fast clamping and fixing methodGear-cutting machinesGear teethGear grindingGear wheel

The invention relates to the field of gear machining, and discloses a gear finish machining device. The gear finish machining device comprises a cutter mounting unit and a gear mounting unit, whereinthe gear mounting unit comprises a mounting table and a fixture; a rotating piece for driving the fixture to rotate is mounted on the mounting table; the fixture comprises a support box, a fixed column, a positioning shaft and a stop cover; the fixed column is positioned at the top end of the support box, and is fixedly connected with the support box; the bottom of the positioning shaft penetratesthrough the top end of the support box; the top end of the positioning shaft penetrates through the top end of the fixed column, and is in vertical sliding fit with the fixed column; a gear is inserted in the outer side of the fixed column; the stop cover can cover the upper part of the fixed column; the stop cover is provided with a first shaft hole for penetrating through the positioning shaft;a limiting block is arranged at the upper part of the positioning shaft; a lifting unit for driving the positioning shaft to vertically move back and forth is mounted in the support box; when the positioning shaft downwards moves, the limiting block can press the stop cover; and the stop cover is provided with a through groove for penetrating through the limiting block. The gear finish machiningdevice can improve the gear grinding efficiency, and is fast and convenient to clamp the gear.

Owner:CHONGQING XINGJI GEAR

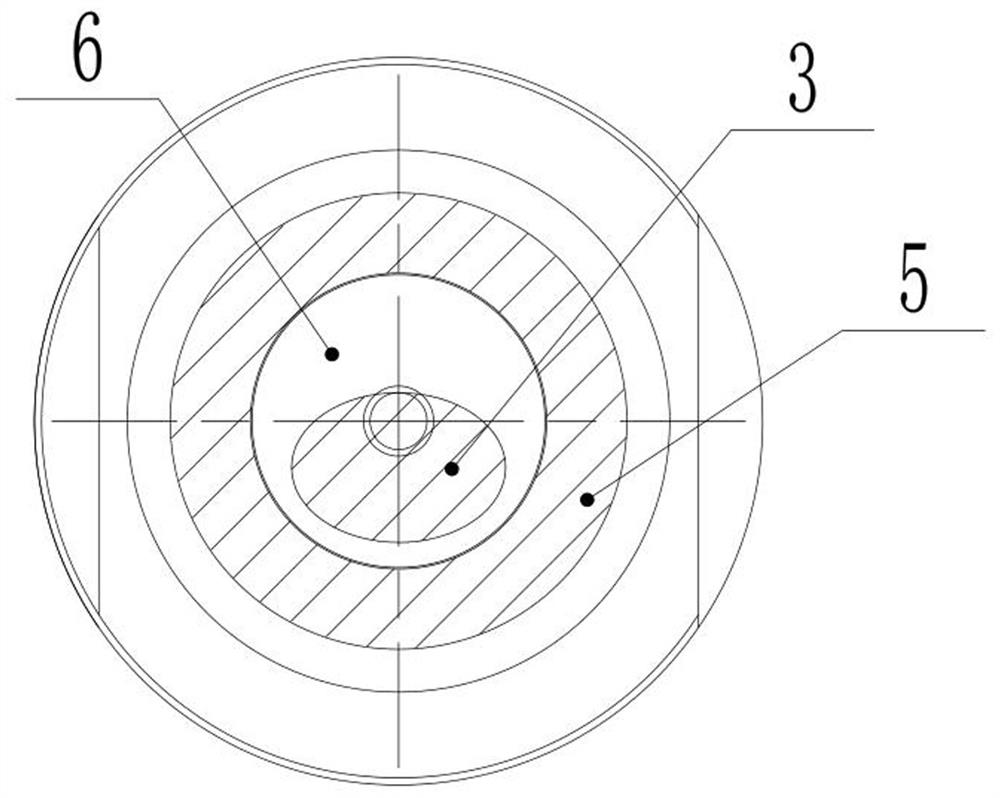

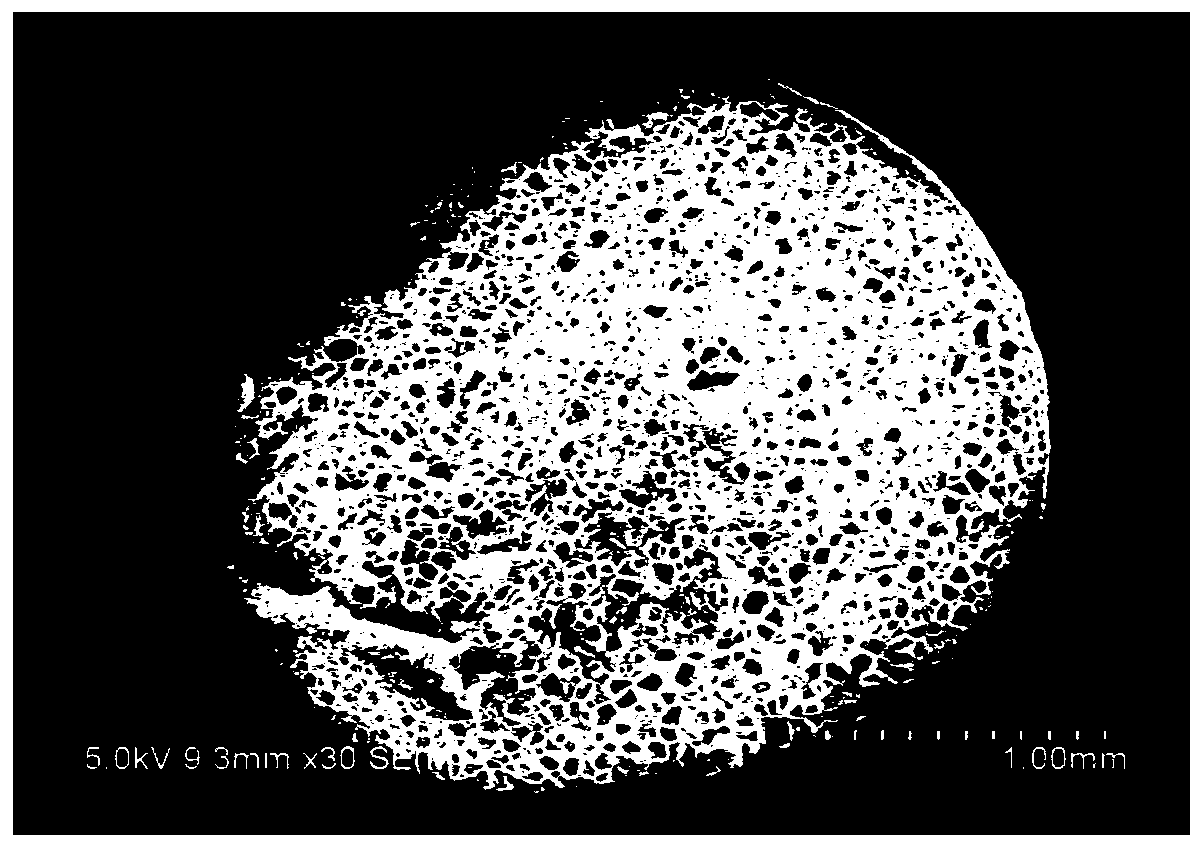

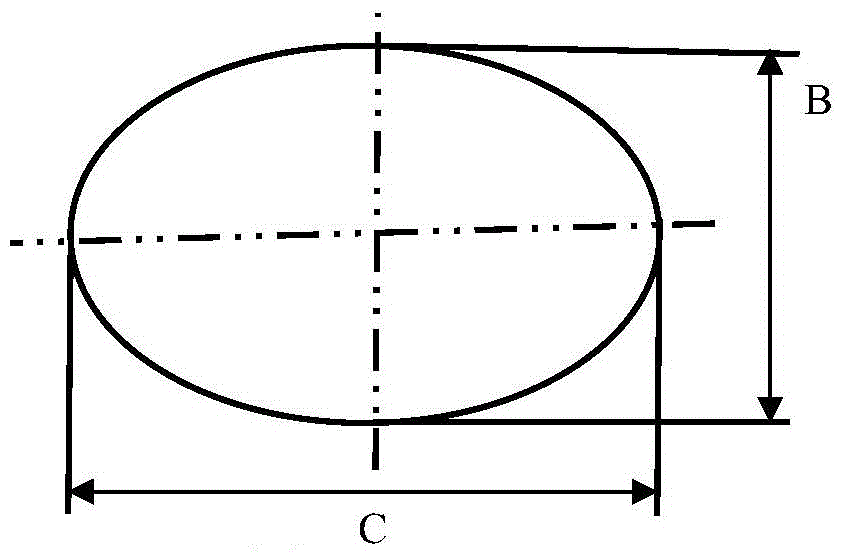

Manufacturing equipment of NdFeB spheres

ActiveCN104028754BIncrease productivityReduce grinding allowanceInductances/transformers/magnets manufactureEngineeringMechanical engineering

