Carburizing and quenching method for cylindrical gear

A cylindrical gear, carburizing and quenching technology, applied in the field of heat treatment, can solve the problems of reducing gear quenching deformation, reducing phase transition stress, and increasing deformation tendency, so as to reduce heat treatment deformation, reduce manufacturing cost, and reduce grinding time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

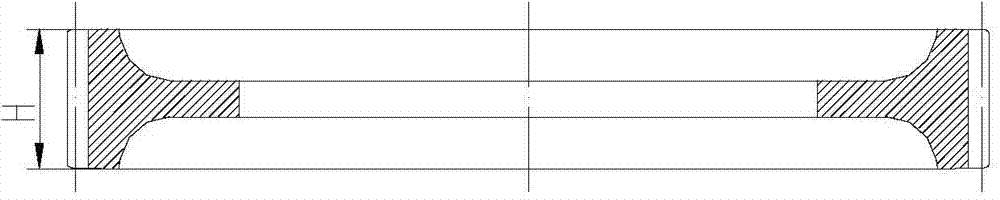

[0029] The spur gear of the present embodiment is the locomotive driven gear, as figure 1 As shown, the material is low-carbon alloy steel 18CrNiMo7-6, its Ac1 point is 738°C, Ac3 point is 815°C, the original heat treatment process is as follows Figure 4 As shown, direct carburizing-high temperature tempering-quenching treatment-low temperature tempering, the deformation is obvious, a large grinding allowance is required, and the thickness of the carburized layer is difficult to control.

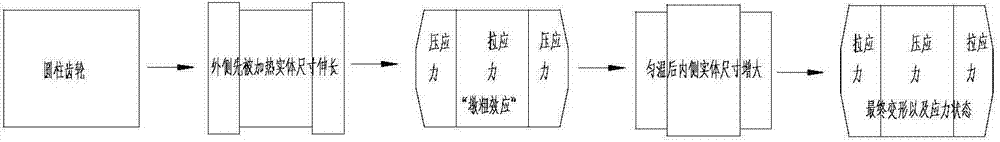

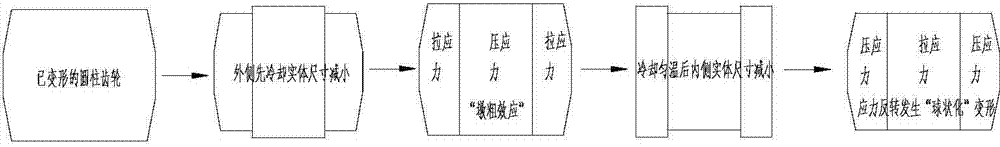

[0030] To this end, the applicant has carried out in-depth test analysis. Studies have shown that the above-mentioned steel materials will change from elastic deformation to plastic deformation when heated above 500°C, and irreversible plastic deformation will occur, and finally become heat treatment deformation and remain. Usually, when the steel is heated rapidly, the initially heated part, that is, the outer side of the steel, first enters the plastic deformation temperature zone, becau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com