Patents

Literature

110results about How to "Avoid processing defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

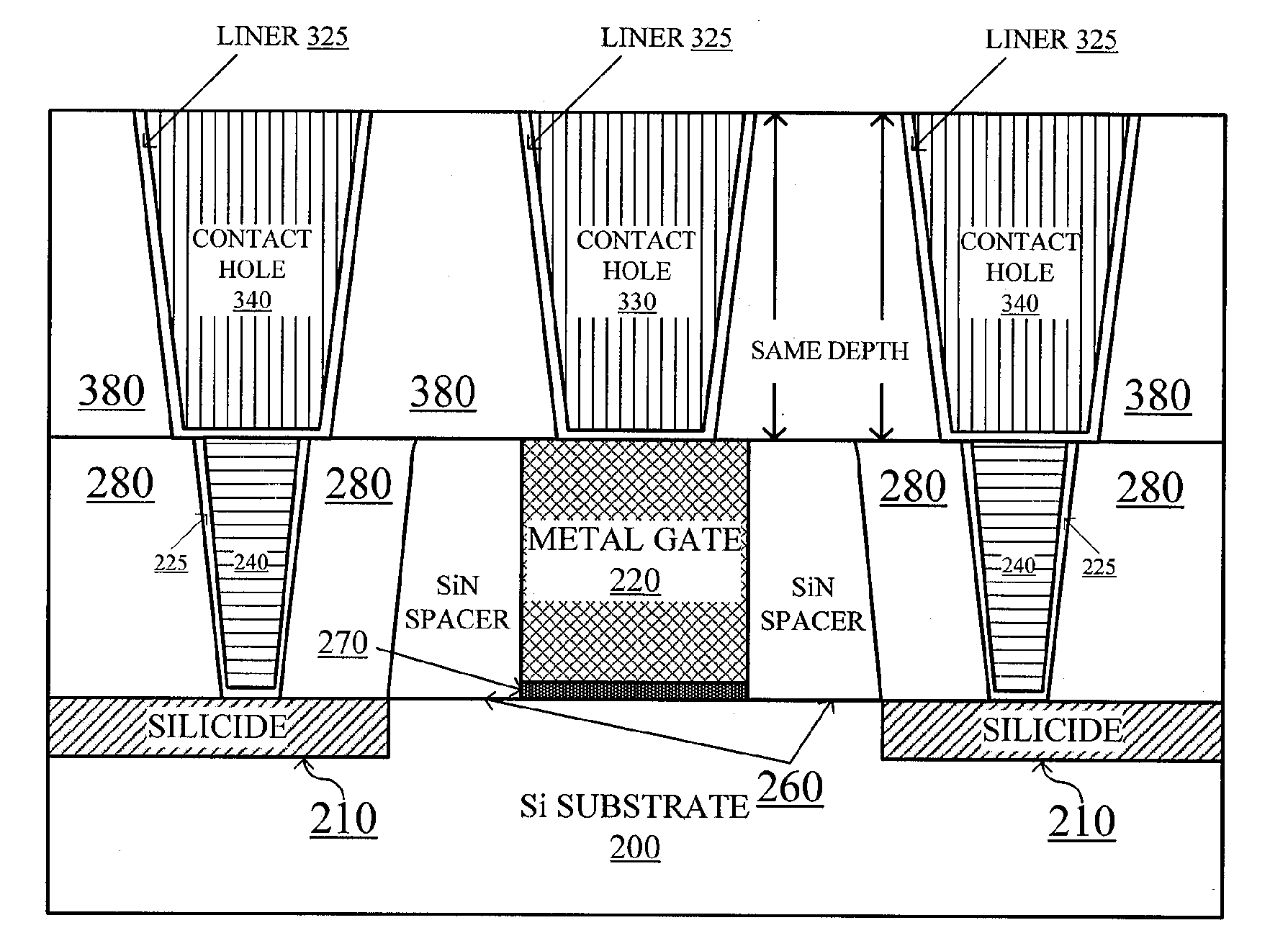

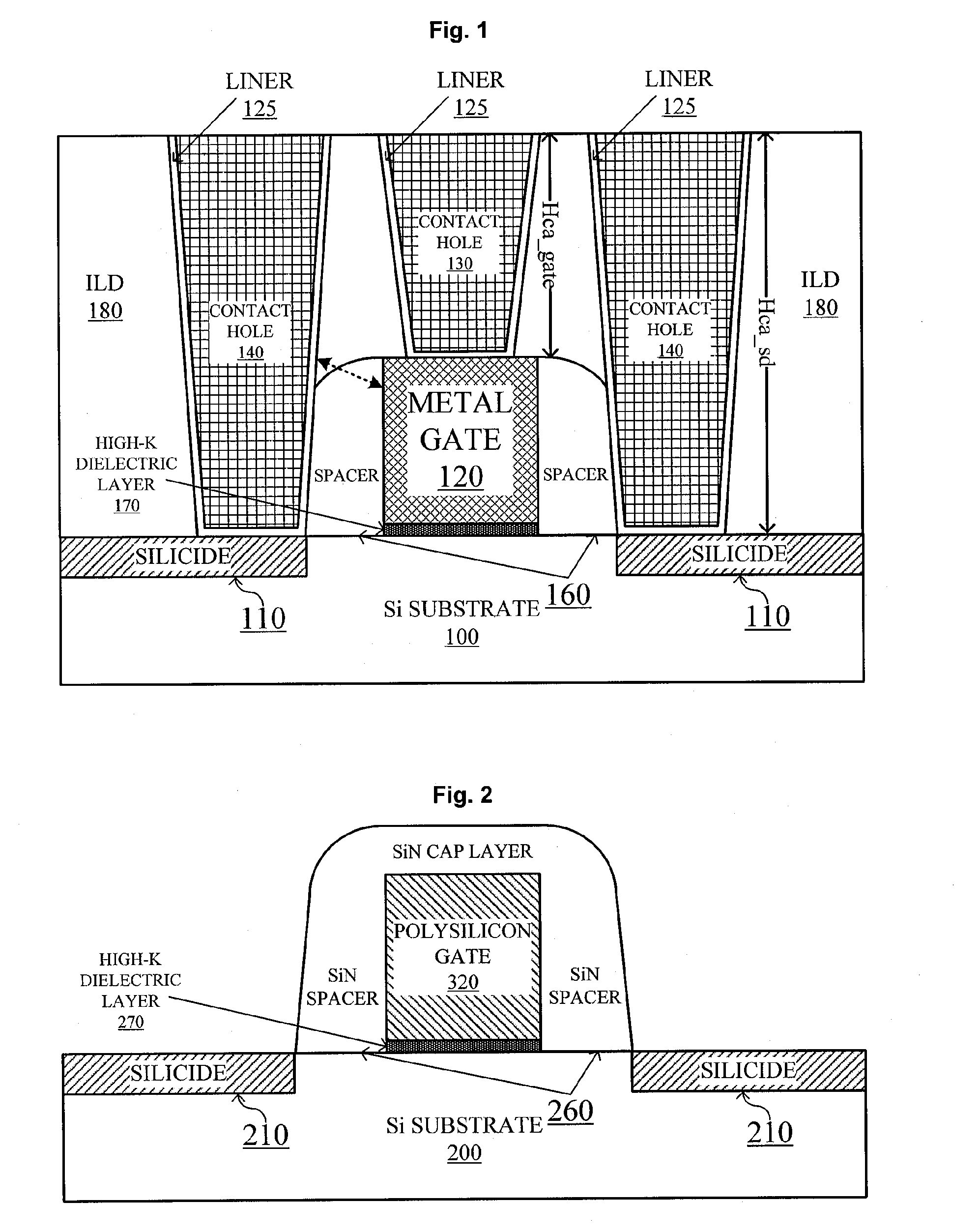

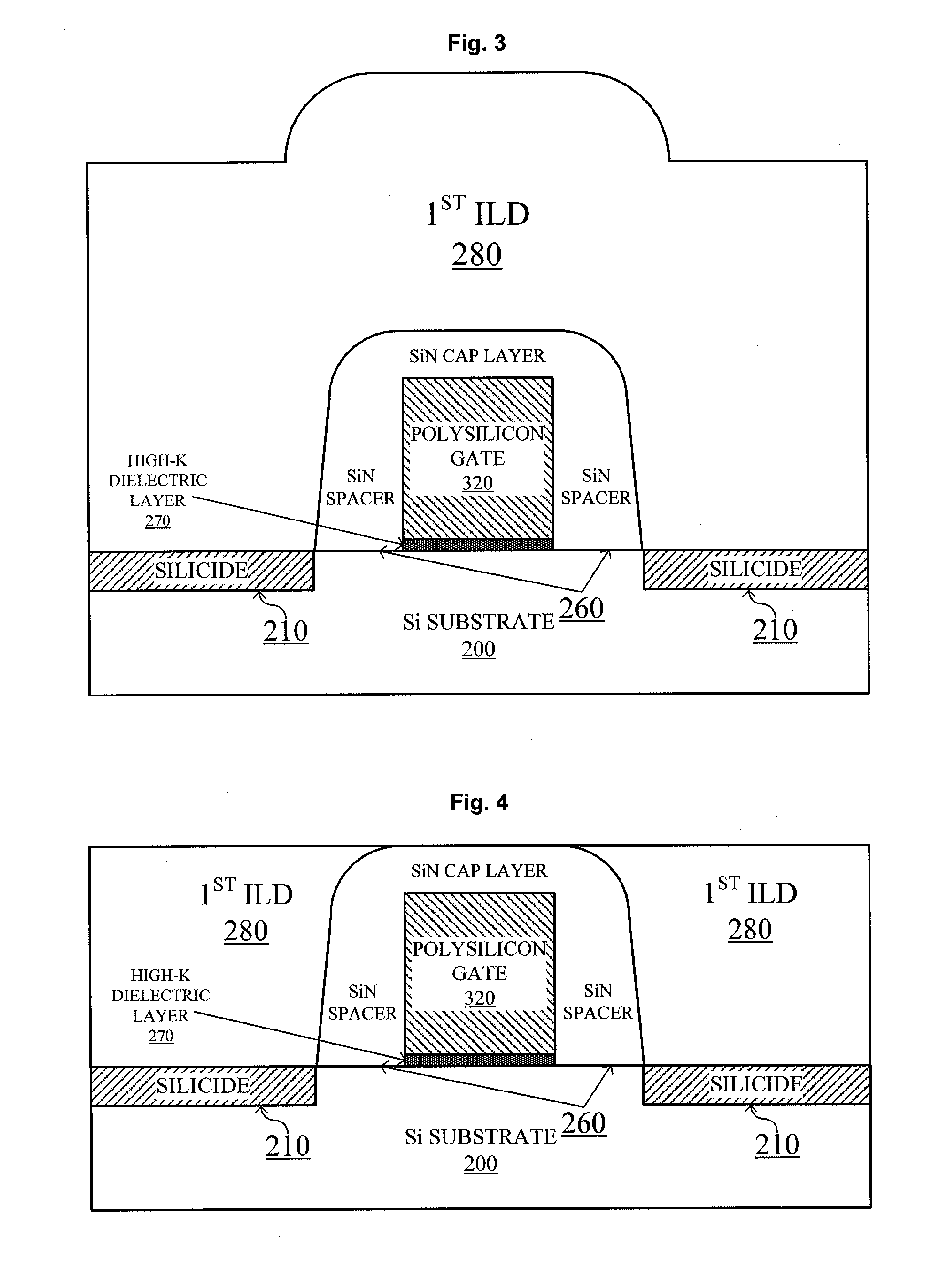

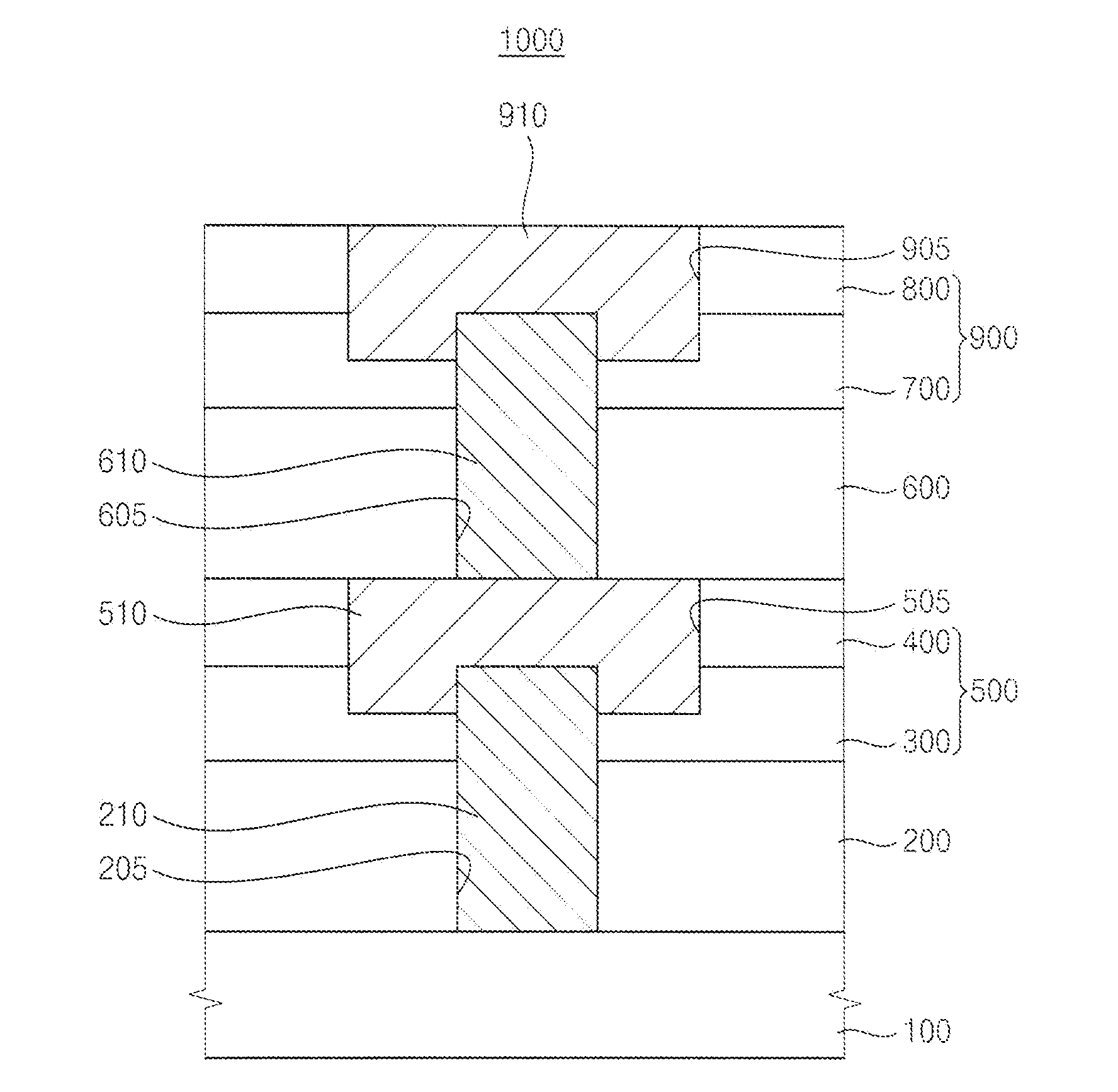

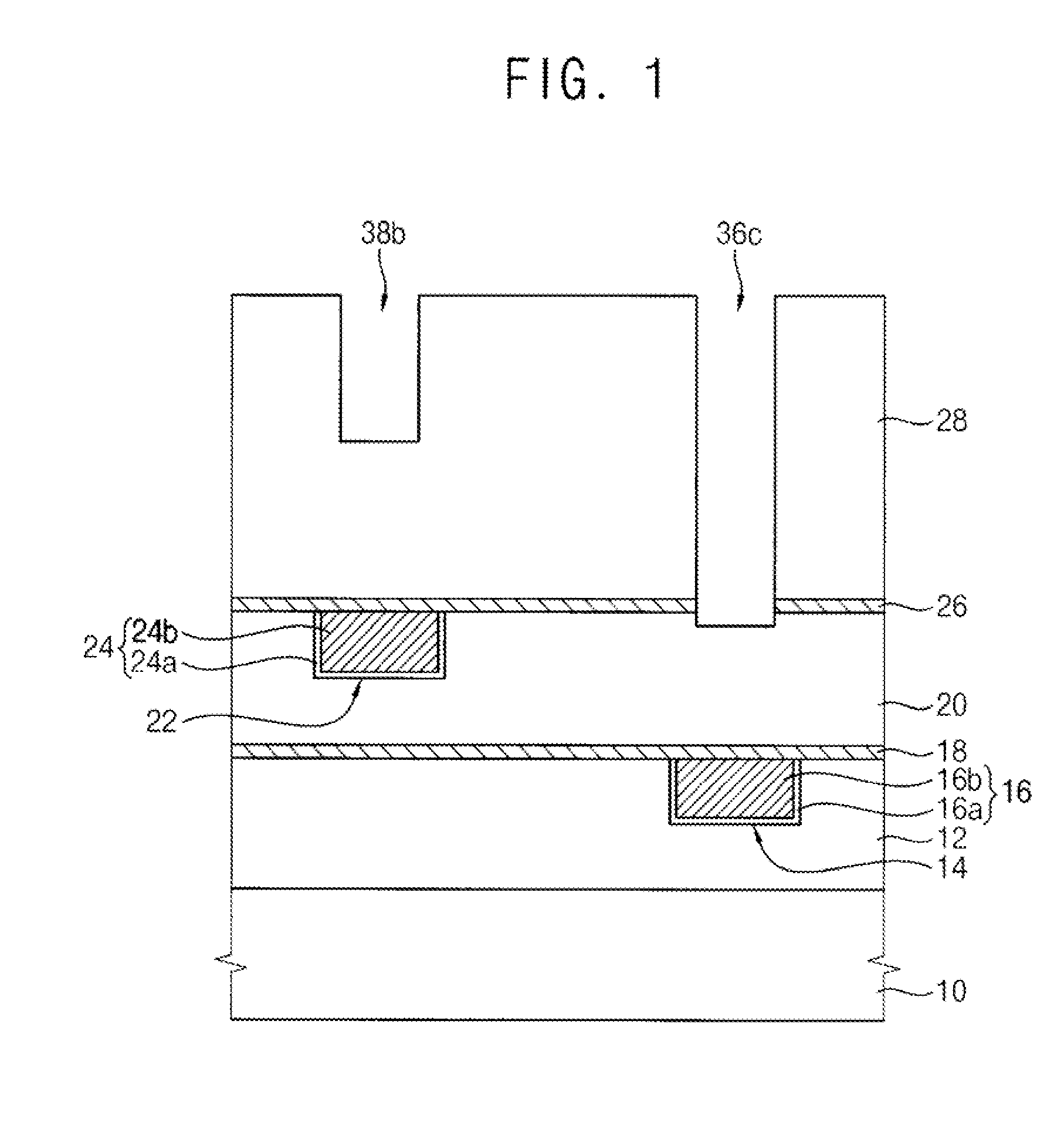

Semiconductor device and method for manufacturing the same

ActiveUS20110062502A1Reduce the possibilityReduce the likelihood of occurrenceSemiconductor/solid-state device detailsSolid-state devicesInter layerDielectric layer

The present invention proposes a method of forming a dual contact hole, comprising steps of: forming a source / drain region and a replacement gate structure on a semiconductor substrate, the replacement gate structure including a replacement gate; depositing a first inter-layer dielectric layer; planarizing the first inter-layer dielectric layer to expose the replacement gate in the replacement gate structure; removing the replacement gate and depositing to form a metal gate; etching to form a first source / drain contact opening in the first inter-layer dielectric layer; sequentially depositing a liner and filling conductive metal in the first source / drain contact opening to form a first source / drain contact hole; depositing a second inter-layer dielectric layer on the first inter-layer dielectric layer; etching to form a second source / drain contact opening and a gate contact opening in the second inter-layer dielectric layer; and sequentially depositing a liner and filling conductive metal in the second source / drain contact opening and the gate contact opening to form a second source / drain contact hole and a gate contact hole. The present invention also proposes a semiconductor device manufactured by the above process.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

