Machining method of guide sleeve type thin-wall part

A processing method and technology for thin-walled parts are applied in the processing field of thin-walled parts such as guide bushes to achieve the effects of reducing grinding allowance, reducing deformation and improving processing qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Below in conjunction with accompanying drawing, the present invention will be further described,

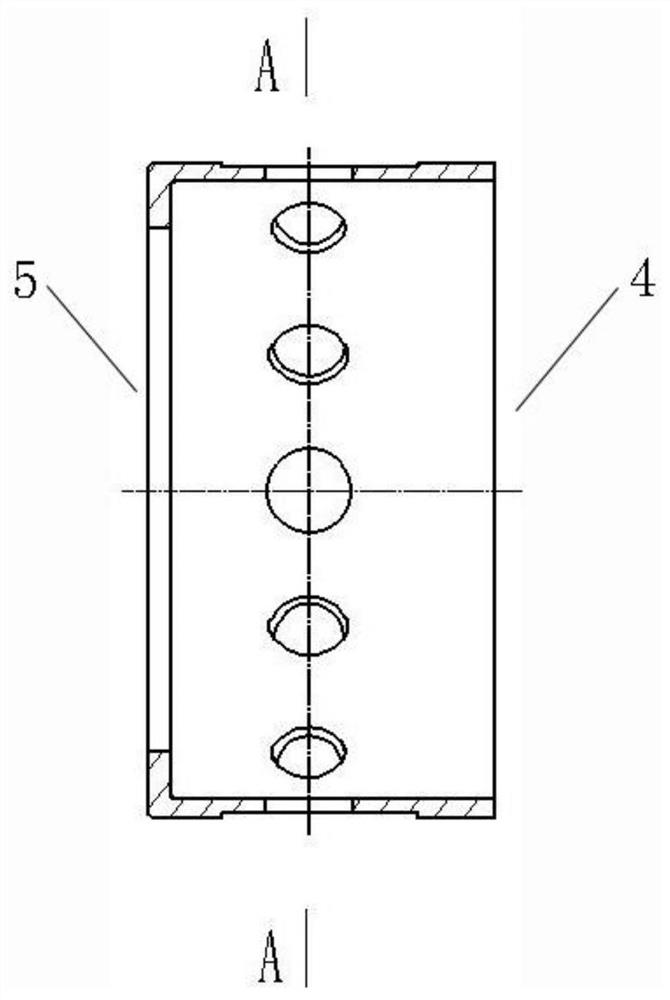

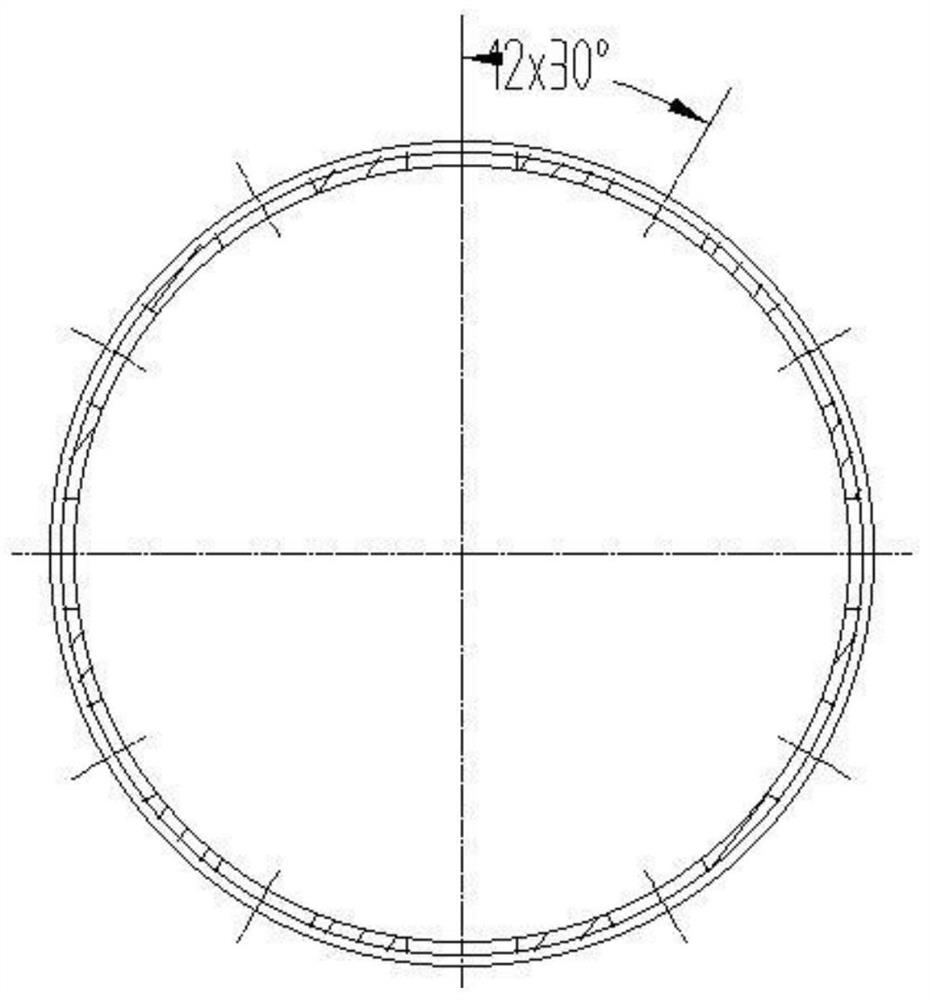

[0060] Guide sleeve thin-walled parts such as figure 1 , figure 2 As shown, the thin-walled parts are evenly distributed with 12 circumferential holes in the circumferential direction. In order to control the deformation