Square cutting, edge cutting and polishing all-in-one machine

An all-in-one machine, grinding and polishing technology, applied in the direction of grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve the problems of inconvenient operation, high labor intensity, and a large number of operators, so as to improve grinding efficiency, The effect of reducing the grinding allowance and saving the rough grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

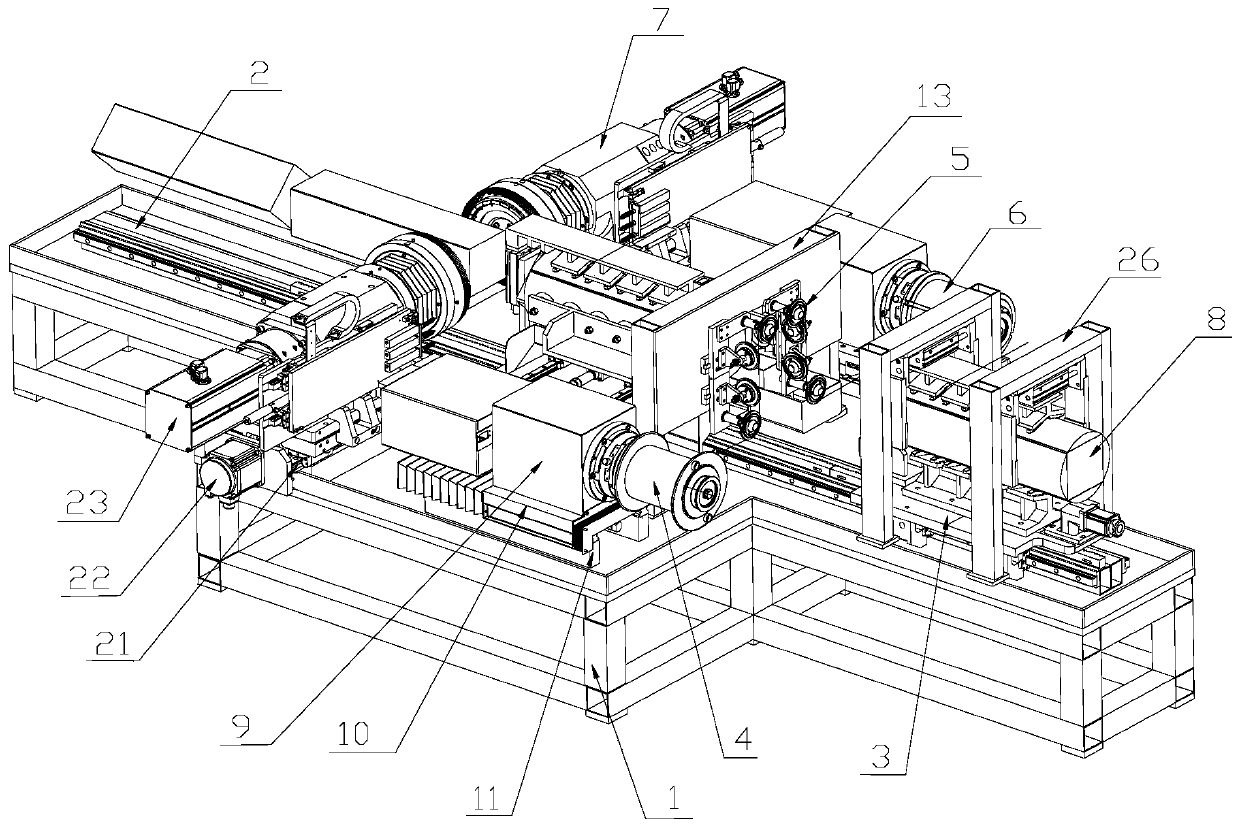

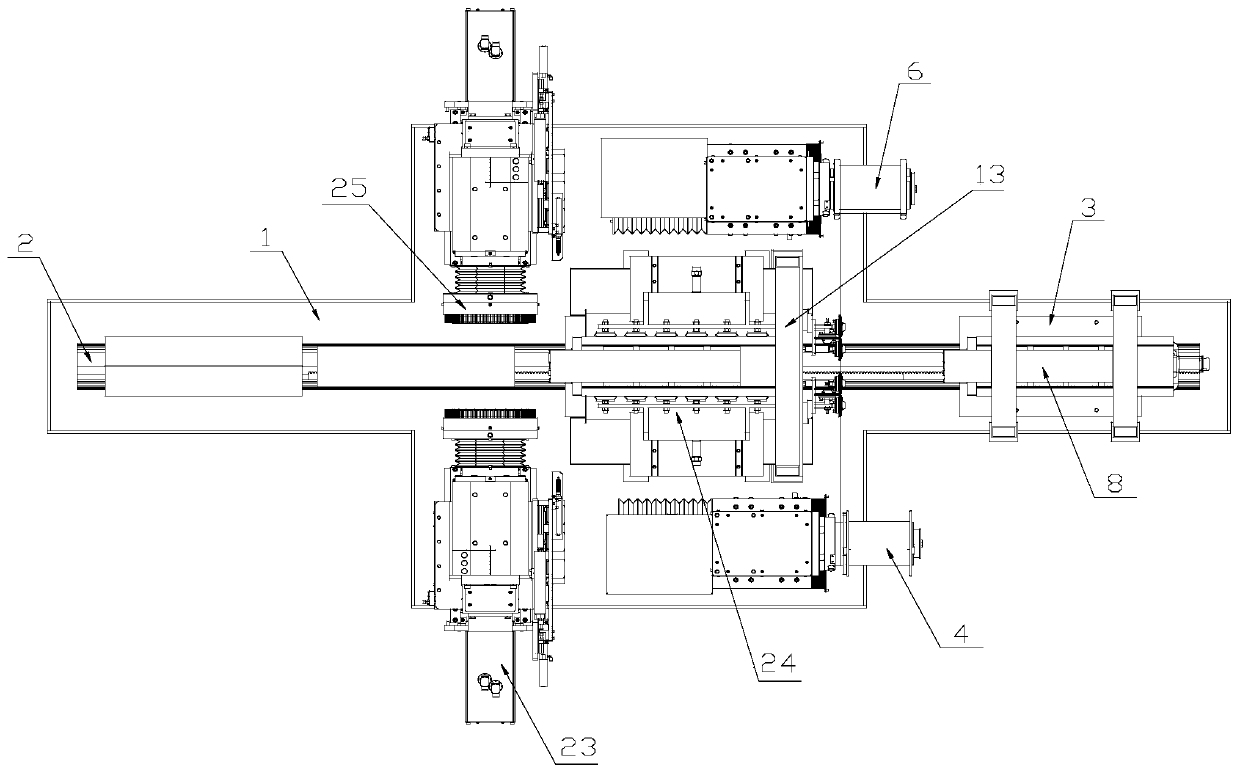

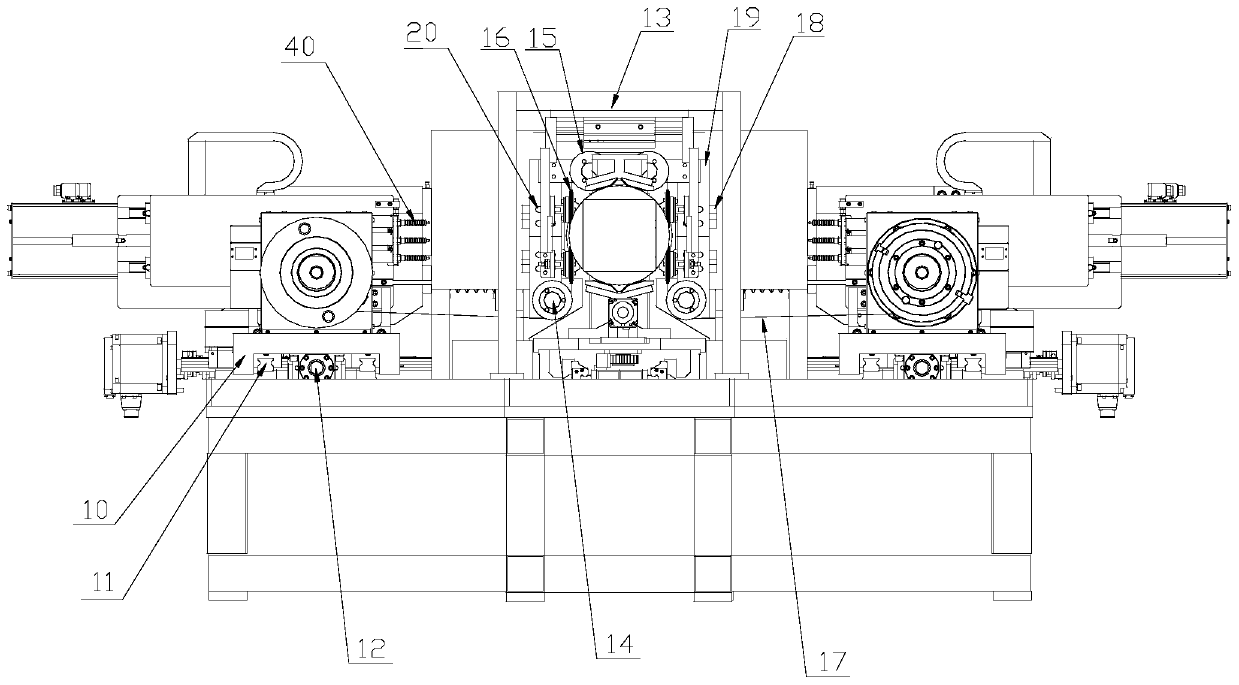

[0031] Such as Figure 1-Figure 3 As shown, an integrated machine for cutting square, edge cutting, grinding and polishing includes a base 1, on which a slide rail 2 is provided, and on the slide rail 2 is sequentially provided with a loading table along the transmission direction of the crystal silicon 8. The mechanism 3, the centering mechanism 26, the square prescribing mechanism, the edge-cutting mechanism 24, and at least two grinding and polishing mechanisms 7, that is to say, the all-in-one machine can combine prescribing and grinding processes, and the crystalline silicon 8 can be squared Grinding and polishing to the edge and corner processing, processing and shaping at one time, saving the rough grinding process, you can directly enter the slicing process.

