Machine tool for automatically milling two end faces and drilling central holes of pin shaft

A technology for drilling a center hole and two end faces, applied in the field of machine tools, can solve the problems that affect the production efficiency and economic benefits of enterprises, large errors in the center hole drilling of workpieces, time-consuming, labor-consuming, and poor precision, and is suitable for mass production and grinding. The effect of low margin and high concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

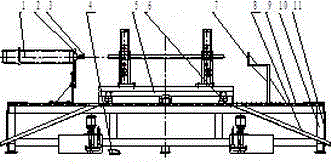

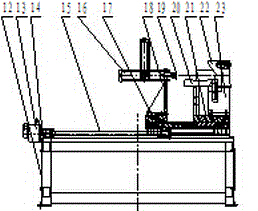

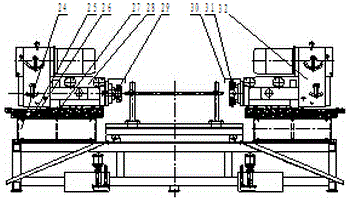

[0011] Such as figure 1 — Image 6 As shown, the pin shaft automatic milling machine tool for drilling center holes at both ends is mainly composed of a bed frame assembly, an automatic positioning device, an automatic clamping device, an automatic feed device, an automatic double-sided milling device, an automatic center hole drilling, a car set device, Composition of automatic unloading device.

[0012] Bed frame assembly: Mainly composed of bed frame panel 9, bed frame 10, bed frame left and right side doors 11, bed frame front and rear side doors 12, and row grooves 8.

[0013] Automatic positioning device: mainly composed of positioning cylinder 1, positioning cylinder block 2, positioning cylinder head 3, material support 20, positioning block 7.

[0014] Automatic clamping device: mainly consists of clamping booster cylinder 16, clamping cylinder seat 18, clamping cylinder head 19, clamping stroke adjustment plate 17, clamping V-shaped iron 22, V-shaped iron fixing seat 23, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com