Tooth direction shaping gear hobbing processing technique

A processing technology and gear hobbing technology, which is applied in the field of gear tooth profile processing technology, can solve the problems of insufficient tooth surface hardness, steps in the tooth root, insufficient depth of the effective hardened layer, etc., and achieve the effect of uniform tooth surface hardness difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

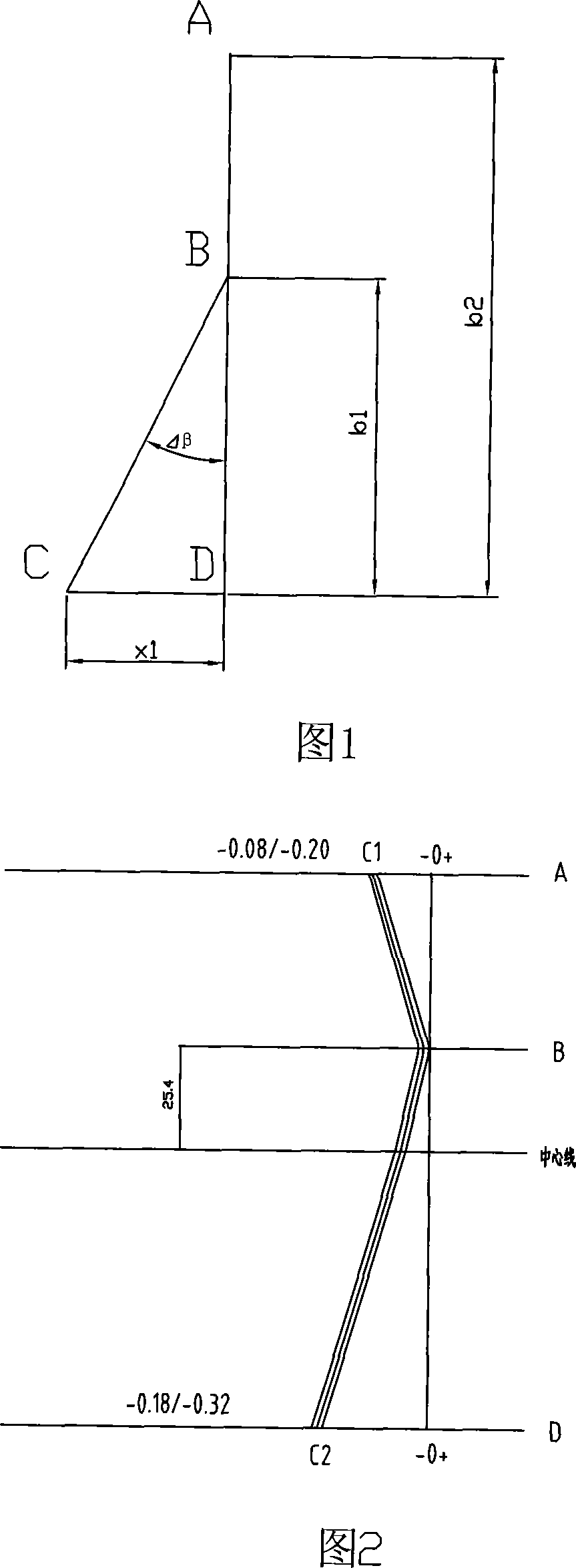

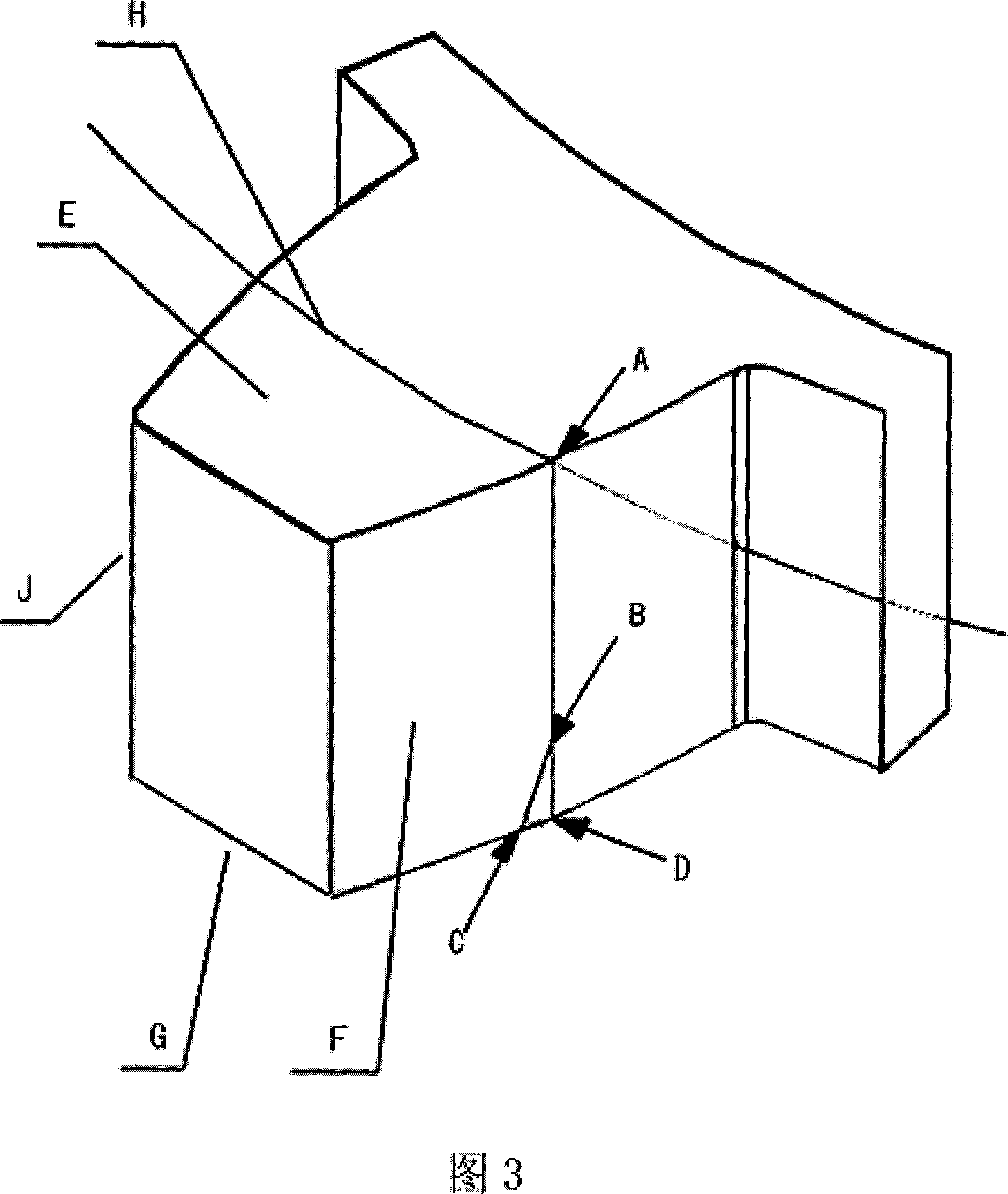

[0015] The gear hobbing process for tooth profile modification includes:

[0016] a. According to the requirements of the hobbing drawings, according to the requirements of the hobbing drawings, hob the outer diameter of the gear blank to the common normal line of the gear or exceed a certain distance; then use the hobbing machine to process the gear hobbing to the tooth width of the gear. The detection point A or detection point D of the end surface, wherein, the detection point A is located at the intersection of the tooth surface F forming the gear groove and one end surface E of the gear and the intersection of the pitch circle H of the gear, and the detection point D is located at the intersection of the tooth surface F forming the gear groove The intersection point of the intersection line between the tooth surface F and the other end surface G of the gear and the pitch circle H of the gear;

[0017] b. Based on the actual helix angle of the CB line and the parameters of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com