Reciprocating swing type four point contact ball rotating disk bearing

A four-point contact and reciprocating swing technology, applied in the direction of ball bearings, bearing components, shafts and bearings, can solve the problems of reduced machining accuracy, increased production costs, and high cost, and achieve improved machining accuracy, simplified processing procedures, and surface The effect of low roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

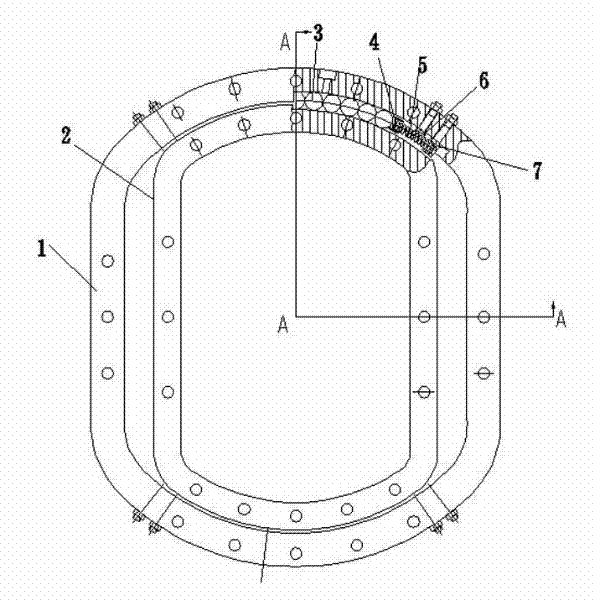

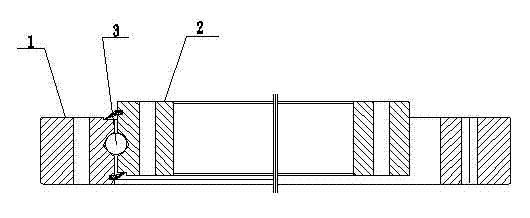

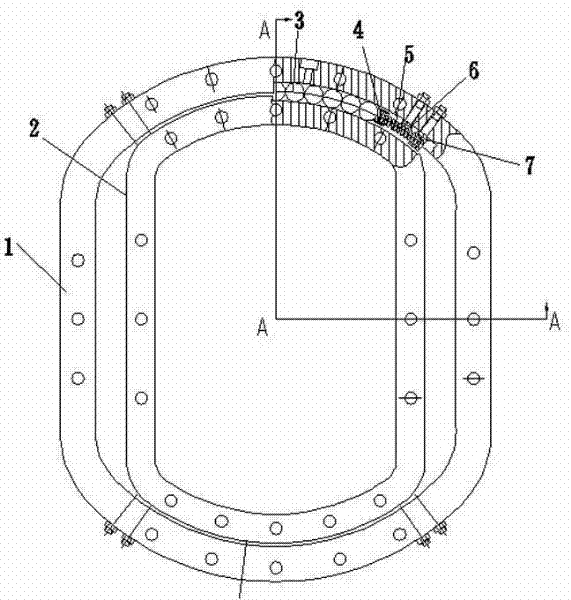

[0014] As shown in the figure, the specific embodiment of the present invention is as follows:

[0015] As shown in the figure, a reciprocating oscillating four-point contact ball slewing bearing is mainly composed of an outer ring, an inner ring and steel balls. The outer ring and the inner ring are connected by two parallel straight line segments and two arc segments. The two arc segments are respectively located at the two ends of the two straight line segments and connected to them. The junction is a smooth arc transition. The curvature of the outer ring arc segment and the inner ring arc segment are equal, and the curvature coefficient is generally 0.55. , that is, the arc radius of the arc groove is 0.55 times the diameter of the steel ball, and the angle of the arc section of the inner ring is smaller than that of the arc section of the outer ring; peach-shaped raceways are processed on the arc section of the outer ring and the arc section of the inner ring, There are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com