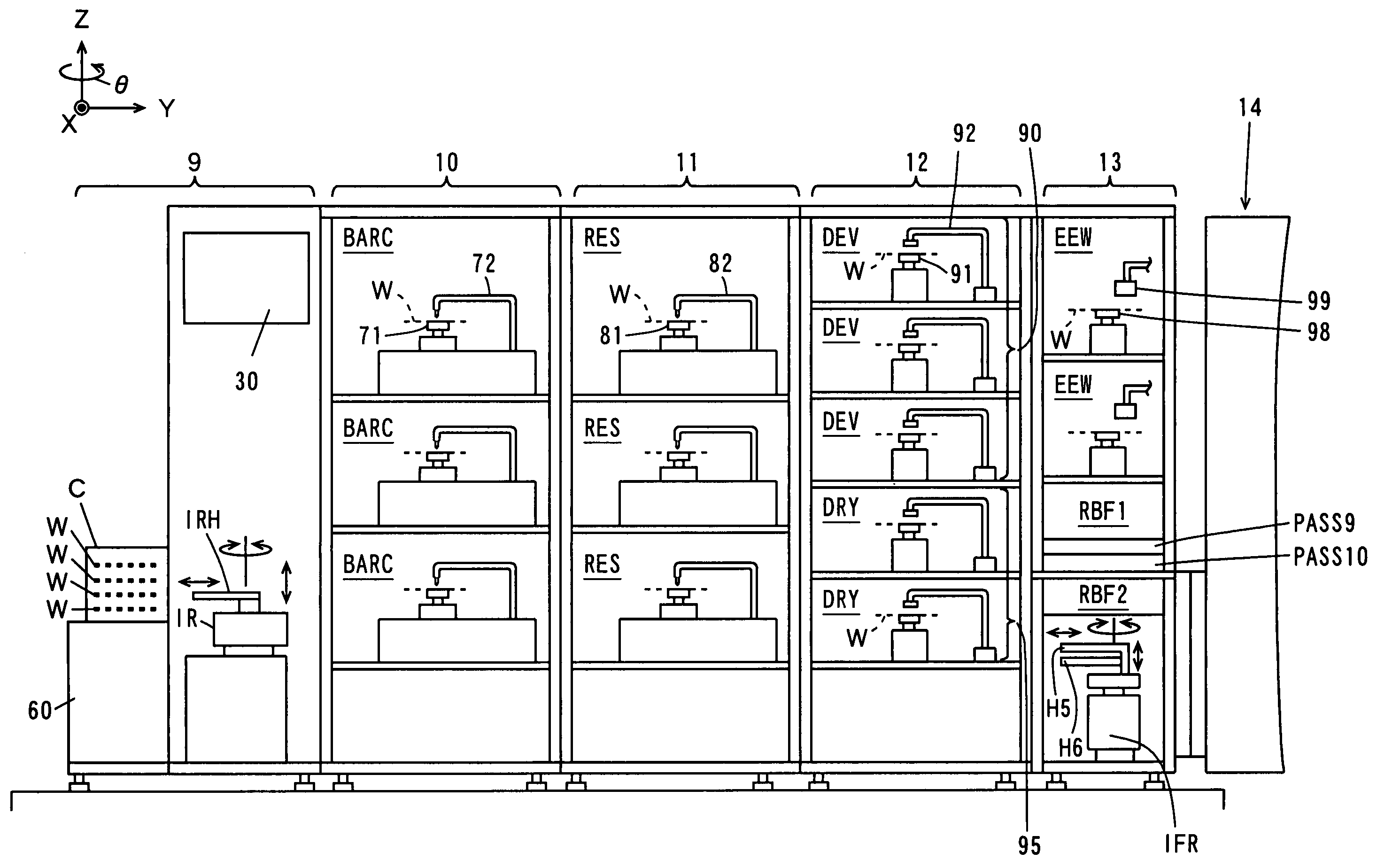

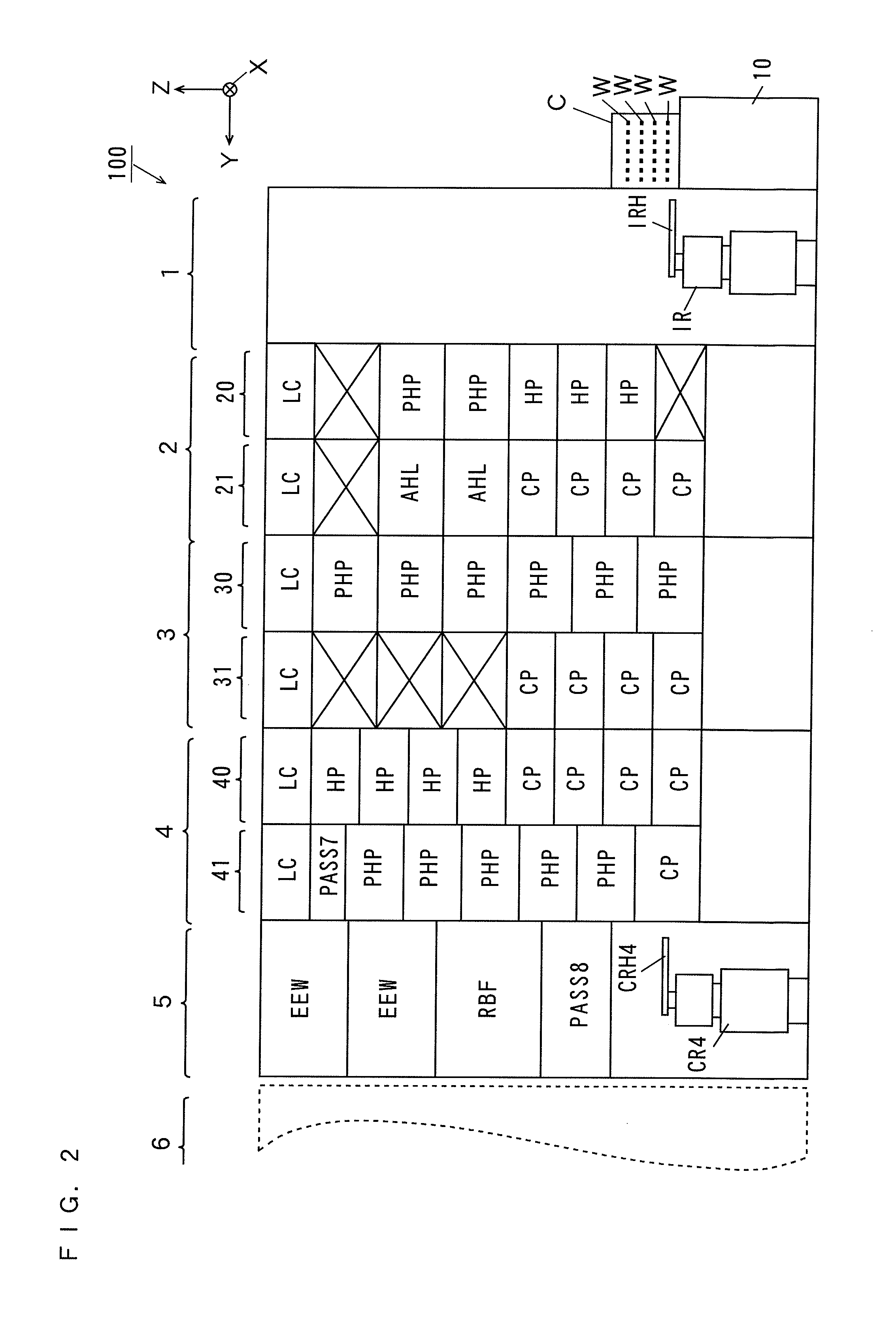

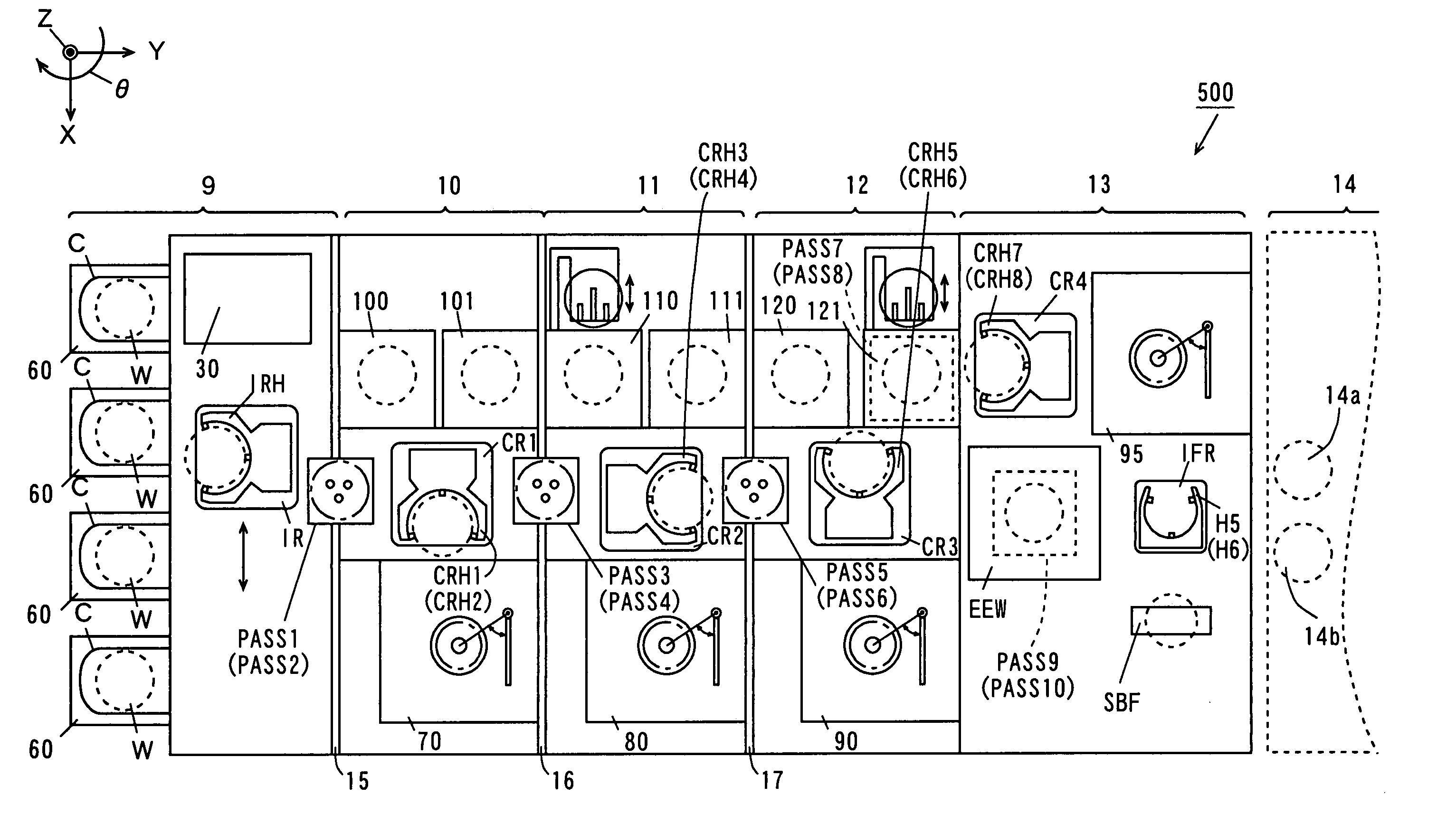

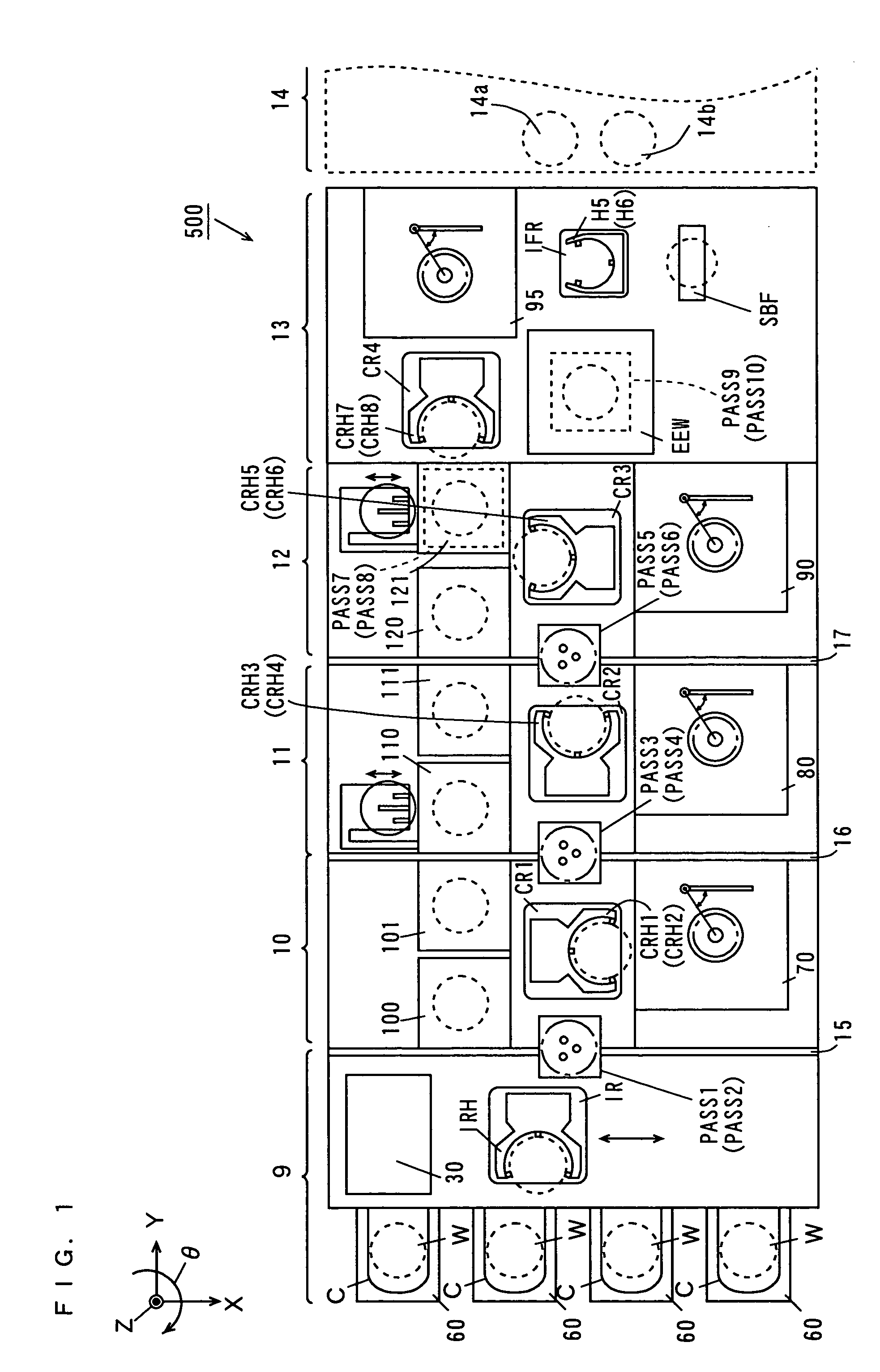

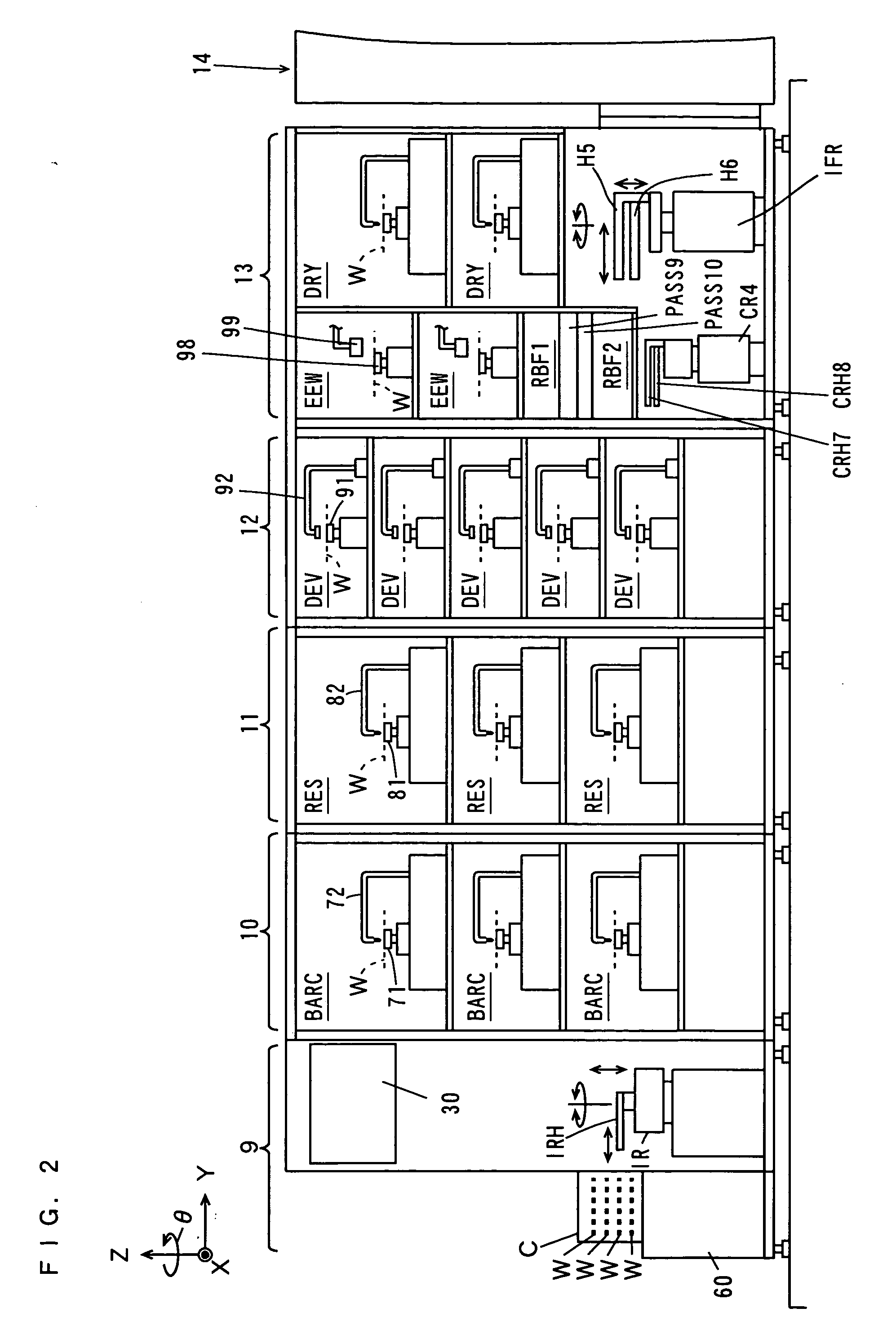

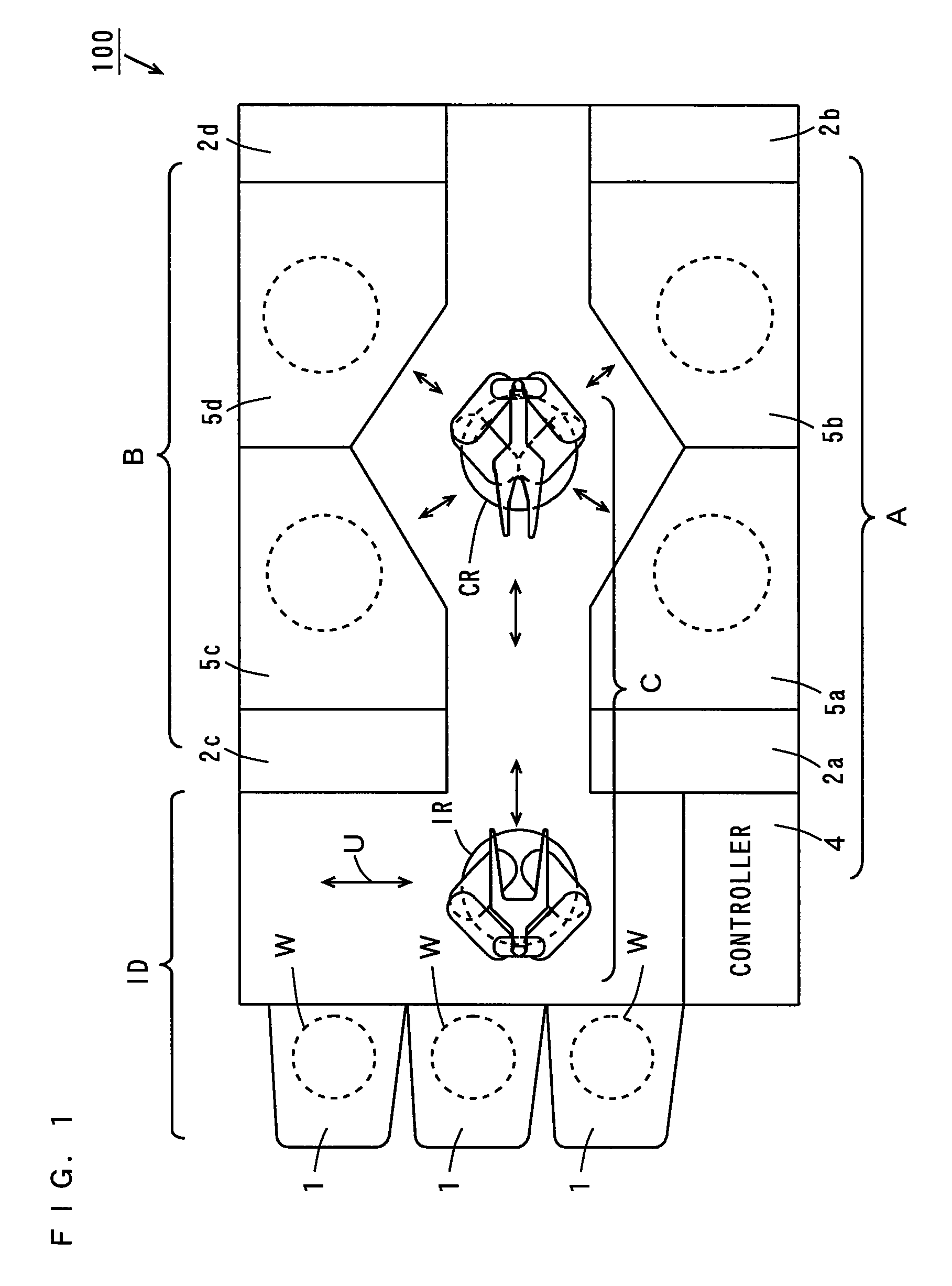

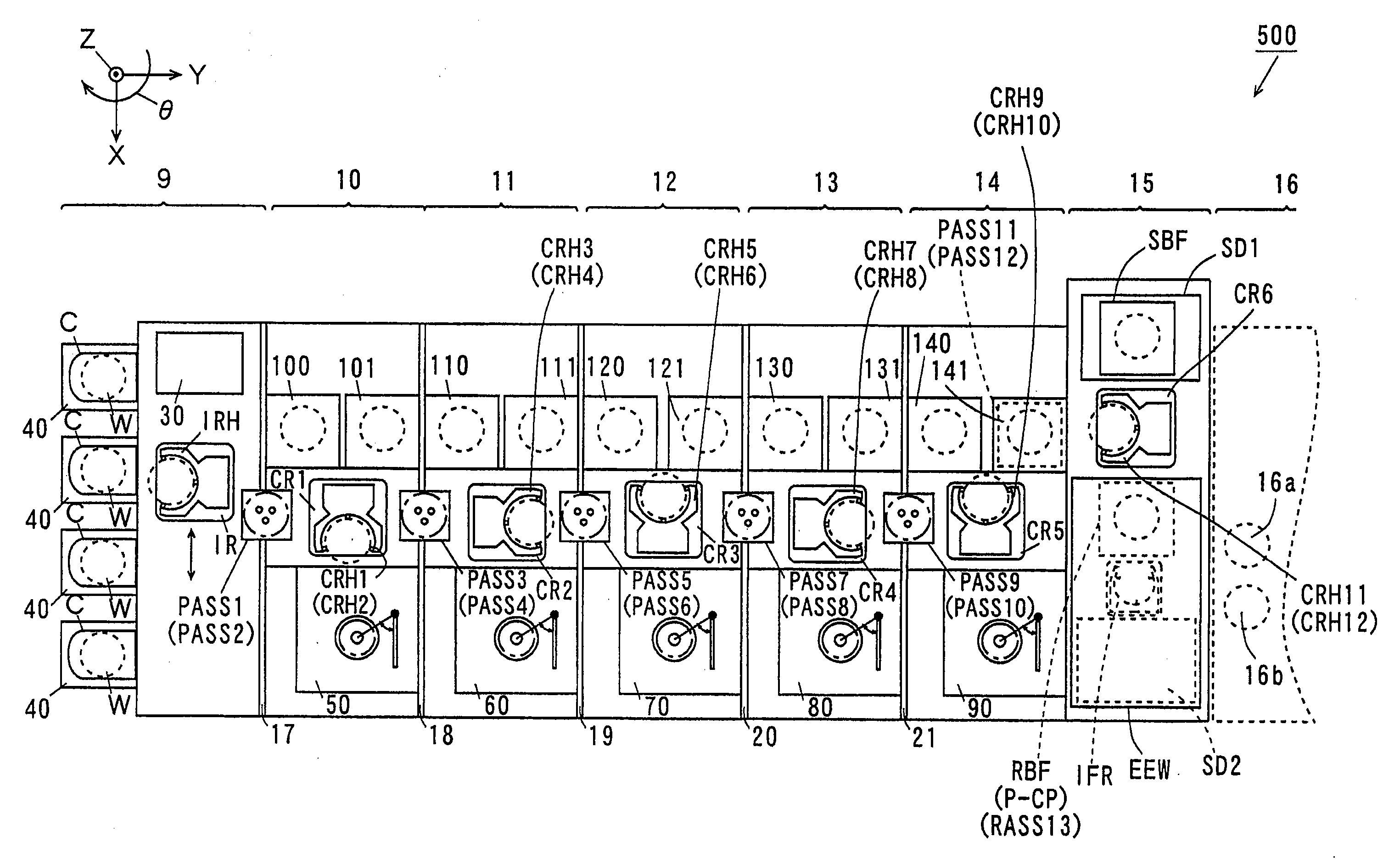

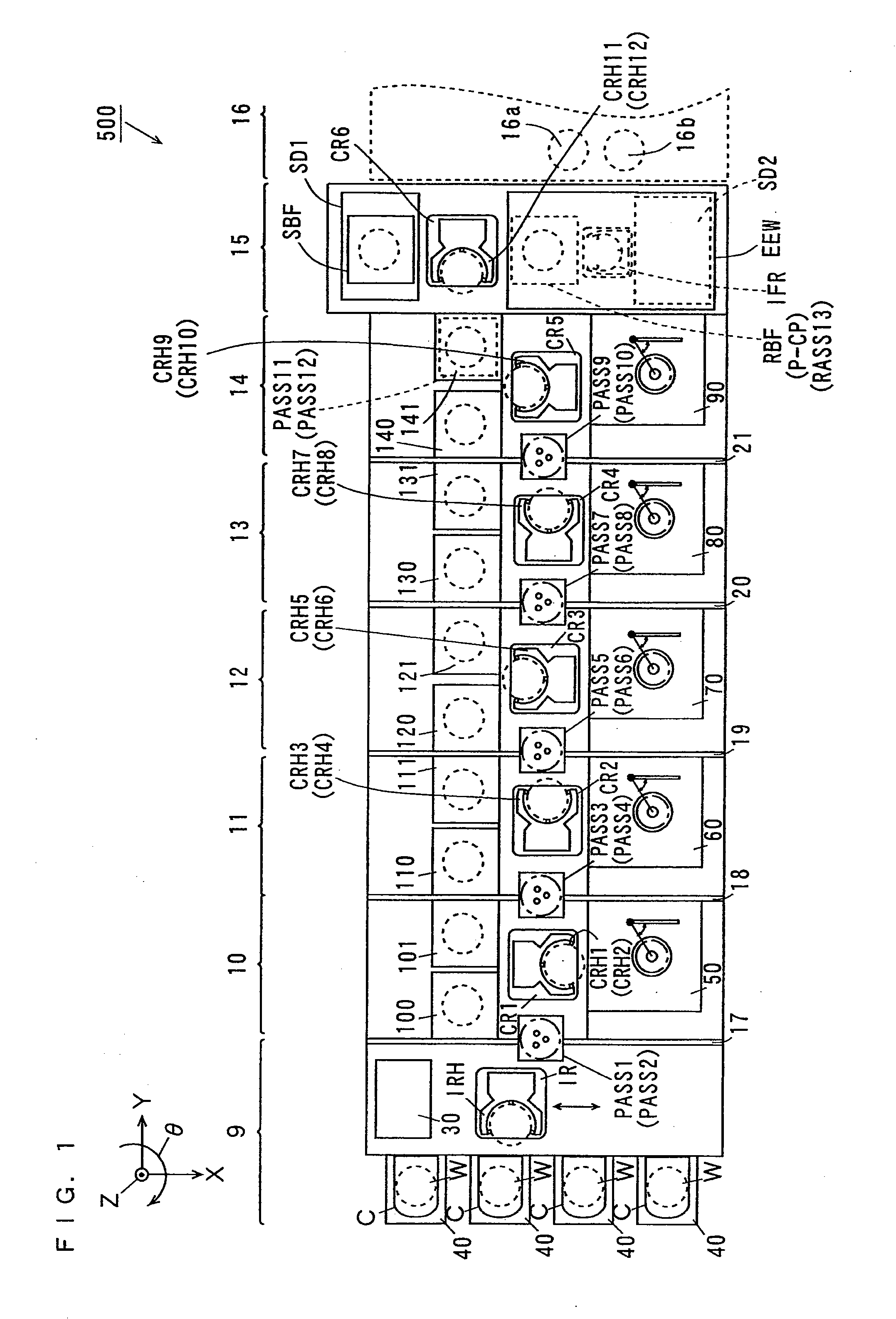

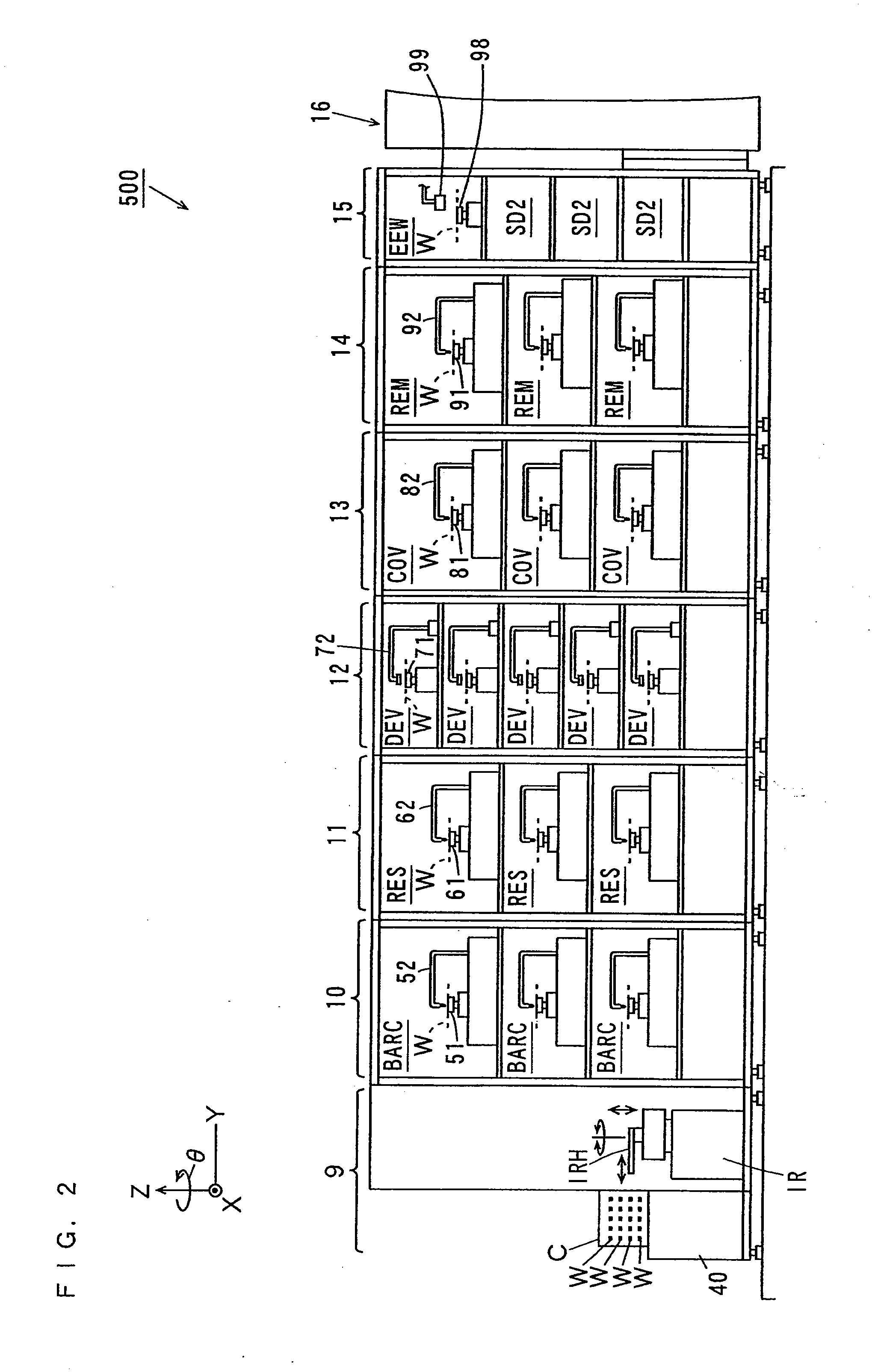

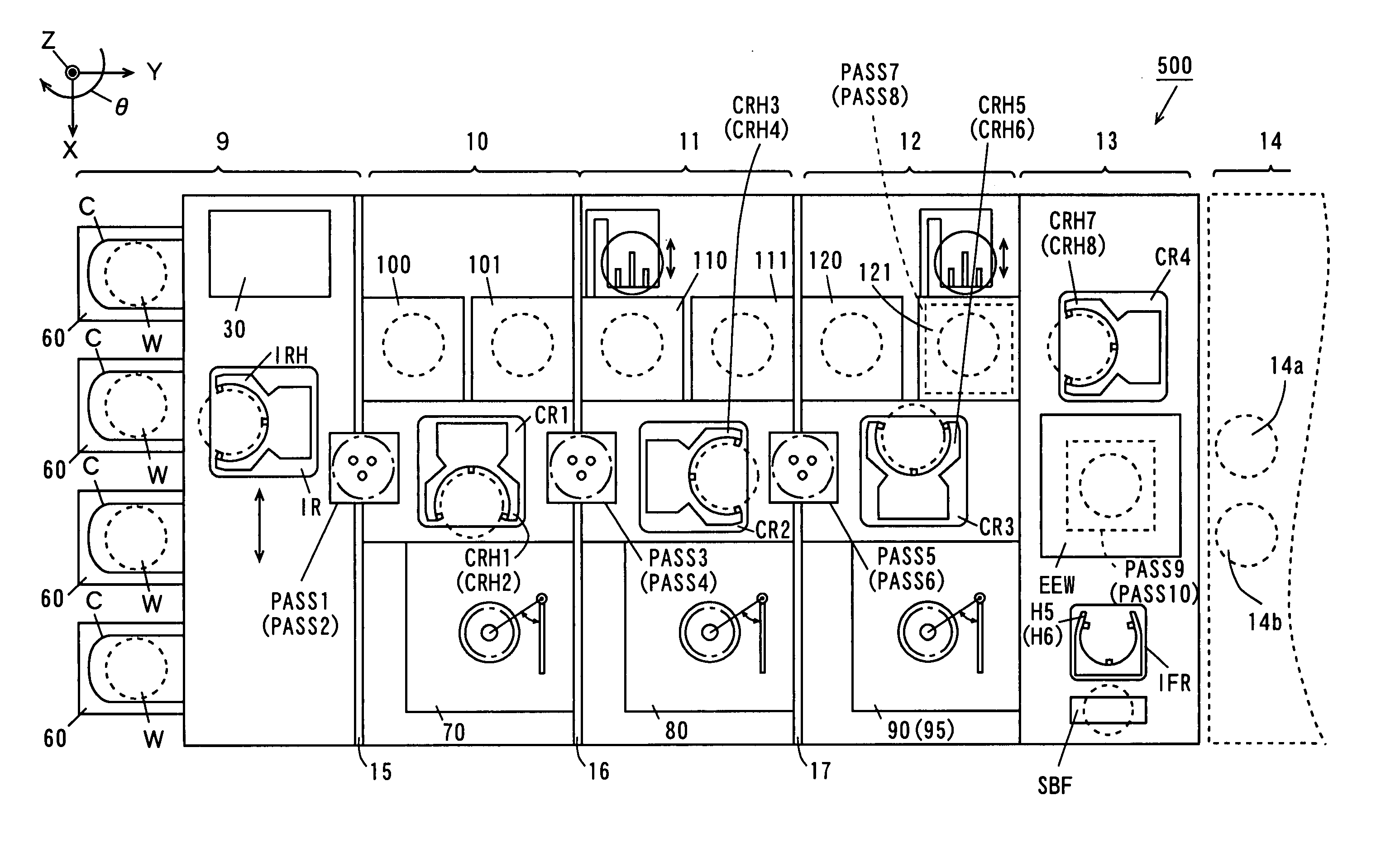

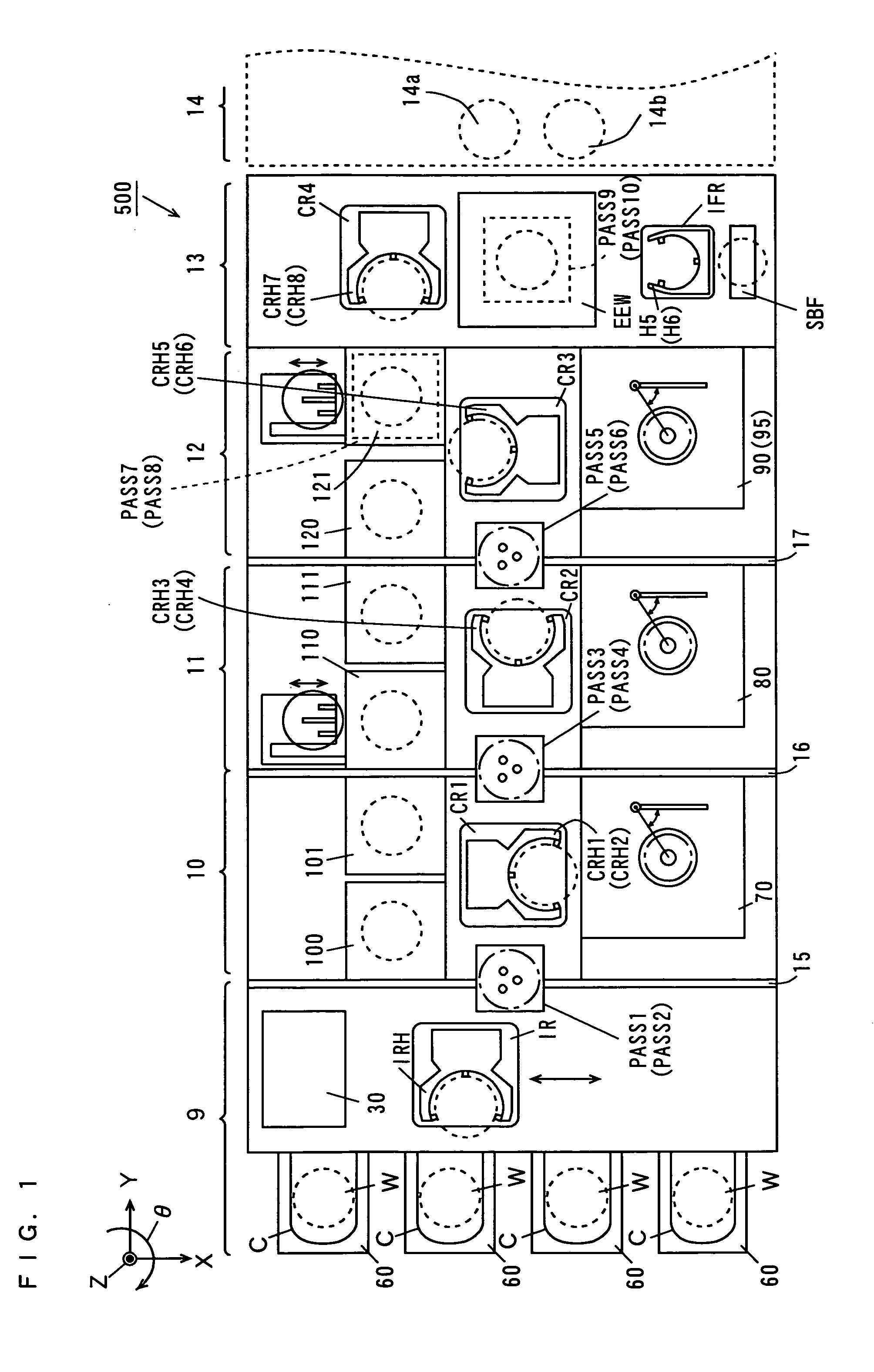

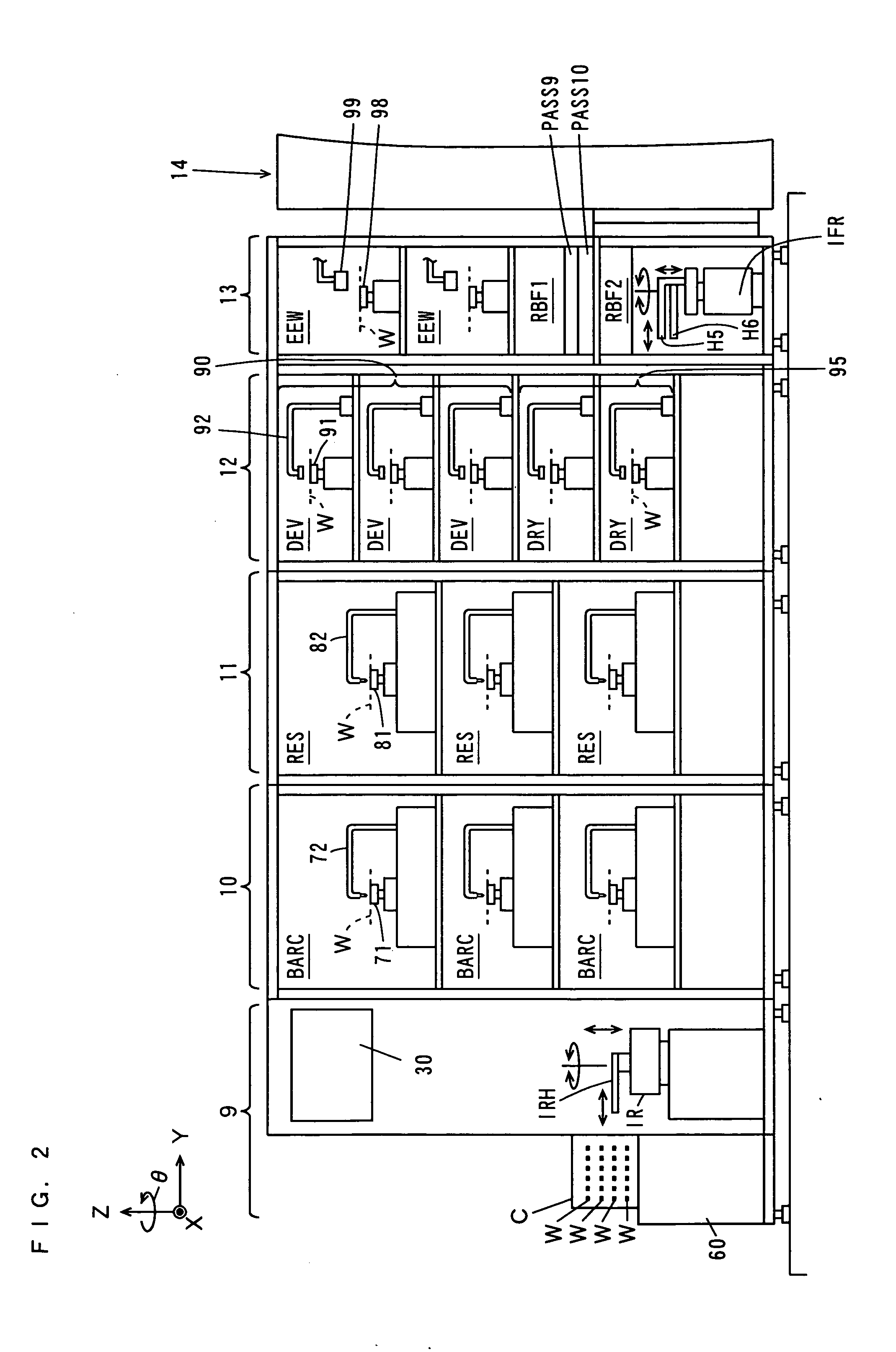

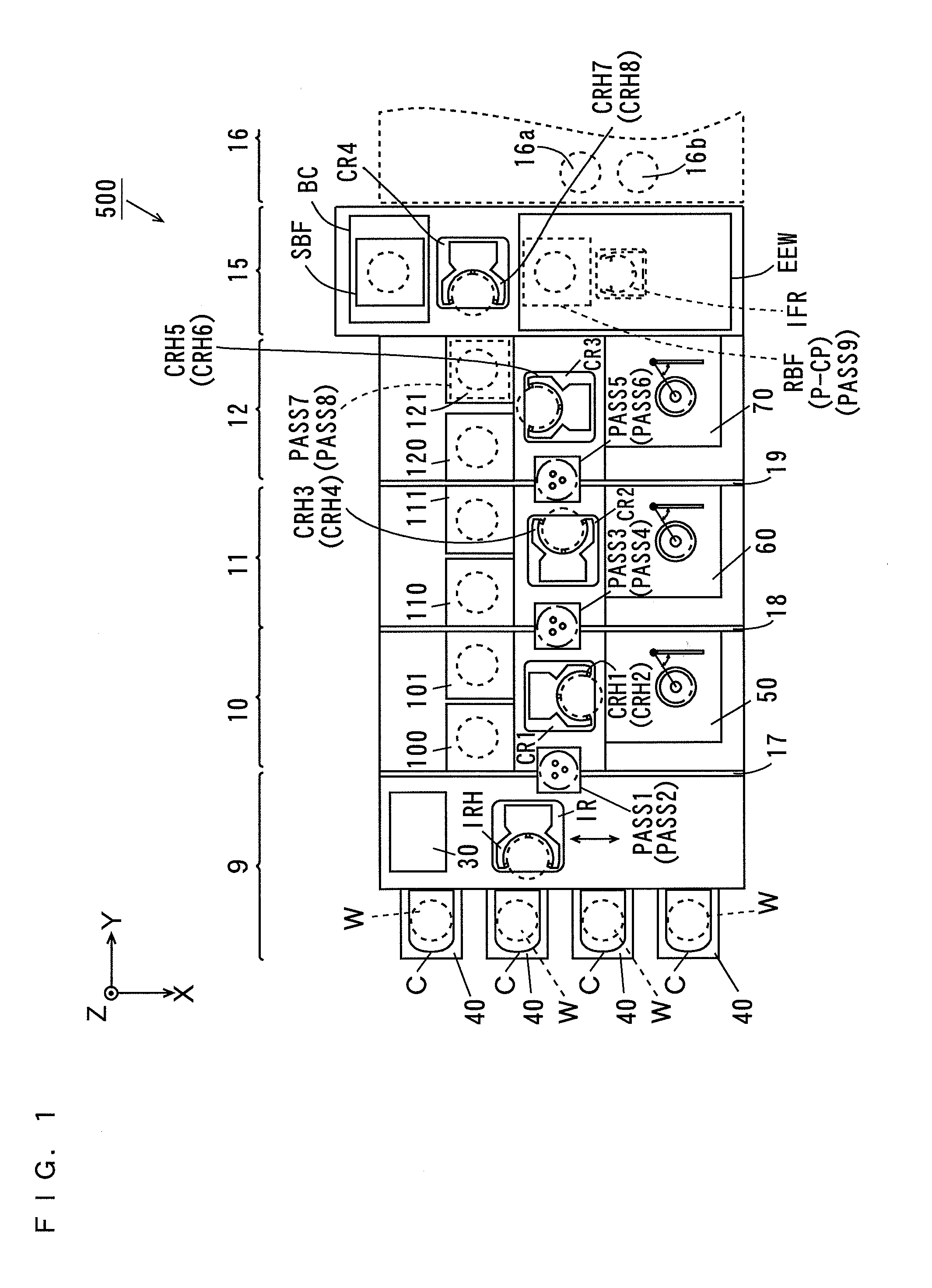

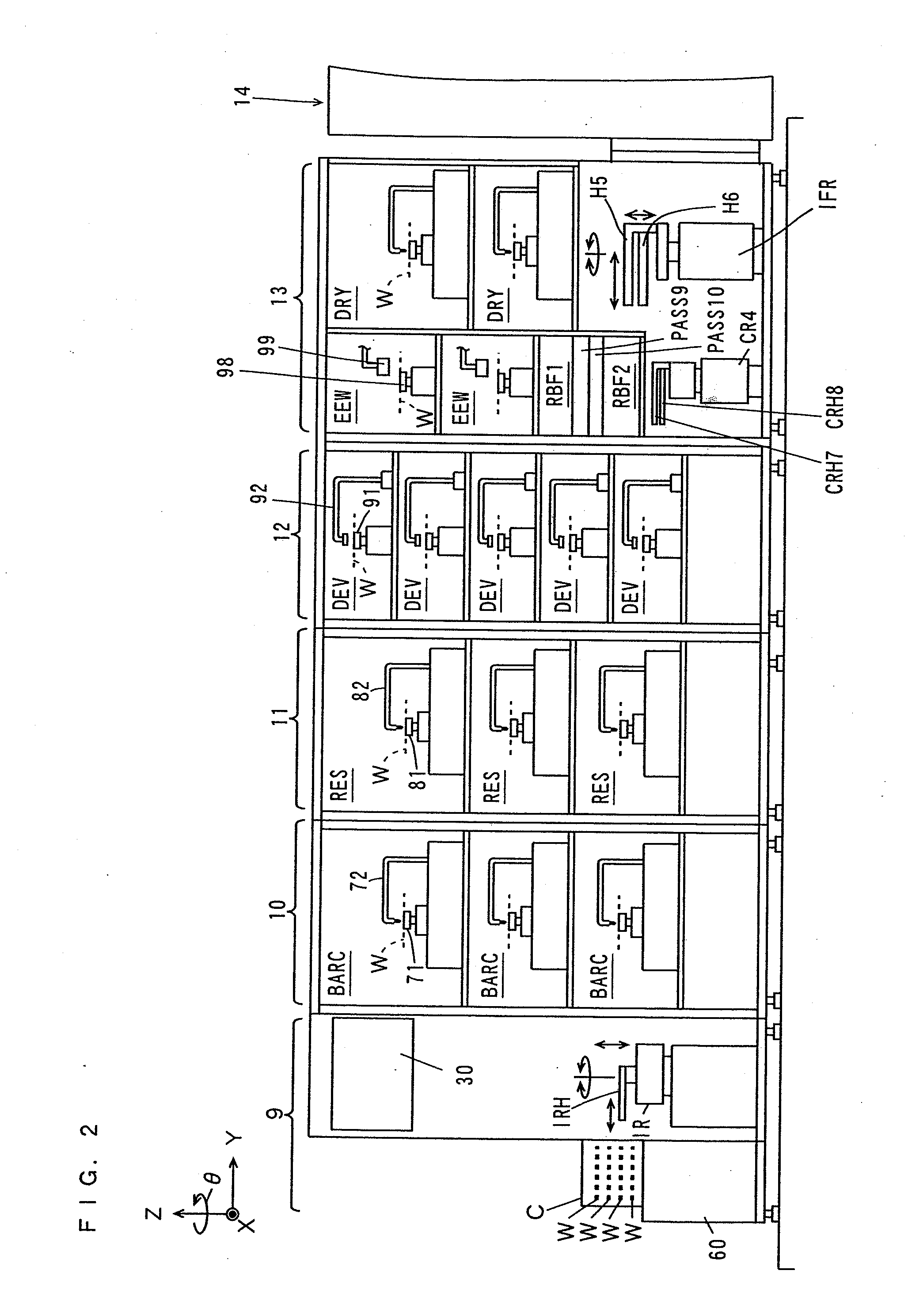

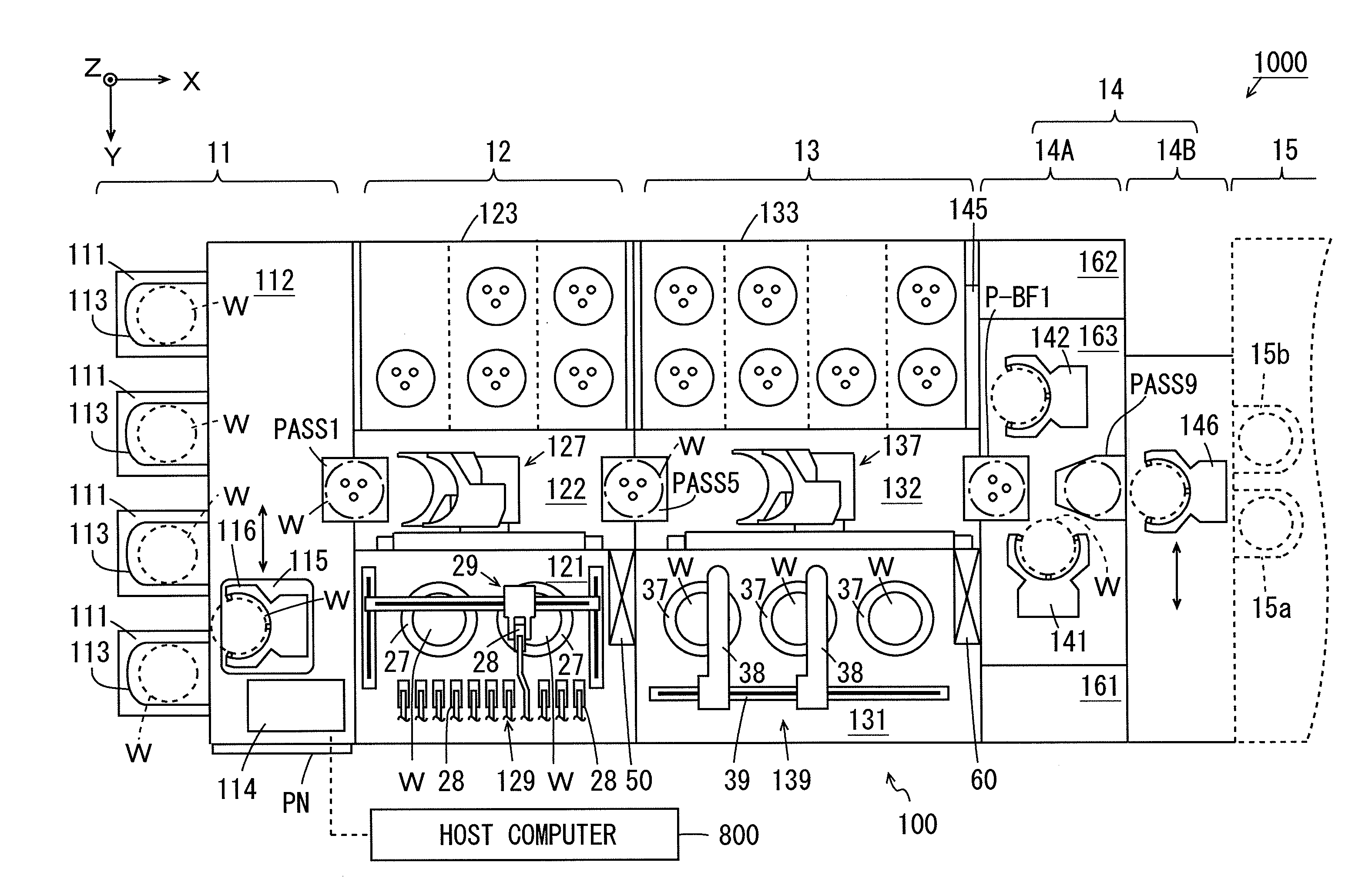

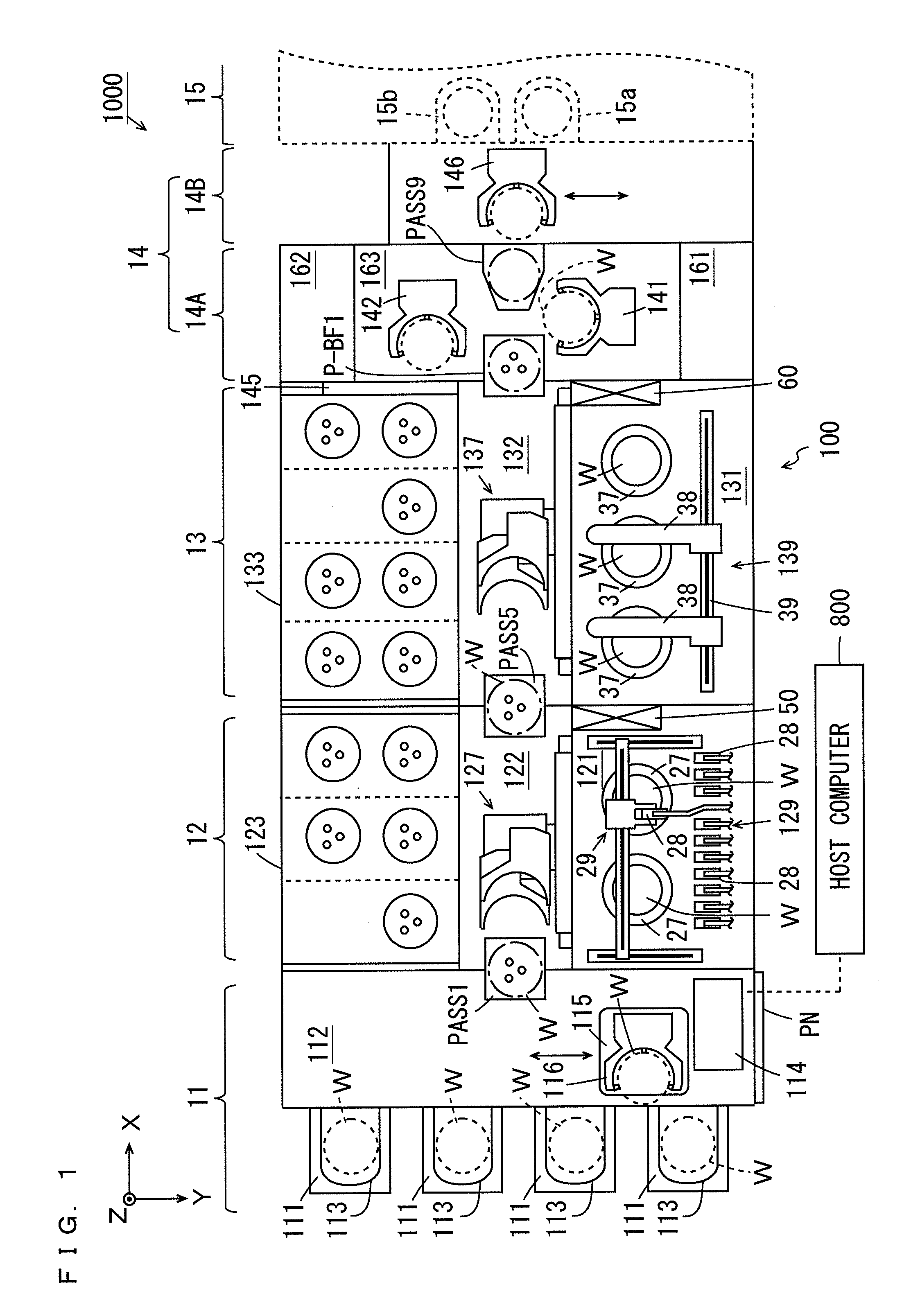

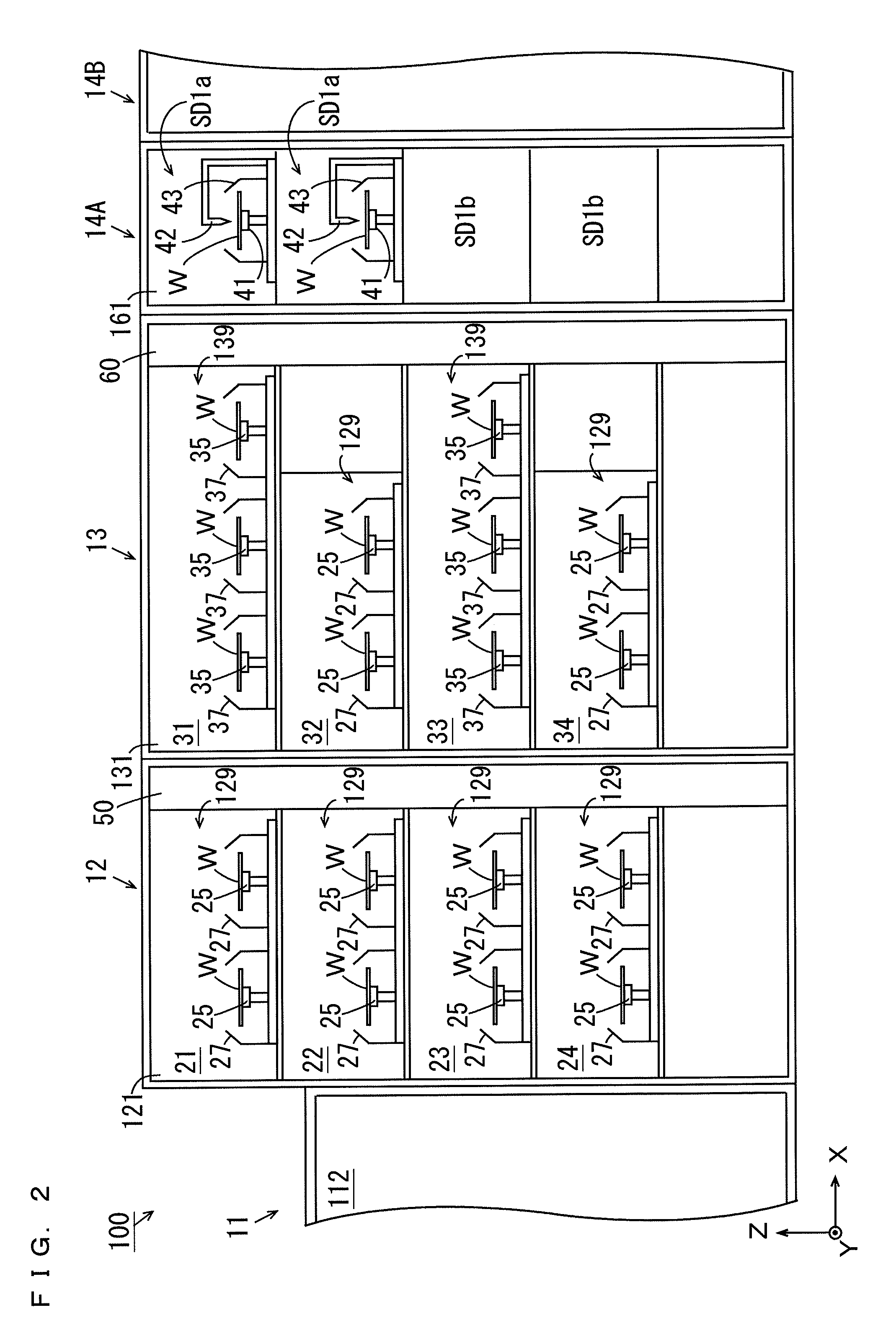

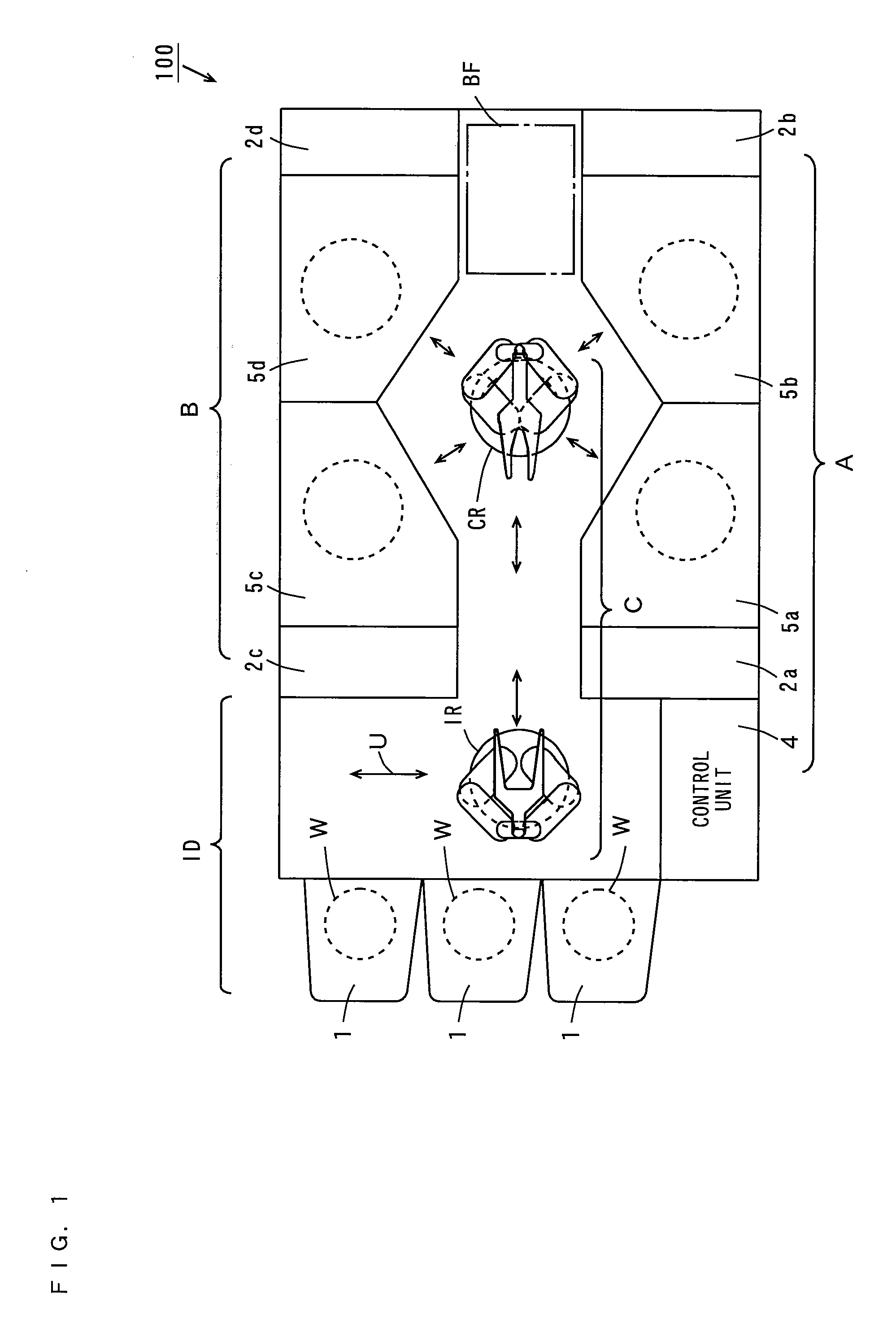

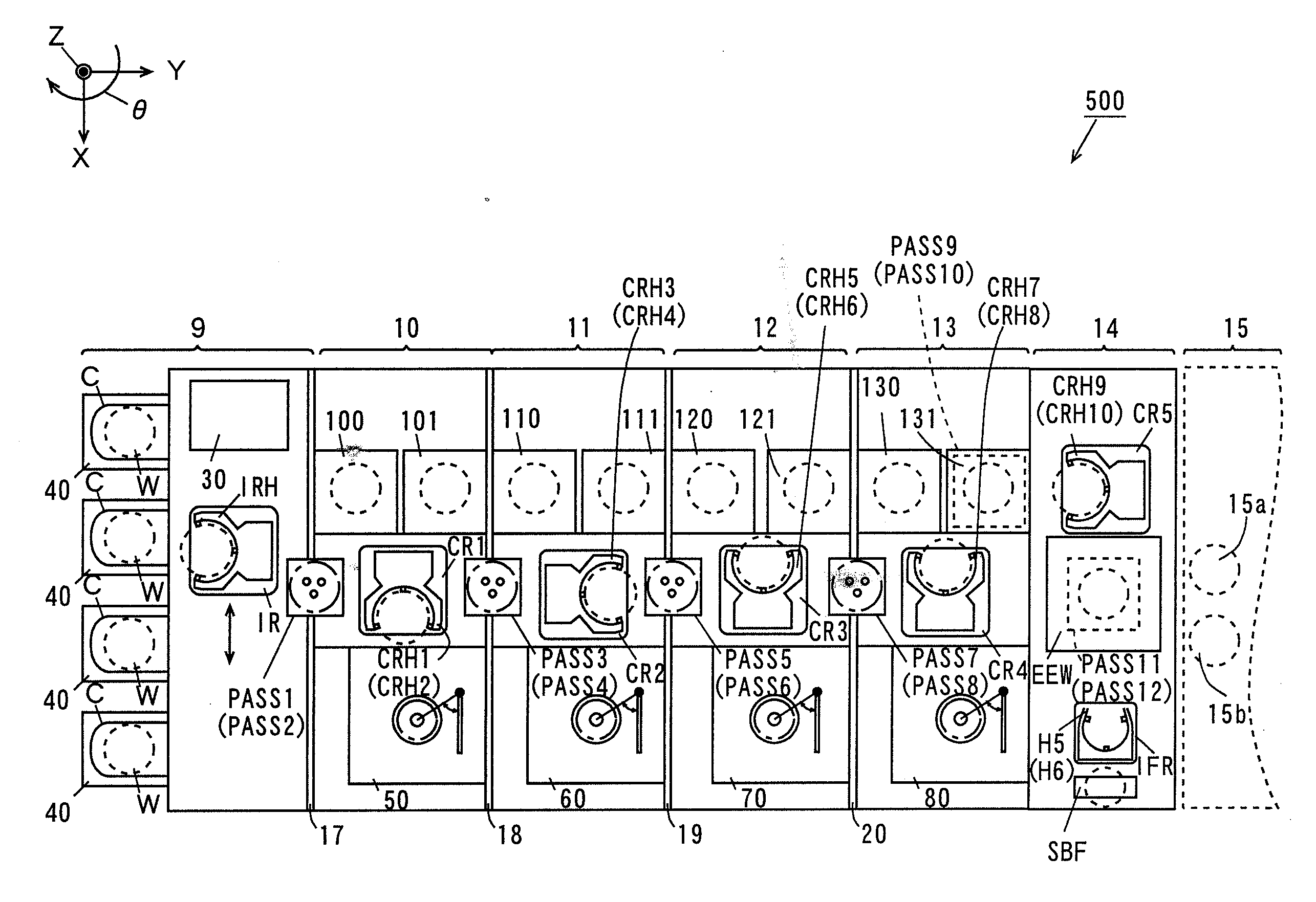

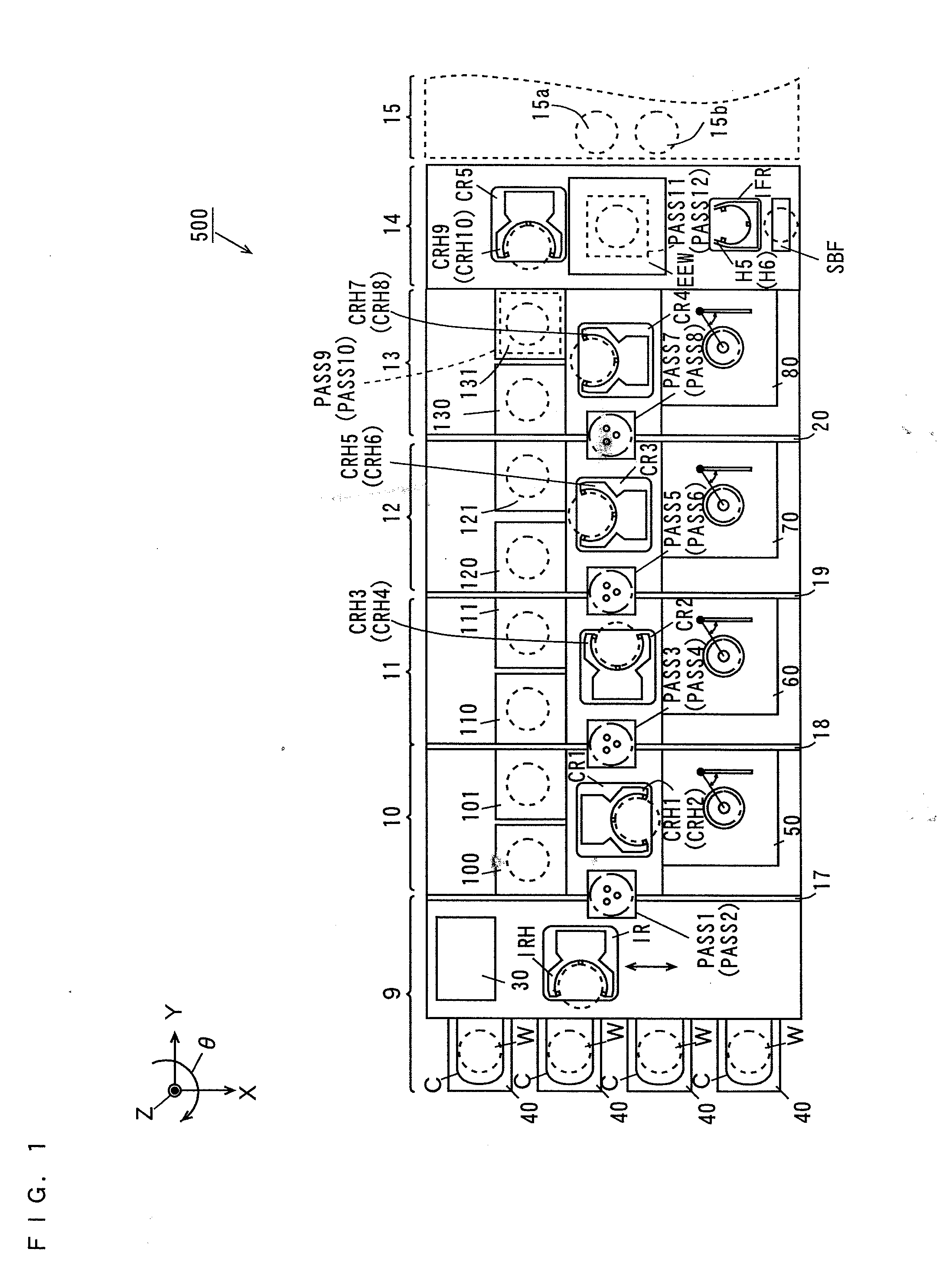

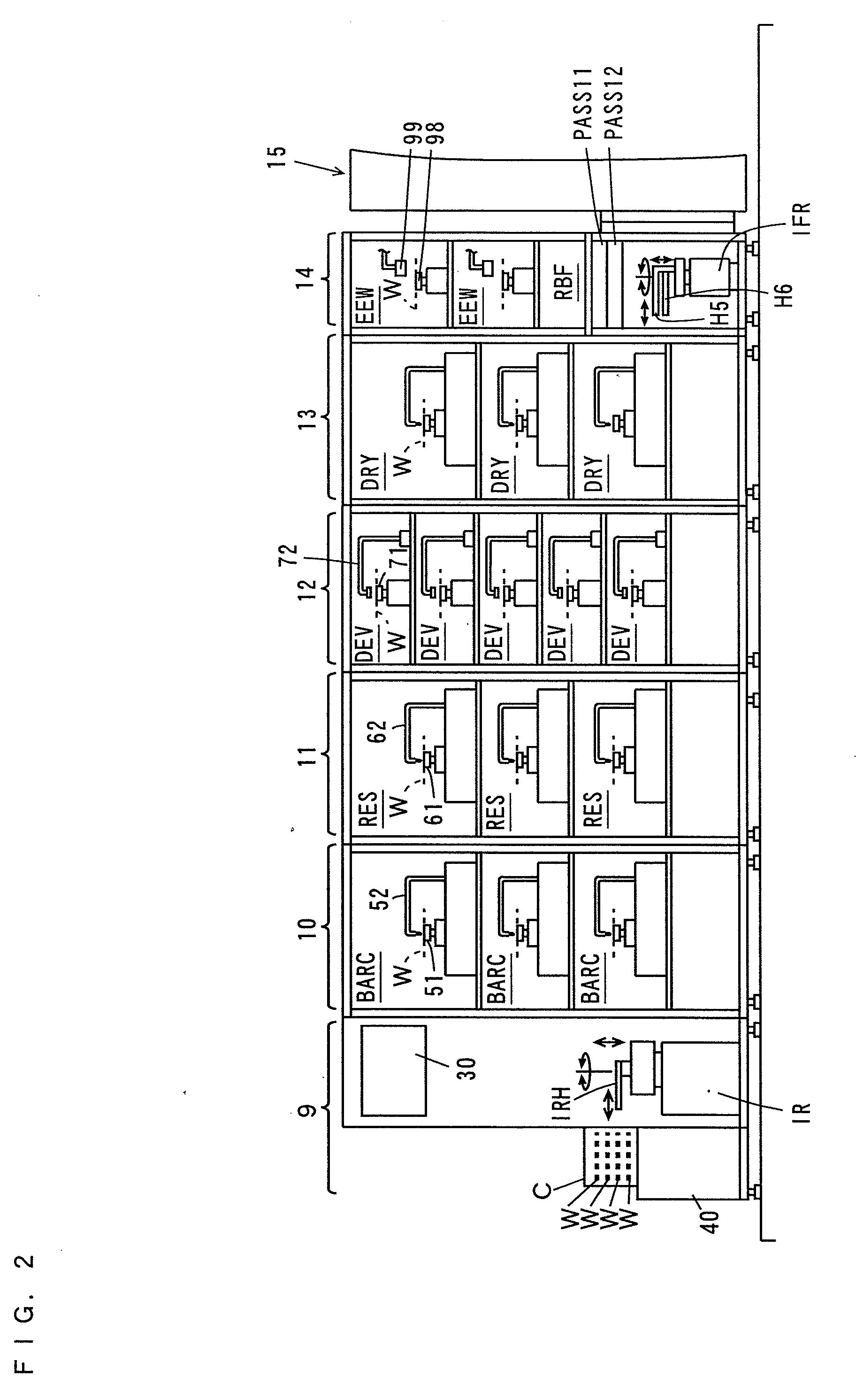

Substrate processing apparatus and substrate processing method

ActiveUS7497633B2Operation is troublesomeAvoid processing defectsLiquid surface applicatorsLiquid processingComputer science

A substrate processing apparatus comprises an indexer block, an anti-reflection film processing block, a resist film processing block, a drying / development processing block, and an interface block. An exposure device is arranged adjacent to the interface block. The drying / development processing block comprises a drying processing group. The interface block comprises an interface transport mechanism. A substrate is subjected to exposure processing by the exposure device, and subsequently transported to the drying processing group by the interface transport mechanism. The substrate is cleaned and dried by the drying processing group.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

Substrate cleaning method and substrate cleaning device