The invention discloses an Nd-Fe-B sphere manufacturing device. The manufacturing device comprises two blocks of magnetic conductive plates buckled with each other, two flitch plates, an upper die punch and a lower die punch, wherein a plurality of semi-cylindrical die surfaces arranged side by side are respectively arranged on the opposite surfaces of the two magnetic conductive plates, and flitch plate grooves are respectively formed in the two sides of the die surfaces; the two flitch plates are respectively arranged in the flitch plate grooves of the two magnetic conductive plates buckled with each other, and a plurality of cylindrical die cavities arranged side by side are jointly formed by the semi-cylindrical die surfaces of the two magnetic conductive plates and the inner side surfaces of the flitch plates; the upper die punch and the lower die punch are cylinders matched with the cylindrical die cavities and can be arranged in the die cavities in a relative sliding way, and semi-ellipsoidal molding grooves are respectively formed in the opposite surfaces of the upper die punch and the lower die punch. With the Nd-Fe-B sphere manufacturing device, the sizes in all directions are consistent after the Nd-Fe-B sphere shrinks, the grinding allowance is small, the material investment cost is lowered, and the magnetic steel production efficiency is improved.

Owner:SINO MAGNETICS TECH

Reciprocating swing type four point contact ball rotating disk bearing

Owner:HENAN UNIV OF SCI & TECH

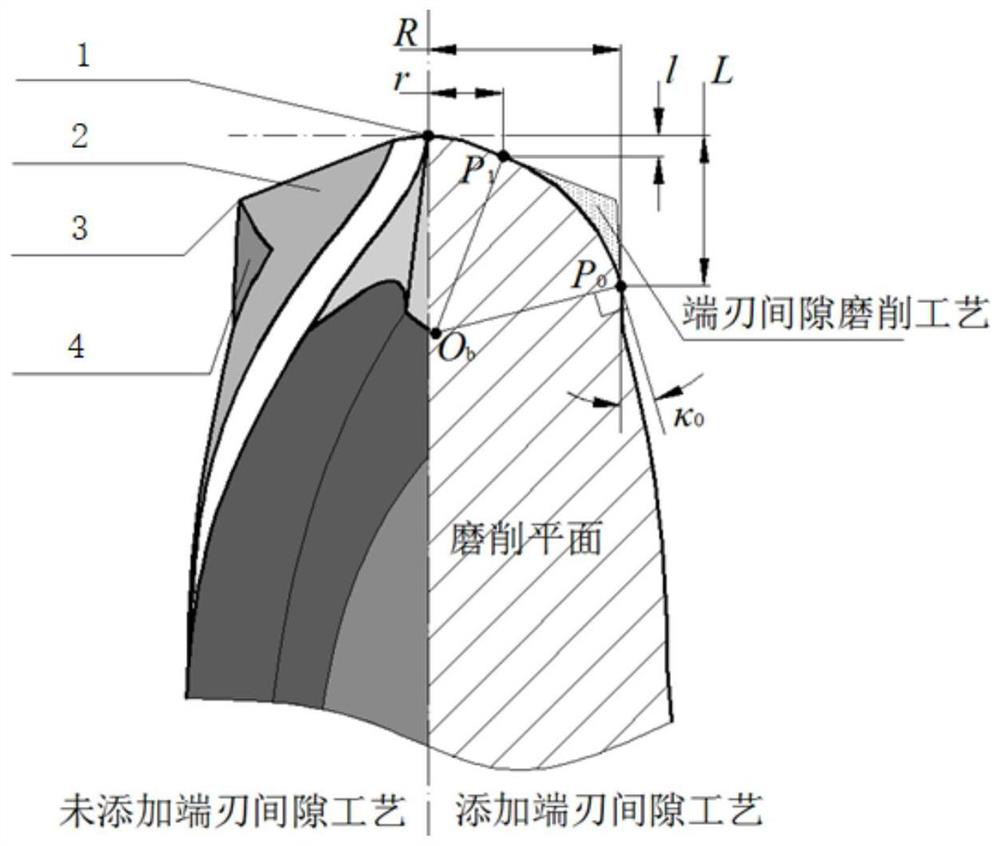

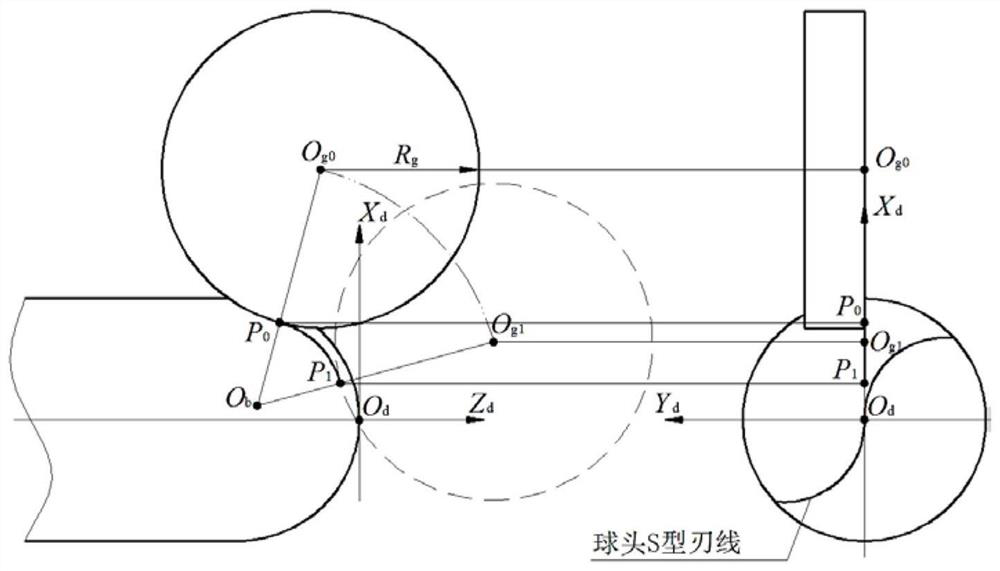

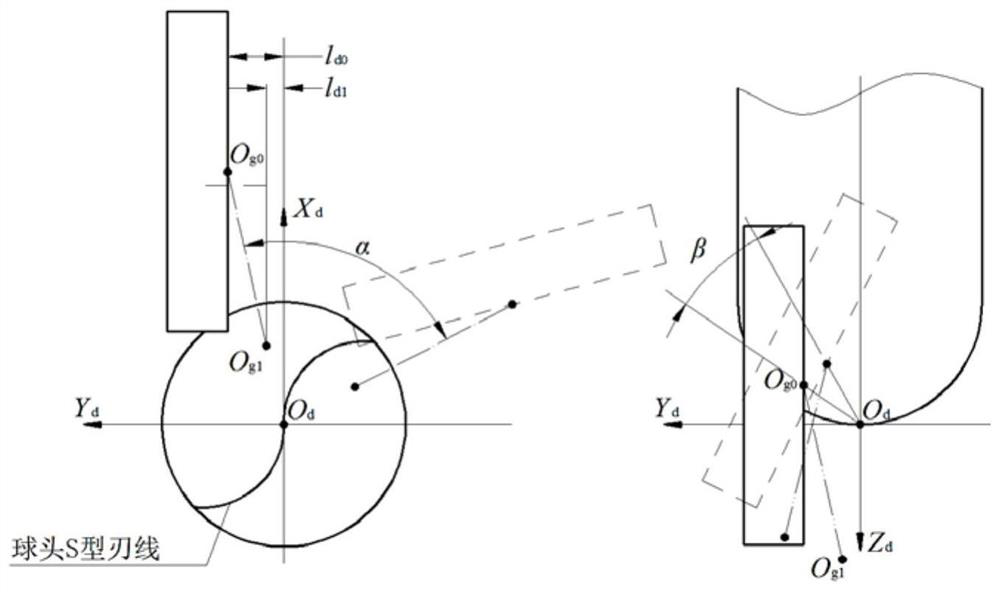

A method for solving the grinding wheel track in the end edge clearance grinding process of ball end mills

ActiveCN110355615BImprove the shape of the revolutionReduce grinding allowanceMilling cuttersControl engineeringEngineering

The present invention proposes a method for solving the grinding wheel trajectory of the end edge clearance grinding process of a ball end mill. Firstly, the geometric parameters of the end edge clearance and the grinding wheel grinding posture are defined, and then the initial grinding trajectory and the end edge under the grinding coordinate system are calculated. The grinding trajectory after adding various process parameters during the grinding process of gap technology, then calculate the axis vector of the grinding wheel, and finally transform the grinding trajectory to the workpiece coordinate system. The grinding trajectory of the present invention can remove the sharp point of the end edge, improve the rotary shape of the end of the ball end mill, thereby making up for the deficiency of the end edge technology of the ball end mill; and can be used as a rough machining process to reduce the grinding residue of the flank amount, to achieve the purpose of protecting the workpiece and the grinding wheel.

