Bulletproof vehicle shell and production method thereof

A production method and bulletproof vehicle technology, which is applied to vehicle parts, superstructures, superstructure sub-assemblies, etc., can solve the problems of bulletproof performance decline, breakdown, difficulty in meeting the protection requirements of bulletproof vehicles, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

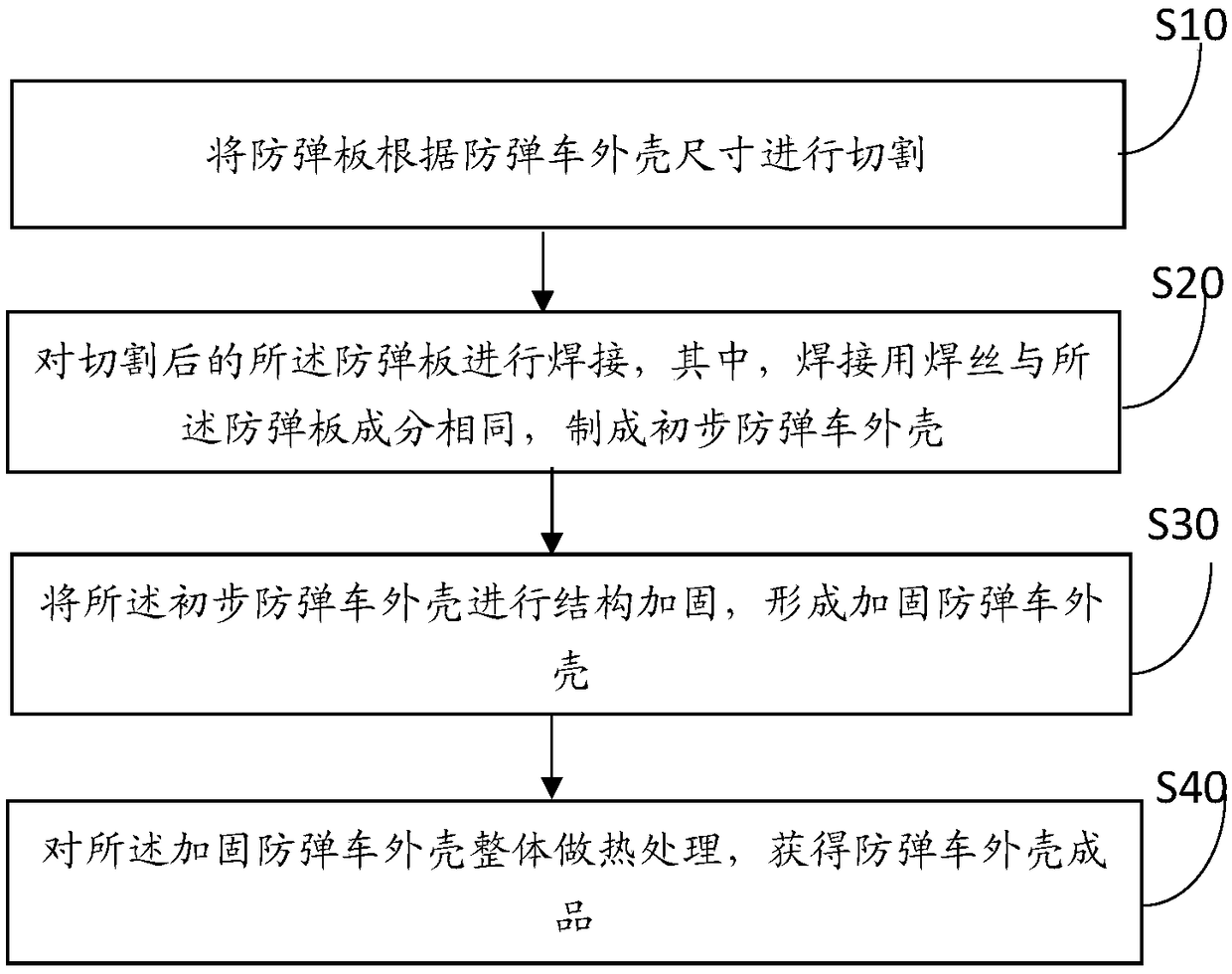

[0023] figure 1 It is a schematic flow diagram of a method for producing a shell of a bulletproof car in an embodiment of the present invention. Such as figure 1 As shown, the method includes:

[0024] Step 10: Cut the bulletproof board according to the shell size of the bulletproof car;

[0025] Further, the bulletproof board is cut according to the size of the shell of the bulletproof car, and the cutting method is laser cutting or underwater plasma cutting.