ActiveUS20120006361A1Avoid processing defectsSemiconductor/solid-state device manufacturingCleaning using liquidsSpray nozzleEngineering

A substrate rotates, and a liquid nozzle of a gas / liquid supply nozzle moves to a position above the center of the rotating substrate. In this state, a rinse liquid is discharged from the liquid nozzle onto the rotating substrate. The gas / liquid supply nozzle moves toward a position outside the substrate. A gas nozzle reaches the position above the center of the rotating substrate, so that the gas / liquid supply nozzle temporarily stops. With the gas / liquid supply nozzle stopping, an inert gas is discharged onto the center of the rotating substrate for a given period of time. After that, the gas / liquid supply nozzle again moves toward the position outside the substrate.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

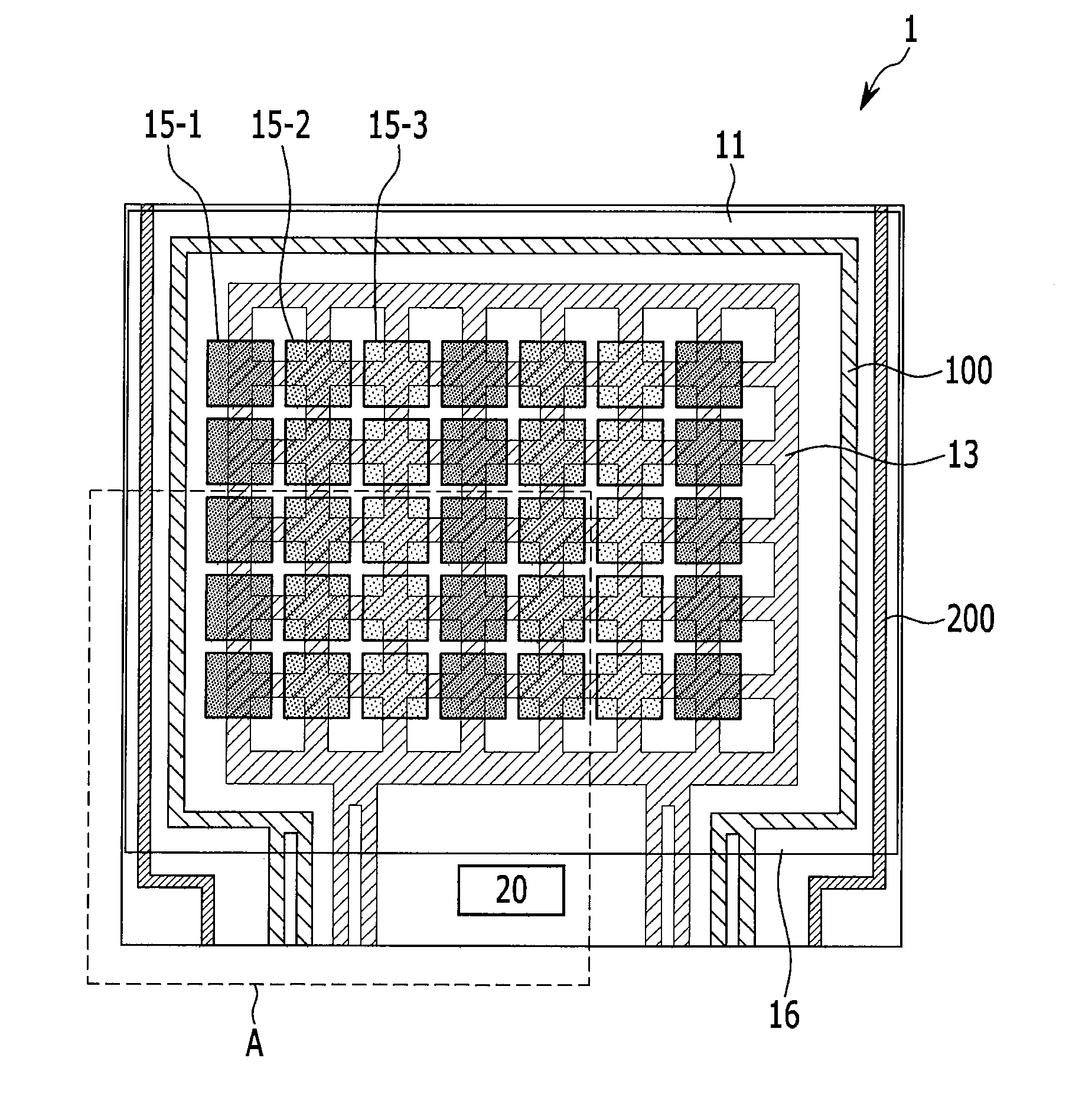

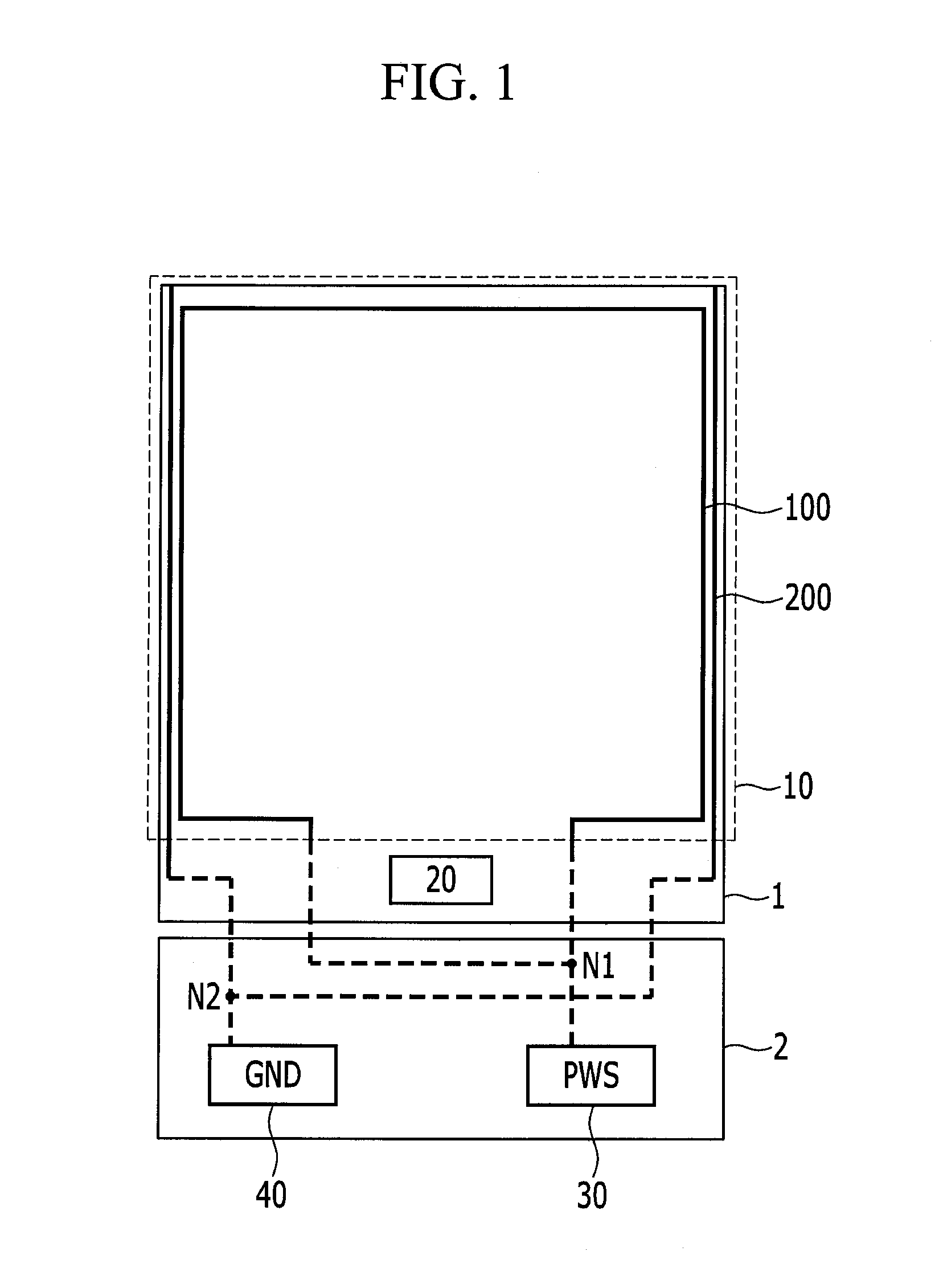

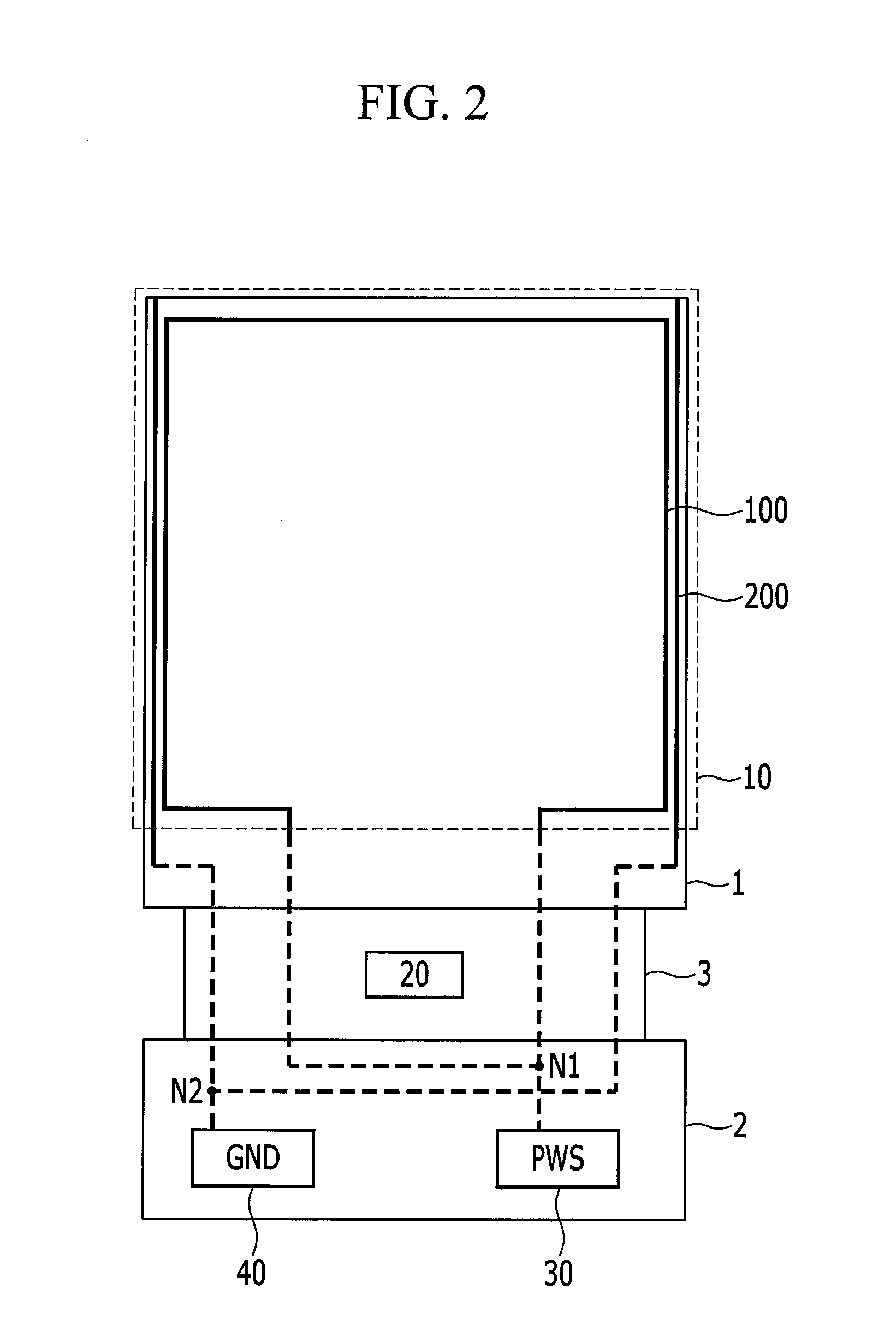

Display panel for preventing static electricity, method for manufacturing the same, and display device including the display panel for preventing static electricity

InactiveUS20140001966A1Efficiency reduce and eliminateExcellent qualitySparking plugsStatic indicating devicesEngineeringDisplay device

A display panel, a manufacturing method of the display panel, and a display device including the display panel are provided. The display panel includes: a substrate; a display unit on the substrate and including a plurality of pixels for displaying an image according to a video signal; a power supply wire on the substrate, coupled to the plurality of pixels, and configured to transmit a driving voltage for driving the plurality of pixels; and a dummy wire on the substrate, separated from the display unit and the power supply wire, and coupled to a ground electrode or a power supply unit for supplying the driving voltage.

