Vacuum clamp for machining circular arc of salt core

A technology of vacuum clips and arcs, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

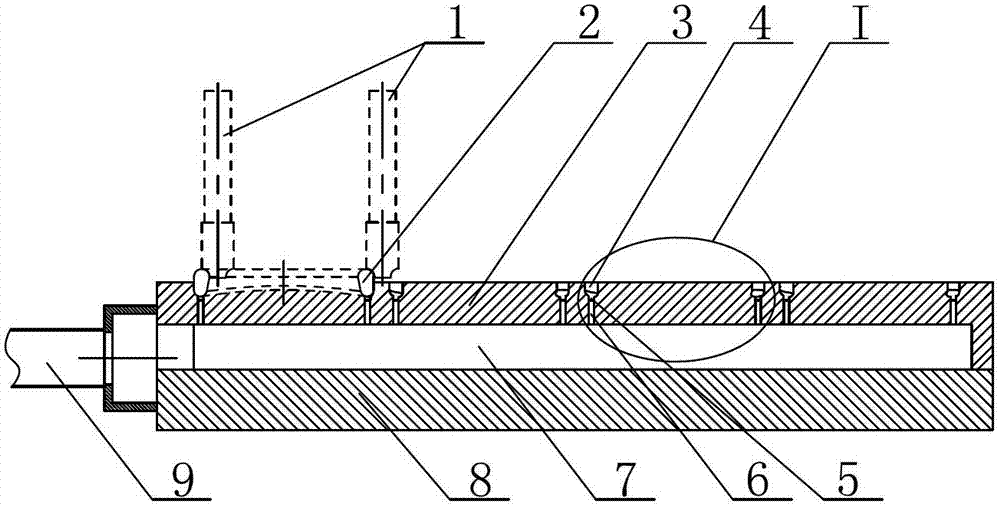

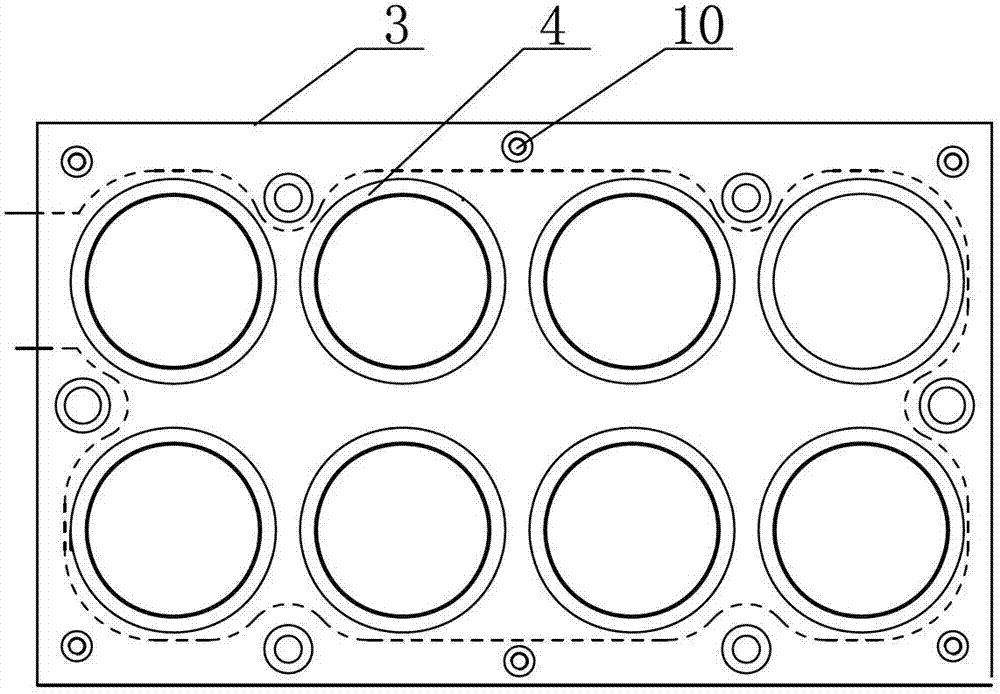

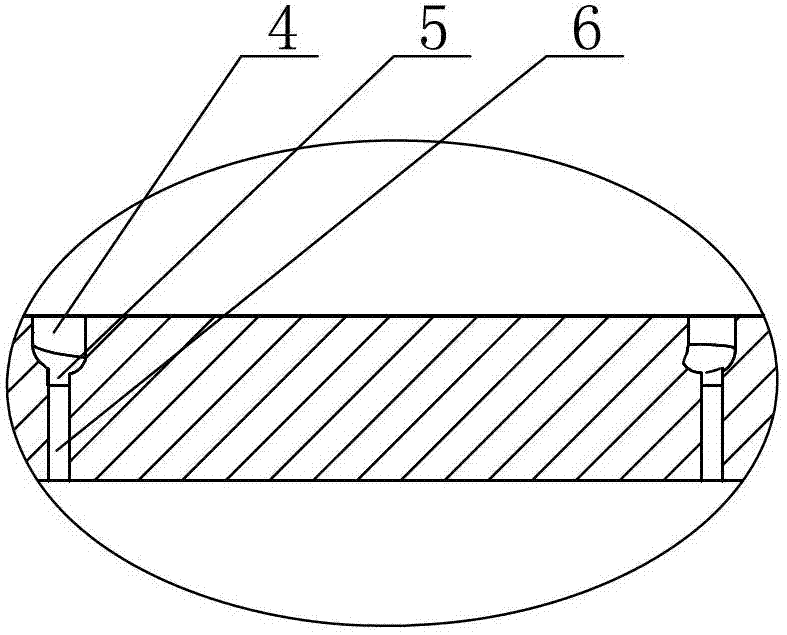

[0021] Such as figure 1 , 2 As shown in , 4, the vacuum fixture for processing the arc of salt core includes an upper mold 3 and a lower mold 8, the upper mold 3 and the lower mold 8 are connected by bolts 10, and the two parts are connected as a whole by liquid sealant sealing, and the upper mold 3 is provided with several workpiece positioning annular grooves 4, and the lower part is a vacuum suction cavity 7. A plurality of small holes 6 communicating with the cavity 7 are evenly distributed on the workpiece positioning annular groove 4. The cavity 7 is connected to the tube of the vacuum pump unit. 9. The lower die 8 is an entity.

[0022] This fixture can determine the number of stations of the fixture (that is, the number of workpiece positioning annular grooves) according to the size of the product and the stroke of the milling machine. In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com