Anti-decarbonizing agent for bearing steel thermal treatment for preparing bearing and preparation method thereof

An anti-decarburization agent and bearing steel technology, which is applied in the field of anti-decarburization agent for heat treatment of bearing steel, can solve the problems of poor comprehensive performance of high-temperature protective coatings, achieve the effects of reducing oxidation, improving processing efficiency, and reducing steel decarburization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

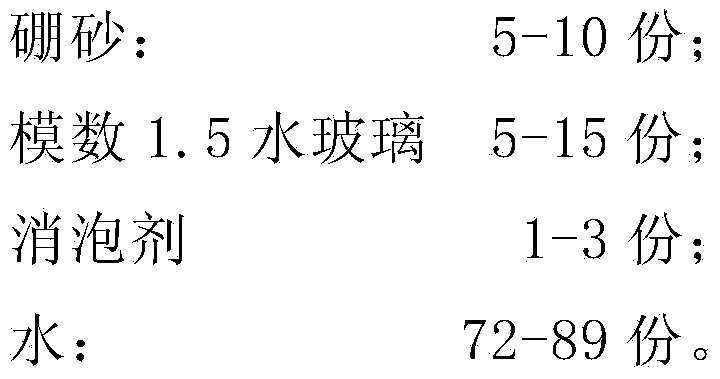

[0020] The bearing steel heat treatment anti-decarburization agent for preparing bearings is prepared from the following raw materials in parts by weight:

[0021]

[0022] The preparation method of the above bearing steel heat treatment anti-decarburization agent for bearings is to first heat water to 60-70°C, add borax and stir to dissolve, after it is completely dissolved, add defoamer, stir well and then gradually add modulus 1.5 water glass and stir well.

[0023] Use Φ10 GCr15 bearing round steel samples to conduct experiments. The initial steel samples have no decarburized layer, and the height of each sample is 50mm. The samples are first heated in a heating furnace to 400°C-500°C to remove the oil on the surface. , wash the residual dirt and rust on the surface with dilute hydrochloric acid solution, then wash it with ultrasonic vibration water three times, and dry it for later use.

[0024] Heat the anti-decarburization agent for heat treatment of bearing steel u...

Embodiment 2

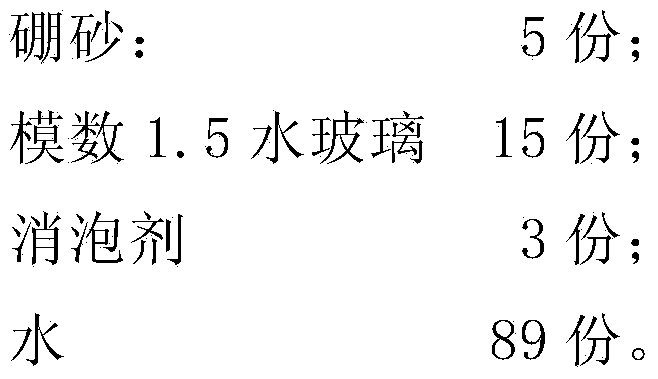

[0026] The bearing steel heat treatment anti-decarburization agent for preparing bearings is prepared from the following raw materials in parts by weight:

[0027]

[0028] All the other are the same as Example 1, and the results are shown in Table 1.

Embodiment 3

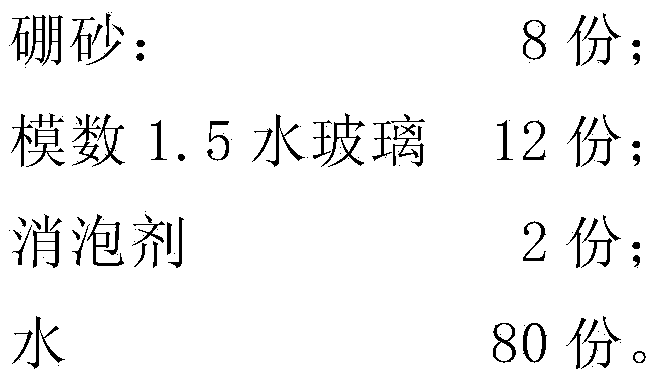

[0030] The bearing steel heat treatment anti-decarburization agent for preparing bearings is prepared from the following raw materials in parts by weight:

[0031]

[0032] All the other are the same as Example 1, and the results are shown in Table 1.

[0033] Table 1

[0034] sample

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com