Owner:SAMSUNG DISPLAY CO LTD

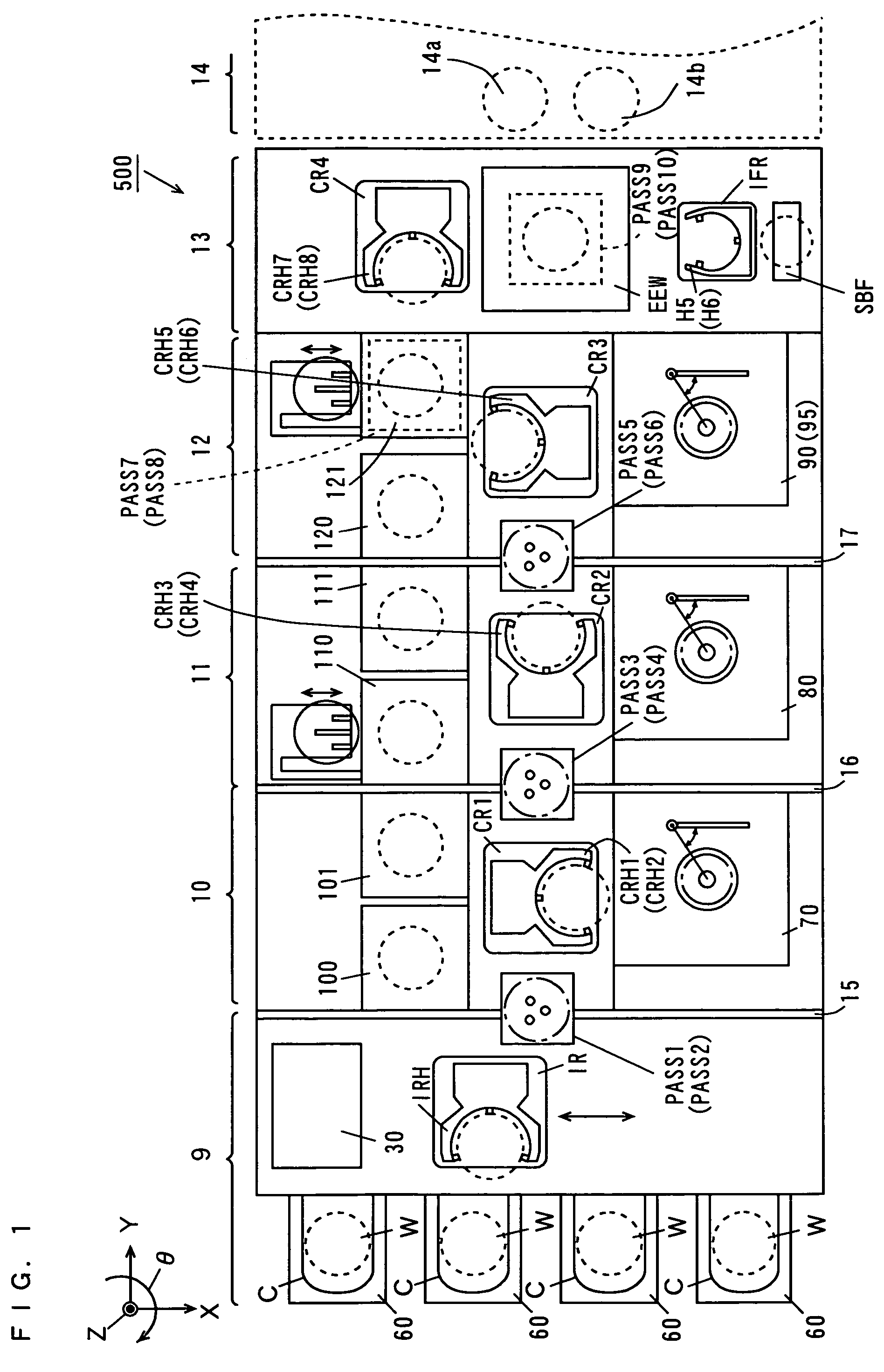

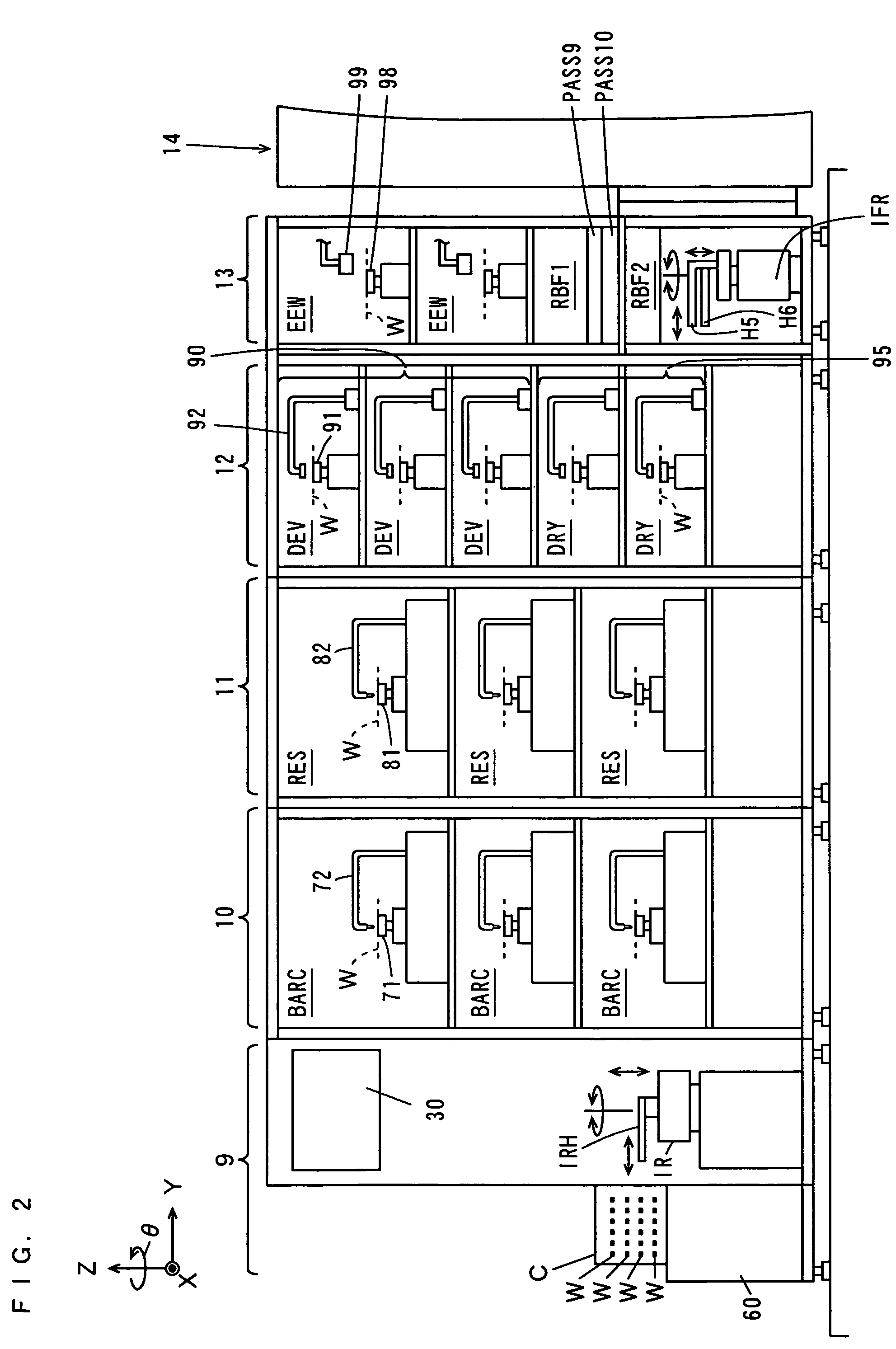

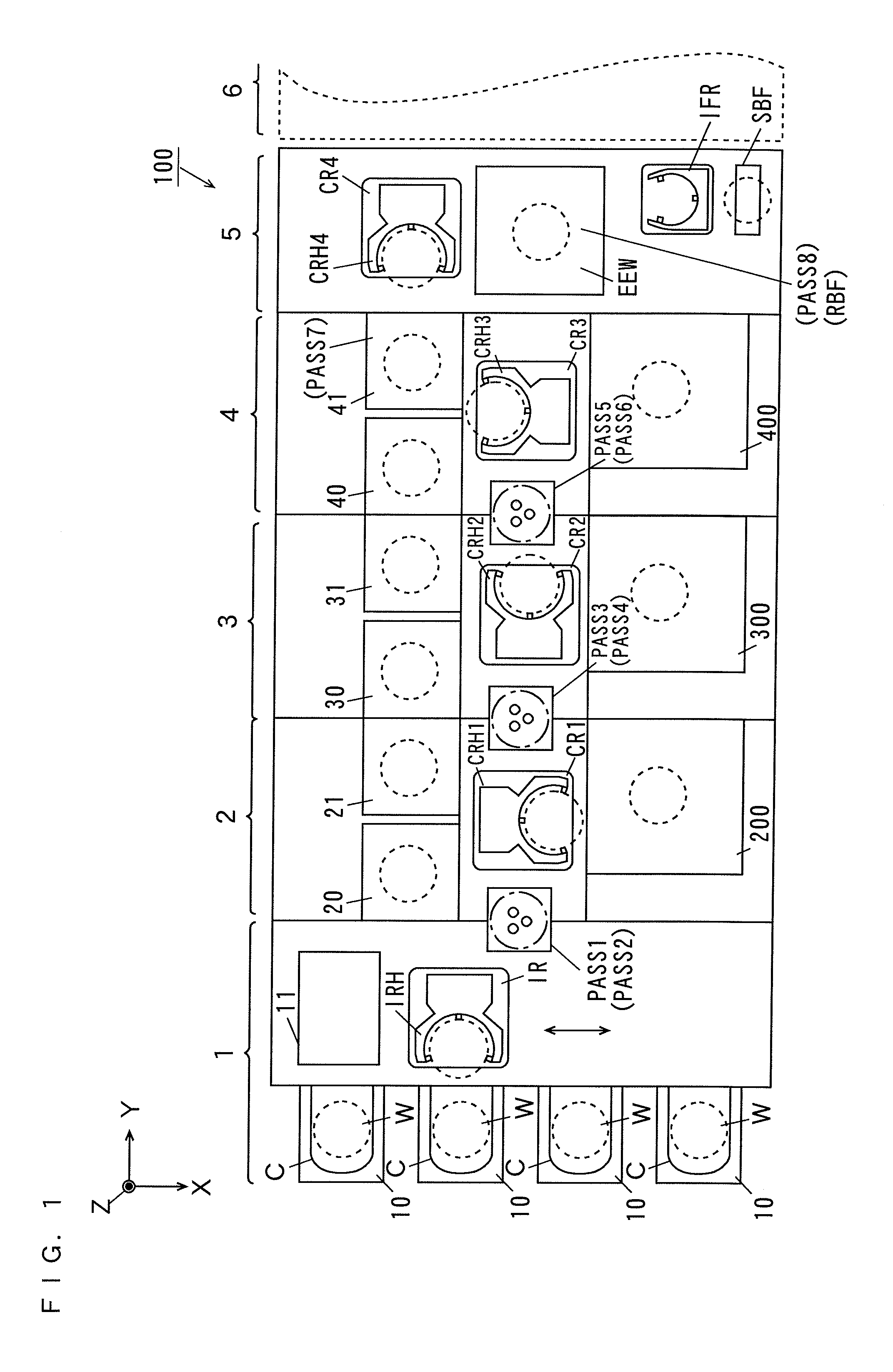

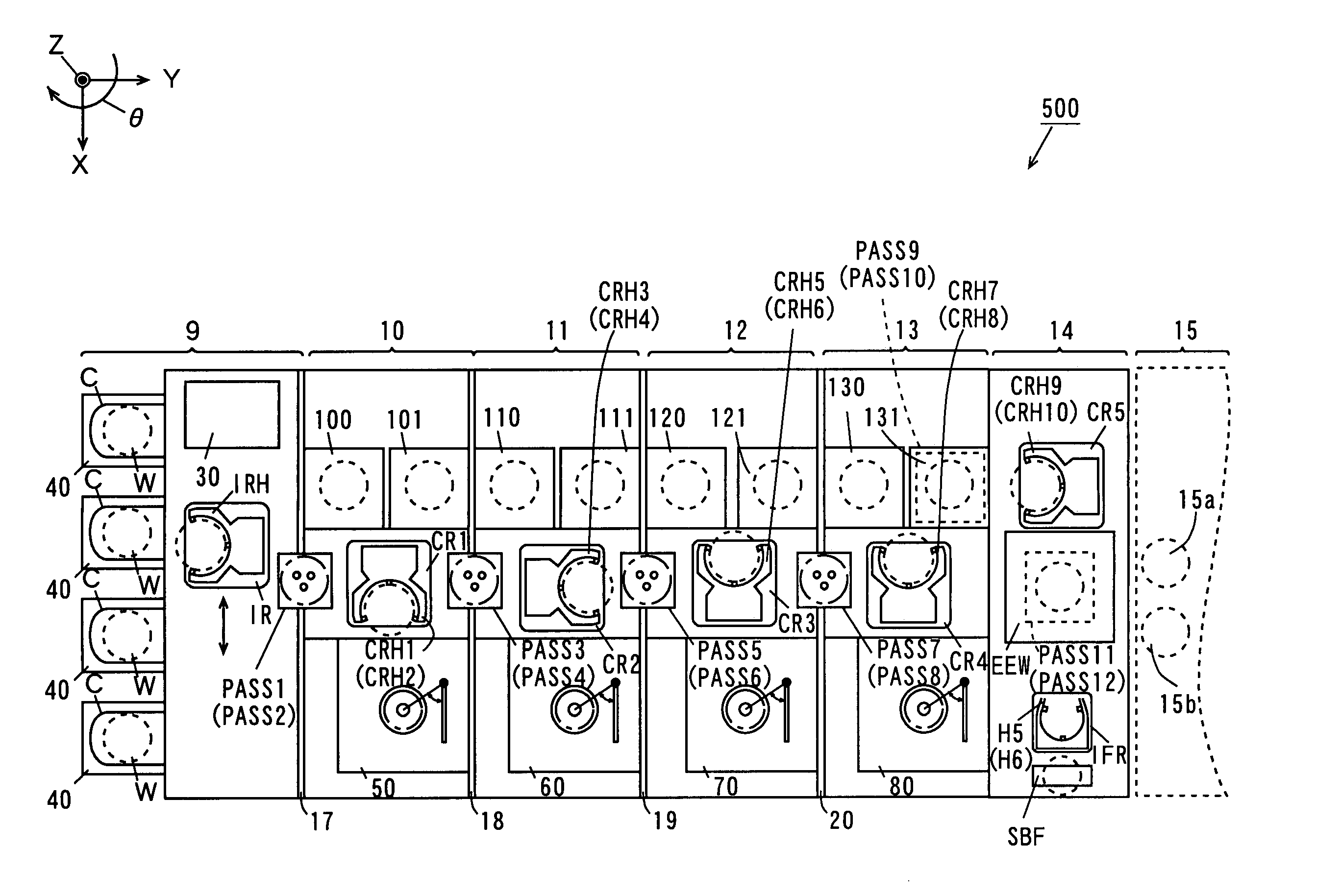

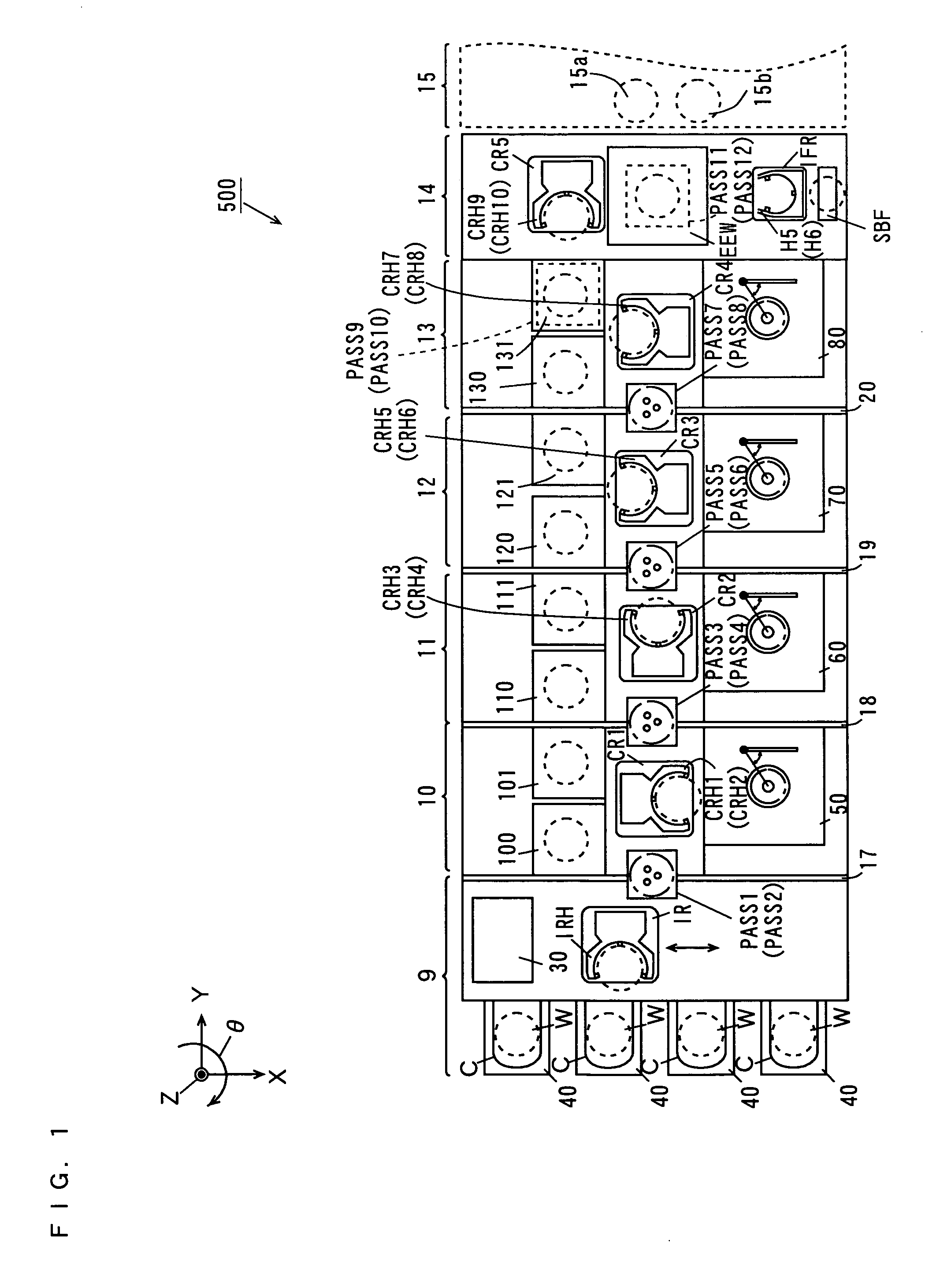

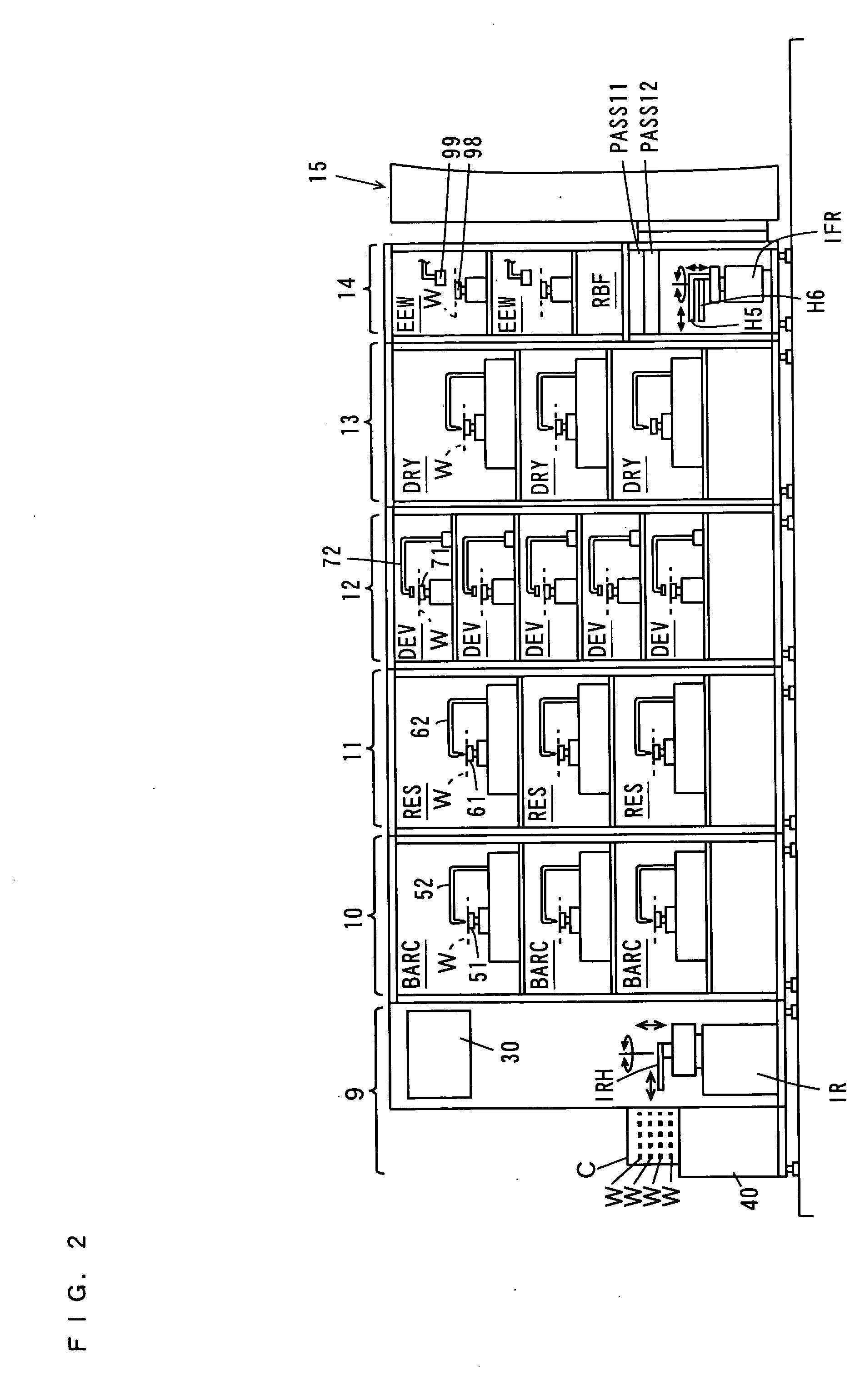

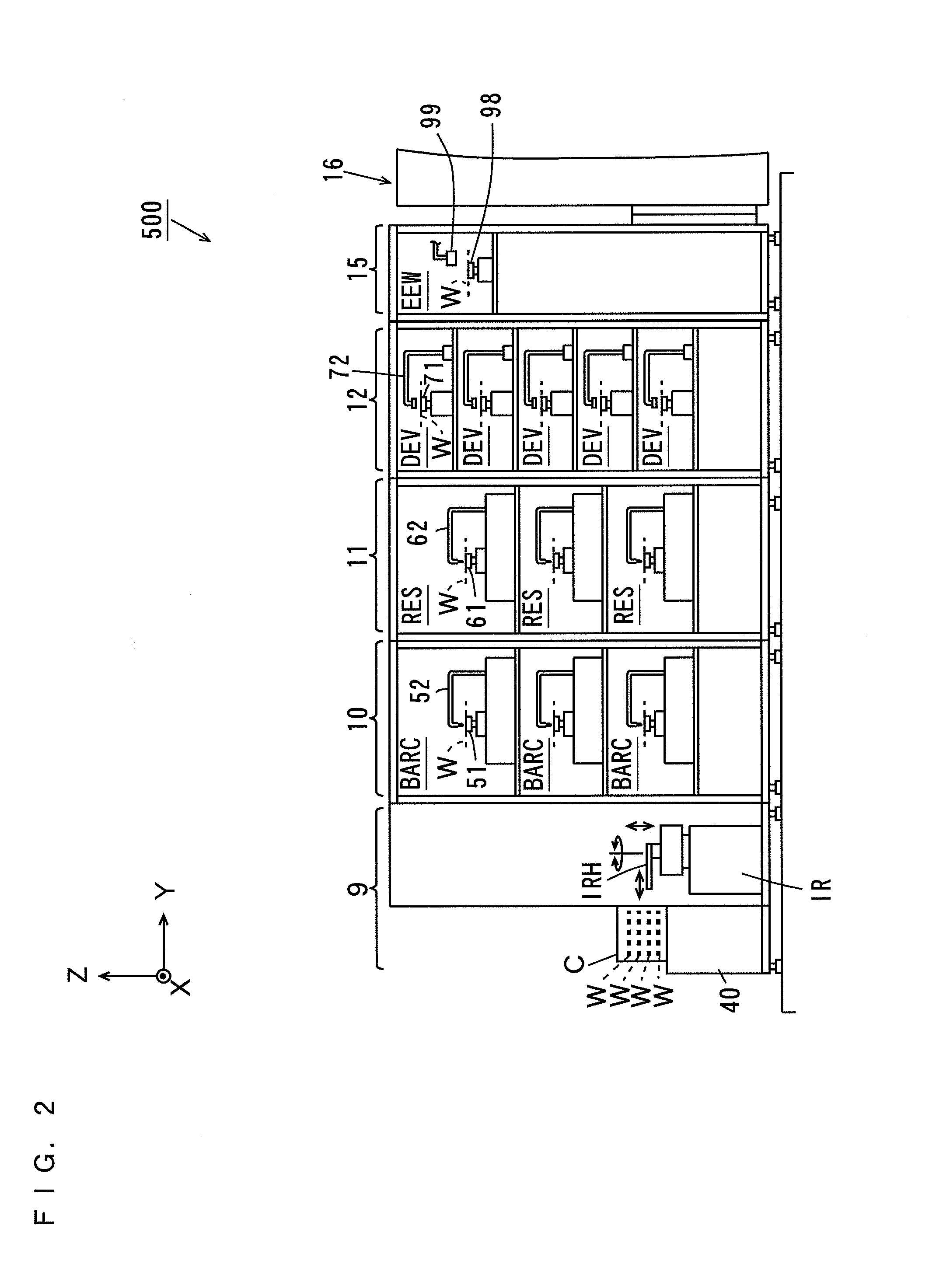

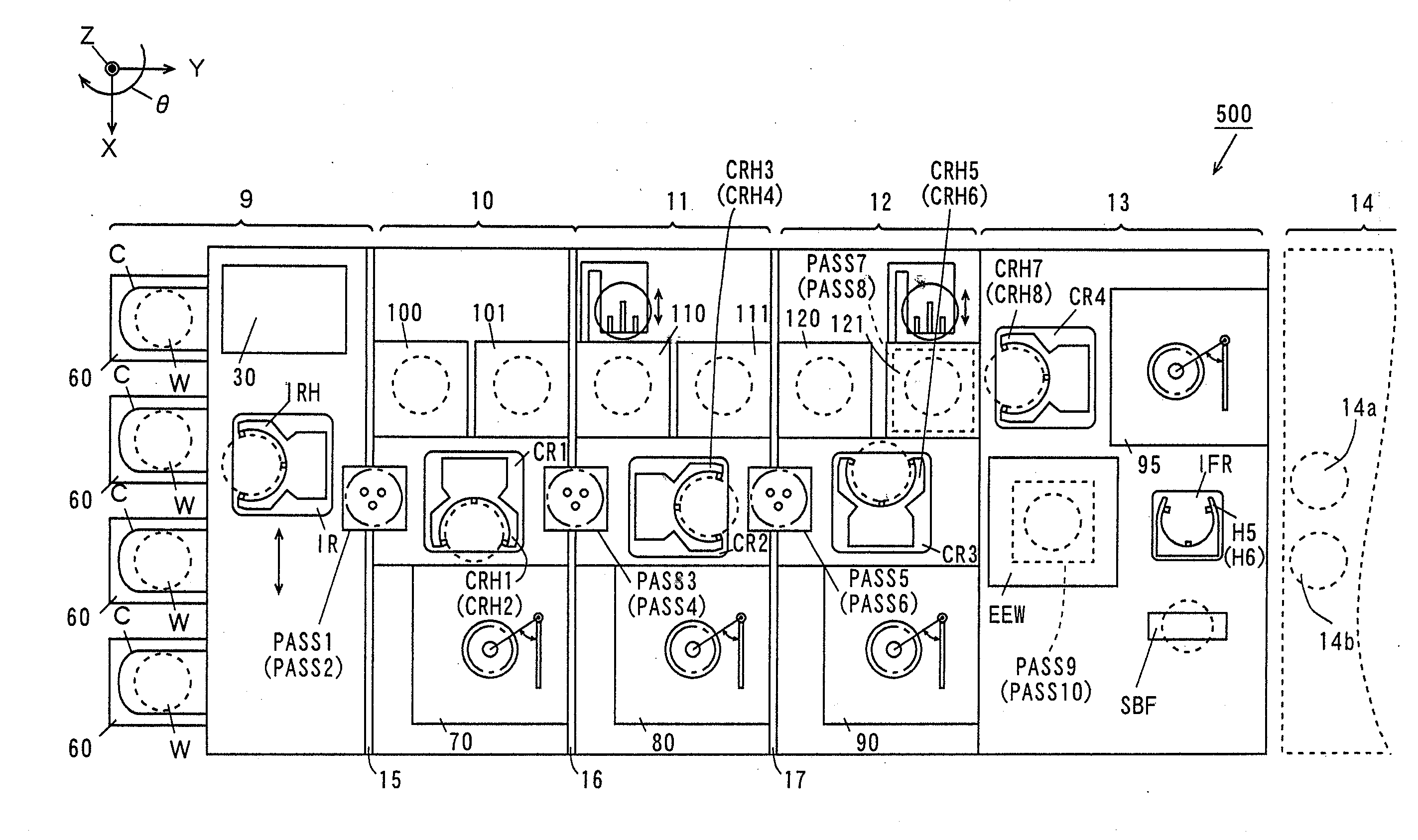

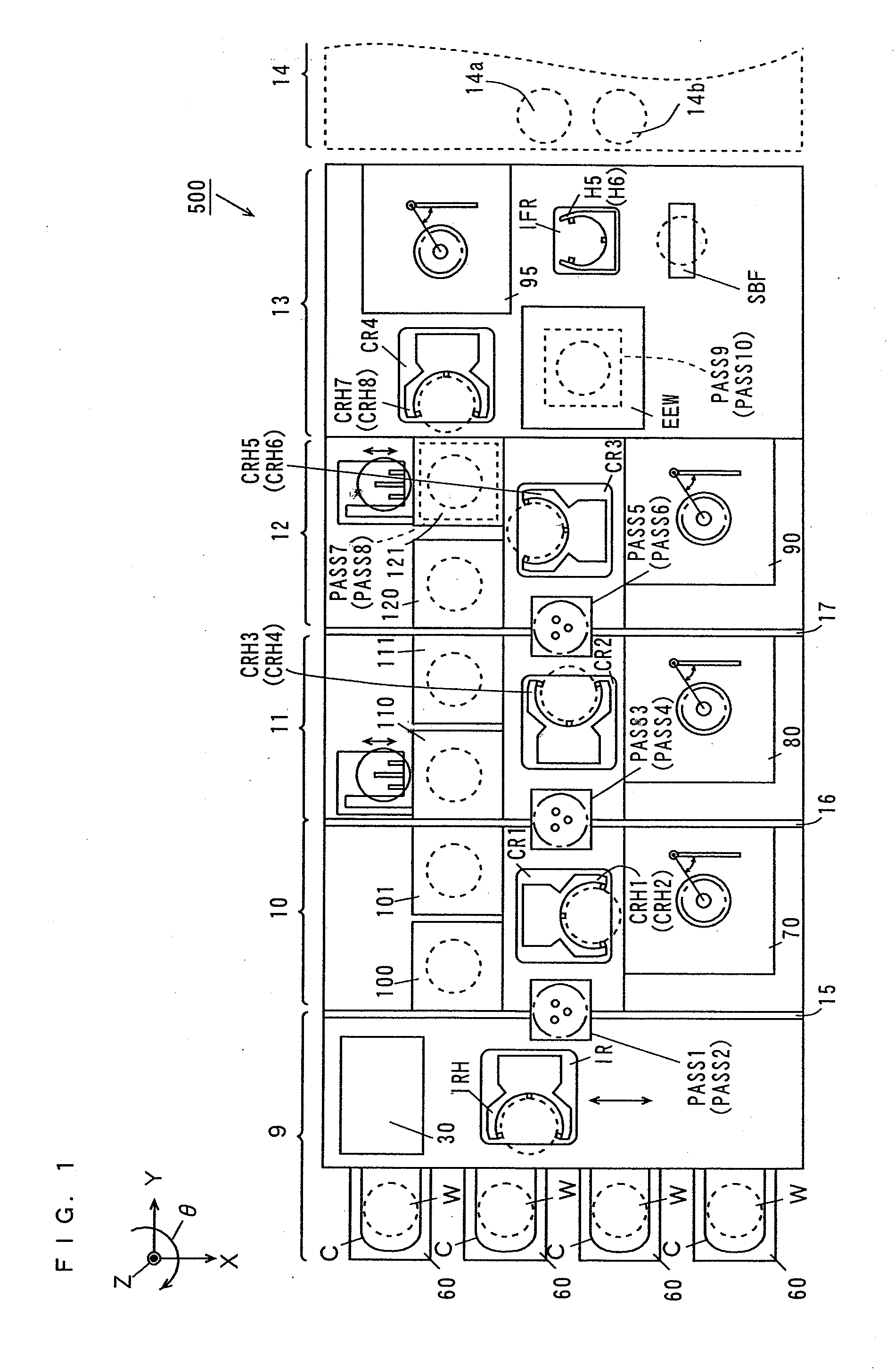

Substrate processing apparatus and substrate processing method

InactiveUS20060098979A1Reduce stepsOperation is troublesomeLiquid processingPhotomechanical apparatusComputer science

A substrate processing apparatus comprises an indexer block, an anti-reflection film processing block, a resist film processing block, a development processing block, and an interface block. An exposure device is arranged adjacent to an interface block. The interface block comprises a drying processing group including two drying processing units and an interface transport mechanism. After a substrate is subjected to exposure processing by the exposure device, the substrate is transported to the drying processing units in the drying processing group by the interface transport mechanism, where the substrate is subjected to cleaning and drying processings.

Owner:SOKUDO CO LTD

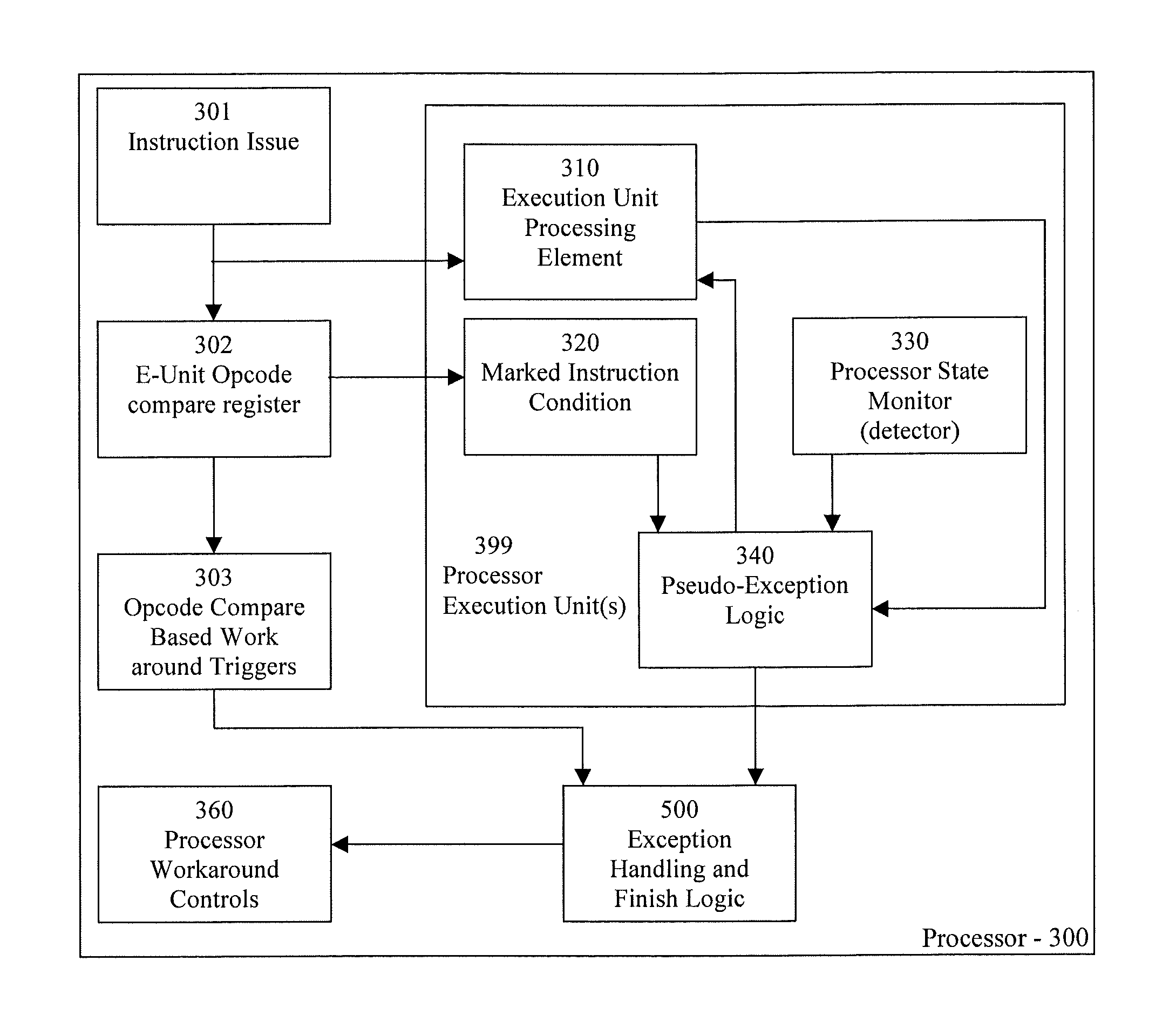

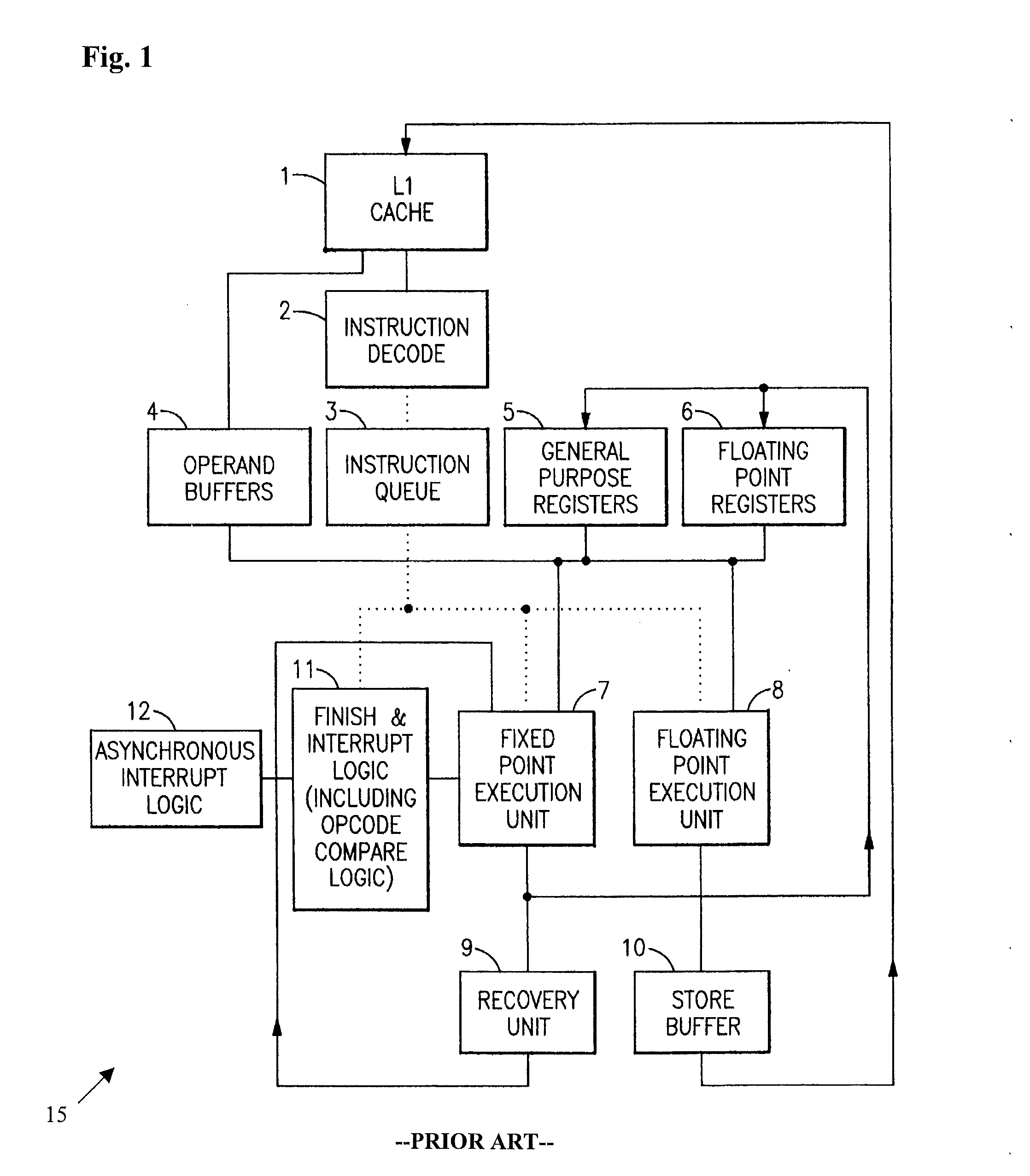

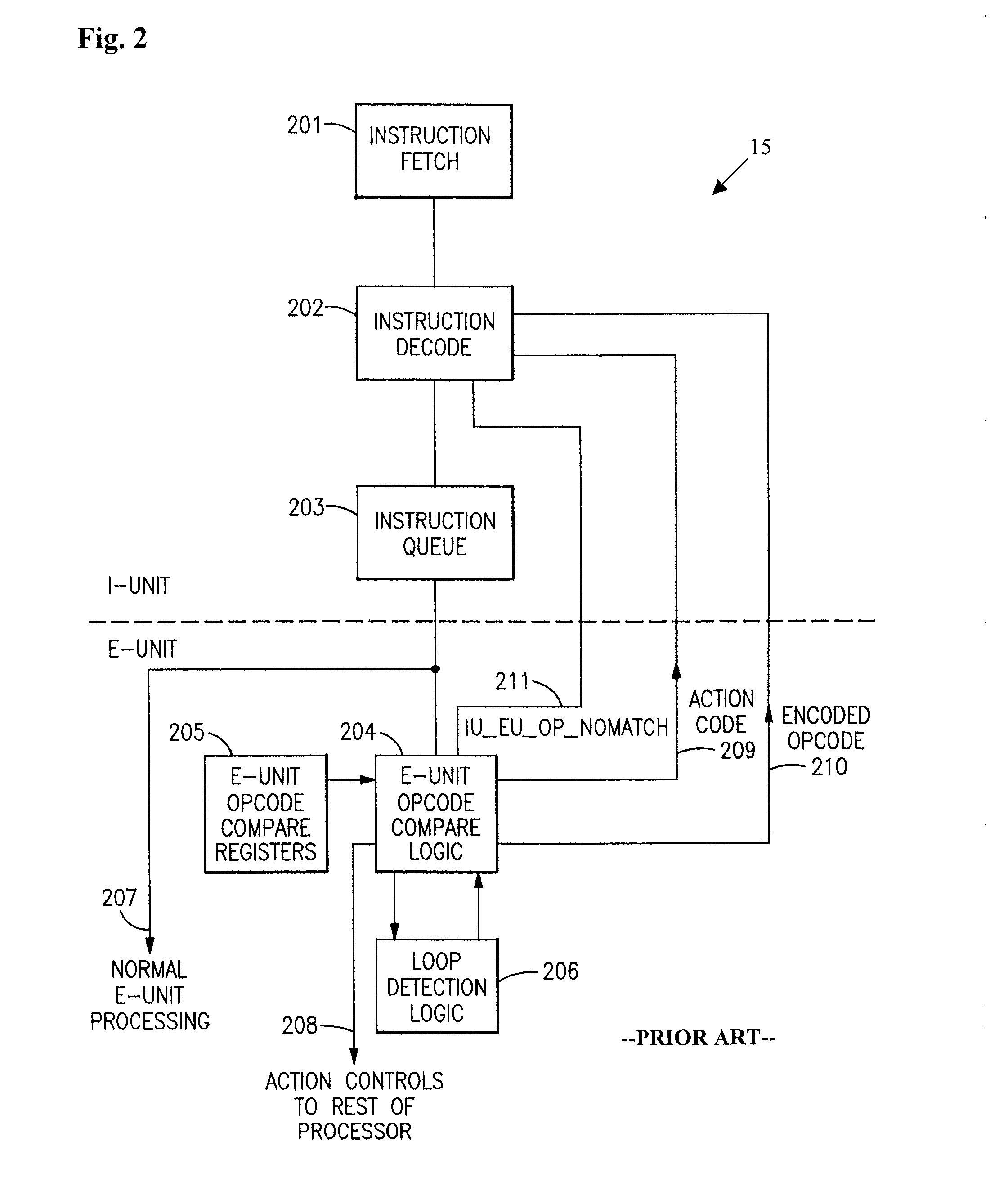

Processor and method for workaround trigger activated exceptions

InactiveUS20090210659A1Avoid processing defectsRuntime instruction translationDigital computer detailsWorkaroundMicroarchitecture

A processor includes a microarchitecture for working around a processing flaw, the microarchitecture including: at least one detector adapted for detecting a predetermined state associated with the processing flaw; and at least one mechanism to modify default processor processing behavior; and upon modification of processing behavior, the processing of an instruction involving the processing flaw can be completed by avoiding the processing flaw.

