Control method for preventing deformation in quenching process of 9Cr18 thin-wall bearing ring

A technology of thin-walled bearings and control methods, applied in the field of heat treatment, to achieve good roundness, improve grinding efficiency, and reduce grinding allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

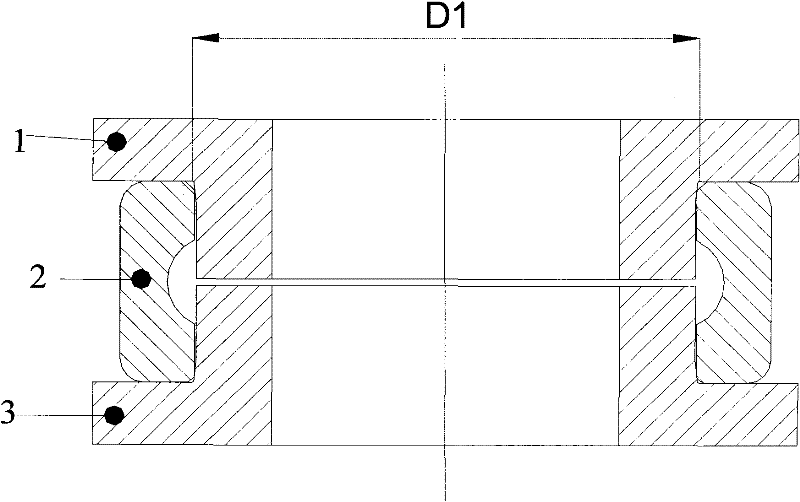

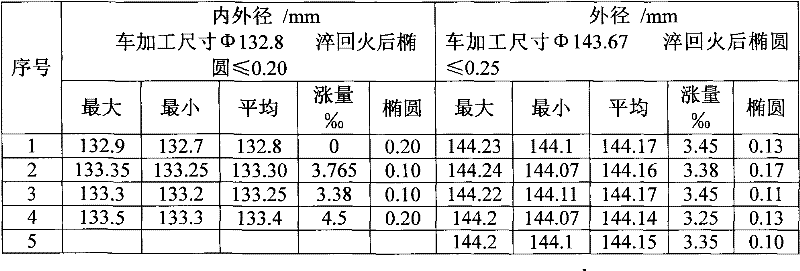

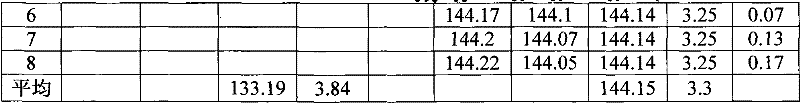

[0016] combine figure 1 , the anti-deformation control method used in the quenching treatment of 9Cr18 thin-walled bearing rings in the present invention is to design a set of quenching molds first, and the quenching mold is composed of an upper mold 1 and a lower mold 3. The contact outer diameter D1 of the die or the lower die is 100.32% of the inner diameter of the 9Cr18 thin-walled bearing ring 2, the maximum outer diameter of the upper die or the lower die is greater than the outer diameter of the 9Cr18 thin-walled bearing ring, and the contact outer diameter of the upper die or the lower die The wall thickness at D1 is greater than the maximum wall thickness of the 9Cr18 thin-walled bearing ring, and the sum of the effective widths at the contact outer diameter D1 of the upper and lower dies is less than the width of the 9Cr18 thin-walled bearing ring.

[0017] If the outer diameter of the 9Cr18 thin-walled bearing ring is Φ143.67mm, the inner diameter is Φ132.8mm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com