Owner:SOUTHWEST JIAOTONG UNIV +1

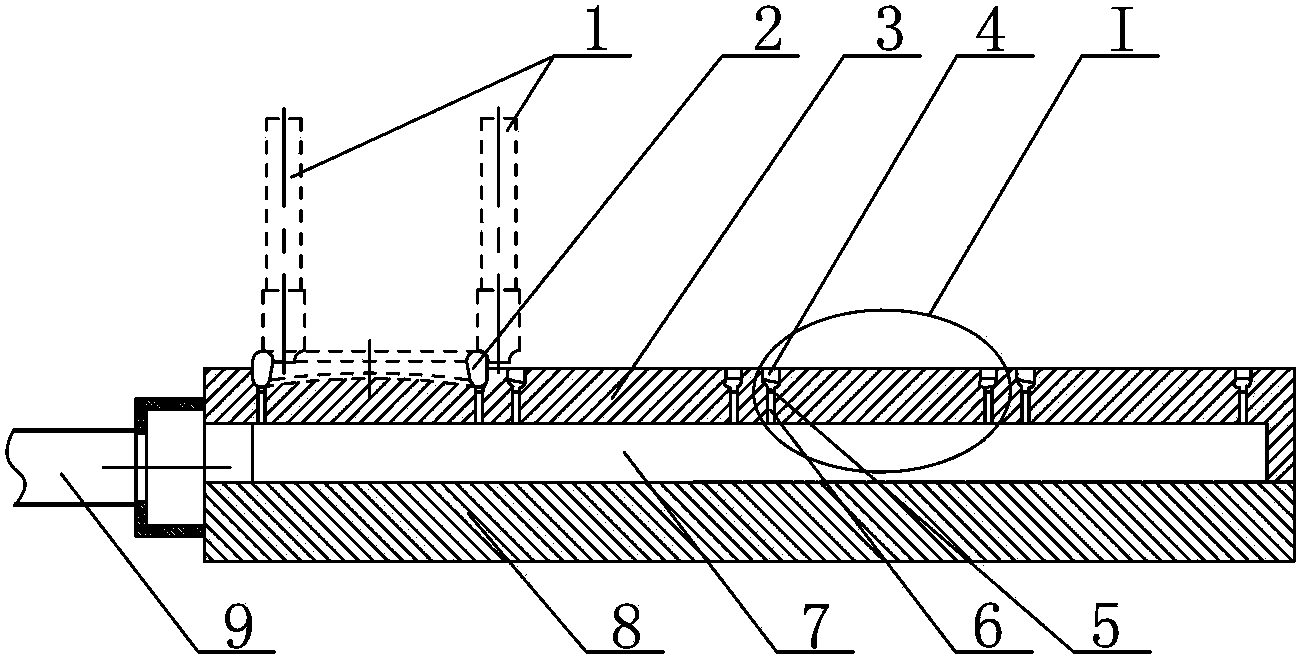

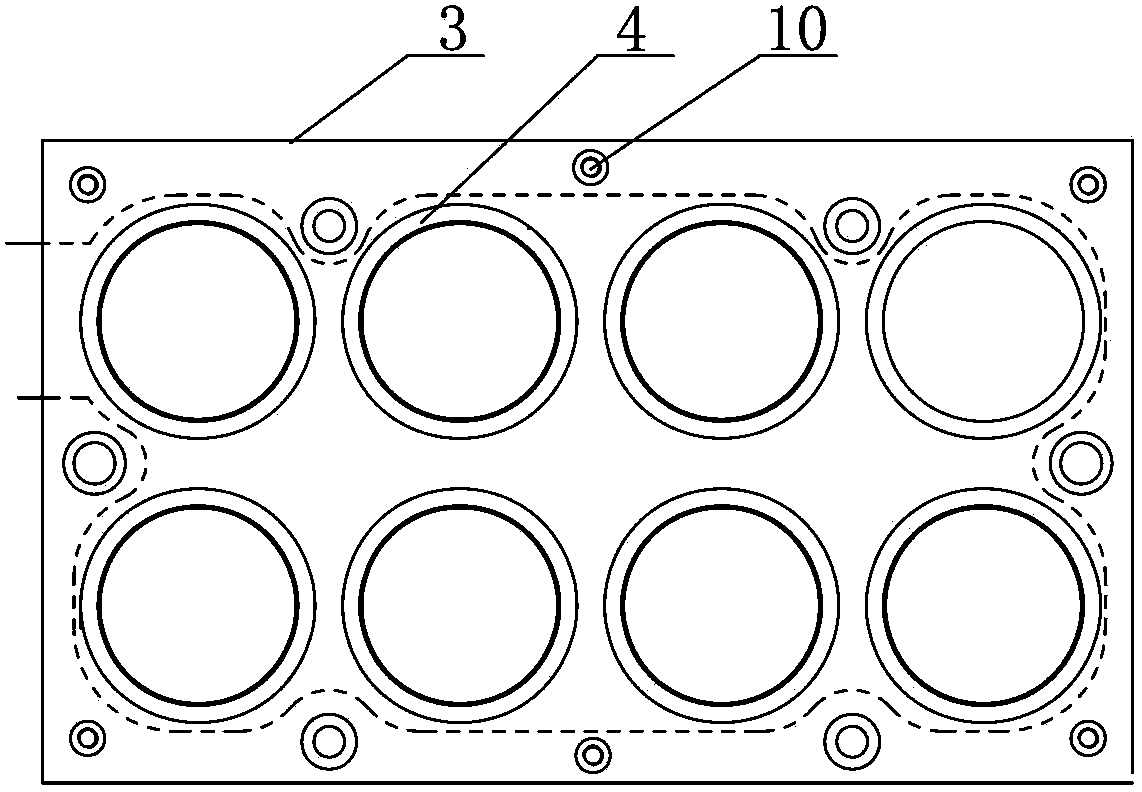

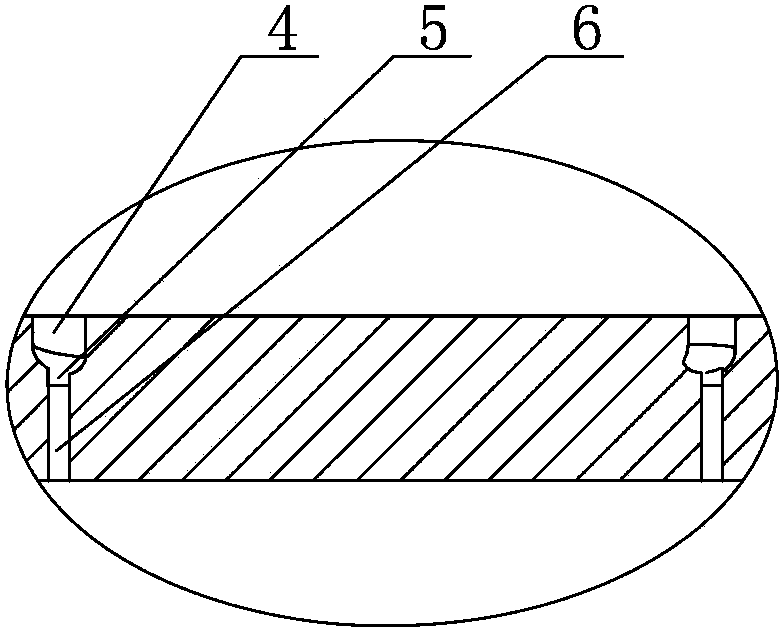

Vacuum clamp for machining circular arc of salt core

ActiveCN102825475BGuaranteed arc size requirementsSolve the problem that the arc cannot be clamped and processed on the lathePositioning apparatusMetal-working holdersEngineeringMachining process

The invention belongs to the technical field of a manufacturing industry and specifically relates to a vacuum clamp for machining a circular arc of a salt core; the vacuum clamp comprises an upper mold and a lower mould integrally connected from top to bottom; a plurality of workpiece positioning ring-shaped slots are arranged at the upper part of an upper die, and an vacuum evacuation mold cavity is arranged at the lower part of the upper die; a plurality of small holes mutually communicated with the vacuum evacuation mold cavity are evenly distributed on the workpiece positioning ring-shaped slots; the mold cavity is connected with a pipe of a vacuum pump unit; a lower mold is of a solid. The vacuum clamp is used for clamping a fragile workpiece (the salt core), the workpiece is clamped and released in a vacuum evacuation mode, a vacuum evacuation clamp can reduce stress of the workpiece in clamping and machining processes, so that the workpiece is not easily to be broken in the clamping and machining processes, thereby ensuring a size requirement of the circular arc; the clamp is simple in structure, easy to manufacture, convenient to operate in a clamping operation; by using the vacuum clamp to machine workpieces, most polishing allowance is reduced, production efficiency is high, machining quality is ensured in a certain degree, labor intensity is reduced, production cost is reduced, so that the vacuum clamp is worthy to be popularized and can machine salt cores in various special shapes.