Owner:IBM CORP

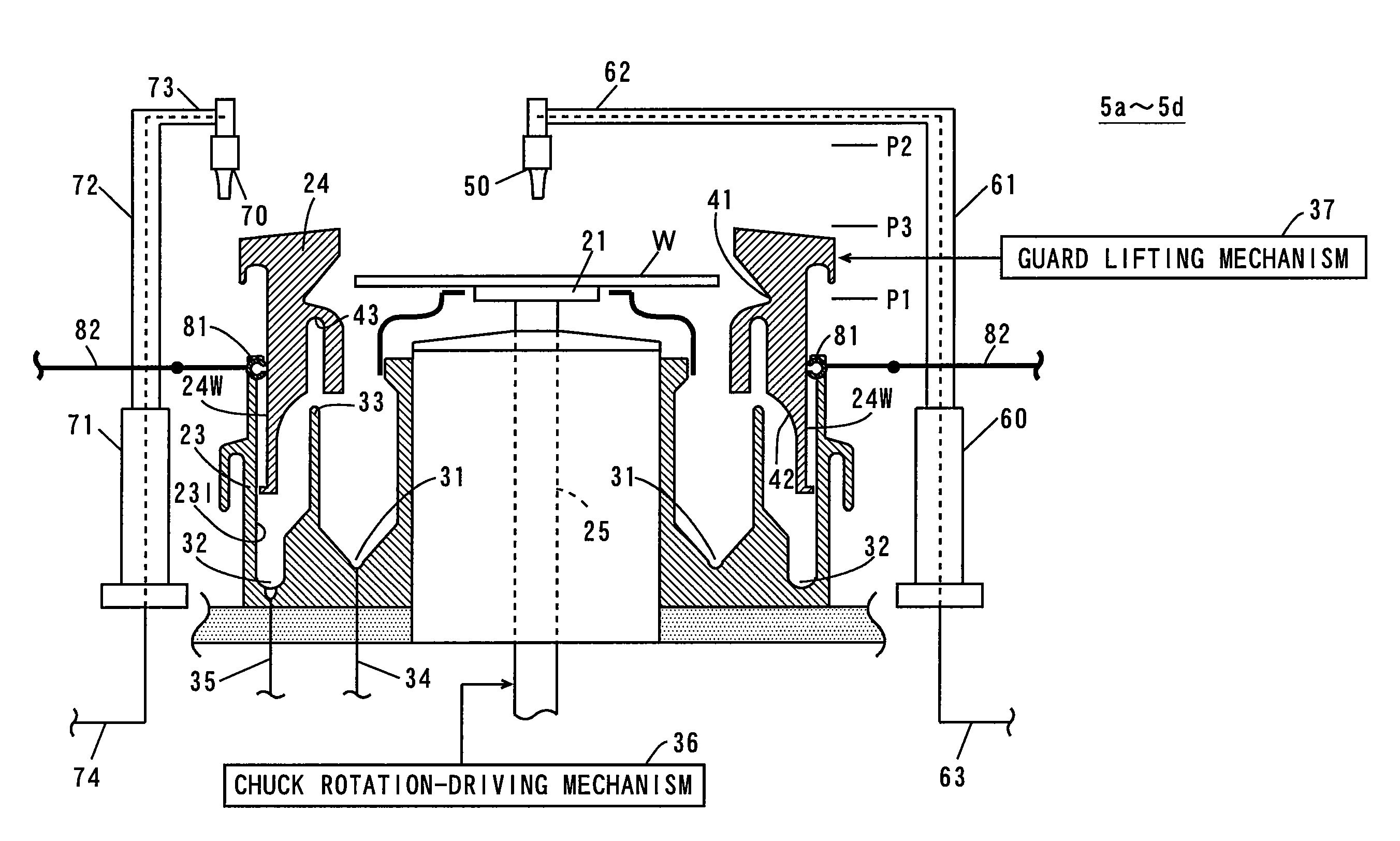

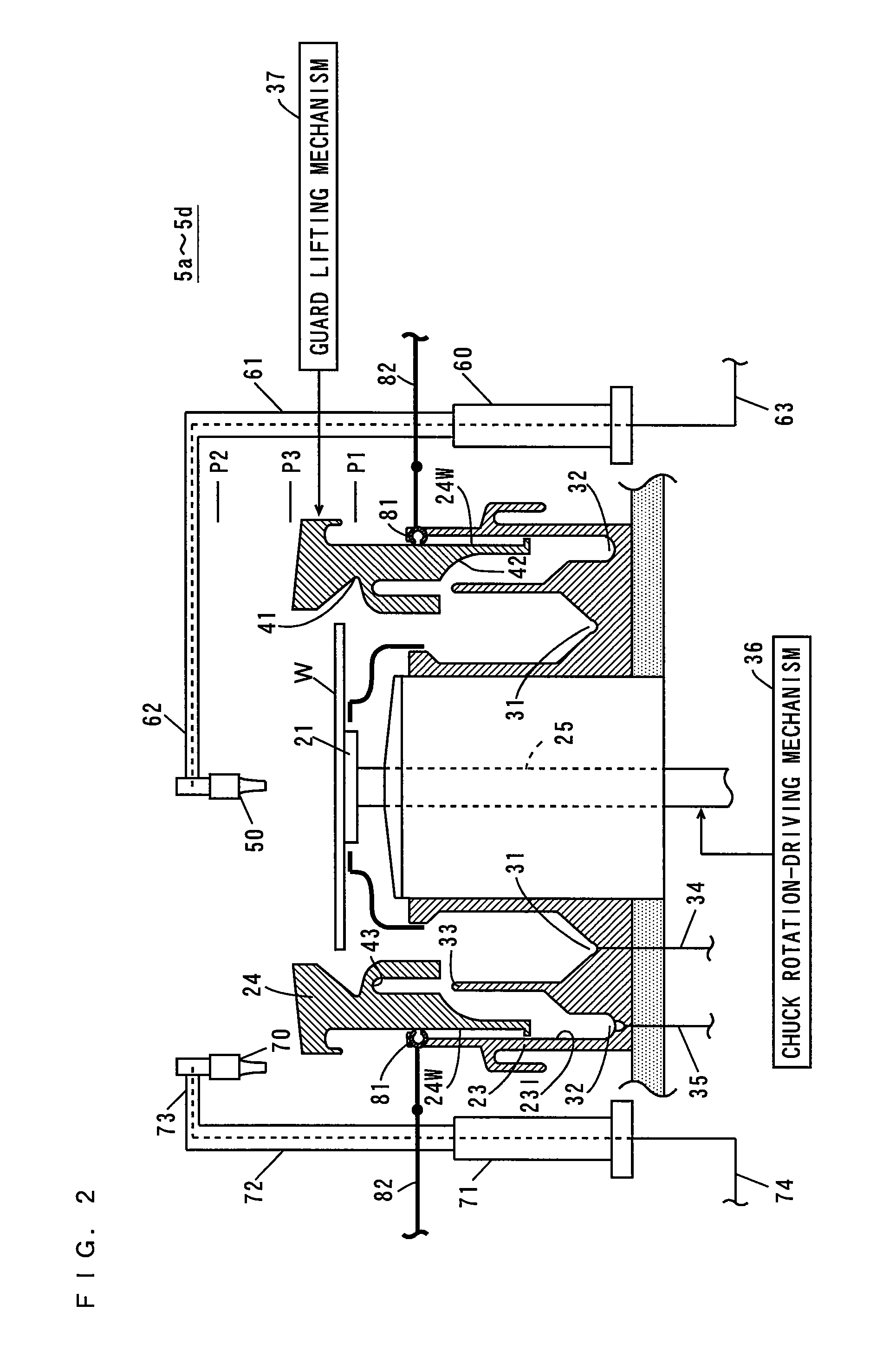

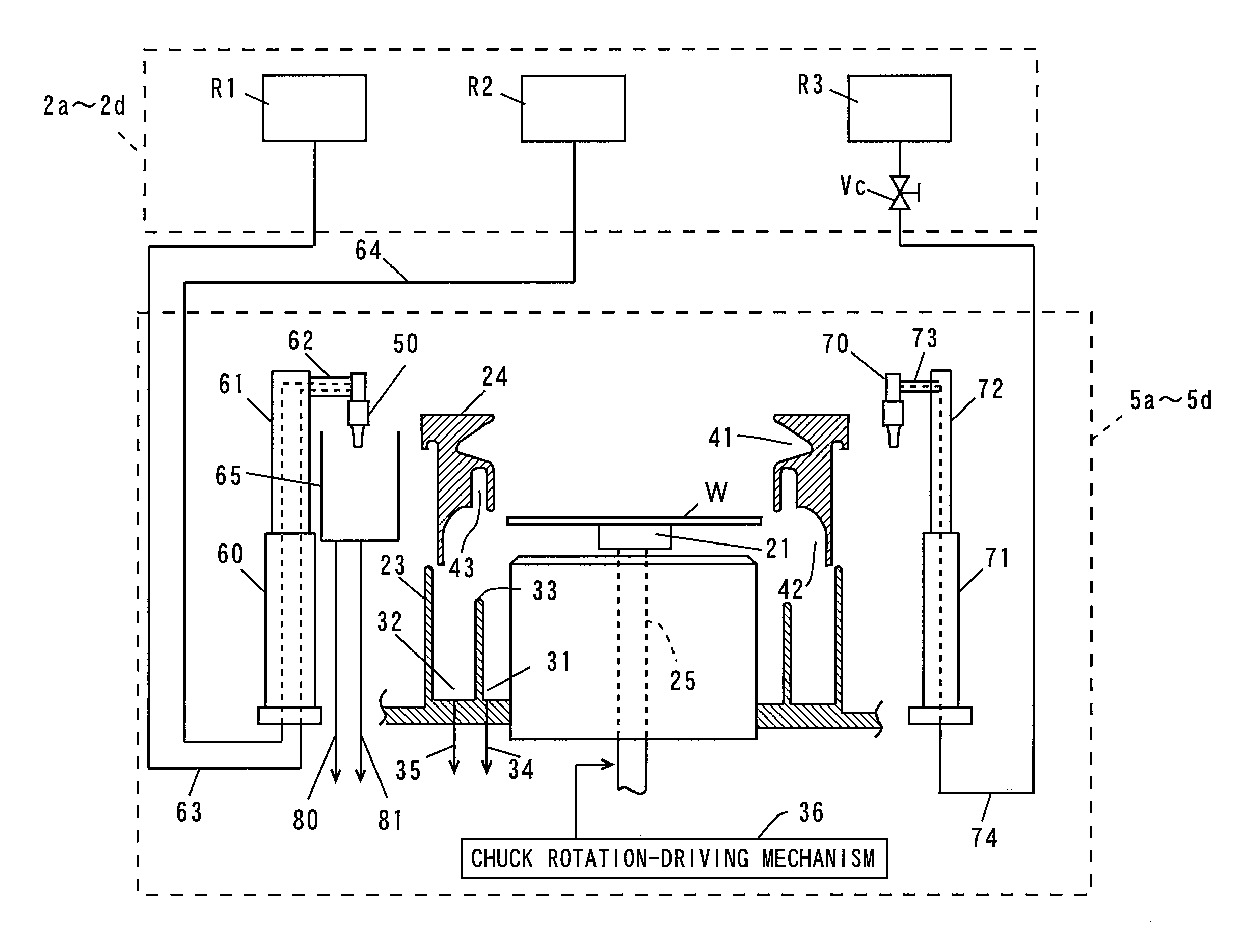

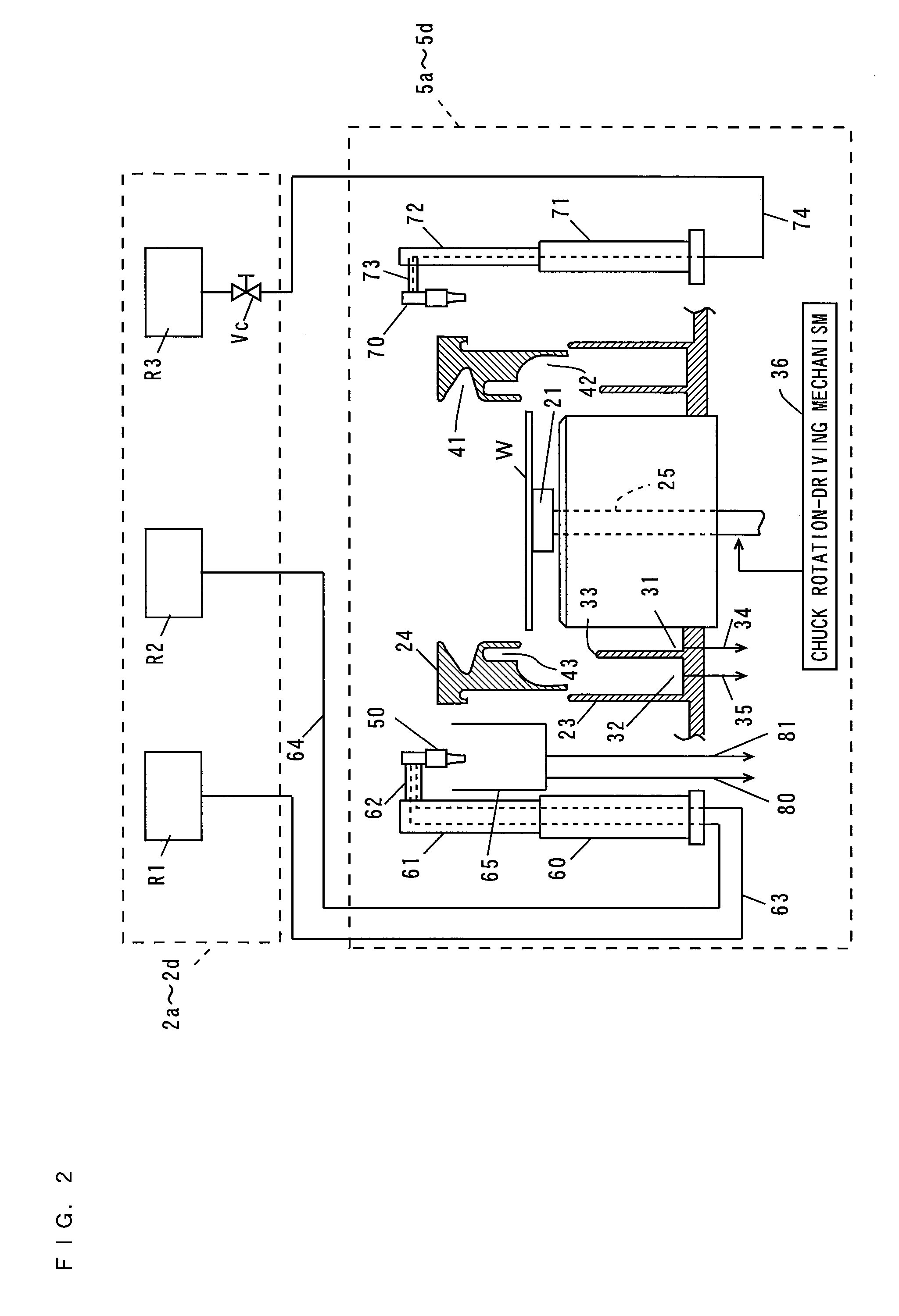

Substrate processing apparatus and substrate processing method

InactiveUS20070119476A1Reduce throughputAvoid processing defectsElectrostatic cleaningSemiconductor/solid-state device manufacturingChemical solutionAdditive ingredient

A substrate held by a spin chuck is supplied with a chemical solution by a chemical solution nozzle and a processing of the substrate is performed. At this time, the chemical solution supplied to the substrate scatters around and adheres to members (processing cup and splash guard) residing near the substrate. In the process of the substrate, a first cleaning liquid having the same ingredients as those of the chemical solution is supplied to an outer wall face of the splash guard from the guard cleaning nozzles without being in contact with the substrate. Thus, the outer wall face of the splash guard and the inner wall face of the processing cup are cleaned by the clean first cleaning liquid. The chemical solution supplied to the substrate and the first cleaning liquid supplied to the outer wall face of the splash guard are reused.

Owner:DAINIPPON SCREEN MTG CO LTD

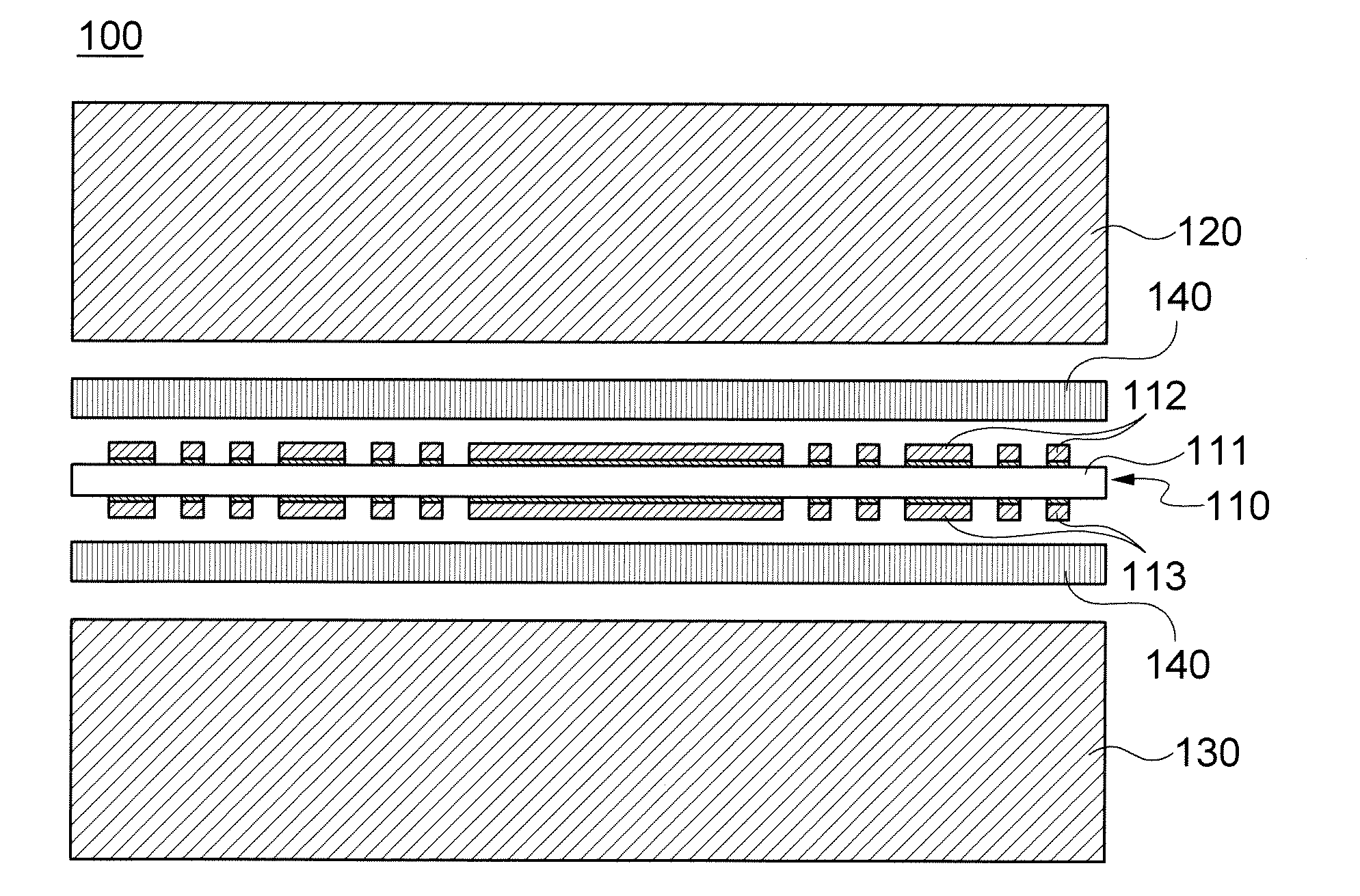

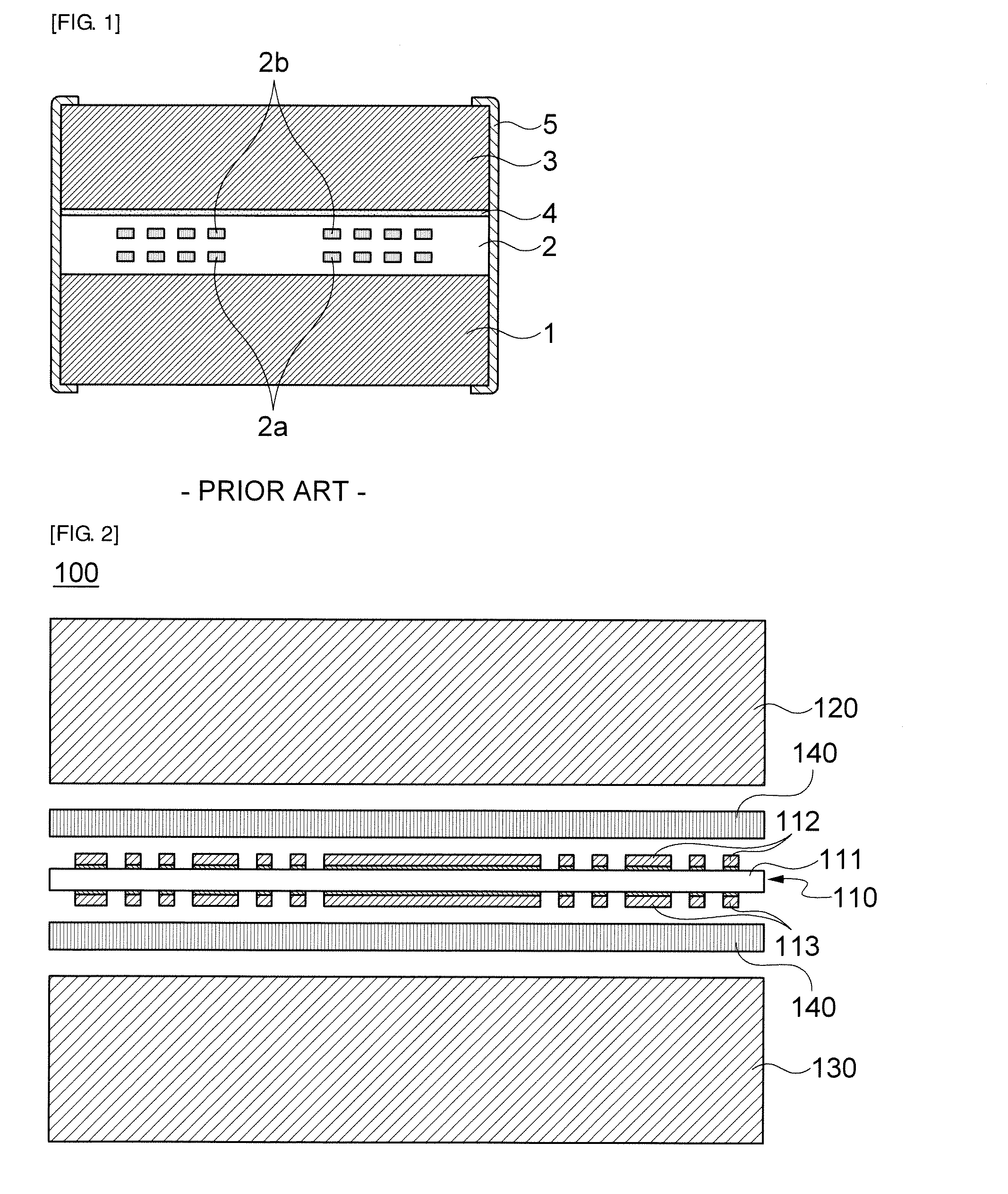

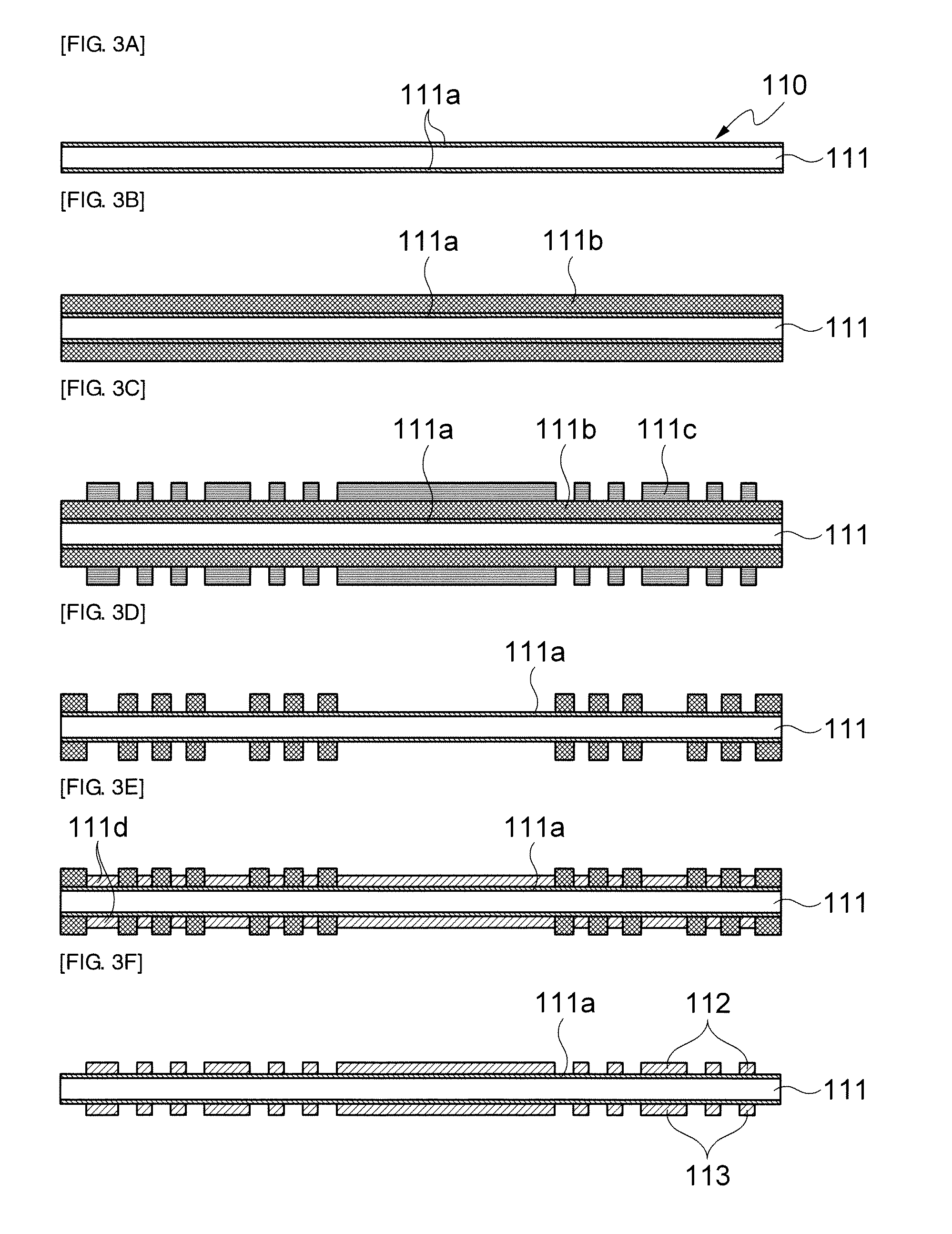

Coil parts and method of fabricating the same

ActiveUS20130082812A1Improve fabrication processSimple preparation processCoils manufactureElectromagnetsProduction rateMagnetic layer

A coil part is provided. The coil part includes a coil layer including a core and a first coil and a second coil disposed on and under the core, a lower magnetic layer bonded under the coil layer, and an upper magnetic layer bonded on the coil layer. Accordingly, it is possible to improve process and productivity and cut fabrication costs by preventing process defects that occur during the fabrication process of a coil part using a ferrite substrate.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

