Bottle preform injection molding model machining tool and method for machining model

A technology for machining tools and models. It is used in the manufacture of tools, accessories for tool holders, metal processing equipment, etc. It can solve the problems of increased machining allowance, increased working hours, and large coaxiality errors in universal grinding, so as to ensure rigidity and avoid problems. vibrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

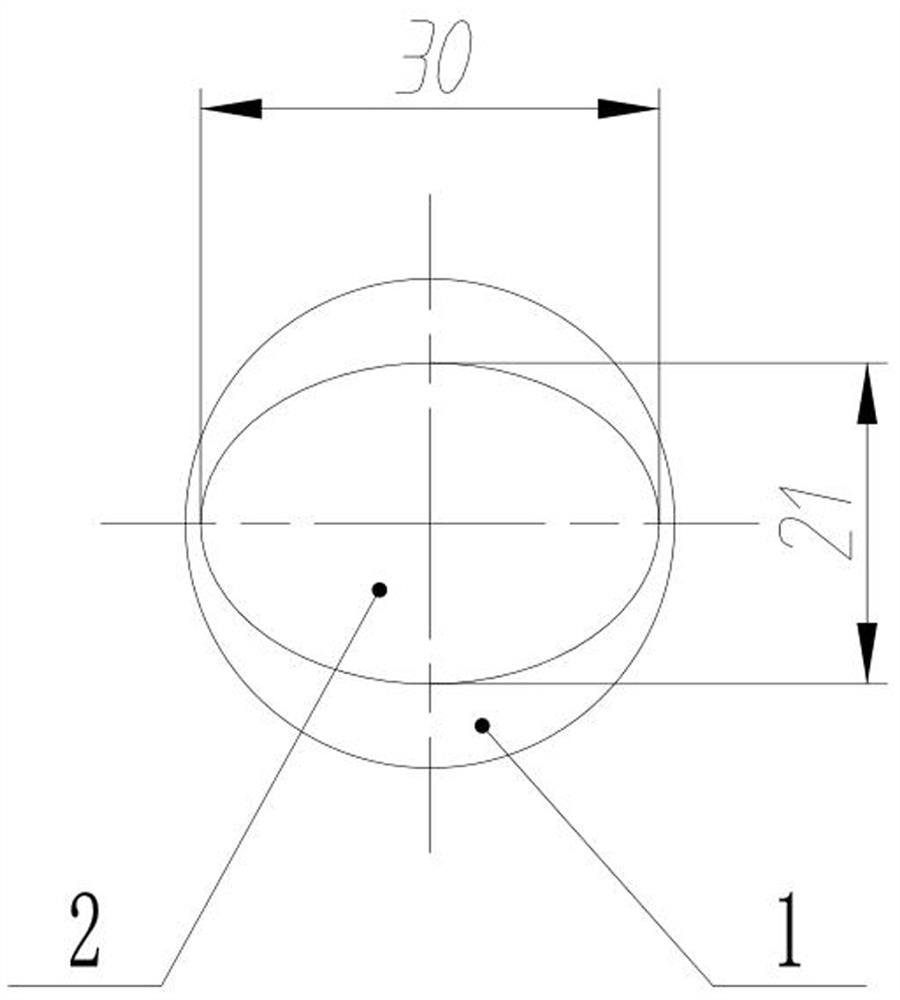

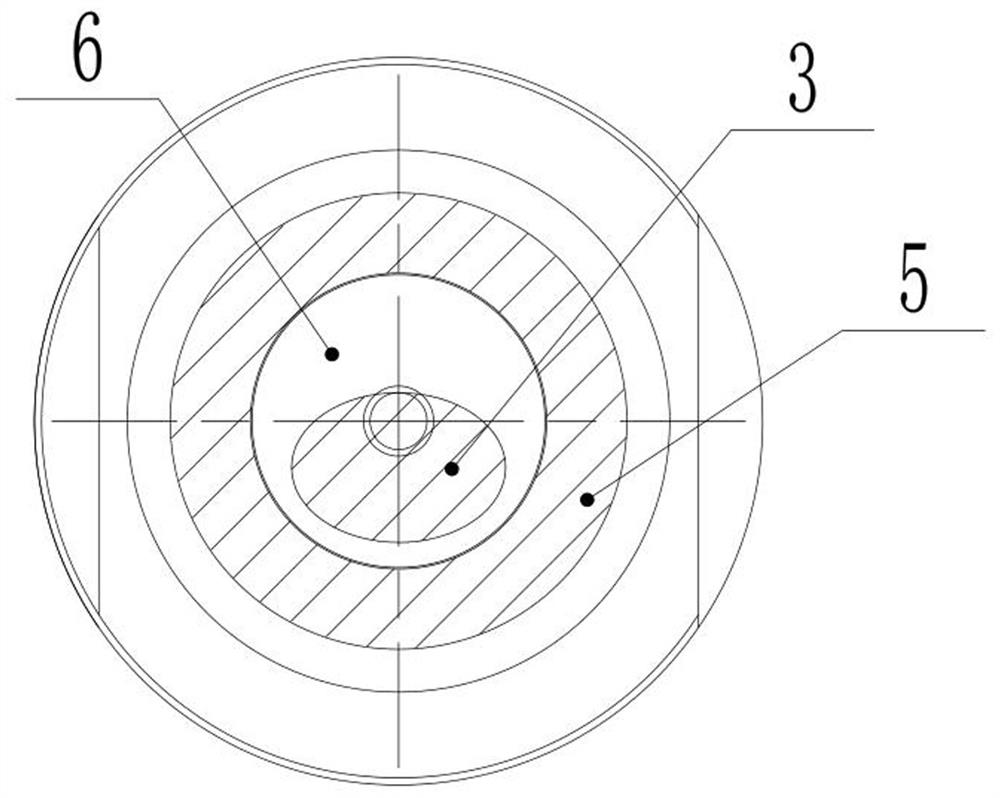

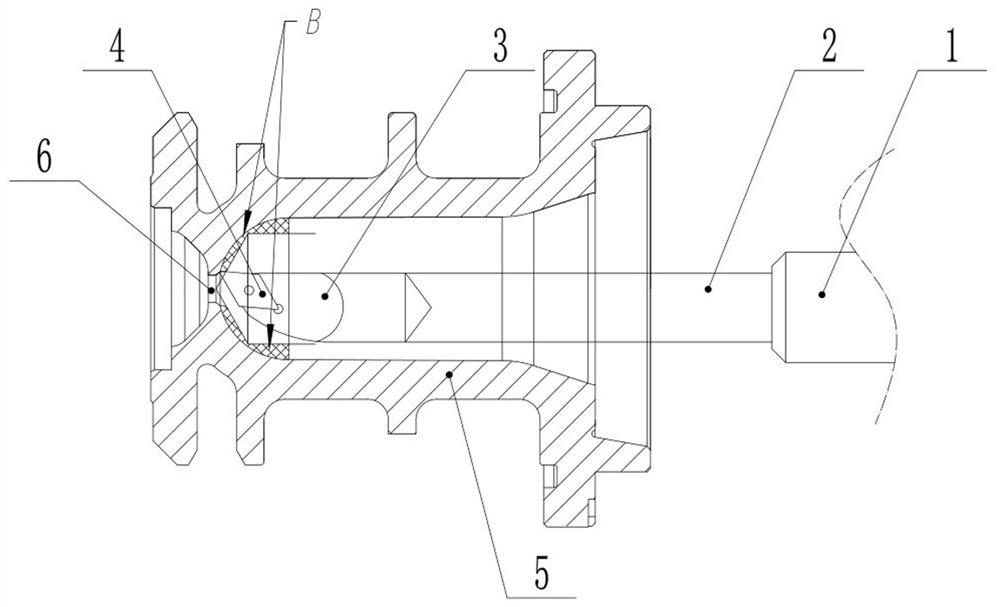

[0022] like figure 2 , image 3 , Figure 4 As shown, this embodiment describes a preform injection mold processing tool, which includes a clamping part 1, an overhanging part 2, a cutter head 3 and a blade 4 connected in sequence. The clamping part 1 is a circle with a diameter of The length of 16mm is 70mm, the section of the overhang 2 is an ellipse with a major axis of 15mm and a minor axis of 10.5mm, the maximum length of the overhang 2 is 55mm, and the distance from the end of the overhang 2 to the front end of the blade 4 is 80mm, the front end of the overhang 2 is welded with the cutter head 3, the front end of the cutter head 3 is equipped with a blade 4, and the distance from the tip 7 of the blade 4 to the tool axis is 5.25mm. like Figure 4 As shown, the centerlines of the clamping portion 1 and the overhanging portion 2 are concentric, and the tip 7 of the blade 4 is close to the projection on the cutting tool section and is close to the top end of the short a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com