Preparation method of brake friction plate processed by flat plate mold

A mold processing and friction plate technology, which is applied to friction linings, mechanical equipment, gear transmission mechanisms, etc., can solve problems such as low precision, loss of force transmission, and too tight on both sides, so as to improve the quality pass rate and reduce The effect of bending cracks and reducing the grinding allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

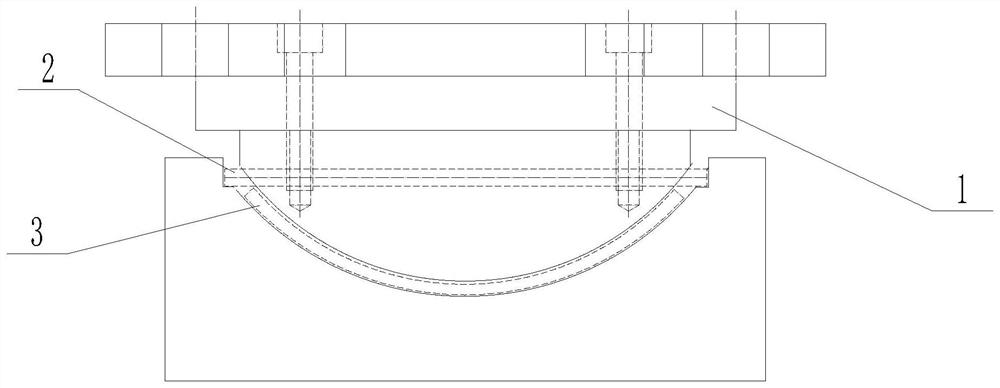

[0027] The invention provides a method for preparing a brake friction lining processed by a flat mold, comprising the following steps:

[0028] Step S1: Plate preheating and pressing: Lay the prepared raw material of the friction plate horizontally in the plate mold, lay flat wax paper on the contact surface of the upper and lower molds of the plate mold and the friction material, and heat press the upper and lower molds of the plate mold to form friction Sheet flat green body, in this step, the hot pressing temperature in the flat mold is 100 ℃, and the hot pressing pressure is 200 kg / cm 2 , deflate 4 times;

[0029] Step S2: Hot press bending: put the friction plate blank body prepared in step S1 directly into the bending mold while it is hot, and press it into the rough shape of the long curved friction plate, which is an arc-shaped friction plate blank. In this step, the mold is bent The hot-pressing temperature is 60°C, and the hot-pressing pressure is 20 kg / cm 2 ;

[...

Embodiment 2

[0035] The invention provides a method for preparing a brake friction lining processed by a flat mold, comprising the following steps:

[0036] Step S1: Plate preheating and pressing: Lay the prepared raw material of the friction plate horizontally in the plate mold, lay flat wax paper on the contact surface of the upper and lower molds of the plate mold and the friction material, and heat press the upper and lower molds of the plate mold to form friction Sheet flat green body, in this step, the hot pressing temperature in the flat mold is 110 ℃, and the hot pressing pressure is 200 kg / cm 2 , deflate 8 times;

[0037] Step S2: Hot press bending: put the friction plate blank body prepared in step S1 directly into the bending mold while it is hot, and press it into the rough shape of the long curved friction plate, which is an arc-shaped friction plate blank. In this step, the mold is bent The hot-pressing temperature is 100°C, and the hot-pressing pressure is 20 kg / cm 2 ;

...

Embodiment 3

[0043] The invention provides a method for preparing a brake friction lining processed by a flat mold, comprising the following steps:

[0044] Step S1: Plate preheating and pressing: Lay the prepared raw material of the friction plate horizontally in the plate mold, lay flat wax paper on the contact surface of the upper and lower molds of the plate mold and the friction material, and heat press the upper and lower molds of the plate mold to form friction Sheet flat body, in this step, the hot pressing temperature in the flat mold is 105 ℃, and the hot pressing pressure is 200 kg / cm 2 , deflate 6 times;

[0045] Step S2: Hot press bending: put the friction plate blank body prepared in step S1 directly into the bending mold while it is hot, and press it into the rough shape of the long curved friction plate, which is an arc-shaped friction plate blank. In this step, the mold is bent The hot-pressing temperature is 80°C, and the hot-pressing pressure is 20 kg / cm 2 ;

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com