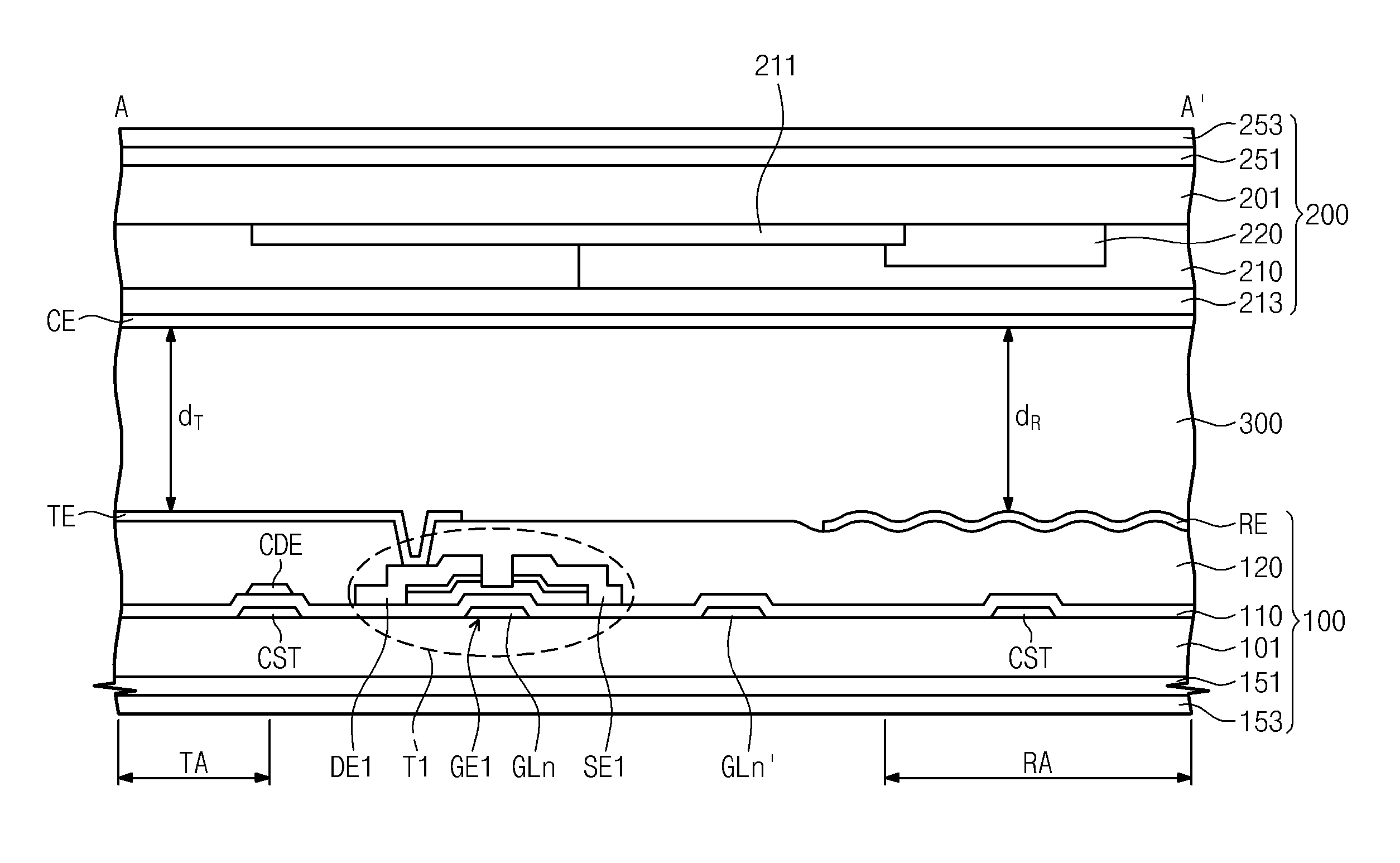

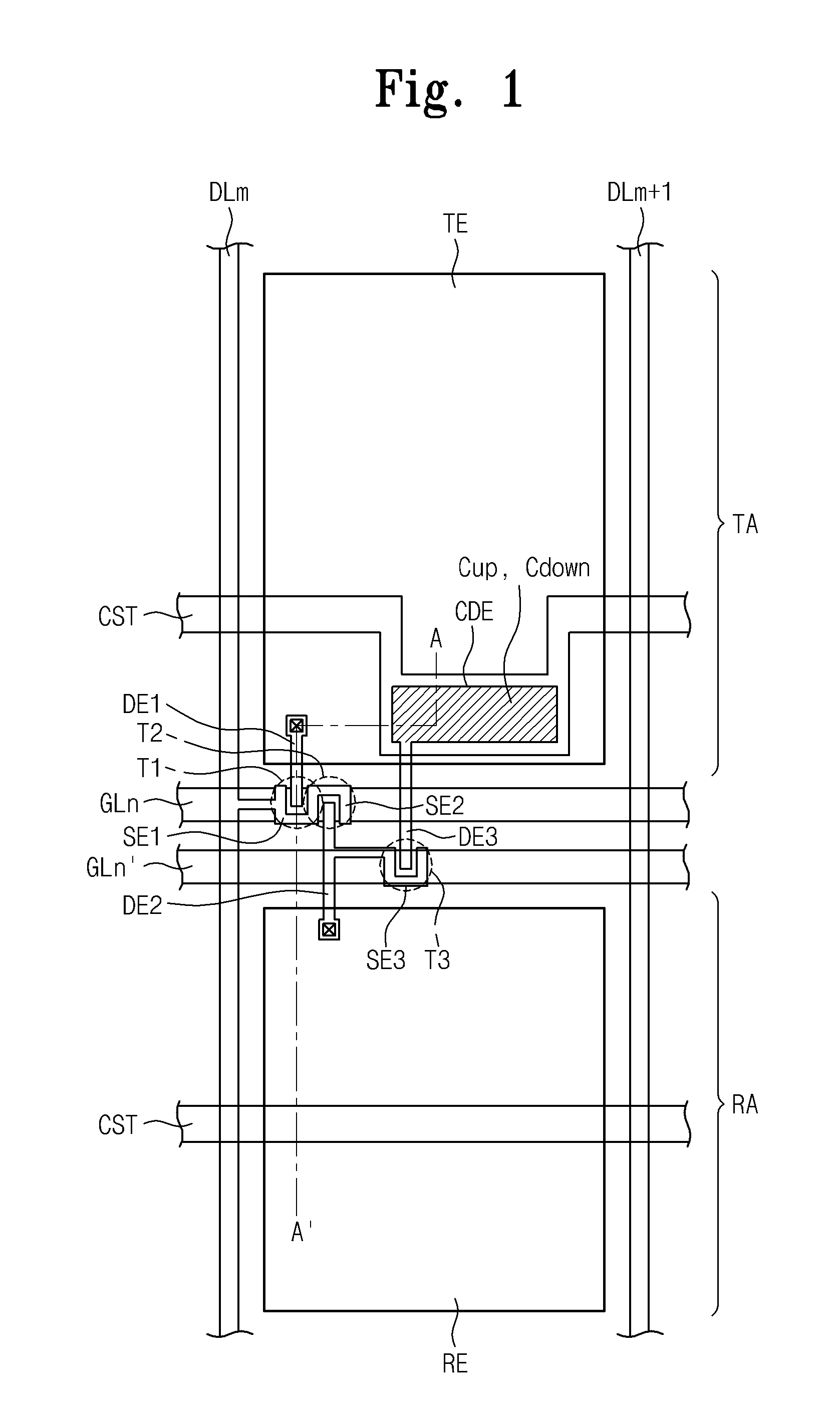

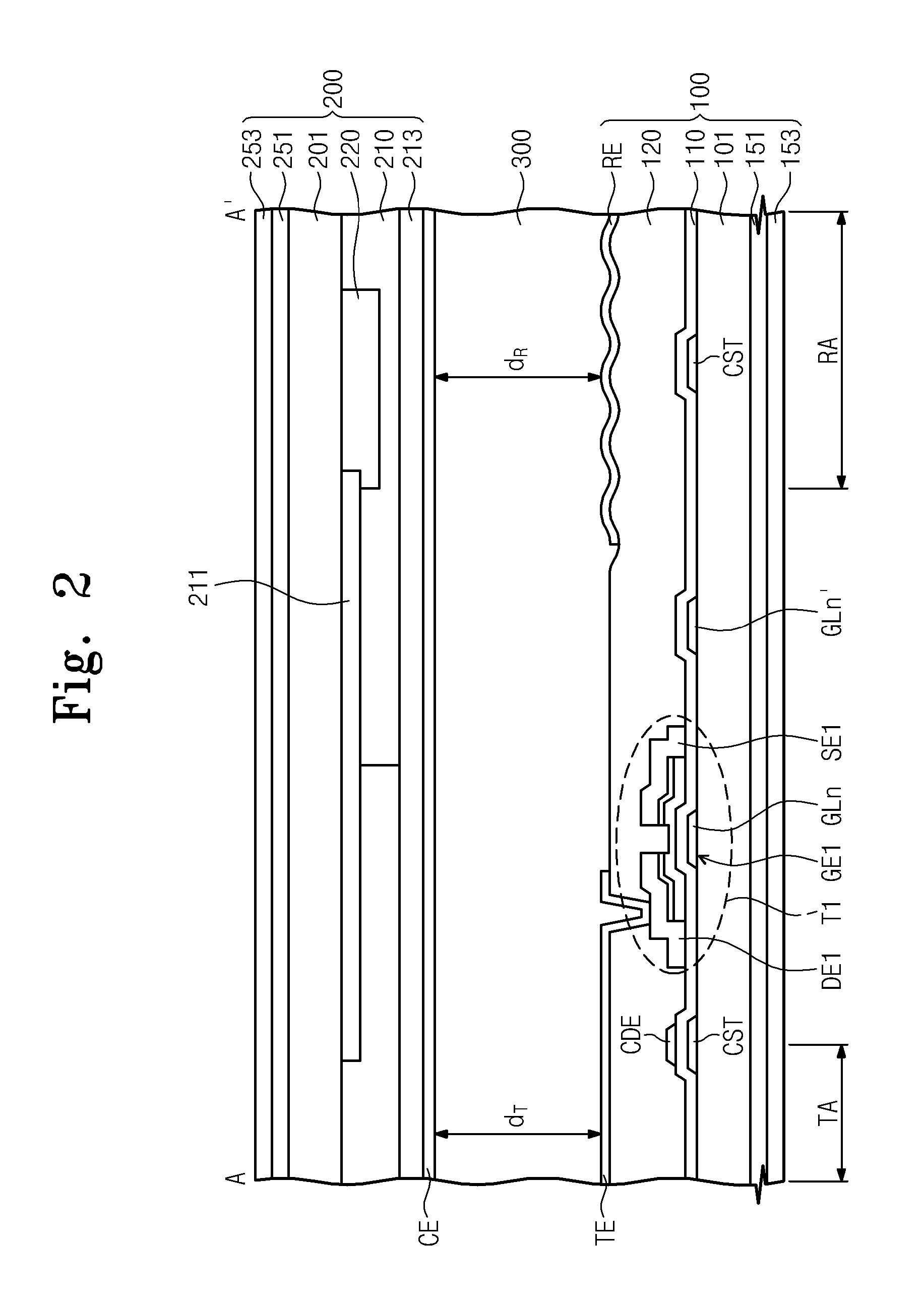

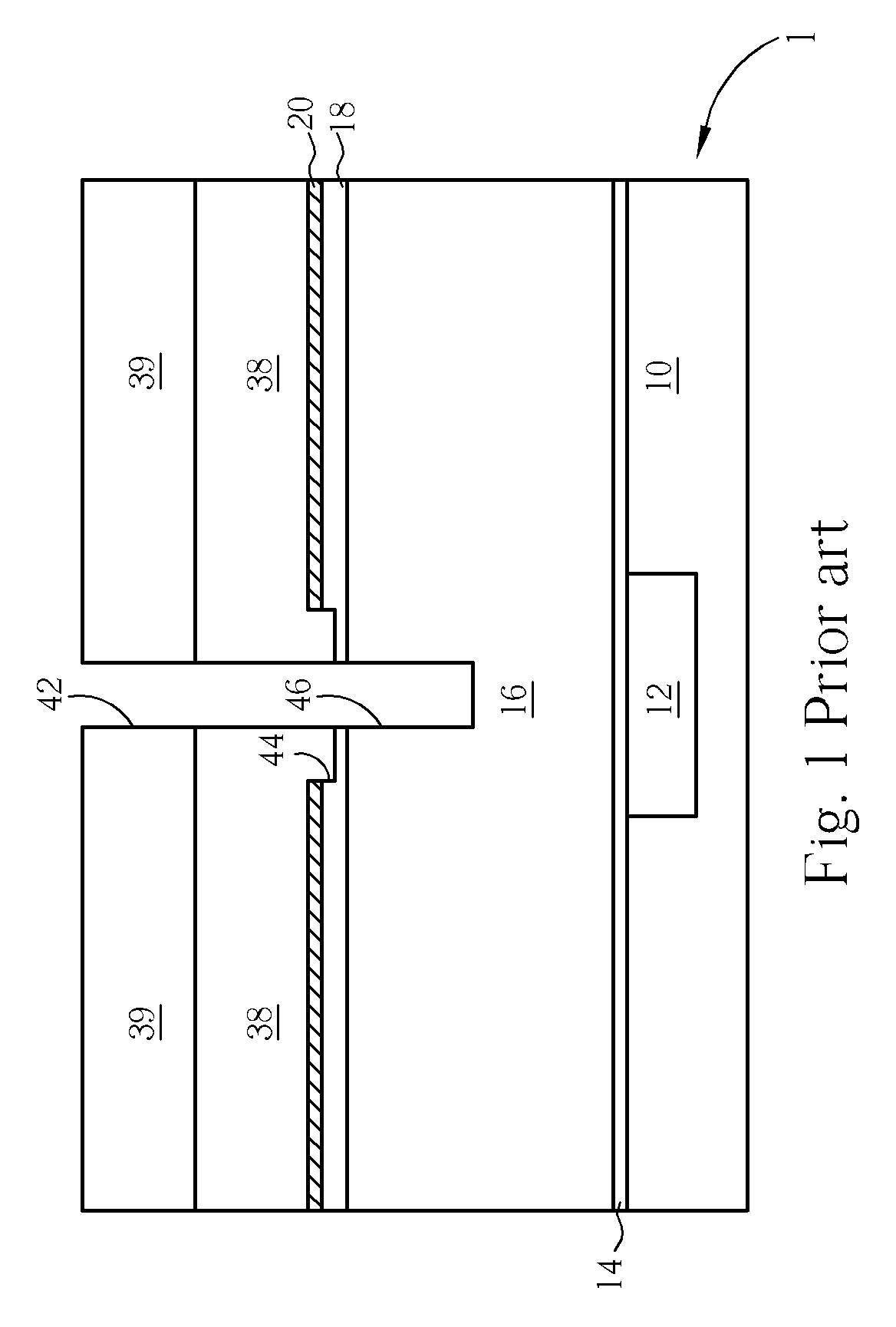

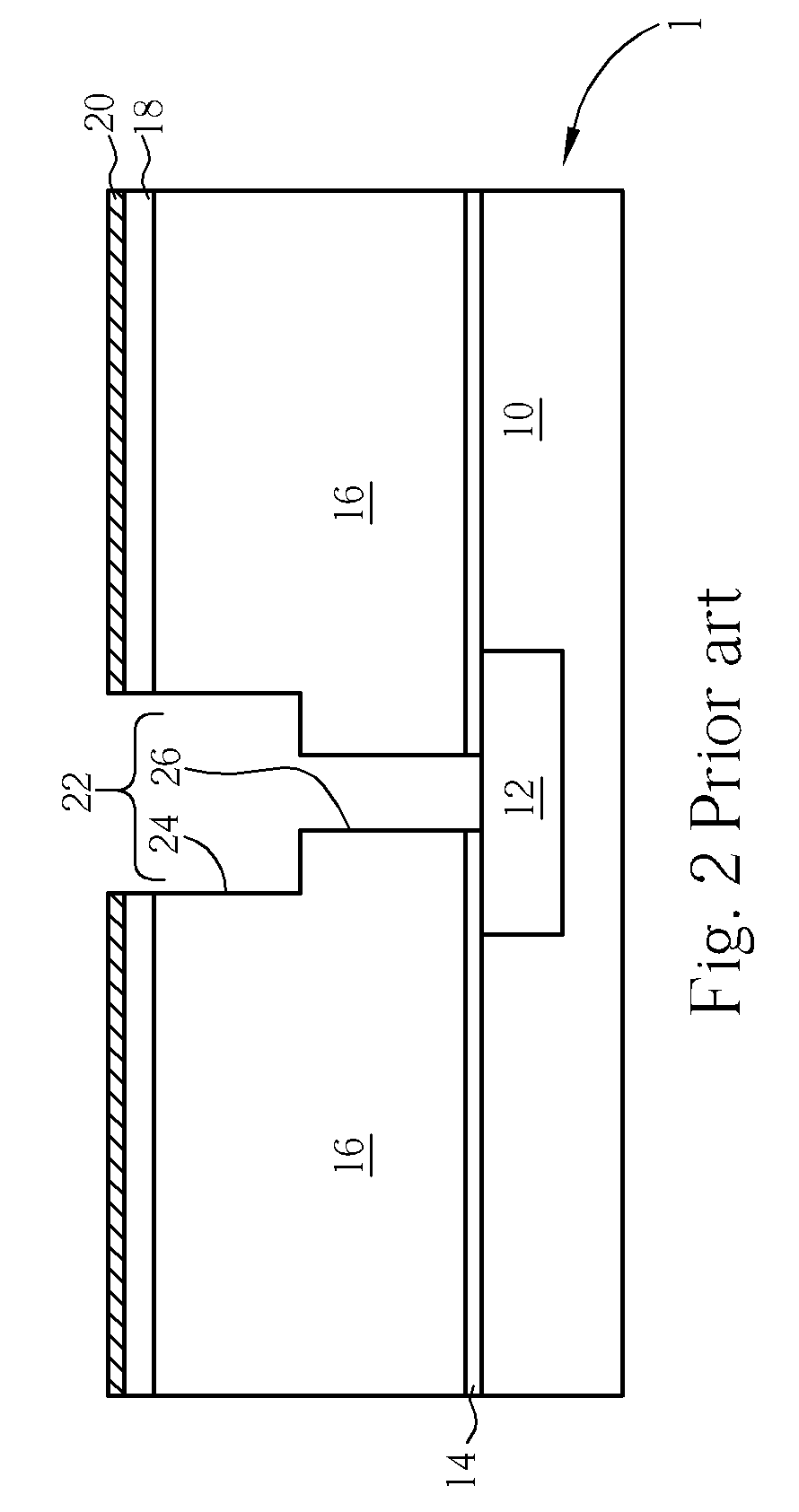

Liquid crystal display and method of manufacturing the same

ActiveUS20100328290A1Improve display qualityDeterioration of electro-optical characteristic of the liquid crystal layer is effectively preventedSemiconductor/solid-state device manufacturingCathode-ray tube indicatorsLiquid-crystal displayData signal

A liquid crystal display includes a first substrate including pixels, each having a transmissive area and a reflective area, a second substrate, and a liquid crystal layer disposed between the first and second substrates. Each of the pixels includes first and second thin film transistors which output a data signal in response to a first gate signal, a transmissive pixel electrode disposed in the transmissive area and electrically connected to the first thin film transistor to charge a first pixel voltage based on the data signal, a reflective pixel electrode disposed in the reflective area and electrically connected to the second thin film transistor to charge a second pixel voltage based on the data signal, and a voltage controller which controls the first pixel voltage and the second pixel voltage in response to a second gate signal, which is generated after the first gate signal.

Owner:SAMSUNG DISPLAY CO LTD

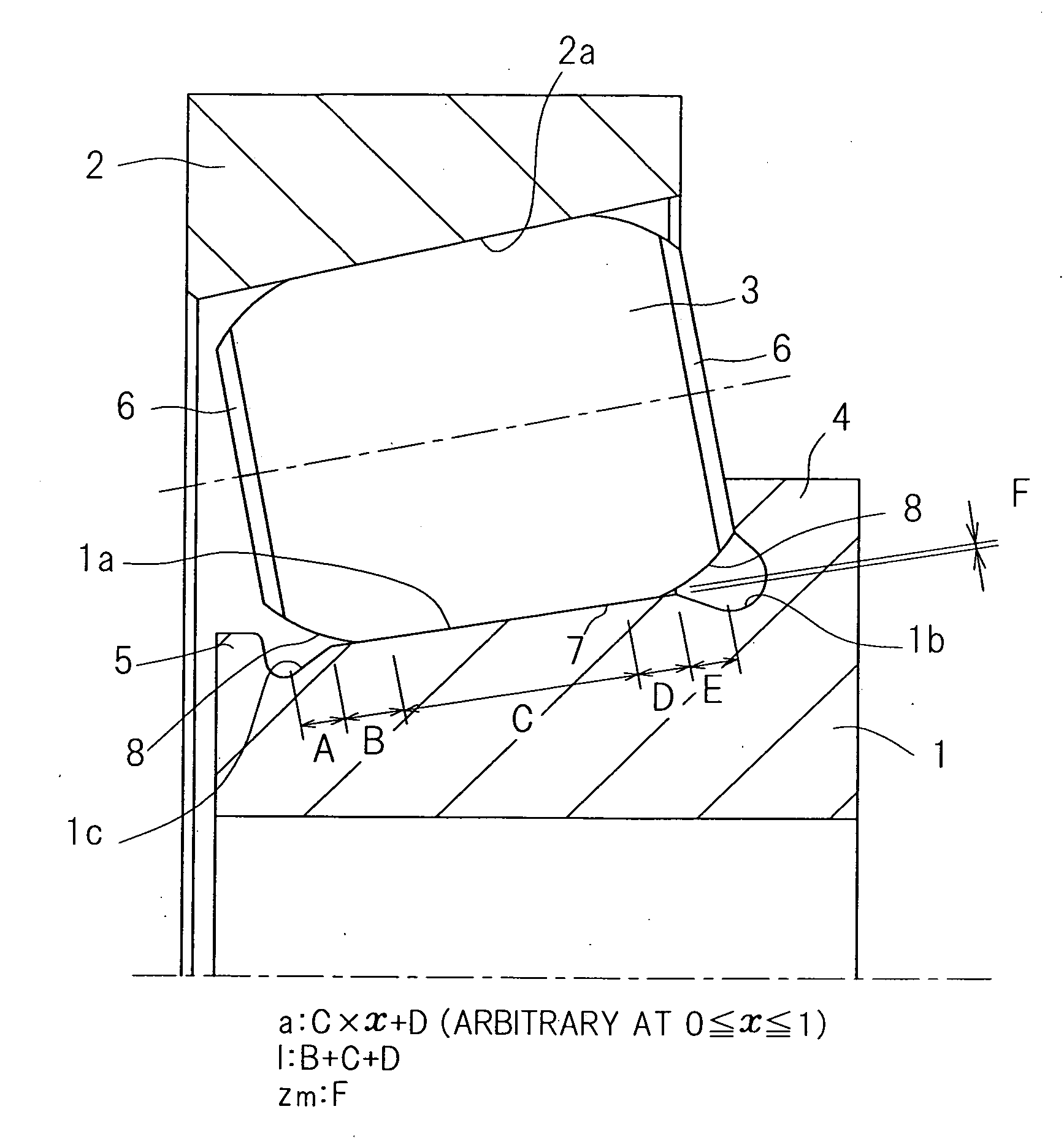

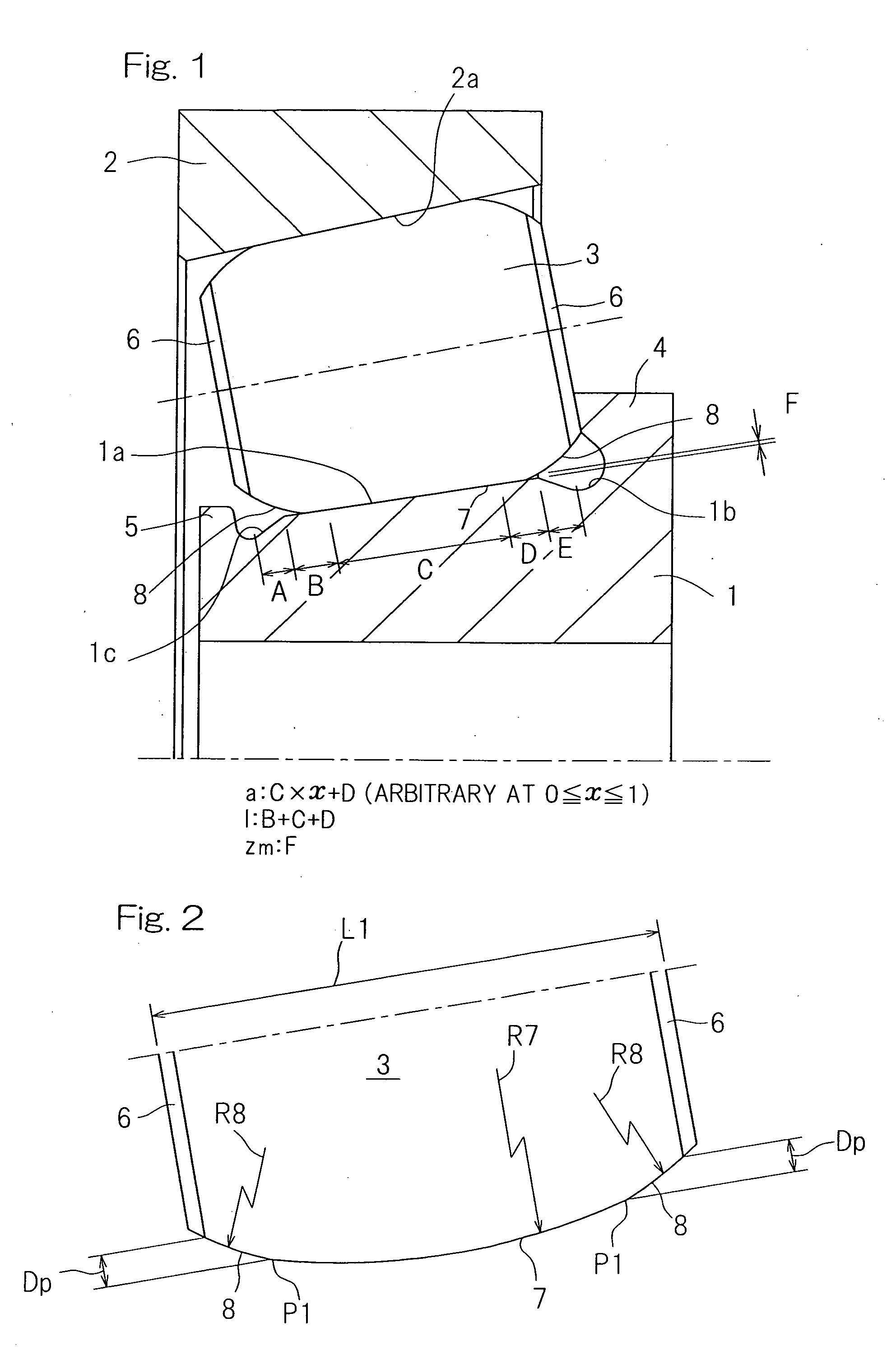

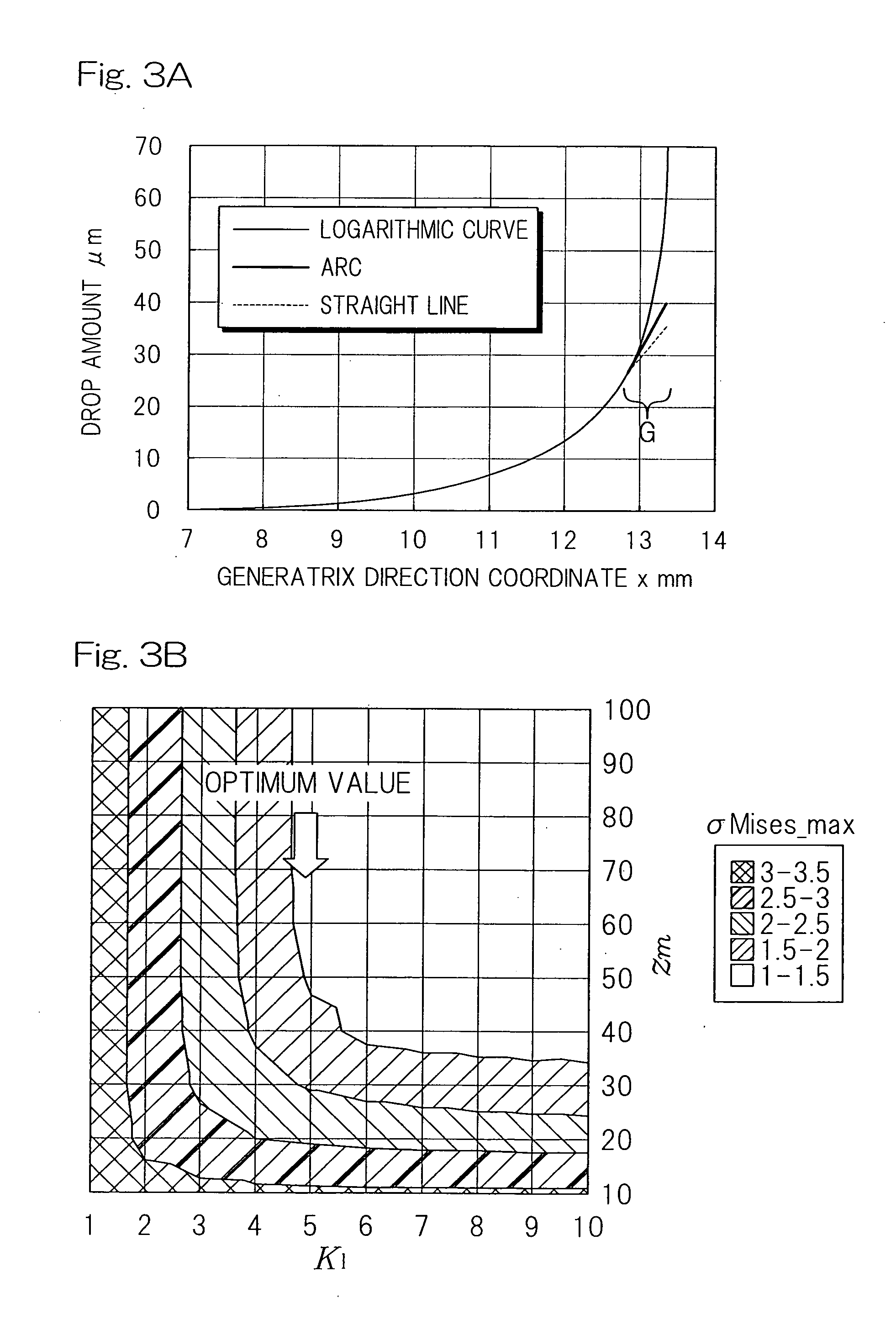

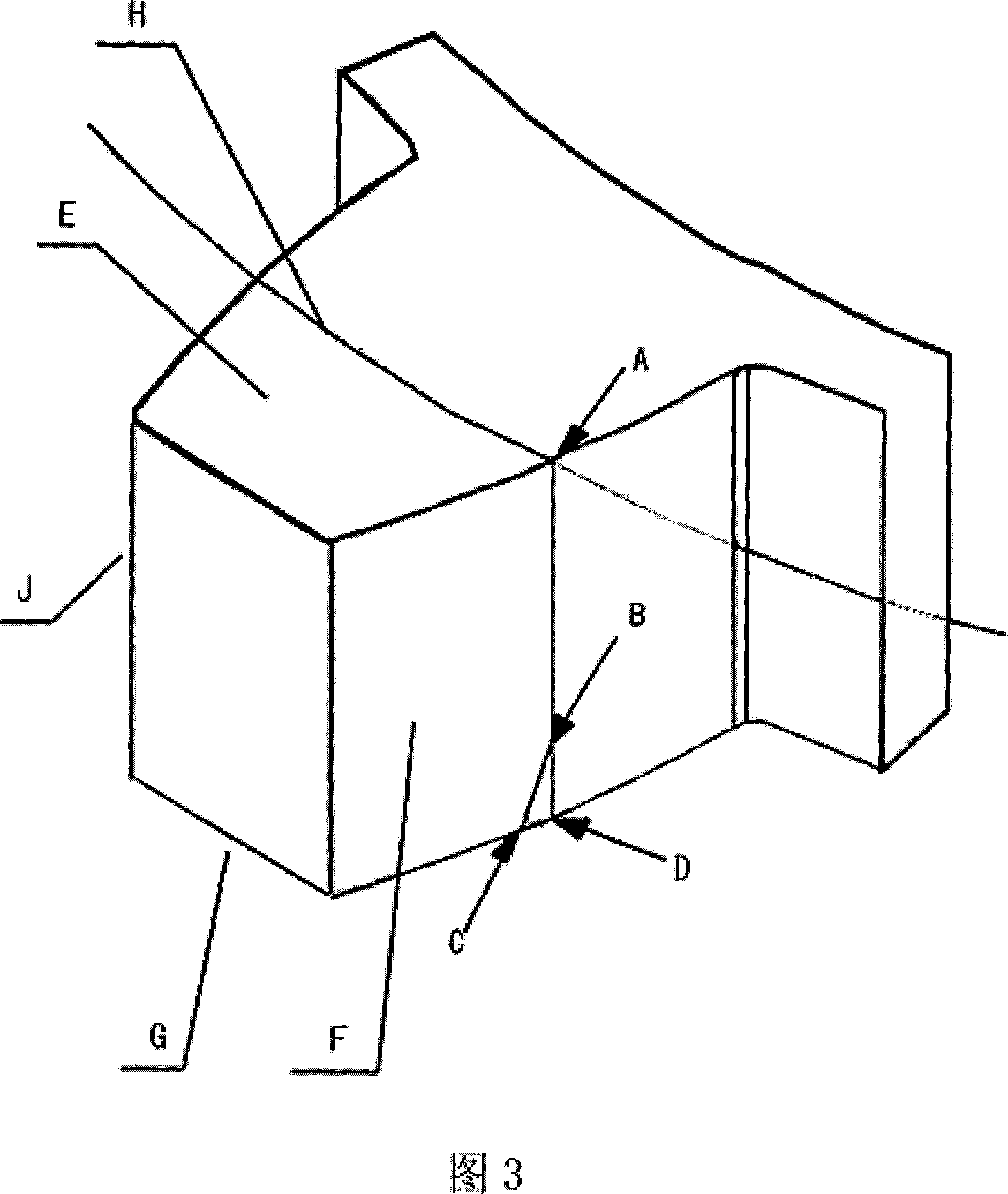

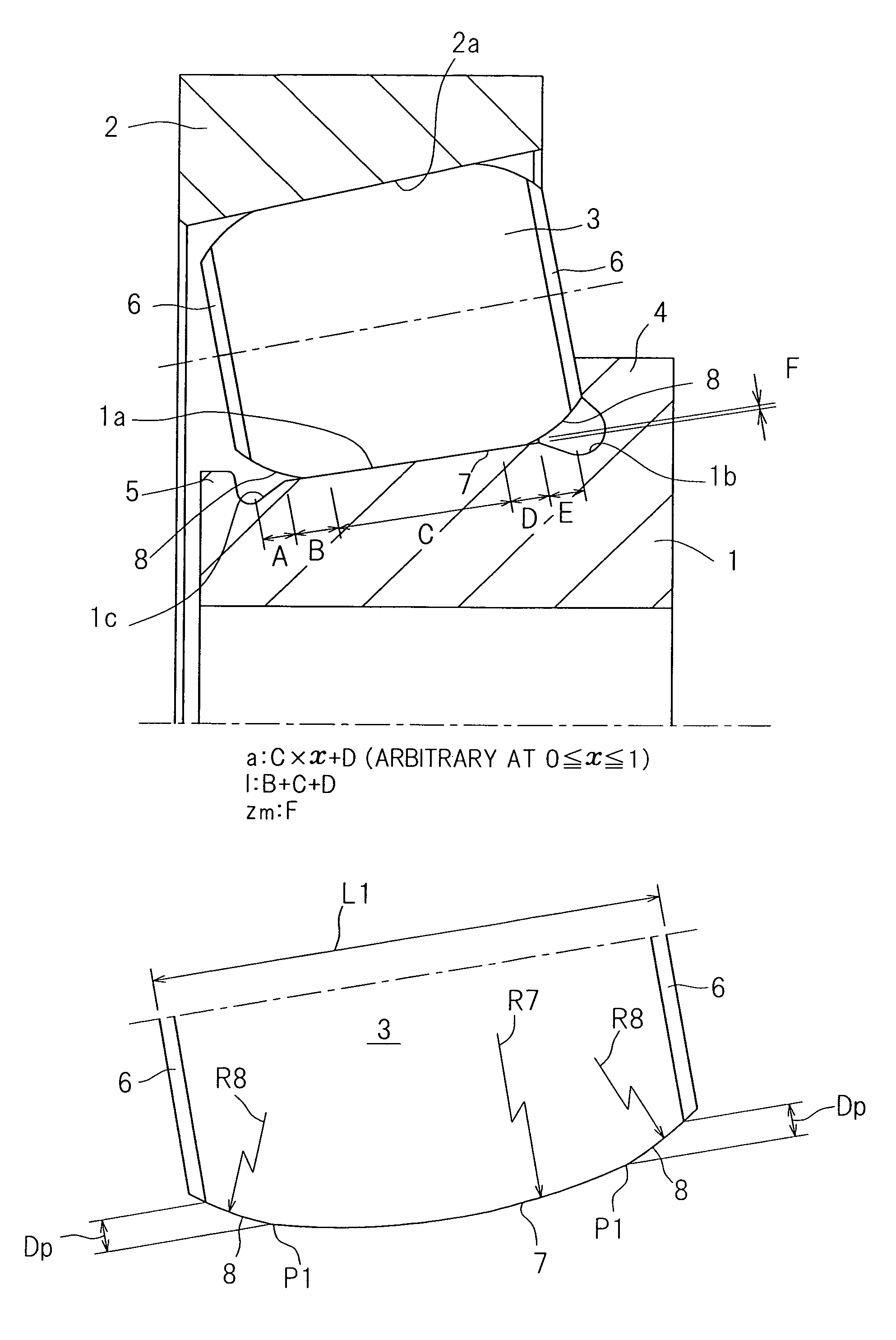

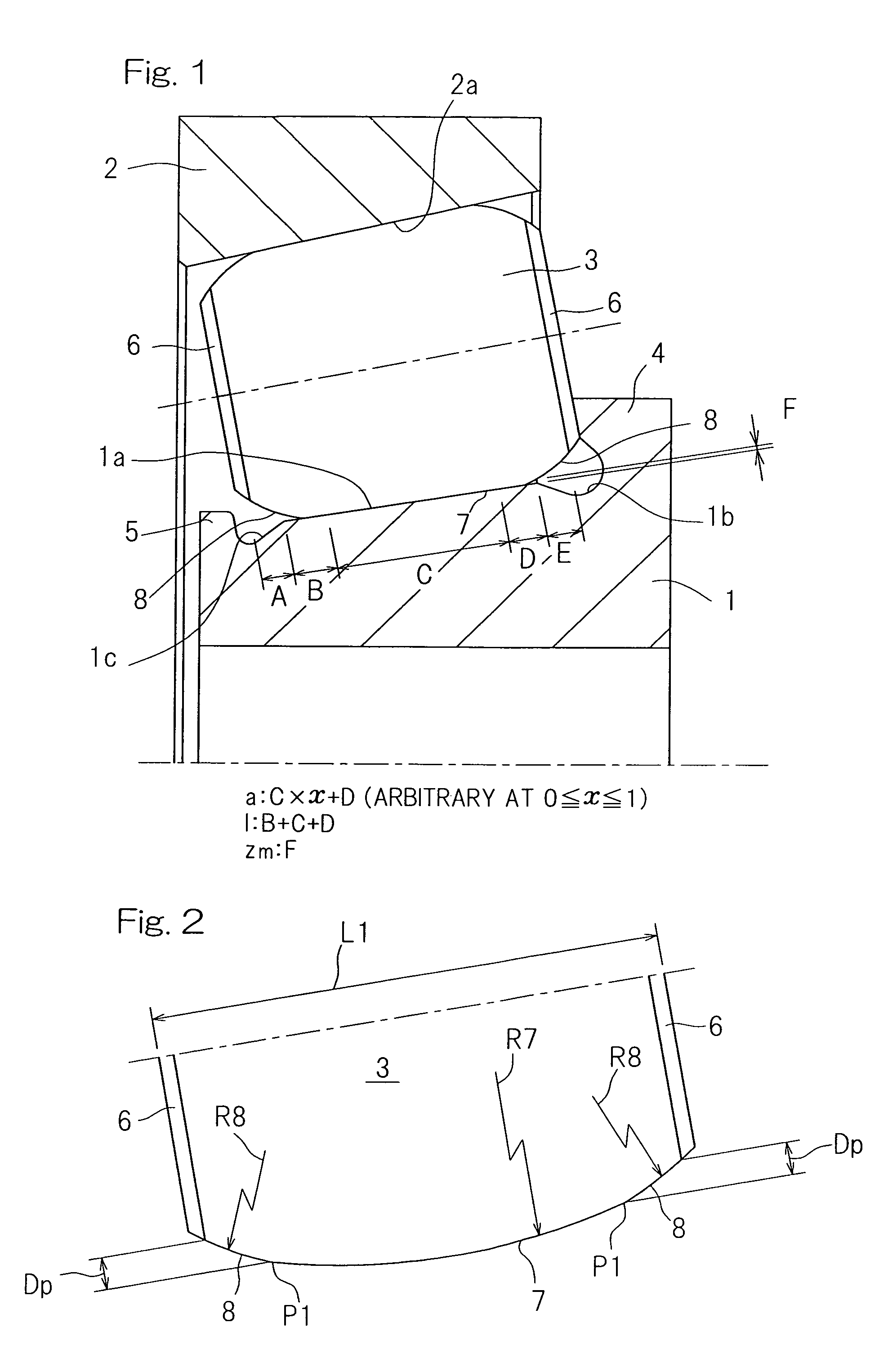

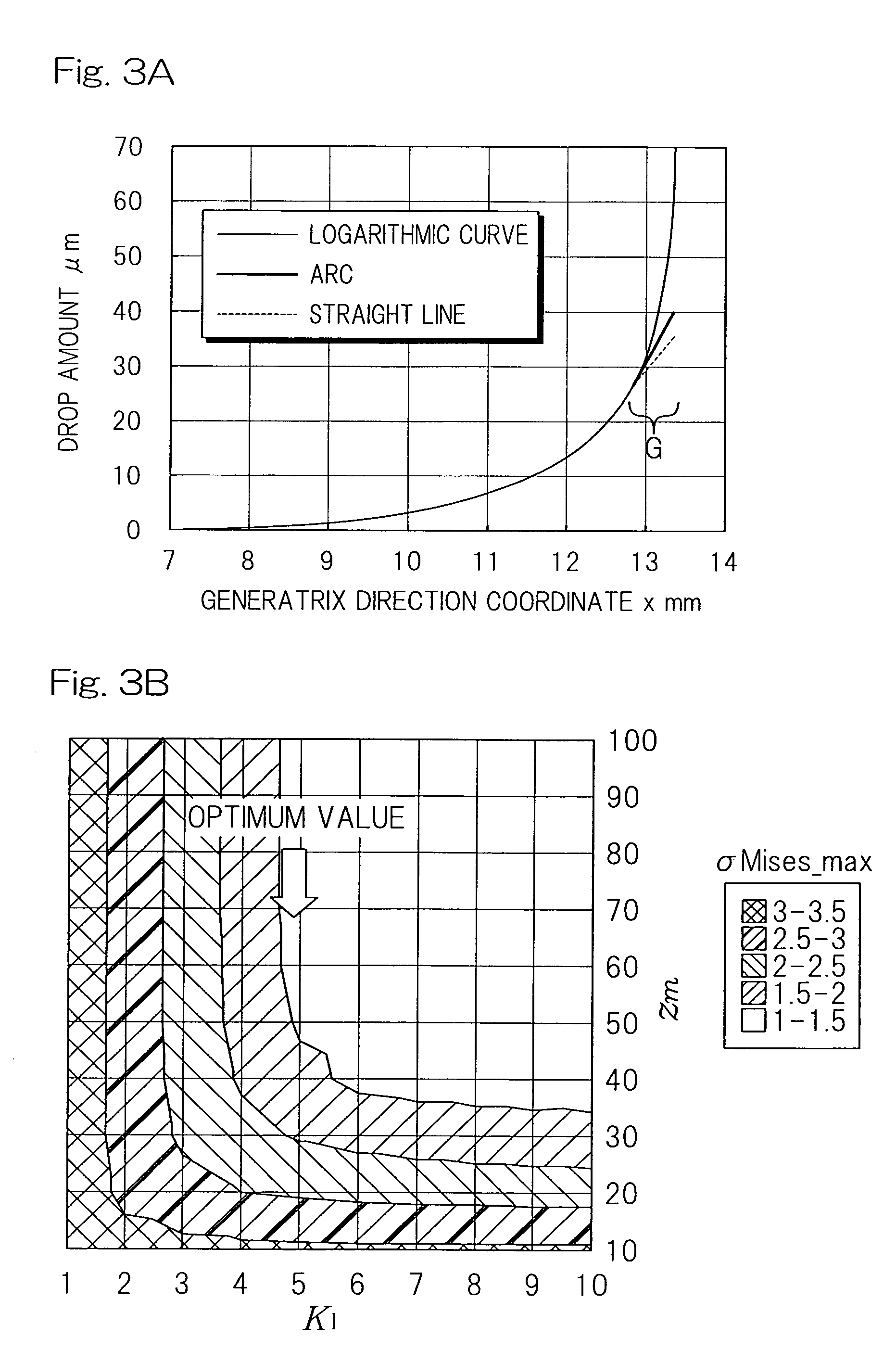

Tapered roller bearing and method of designing the same

ActiveUS20120033909A1Design be relatively longCost reductionRolling contact bearingsShaftsMechanical engineeringContact region

In a tapered roller bearing assembly, a crowning profile formed portion of the roller rolling surface is made up of a contact area crowned portion (7), which is held in contact with an inner ring raceway surface (1a), and a non-contact area crowned portion (8) which is held in non-contact with the inner ring raceway surface (1a). The contact area crowned portion (7) and the non-contact area crowned portion (8) have their generatrices extending in an axial direction of a roller (3), which generatrices are represented by corresponding continuous lines represented by different functions and continued smoothly at a point of connection, and the curvature of the generatrix of the non-contact area crowned portion (8) in the vicinity of the connection point is chosen to be smaller than the curvature of the generatrix of the contact area crowned portion (7).