[0026] Specifically, the outer panel of the bulletproof car that meets the bulletproof requirements is cut by laser cutting or underwater plasma cutting, and the outer panel used for the bulletproof car, that is, the bulletproof plate, is cut into corresponding sizes according to the size of the bulletproof car The laser cutting or underwater plasma cutting method has the characteristics of less cutting heat, which can minimize the impact of thermal stress on the bulletproof board, thereby avoiding the deformation of the b...

Embodiment 2

[0041] An embodiment of the present invention provides an armored car shell, which is processed by the method described in the first embodiment.

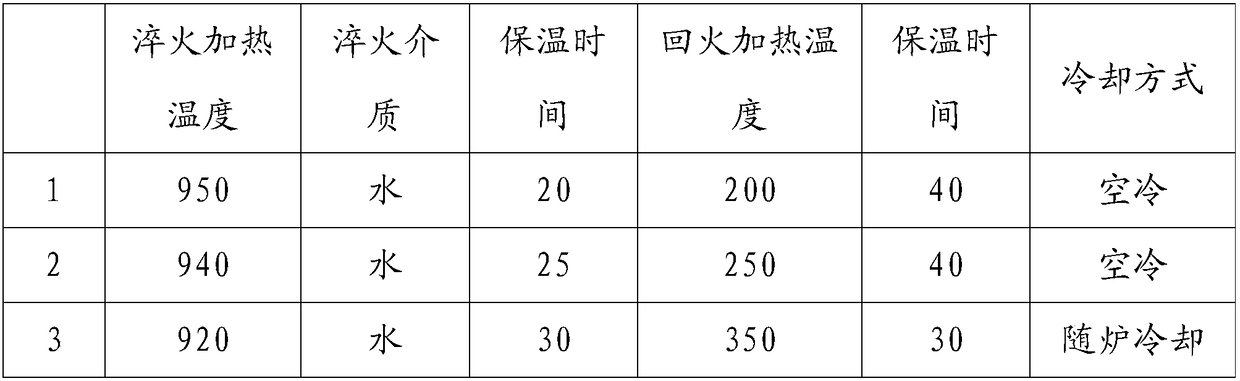

[0042] First, cut the bulletproof board according to the size of the armored car shell, which adopts laser cutting or underwater plasma cutting to reduce the thermal stress on the bulletproof board and avoid deformation; then, use the cut bulletproof board The welding wire with the same composition as the base material can be welded by laser welding or argon arc welding. By using the same material as the bulletproof plate for welding, the protection performance equivalent to the base material, that is, the bulletproof plate can be achieved, so that the manufacturing The shell of the preliminary bullet-proof car has stable anti-ballistic performance during the subsequent heat treatment, which solves the problem that the welding seam and the heat-affected zone are affected by the heating of the welding heat input during the welding proces...

Embodiment 3

[0045] In order to explain the present invention more clearly, the actual production process of the production method of a bulletproof car shell of the present invention and the test results of the overall bulletproof performance will be described in detail below through the embodiments of the present invention.