of the thin-walled parts during processing, the present invention can ensure the outer circle size while controlling the deformation by designing a reasonable process route and special tooling. Tolerance requirements and their runout requirements relative to the datum.

[0061] see Figure 3-Figure 15 , a method for processing a guide sleeve type thin-walled part, comprising the following steps:

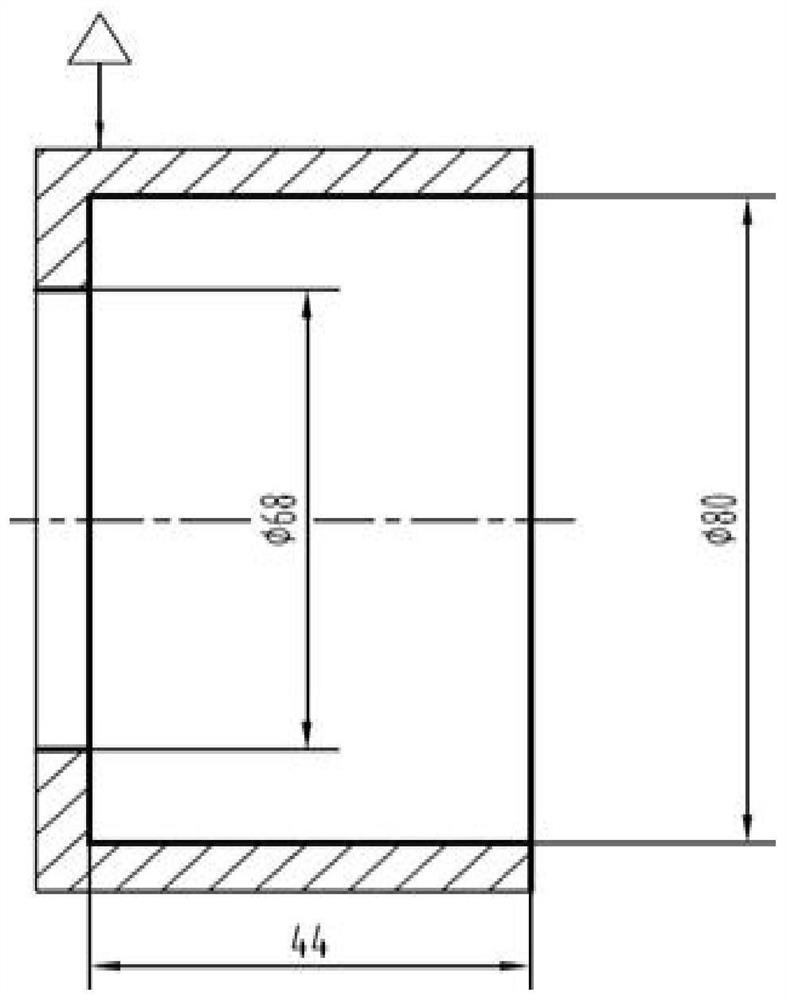

[0062] Step 10 rough car one

[0063] Clamp the outer circle with three claws, align it, and remove the allowance of the 4 end faces of the open end of the thin-walled part and the allowance of the inner hole to image 3 Size requirements;

[0064] Step 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com