Owner:NTN CORP

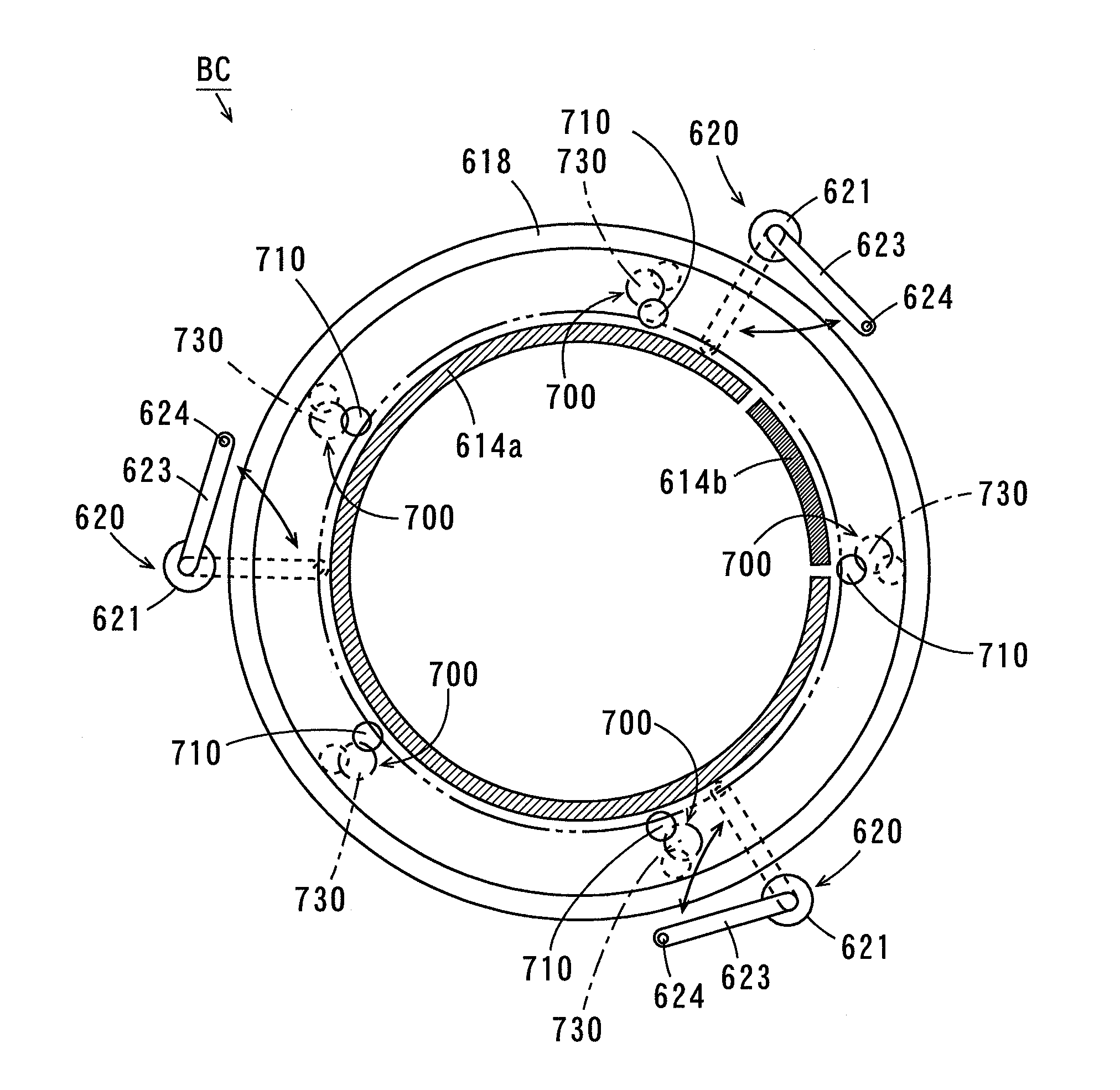

Substrate cleaning and processing apparatus with magnetically controlled spin chuck holding pins

ActiveUS20090120472A1Avoid processing defectsAvoid contactSemiconductor/solid-state device manufacturingCleaning using toolsClosed stateMagnet

When a substrate is subjected to bevel cleaning processing, a first magnet plate is arranged at a lower position, and a second magnet plate is arranged at an upper position. In this case, each of chuck pins enters a closed state in a region outside the first magnet plate, while entering an opened state in a region outside the second magnet plate. That is, a holder in each of the chuck pins is maintained in contact with an outer edge of the substrate when it passes through the region outside the first magnet plate, while being spaced apart from the outer edge of the substrate when it passes through the region outside the second magnet plate.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

Semiconductor manufacturing process

ActiveUS20080146036A1Avoid processing defectsInhibition formationDecorative surface effectsSemiconductor/solid-state device manufacturingTitaniumCompounds of fluorine

Disclosed is a semiconductor manufacturing process, in which a fluorine radical-containing plasma is used to etch a hard mask and a layer therebeneath; and a treatment is carried out using a gas reactive to fluorine radicals for reacting with residual fluorine radicals to form a fluorine-containing compound and remove it. Thus, precipitates formed by the reaction of fluorine radicals and titanium components existing in the hard mask to cause a process defect can be avoided.

Owner:UNITED MICROELECTRONICS CORP

Substrate processing apparatus

InactiveUS20060159449A1Operation is troublesomeAvoid processing defectsLiquid processingSemiconductor/solid-state device manufacturingComputer science

A substrate processing apparatus comprises an indexer block, an anti-reflection film processing block, a resist film processing block, a development processing block, a drying processing block, and an interface block. An exposure device is arranged adjacent to the interface block. The drying processing block comprises a drying processing group. The interface block comprises an interface transport mechanism. A substrate is subjected to exposure processing by the exposure device, and subsequently transported to the drying processing group by the interface transport mechanism. The substrate is subjected to cleaning and drying processing by the drying processing group.

Owner:SOKUDO CO LTD

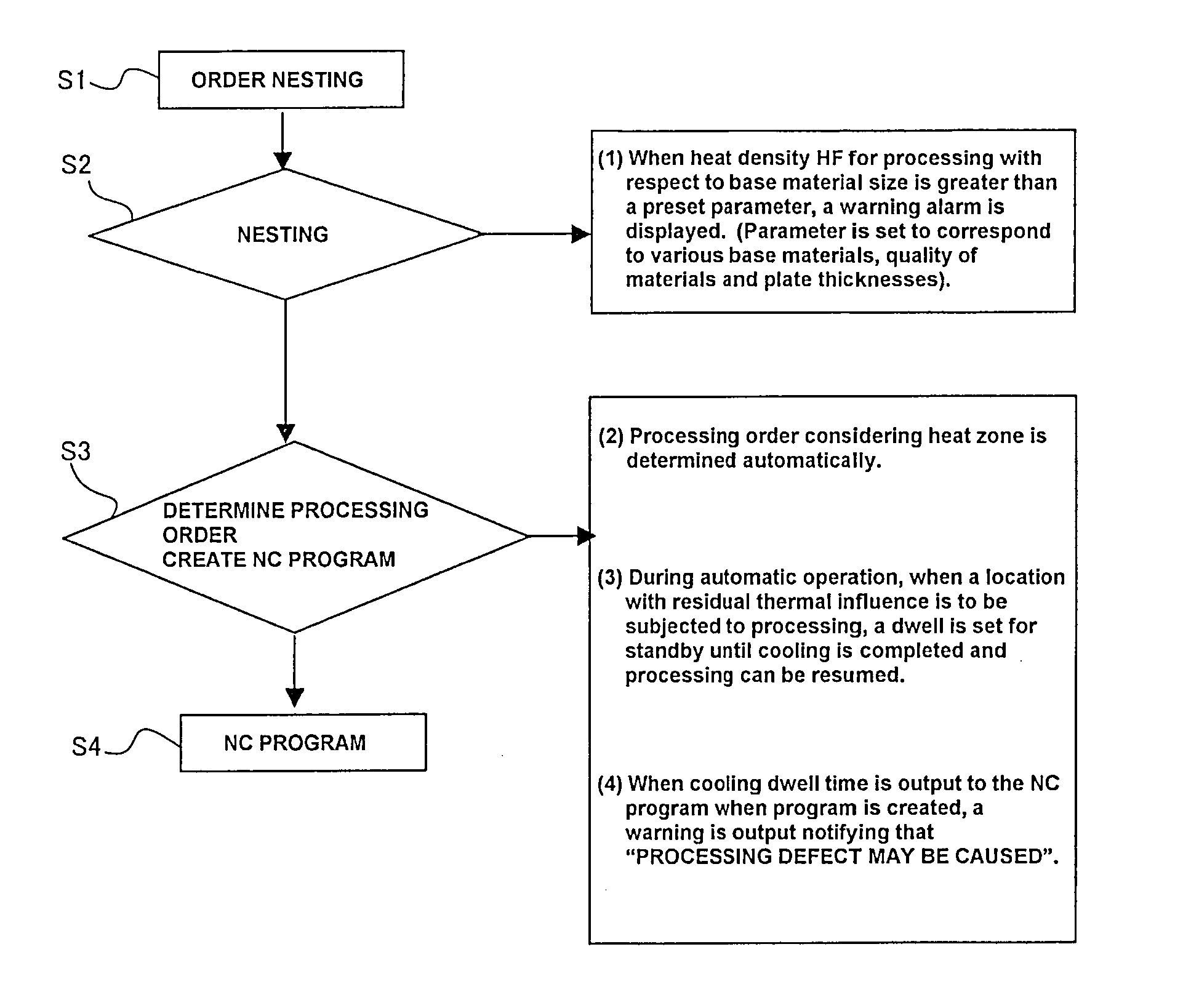

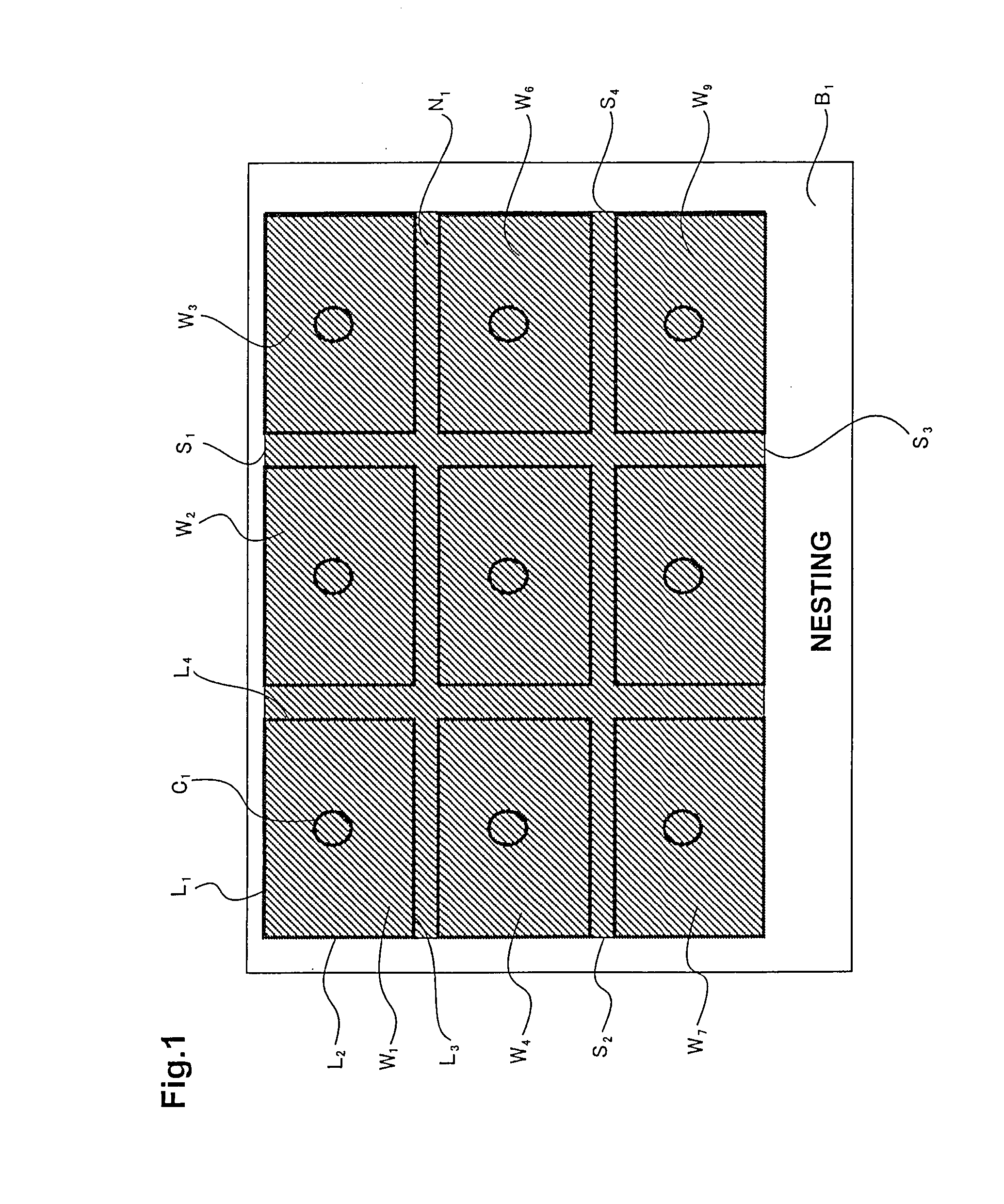

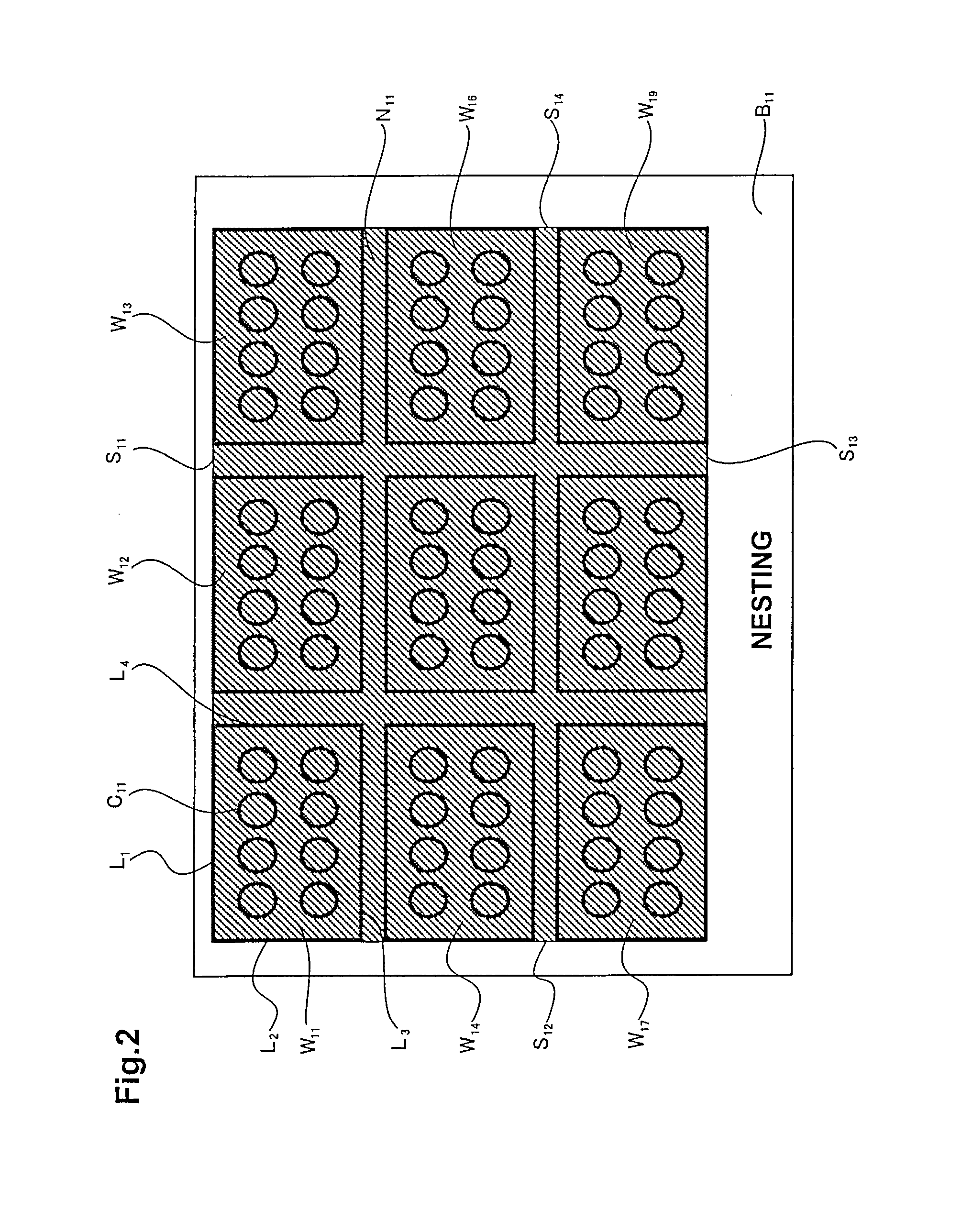

System for preventing processing defect in laser processing

InactiveUS20080053977A1Reduce processingAvoid processing defectsProgramme controlComputer controlLaser processingEngineering

The invention provides a laser processing system in which a heat density accumulated in a base material is computed based on nesting data in order to create an NC program for preventing processing defects. Upon cutting out works W1 through W9 from a base material B1, a nesting area N1 is defined as a sum of the lengths of lines S1 through S4, which is defined as NG1. A laser processing length dimension of the works W1 through W9 is computed by adding the line lengths L1 through L4 and the circumferential length C1 of a round hole and multiplying the result by nine, which is defined as LG1. The heat density HF1 is computed as HF1=LG1 / NG1, and the heat density is compared with a parameter set in advance in order to determine a processing order for preventing processing defects by heat and to create a corresponding program.

Owner:YAMAZAKI MAZAK KK

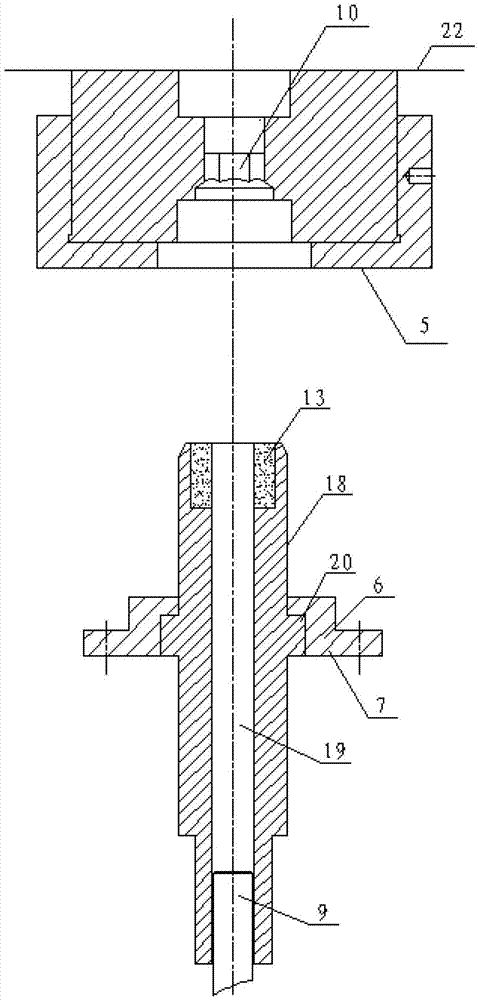

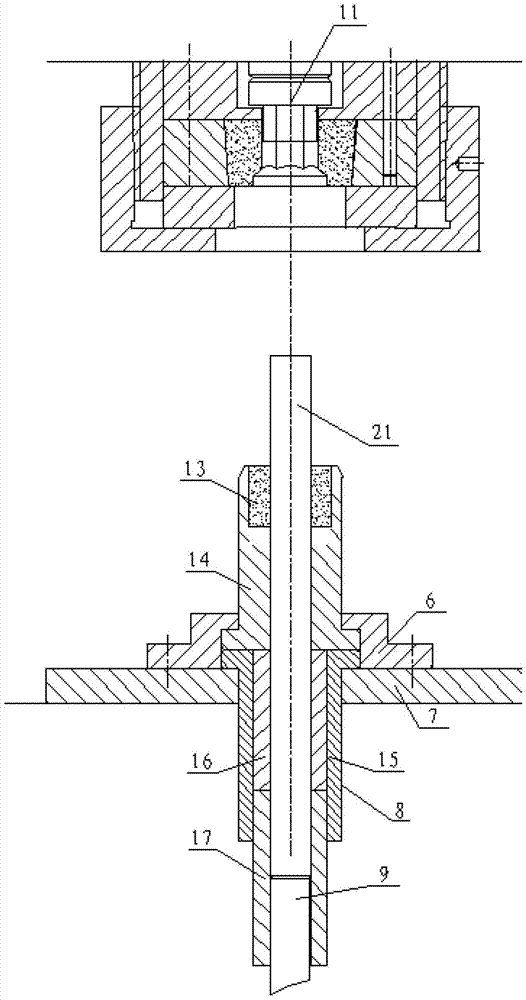

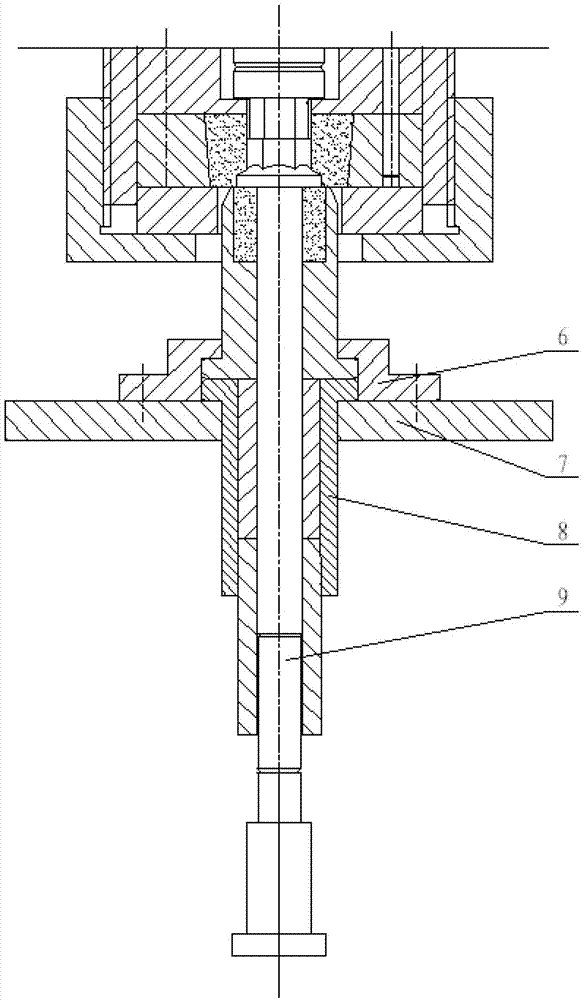

Method and die for processing bolt

ActiveCN102764843AAvoid processing defectsImprove efficiencyBoltsForging/hammering/pressing machinesProduction rateEngineering

The invention provides a method and a die for processing a bolt. The defects that methods for processing long and thin bolts in the prior art are low in unthreaded screw dimensional precision, low in screw straightness and low in production rate are eliminated. The die comprises an upper die and a lower die, an upper die cavity which is matched with a bolt head is arranged on the upper die, the lower die is composed of a lower die sleeve, a lower die sleeve fixing device and a cushion block, an axis center hole is arranged on the lower die sleeve, and the outer diameter of the cushion block is matched with the inner diameter of the axis center hole. The processing method uses the die. By the aid of the method and the die, the production efficiency is high, and the obtained unthreaded screw dimensional precision is also high.

Owner:浙江中航来宝精工科技有限公司

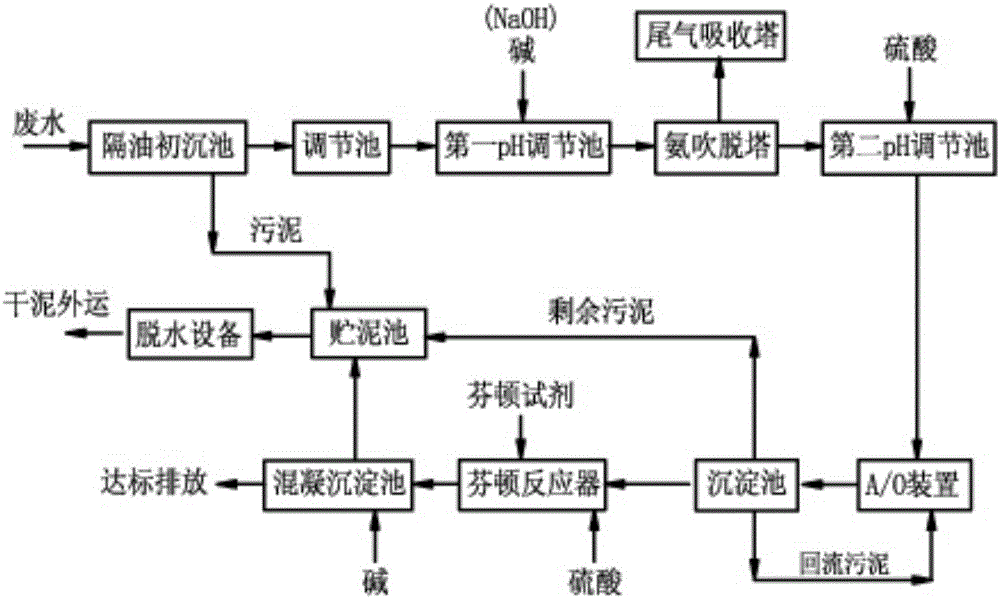

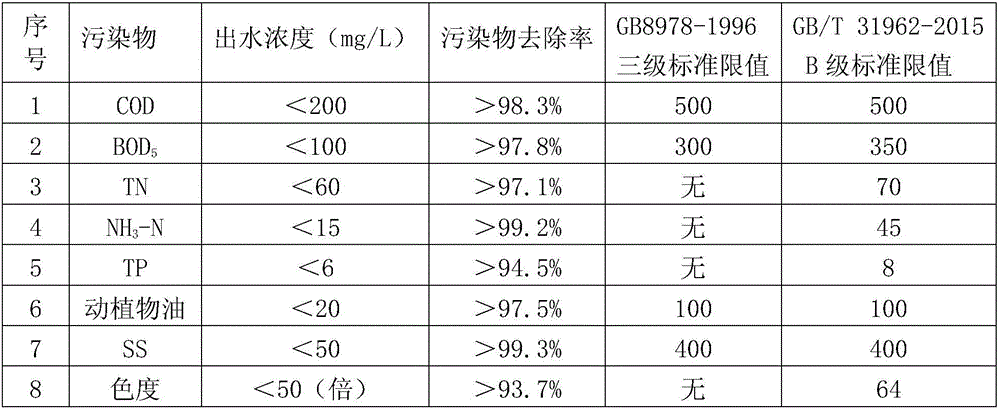

Kitchen garbage slurry anaerobic fermentation wastewater treatment method

InactiveCN106746174AGuaranteed uptimeEfficient removalFatty/oily/floating substances removal devicesWater contaminantsEmission standardWater quality

The invention relates to a kitchen garbage slurry anaerobic fermentation wastewater treatment method, in particular to a treatment method for treating wastewater produced in other procedures through wastewater produced after anaerobic fermentation dehydration of kitchen garbage slurry and kitchen garbage. Wastewater is subjected to oil-separation primary precipitation, water amount and water quality adjustment, first pH value adjustment, free ammonia stripping in an ammonia stripping tower, second pH value adjustment, A / O biochemical treatment, precipitation treatment, treatment in a Fenton reactor and treatment in a coagulative precipitation tank, so that pollutants such as COD, BOD5 and SS in the wastewater are removed, TN and TP can be removed effectively, the wastewater chroma can be lowered effectively, the TN and TP removing rates are increased, and pollutants such as COD, BOD5, TN, NH3-N, TP and chroma in the treated wastewater can stably meet the requirements in Integrated Wastewater Discharge Standard (GB8978-1996, grade III standard) and Wastewater Quality Standards for Discharge to Municipal Sewers (GB / T 31962-2015, grade B).

Owner:CHINA MACHINERY INT ENG DESIGN & RES INST

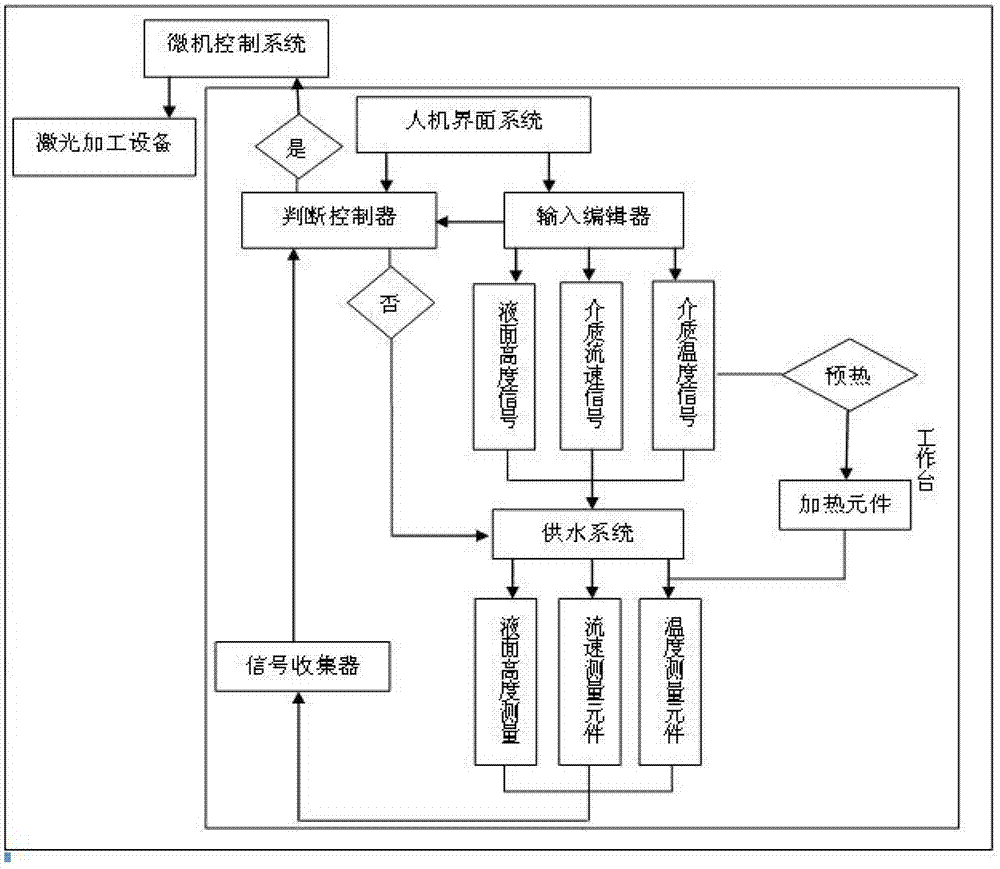

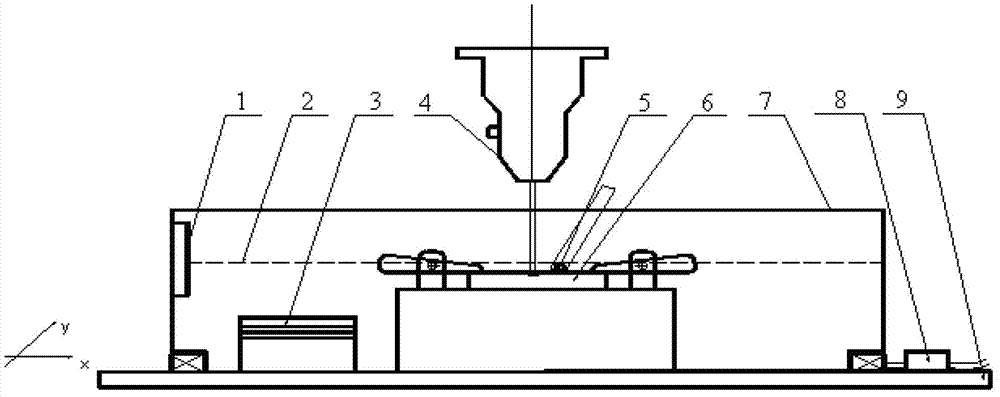

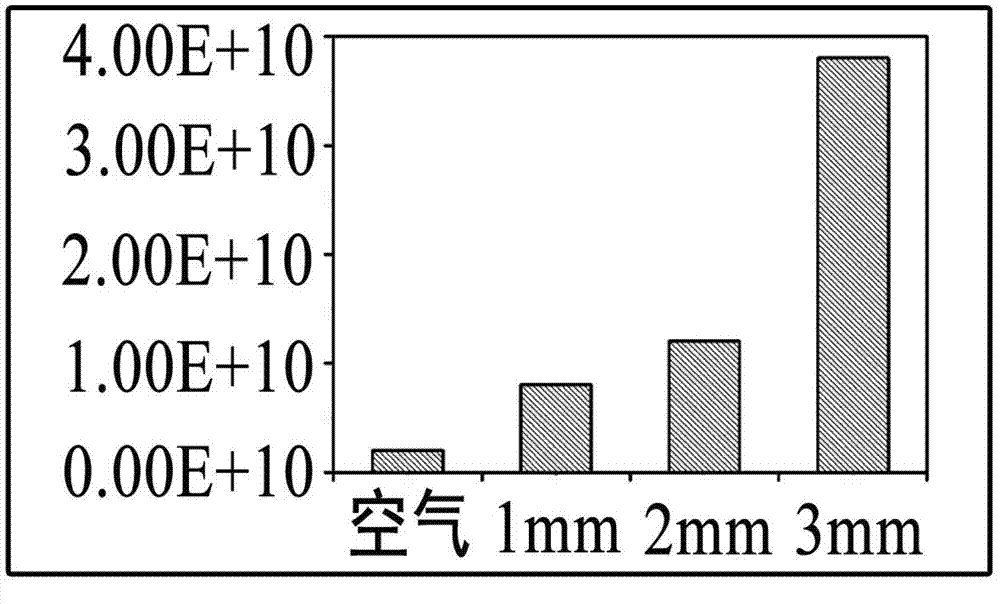

Metal surface laser processing method in liquid medium

The invention relates to a laser surface processing method of a part and a test piece in a liquid medium, especially to a metal surface laser processing method in a liquid medium with excellent treatment structure and special surface performance by the utilization of a laser preparation means. The concrete implementation process is as follows: the part or test piece is immersed in a container filled with some liquid, and a laser terminal permeates through a liquid water film on the surface of the part or test piece and irradiates on the surface of the test piece or part to be processed. Different requirements for processing the part or test piece can be realized through adjusting height of liquid level, speed of liquid flow and temperature. The method can be used as a method for optimizing laser processing structures and also can be used to preheat the part or test piece to be processed, so as to obtain ideal surface mechanical properties and special functions.