Owner:滨州市正道机械制造有限公司

A kind of preparation method of bulk neodymium iron boron

ActiveCN106601400BSmall amount of deformationSmooth degassingInductances/transformers/magnets manufactureMagnetic materialsHydrogen contentEngineering

The invention relates to a preparation method for chunk neodymium iron boron. The preparation method is characterized by comprising the steps of designing multiple convex points which are distributed in a central symmetry manner on an upper pressing surface of a pressing blank during designing the pressing blank of a chunk magnet; designing concave points, corresponding to the convex points designed on the upper pressing surface of the pressing blank, on a surface, corresponding to the upper pressing surface of the pressing blank, of a die when the die is designed; installing the die, and completing powder weighing, pressing, packaging and isostatic pressing to obtain the pressing blank which can be put into a sintering furnace; and enabling the surface, having the convex points, of the pressing blank to be in contact with a sintering basin, forming an interval between the magnet and the sintering basin, and completing sintering. The preparation method has the advantages as follows: by increasing the convex points on the surface of the chunk magnet, the friction force between the magnet and the sintering basin is reduced in the sintering process, and the magnet deformation is lowered; and meanwhile, smooth degasification of the magnet in the sintering process is realized, so that carbon and hydrogen contents in the magnet are reduced, thereby improving the brittleness and magnetic property of the magnet.

Owner:BAOTOU YUNSHENG STRONG MAGNETIC MATERIAL +1

Vacuum clamp for machining circular arc of salt core

ActiveCN102825475ANot easy to rustSimple structurePositioning apparatusMetal-working holdersMachining processVacuum pump

The invention belongs to the technical field of a manufacturing industry and specifically relates to a vacuum clamp for machining a circular arc of a salt core; the vacuum clamp comprises an upper mold and a lower mould integrally connected from top to bottom; a plurality of workpiece positioning ring-shaped slots are arranged at the upper part of an upper die, and an vacuum evacuation mold cavity is arranged at the lower part of the upper die; a plurality of small holes mutually communicated with the vacuum evacuation mold cavity are evenly distributed on the workpiece positioning ring-shaped slots; the mold cavity is connected with a pipe of a vacuum pump unit; a lower mold is of a solid. The vacuum clamp is used for clamping a fragile workpiece (the salt core), the workpiece is clamped and released in a vacuum evacuation mode, a vacuum evacuation clamp can reduce stress of the workpiece in clamping and machining processes, so that the workpiece is not easily to be broken in the clamping and machining processes, thereby ensuring a size requirement of the circular arc; the clamp is simple in structure, easy to manufacture, convenient to operate in a clamping operation; by using the vacuum clamp to machine workpieces, most polishing allowance is reduced, production efficiency is high, machining quality is ensured in a certain degree, labor intensity is reduced, production cost is reduced, so that the vacuum clamp is worthy to be popularized and can machine salt cores in various special shapes.