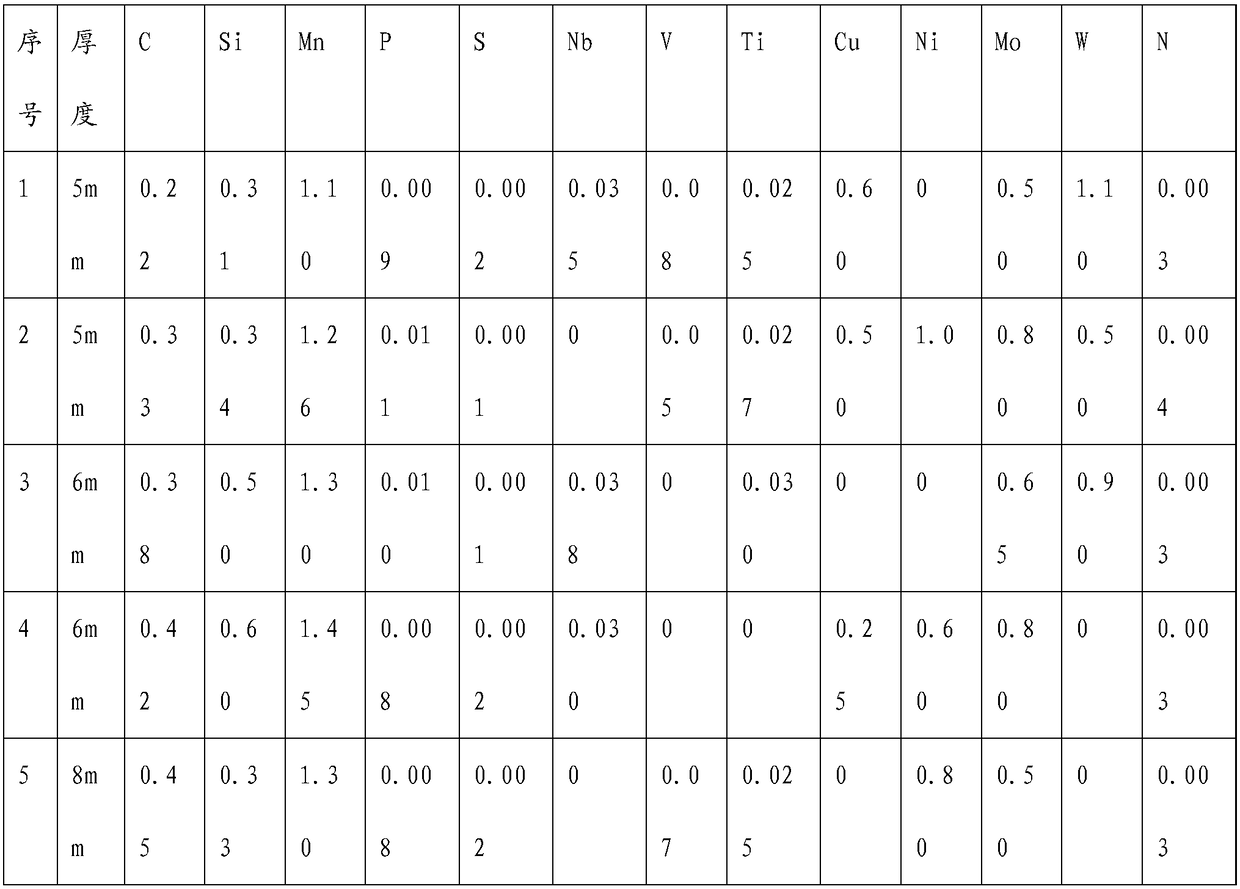

[0046] The chemical composition of the bulletproof plate used in the shell of the bulletproof vehicle according to the embodiment of the present invention is as follows: C: 0.20-0.45%; Si: 0.20-0.80%; Mn: 1.0-1.8%; Nb: 0-0.06%; Mo: 0.4 to 1.0%; V: 0 to 0.10%; Ti: 0 to 0.08%; Al: 0.01 to 0.06%; Ni: 0 to 3.0%; Cu: 0 to 1.0%; W: 0 to 2.0%; P : ≤0.011%; S: ≤0.004%; N: ≤0.008%; the rest is Fe and unavoidable impurities.

[0047] In the embodiment of the present invention, an ultra-high-strength bulletproof board that meets the chemical composition requirements of the above-mentioned bulletproof board is used for specific production. The chemical composition of the adopted bull...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com