A method for solving the grinding wheel track in the end edge clearance grinding process of ball end mills

A technology of ball end mill and gap grinding, which is applied in the direction of milling cutter, milling machine equipment, metal processing equipment, etc., can solve the problems of unsafe ball end milling and large grinding allowance, and achieve the purpose of making up for the end edge technology. Insufficient, reducing grinding allowance, improving the effect of rotary shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0057]Step 1: Define the geometric parameters of the end edge clearance.

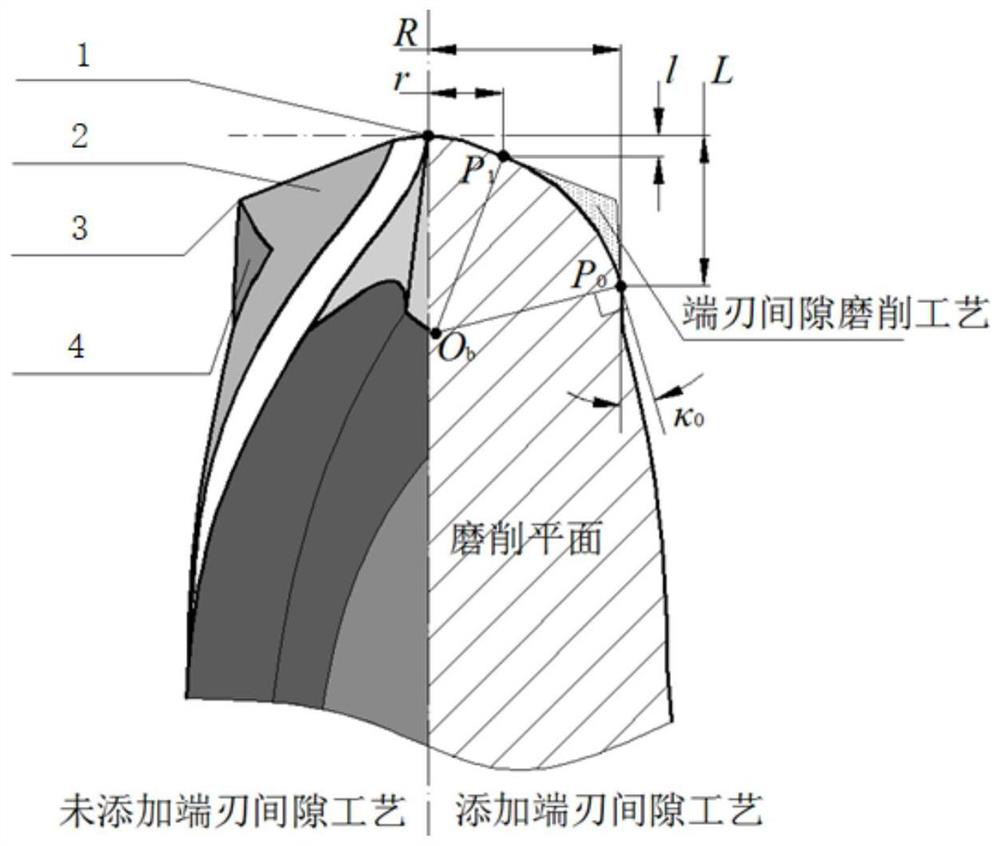

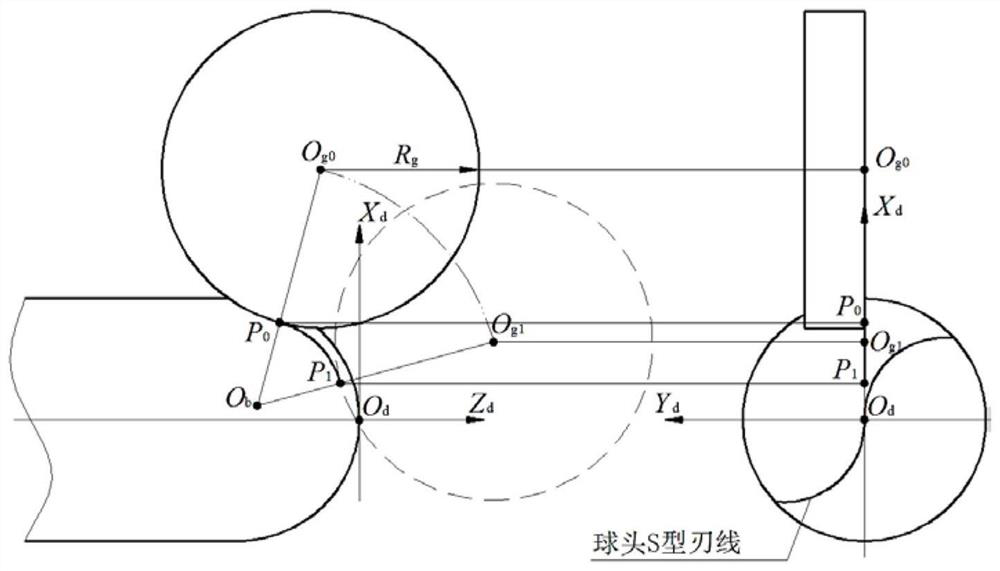

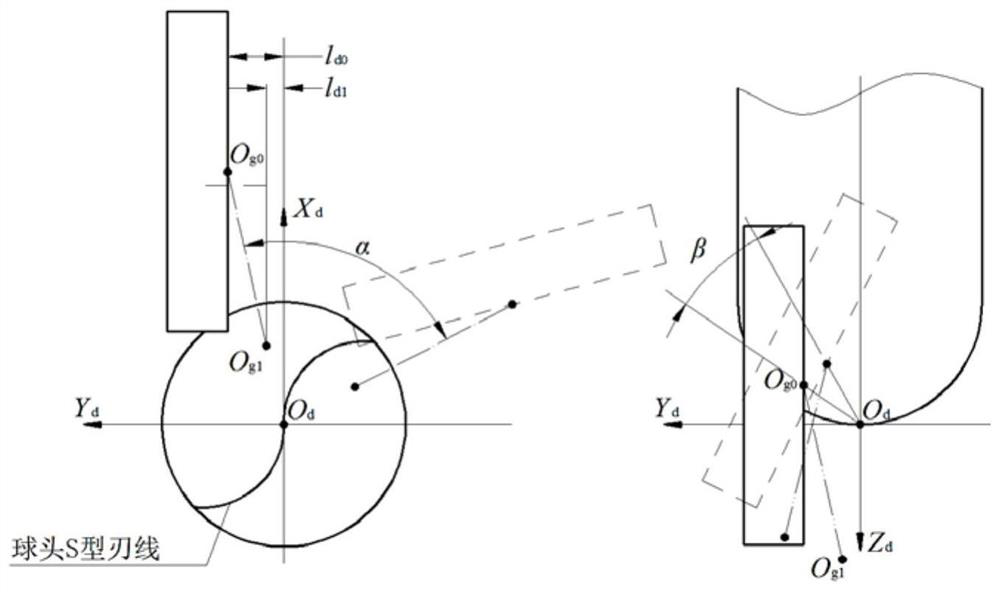

[0058] like figure 1 As shown in Fig. 1, the grinding plane is first selected as a certain plane passing through the axis of the rotating body of the tool, and the angle between it and the cutting edge is specified by the user to achieve the best grinding effect. In order to make the contour between two adjacent edges of the ball-end cutter close to the spherical contour, the present invention defines the outer contour of the end edge gap as a section of arc on the grinding plane. Let the starting point of the arc be P 0 , the end point is P 1 , the arc center is O b .

[0059] (1) Starting position. Arc starting point P 0 The location of is constrained by the starting radius R and the starting length L. where the starting point radius R is defined as p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com