Method for homogenizing gear tooth surface grinding allowance of planar enveloping hourglass worm

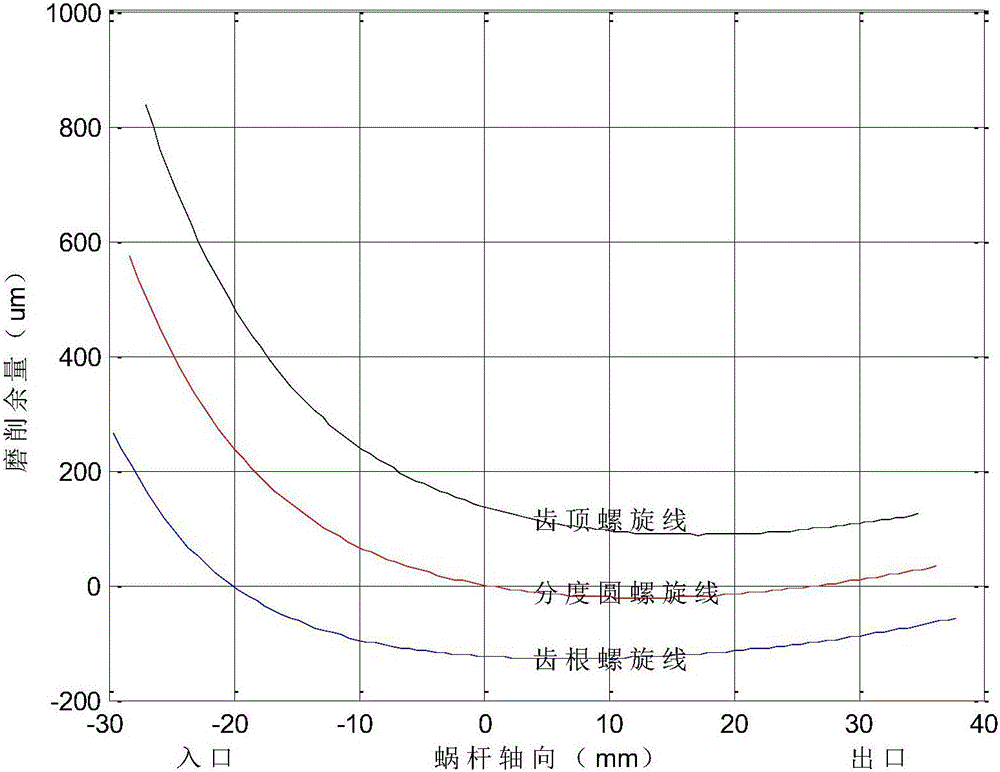

A toroidal worm, grinding allowance technology, applied in the direction of worms, elements with teeth, belts/chains/gears, etc., to reduce the overall grinding allowance and homogenize the tooth root and tooth top grinding allowance , The effect of homogenizing the grinding allowance at the entrance and exit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

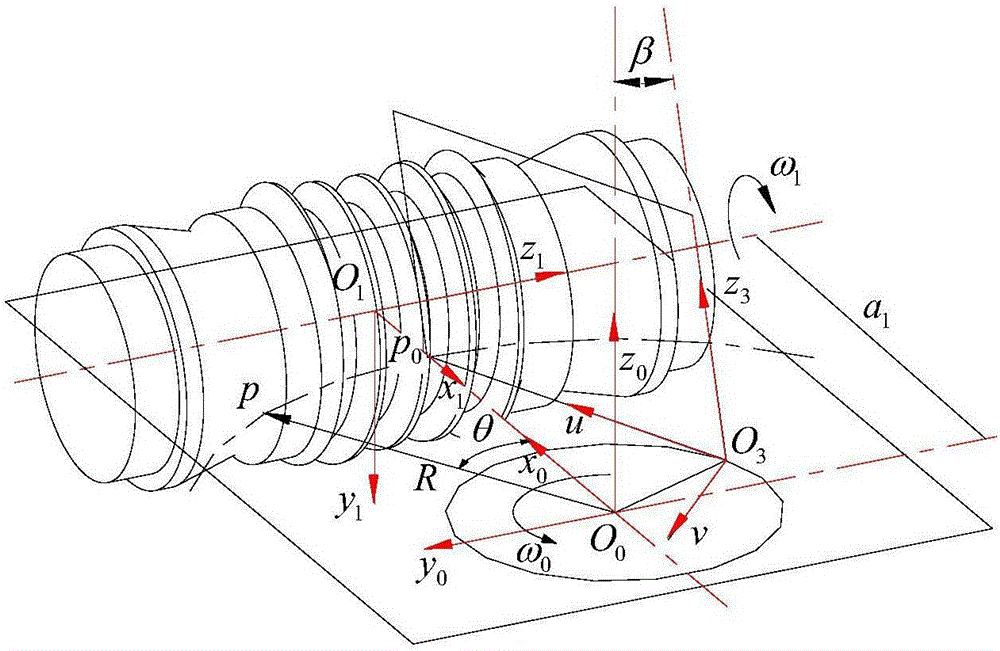

[0032] Below in conjunction with accompanying drawing, the present invention will be further described by embodiment, and the principle of this method is very clear to those skilled in the art.

[0033] center distance a 1 =125.2, transmission ratio i 01 =33, inclination angle of parent plane b=10°, radius of worm pitch circle r 1 =27.5, base circle radius r b =37.5, number of surrounding teeth is 3.5, indexing circle pressure angle a=22.33°, working half angle j w =16.64°, tooth pitch angle t=10.91°, worm addendum arc radius R a1 =94.51, worm tooth root arc radius R f1 =104.08 right-handed plane enveloping toroidal worm as an example. According to the principle of gear meshing and the homogeneous coordinate transformation matrix, the tooth surface equation of the worm is shown in the following equations:

[0034]

[0035] in

[0036] In the middle plane, the point p(x 1 ,y 1 ,z 1 ), should satisfy the following equations:

[0037]

[0038] where q? [0.37,0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com