Method for machining ball screw electric power steering machine rack

An electric power steering and ball screw technology, which is applied in the field of automobile steering system, can solve the problems of high energy consumption of quenching equipment, high requirements on tool materials and high comprehensive cost, so as to improve the quality and production efficiency, and reduce the grinding allowance. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for processing a rack of a ball screw electric power steering machine, comprising the following steps:

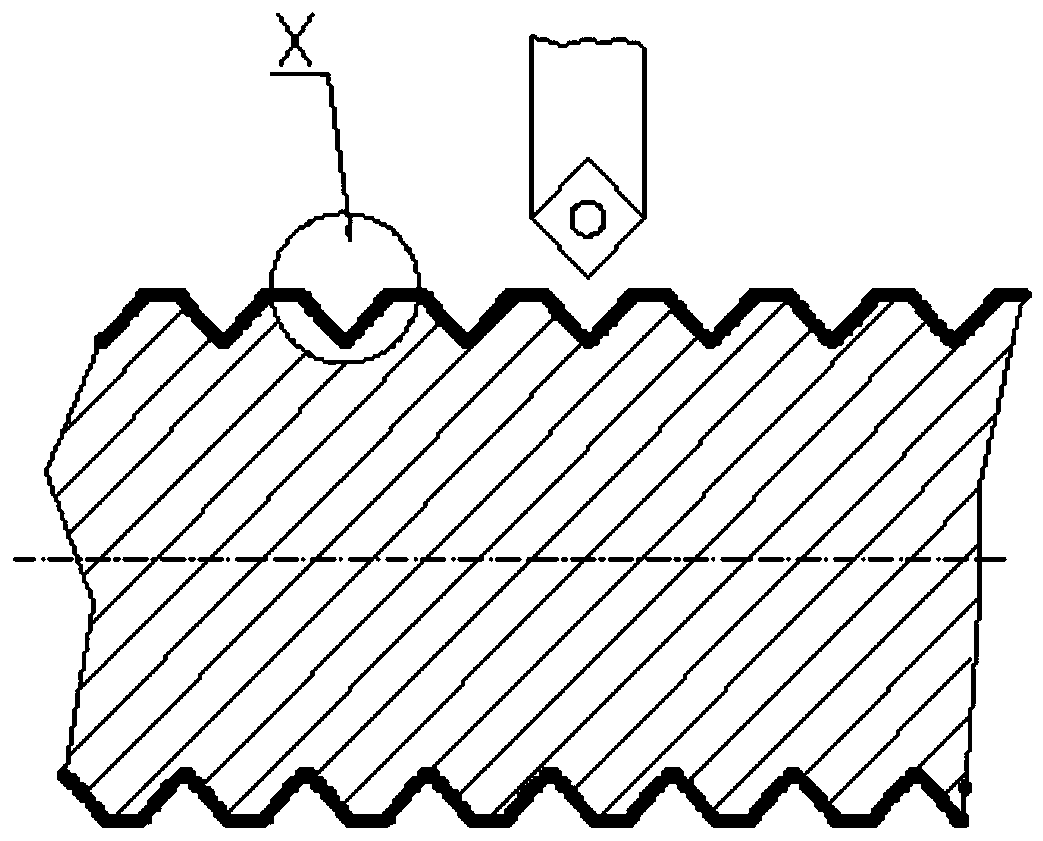

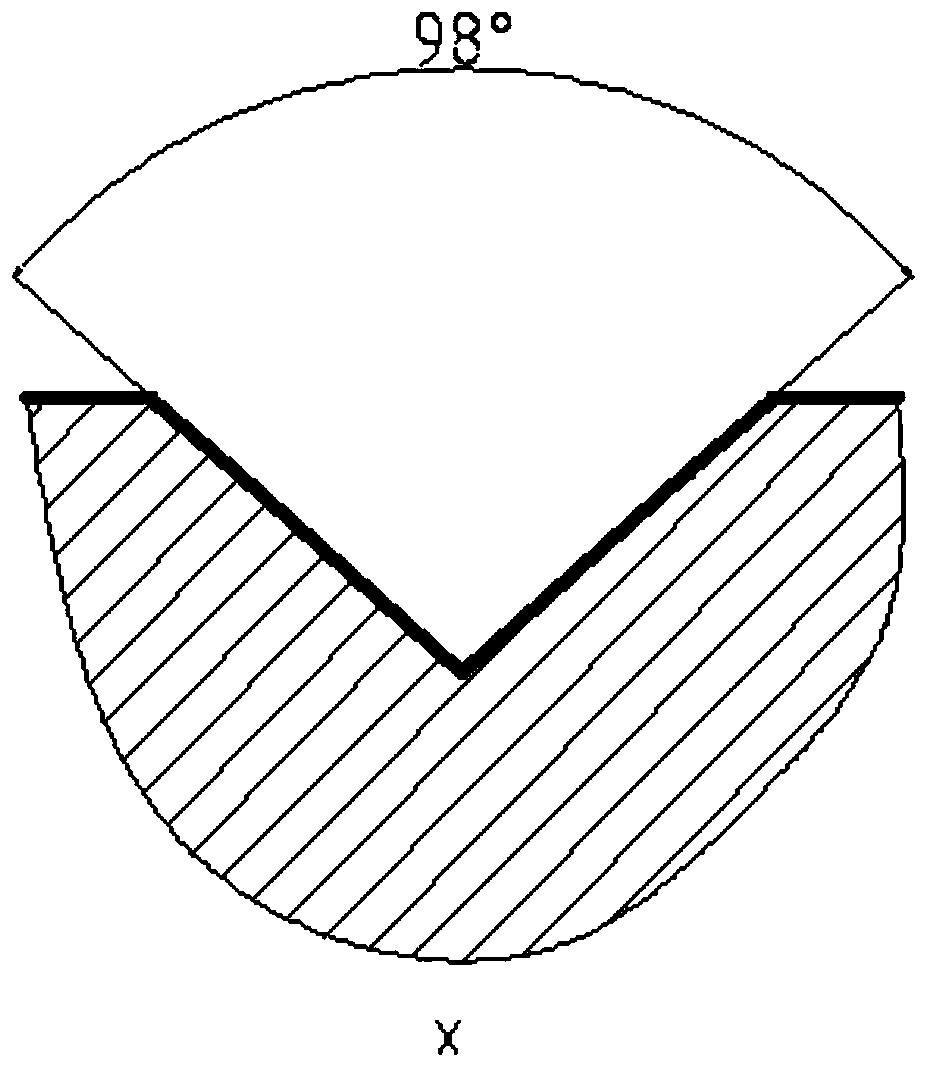

[0029] (1) Use a lathe to turn the part of the screw ballway into a 98° V-shaped spiral path, such as figure 1 , 2 shown;

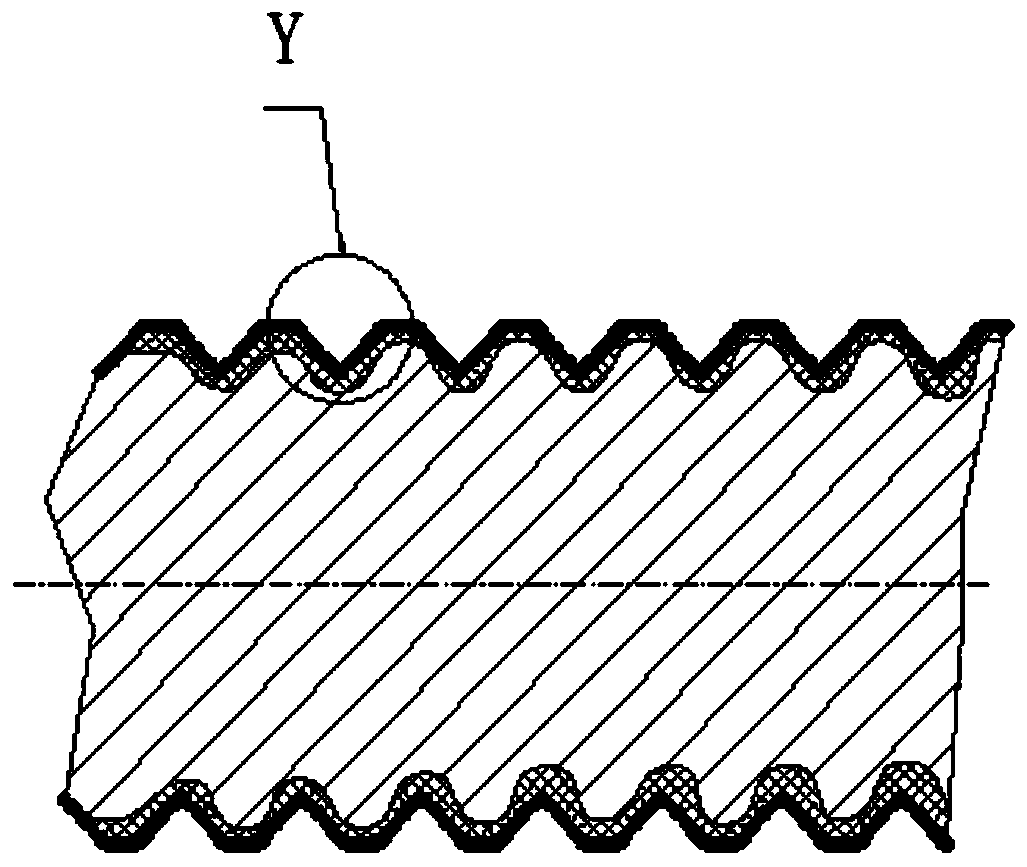

[0030] (2) Use quenching equipment for surface heat treatment to form a uniform quenched layer on the surface, such as image 3 , 4 shown;

[0031] (3) Use special ball-type fine grinding equipment to grind the screw ballway to produce a circular ballway, such as Figure 5 As shown, the central angle between the two deepest surfaces where the edge of the circular fairway is embedded is 85°.

[0032] The rack prepared by the above method only needs an ordinary CNC lathe to perform rough turning on the surface of the fairway. In terms of precision, it can meet most of the turning equipment, reducing the high cost of some special machine equipment and effectively reducing the cost. The processing burden of the follow-up sequence; and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com