[0032] Such as Figure 4 with Figure 5 As shown, the loading table mechanism 3 is used to carry the crystalline silicon 8 and drive the crystalline silicon 8 to move along the slide rail 2. Specifically, the loadin...

Embodiment 2

[0036] Such as figure 1 with Figure 5 As shown, the centering mechanism 26 includes a centering bracket 37, a parallel jaw cylinder 38, and a clamping plate 39. The centering bracket 37 is arranged along a vertical direction, and the bottom of the centering bracket 37 is fixedly connected to the base 1. The jaw cylinder is arranged along the direction perpendicular to the slide rail 2, the cylinder end is fixedly connected with the centering bracket 37, and the piston end is connected with the clamping plate 39 which is arranged along the vertical direction. Both the parallel jaw cylinder 38 and the clamping plate 39 are arranged symmetrically, and the clamping plate is attached to the cut surface of the crystal silicon 8.

[0037] At least one centering mechanism 26 is provided along the length direction of the crystalline silicon 8. In this embodiment, there are two centering mechanisms 26. Along with the extension or retraction of the parallel jaw cylinder 38, the clamping p...

Embodiment 3

[0039] Such as figure 1 with image 3 As shown, the square-opening mechanism includes a pay-off drum 4, a take-up drum 6 and a square wire net 5. The cutting wire 17 bypasses the square wire net 5 and is enclosed for the crystalline silicon 8 to pass through and cut the side skin of the crystalline silicon 8 and Angular cutting channel, and the cutting line is parallel. In this embodiment, the cutting wire 17 uses, but is not limited to, a loop wire or an ultra-fine diamond wire to realize high-precision square extraction, ensure the size and surface quality, and facilitate the processing of the crystalline silicon 8 through rapid grinding. The pay-off drum 4 and the take-up drum 6 are both arranged in parallel along the sliding rail 2. At the same time, the pay-off reel 4 and the take-up reel 6 are provided with a winding drive assembly and a winding drive assembly. The winding drive assembly is used to drive the pay-off reel 4 or the reel 6 to rotate. The wire drive assembly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com