Owner:滨州市正道机械制造有限公司

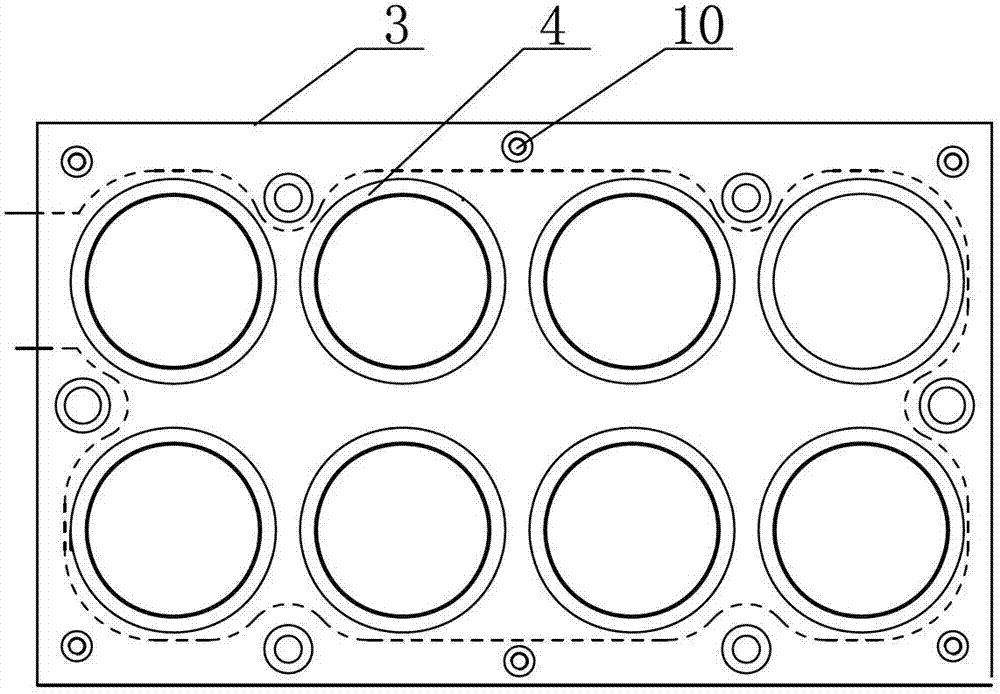

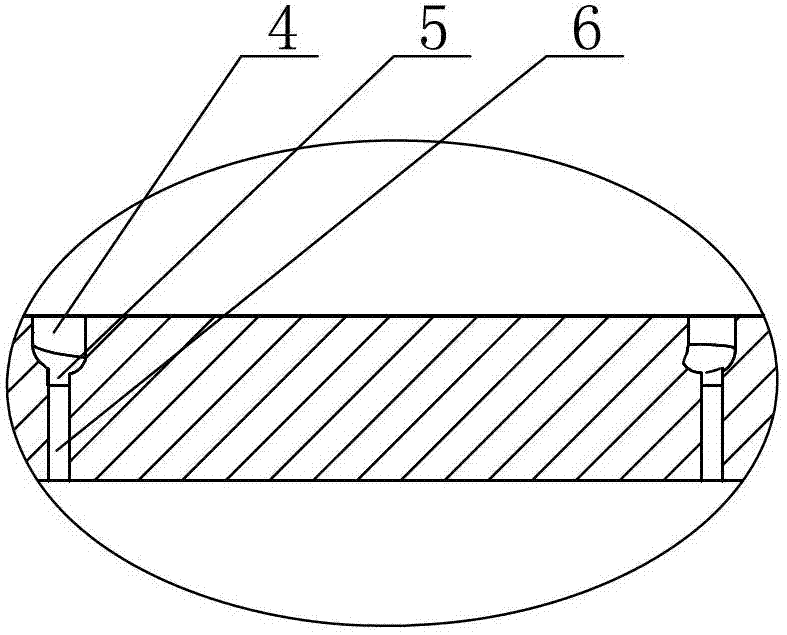

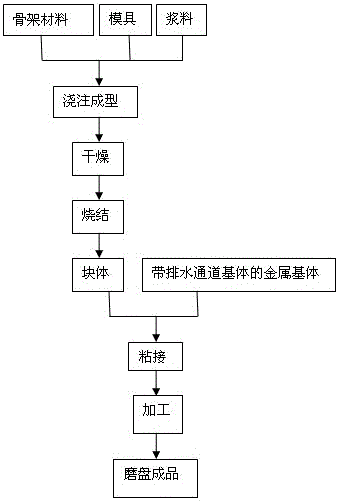

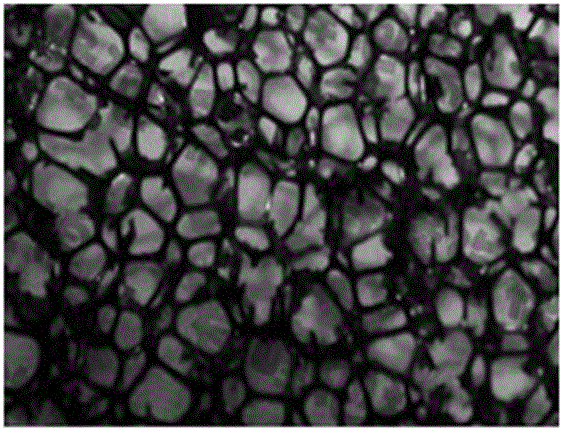

Diamond grinding plate used for accurately grinding double end surfaces of sapphire and manufacturing method of diamond grinding plate

ActiveCN106002652AContinuous flow of waterReduce grinding allowanceAbrasion apparatusGrinding devicesLead oxideCerium

The invention relates to a diamond grinding plate used for accurately grinding the double end surfaces of a sapphire and a manufacturing method of the diamond grinding plate. The diamond grinding plate comprises a metal matrix and a diamond grinding layer on the metal matrix. The diamond grinding layer is made of, by weight, 20-50 pats of diamond micro powder with the particle size being 1-10 [mu]m, 20-30 pats of white corundum micro powder with the particle size being 1-10 [mu]m, 3-5 parts of cerium oxide, 15-30 parts of a ceramic binder, 2-5 parts of bentonite, 4-10 pats of starch and 20-40 pats of water. The ceramic binder is formed by mixing lead oxide, sodium feldspar, boron glass and quartz at the ratio of 1:(1-5):(4-15):(4-25). According to the manufactured diamond grinding plate used for accurately grinding the double end surfaces of the sapphire, the high water permeability can be kept through the grinding layer; the purposes of grinding removing and continuous self sharpness are achieved due to the fact that water permeates outwards inside the grinding plate while grinding is conducted; the machining efficiency of the double end surfaces of the sapphire is improved; and the high surface quality can be ensured.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com