Owner:JILIN UNIV

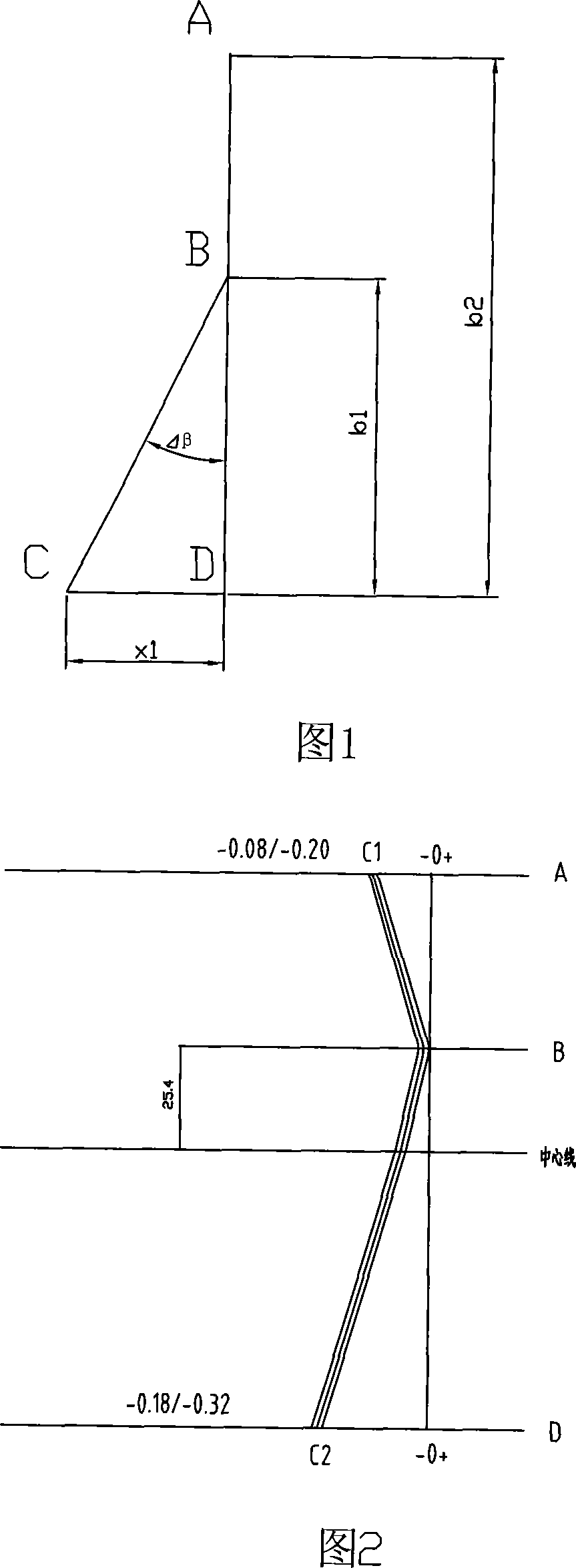

Tooth direction shaping gear hobbing processing technique

ActiveCN101085480AUniform tooth surface hardness differenceMeet the design requirementsGear teethEngineeringMachining process

The invention relates to the machining of gear teeth. The machining process comprises: Based on the drawing, it uses the hobber machining the gear to the inspection point A or D, computing the differential change wheel angle t based on the hobber differential mechanism with CB line actual spiral angle and gear and hobber parameter, loosening the differential change wheel, holding the change angle t, imitating the difference of machining small spiral gears, forming fixing point from the end surface fixing theoretical point C. It can get rid of the deficiencies of step, insufficient effective hardening and teeth surface hardness.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

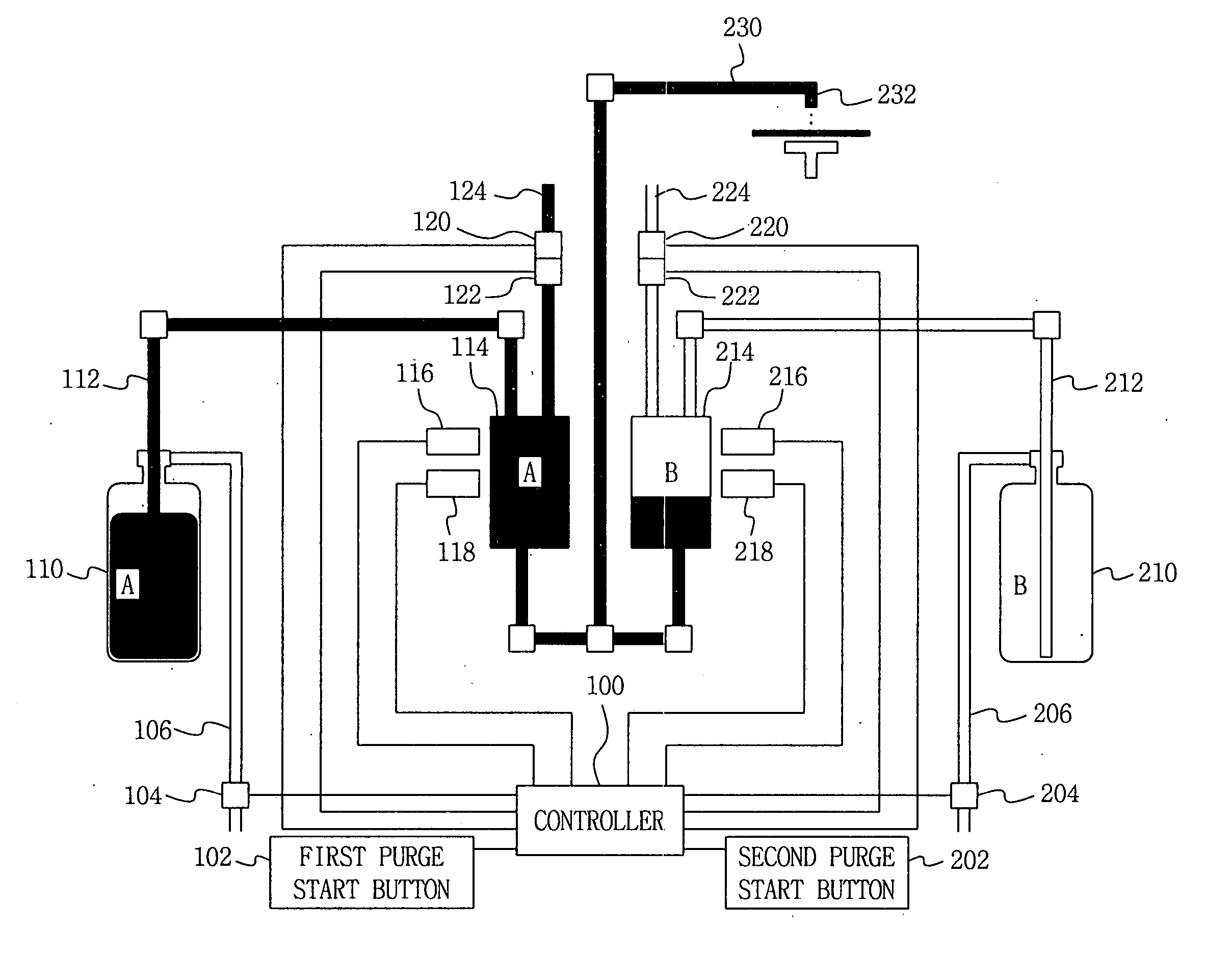

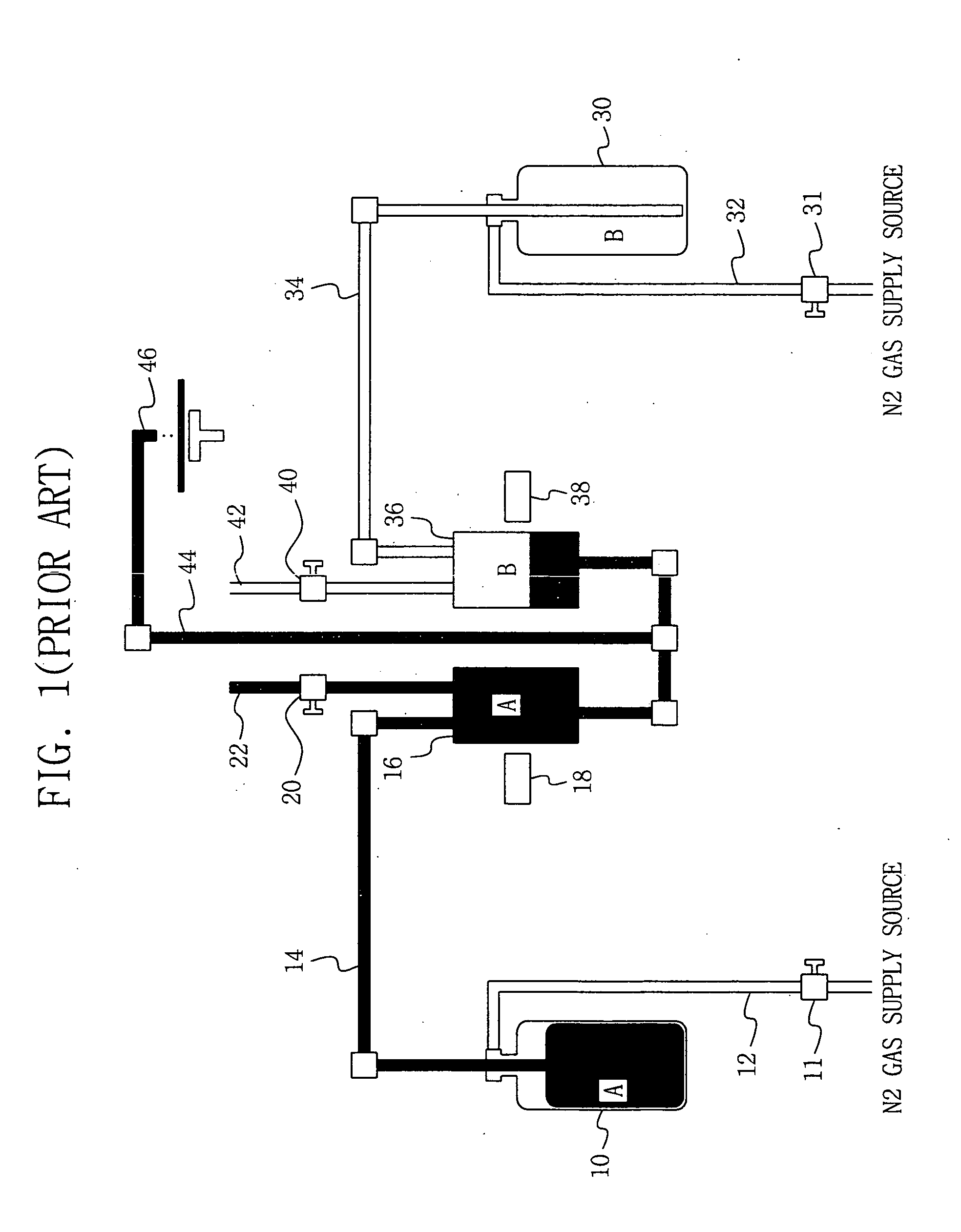

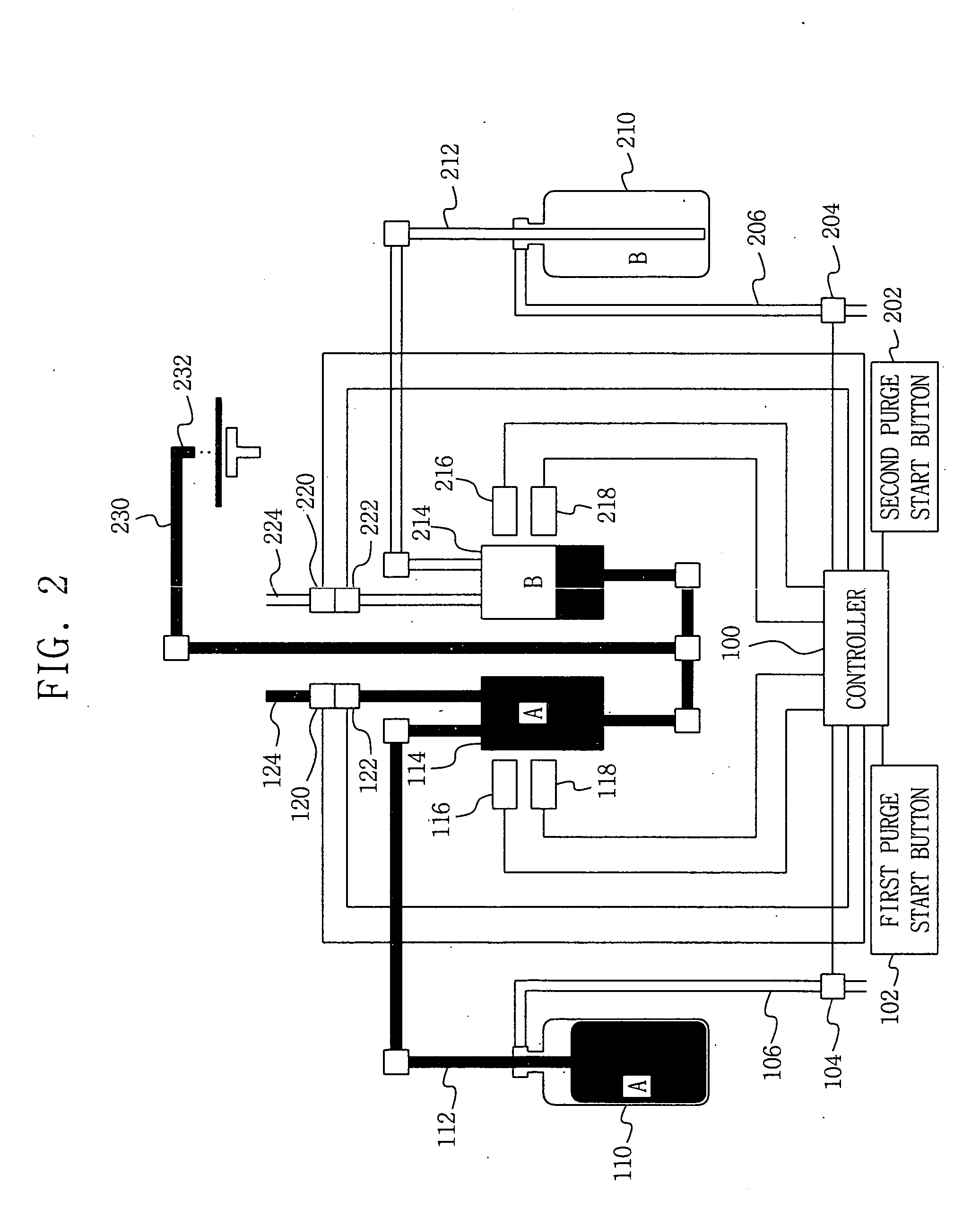

Photoresist supply apparatus and method of controlling the operation thereof

InactiveUS20050069631A1Avoid unnecessary consumptionAvoid consumptionSemiconductor/solid-state device manufacturingSpray nozzlesSolenoid valveLevel sensor

A photoresist supply apparatus of semiconductor coating equipment fills a supply line with new photoresist when a used photoresist bottle is replaced. The photoresist supply apparatus includes first and second photoresist bottles, first and second gas supply pipes connected to the bottles, first and second solenoid valves disposed along the gas supply pipes, first and second purge start buttons, first and second photoresist supply pipes, first and second trap tanks to which the supply pipes are connected, a third photoresist supply pipe connected to the trap tanks, a nozzle connected to the third photoresist supply pipe, first and second level sensors disposed at an upper level of the trap tanks, third and fourth level sensors disposed at a lower level of the trap tank, first and second discharge pipes connected to the trap tanks, third and fourth solenoid valves disposed along the discharge pipes, first and second drain sensors associated with the discharge pipes, and a controller.

Owner:SAMSUNG ELECTRONICS CO LTD

Substrate processing apparatus and substrate processing method

ActiveUS20060108068A1Reduce stepsOperation is troublesomeLiquid surface applicatorsLiquid processingComputer science

A substrate processing apparatus comprises an indexer block, an anti-reflection film processing block, a resist film processing block, a drying / development processing block, and an interface block. An exposure device is arranged adjacent to the interface block. The drying / development processing block comprises a drying processing group. The interface block comprises an interface transport mechanism. A substrate is subjected to exposure processing by the exposure device, and subsequently transported to the drying processing group by the interface transport mechanism. The substrate is cleaned and dried by the drying processing group.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

Substrate cleaning apparatus and substrate processing apparatus including the substrate cleaning apparatus

ActiveUS20130255031A1Avoid formingAvoid pollutionDispersed particle filtrationSuction cleanersEngineeringMechanical engineering

An ULPA filter is arranged at the upper portion in a casing. Air outside of the casing is supplied to the ULPA filter through a duct. Clean air that has passed through the ULPA filter is led to an opening of a spin plate through a passage forming member, a connection member, a base, a motor supporting member and a rotating shaft of a spin motor. The spin chuck holds a substrate such that the upper surface of the substrate is opposite to the spin plate. In this state, the spin motor operates, causing the spin plate to rotate and thus the lower surface of the rotating substrate to be cleaned by a cleaning brush.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

Substrate processing apparatus and substrate processing method

ActiveUS20100190116A1Operation is troublesomeAvoid processing defectsSemiconductor/solid-state device manufacturingPretreated surfacesComputer science

A substrate processing apparatus comprises an indexer block, an anti-reflection film processing block, a resist film processing block, a development processing block, and an interface block. An exposure device is arranged adjacent to an interface block. The interface block comprises a drying processing group including two drying processing units and an interface transport mechanism. After a substrate is subjected to exposure processing by the exposure device, the substrate is transported to the drying processing units in the drying processing group by the interface transport mechanism, where the substrate is subjected to cleaning and drying processings.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

Substrate processing apparatus and substrate processing method

ActiveUS20140065309A1Avoid processing defectsInhibit transferPretreated surfacesSemiconductor/solid-state device manufacturingHand heldEngineering

Transport mechanisms are respectively provided in first and second processing blocks. Each transport mechanism has a hand. The hand holds the other surface of a substrate without coming into contact with an edge of the substrate. The hand is moved such that the substrate is transported between an adhesion reinforcement processing unit or a cooling unit and a coating processing unit or a development processing unit. In the adhesion reinforcement processing unit and the cooling unit, temperature processing is performed on the substrate while the back surface of the substrate is held by suction. In the coating processing unit and the development processing unit, a processing liquid is supplied to the main surface of the substrate while the back surface of the substrate is held by suction by a spin chuck.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

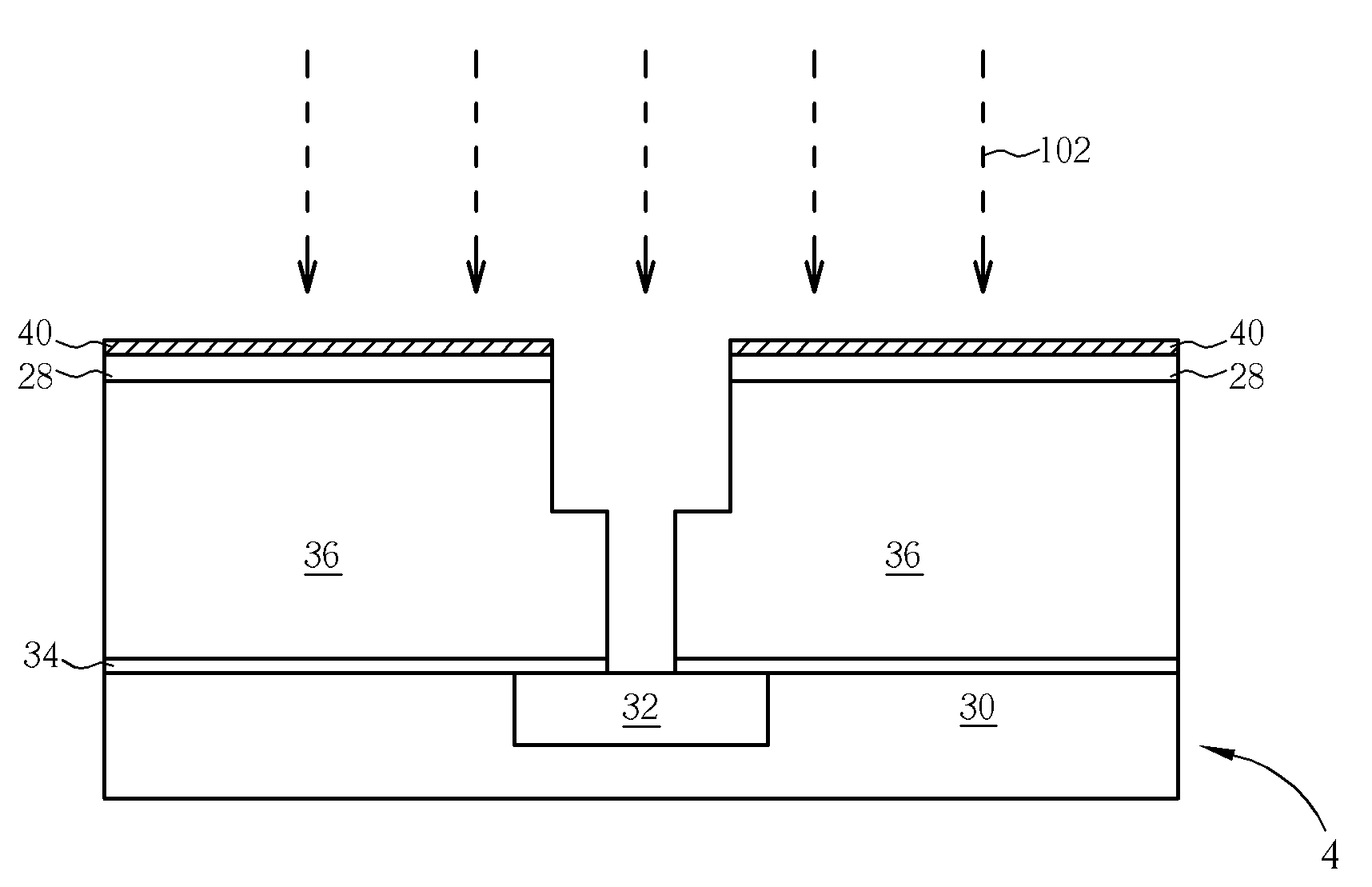

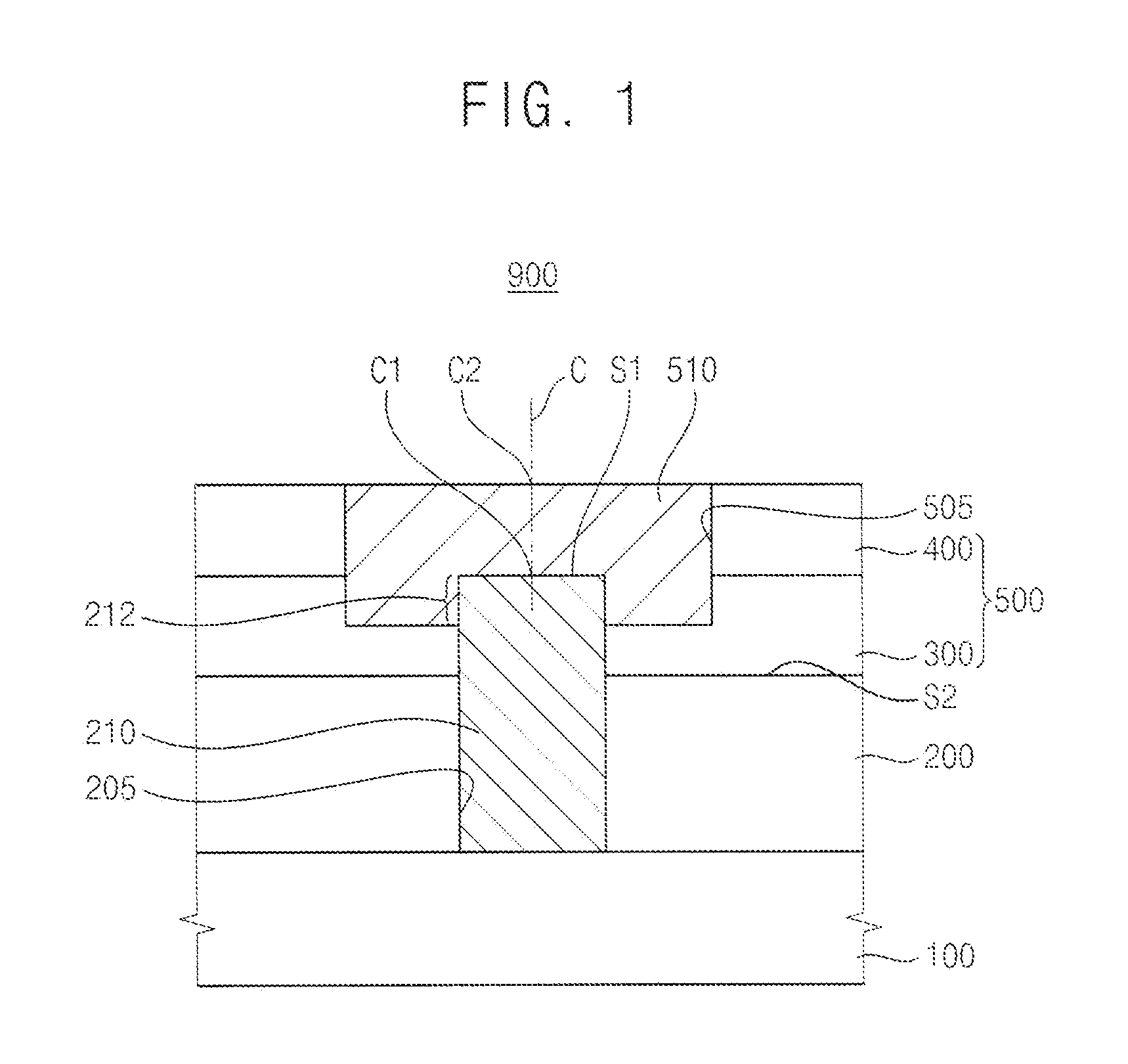

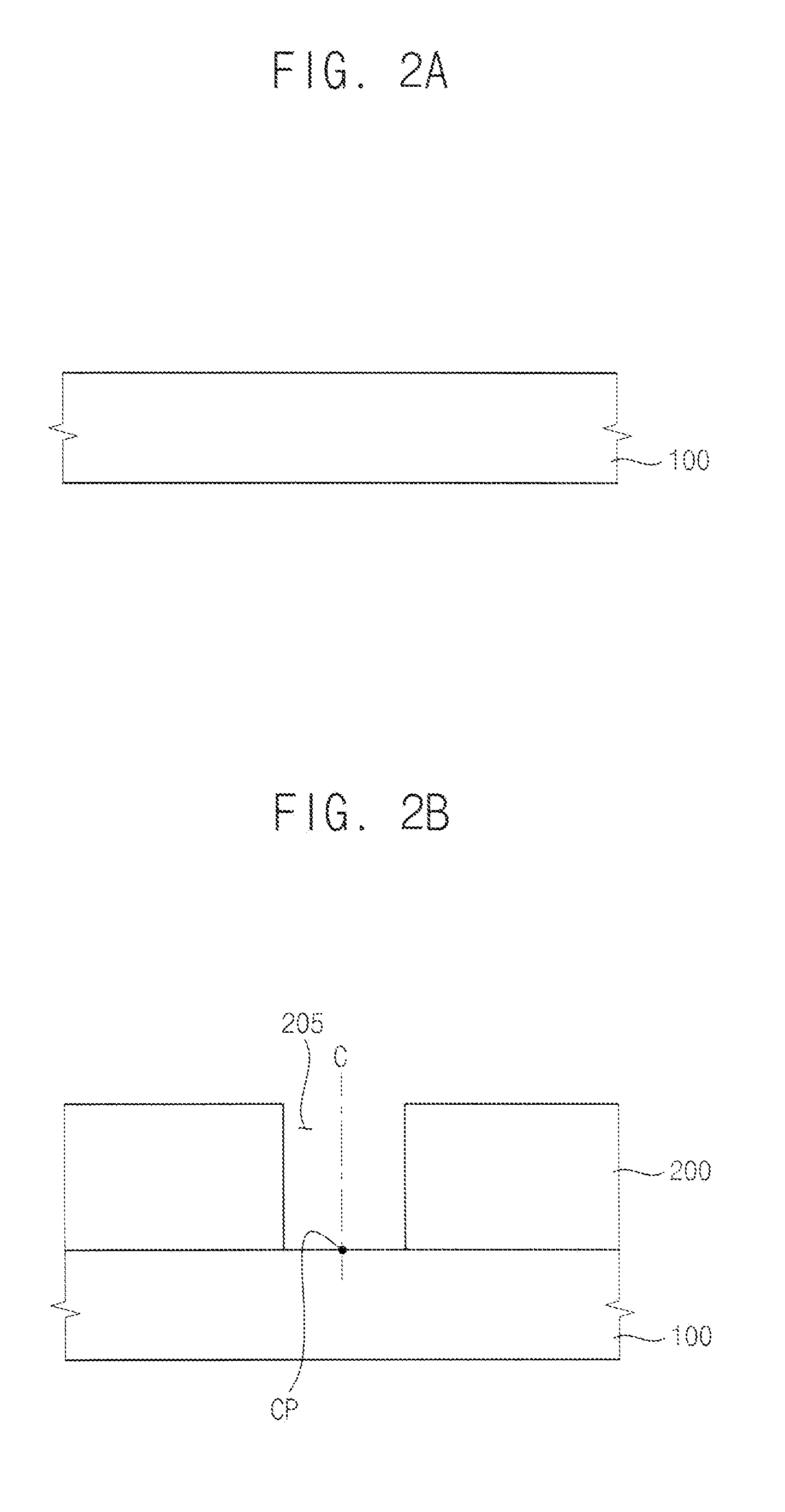

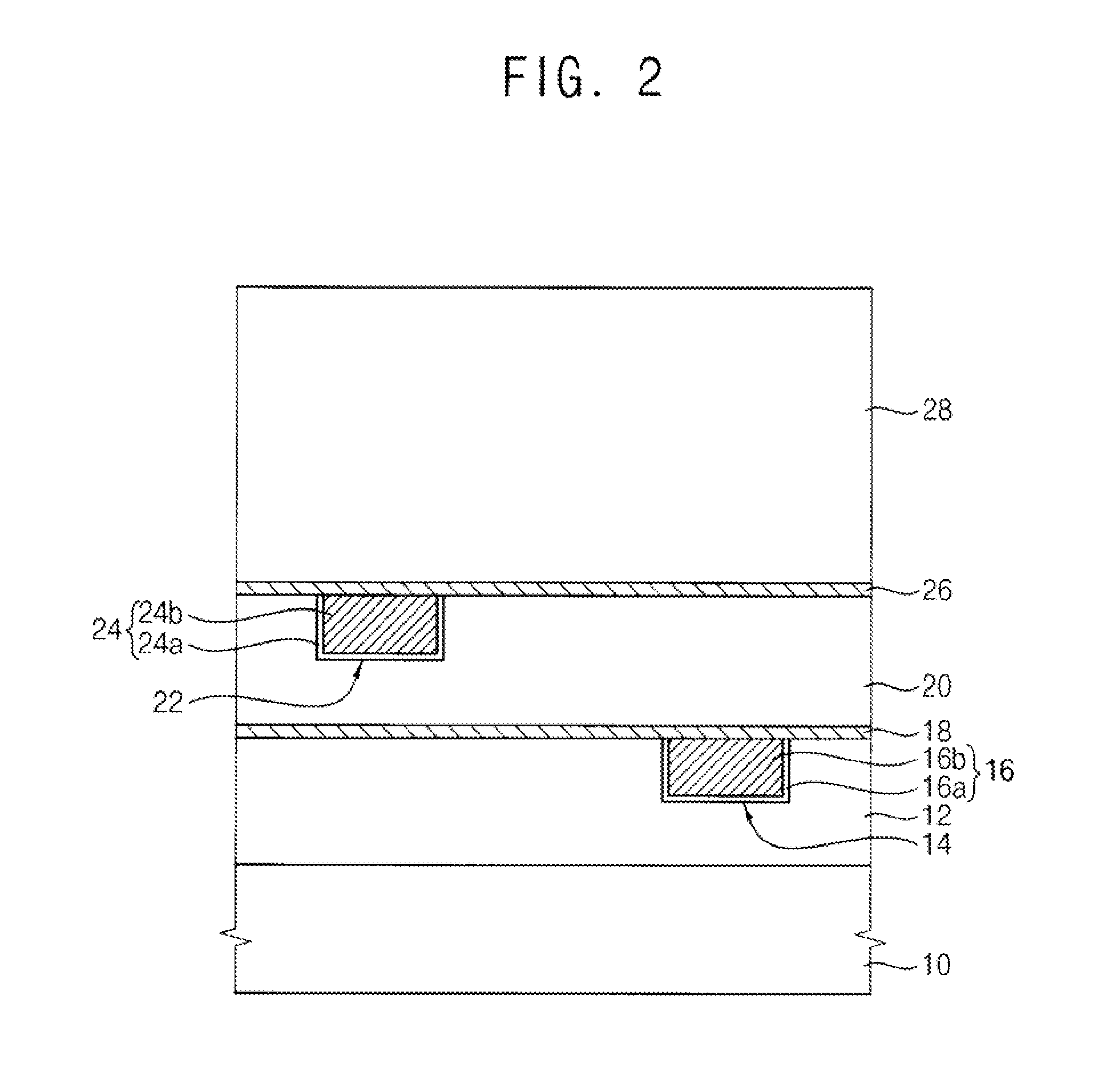

Method of manufacturing a semiconductor device

InactiveUS20100261345A1Avoid processing defectsSemiconductor/solid-state device manufacturingEngineeringInterconnection

In a semiconductor device and method of manufacturing thereof, a first insulation interlayer is formed on a substrate including a lower conductive pattern. The first insulation interlayer has a first opening through which the lower conductive pattern is exposed. An interconnection is formed in the first opening such that the interconnection is contact with the lower conductive pattern and protruded from the first insulation interlayer. A second insulation interlayer is formed on the first insulation interlayer in such a manner that the second insulation interlayer has a second opening through the interconnection is exposed and the second opening is centrally aligned with the interconnection. An upper conductive pattern is formed in the second opening such that the upper conductive pattern is contacted with the interconnection. Accordingly, a mis-alignment between the upper conductive pattern and the interconnection is prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

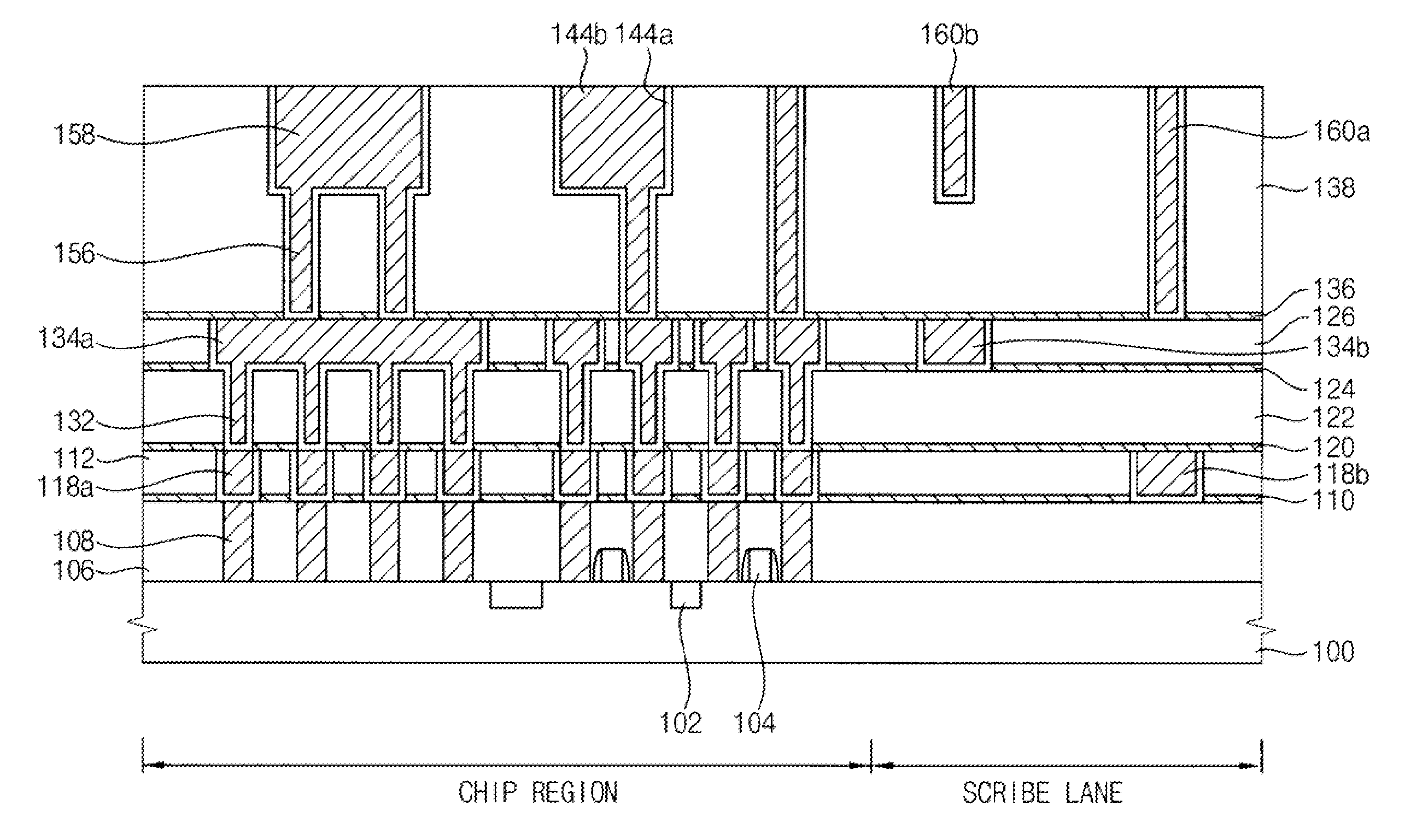

Monitoring test element groups (TEGS) for etching process and methods of manufacturing a semiconductor device using the same

ActiveUS20120231564A1Accurate measurementAvoid processing defectsSemiconductor/solid-state device testing/measurementSolid-state devicesPower semiconductor deviceEngineering

Disclosed is a monitoring TEG for an etching process in a semiconductor device. The TEG includes an etch stopping layer on a substrate and a target layer to be etched provided on the etch stopping layer. The target layer to be etched includes a first opening portion formed by etching a portion of the target layer to be etched and a second opening portion formed by etching another portion of the target layer to be etched. The second opening portion has a smaller depth than the first opening portion. A depth of a partial contact hole formed by a first partial etching process may be measured.

Owner:SAMSUNG ELECTRONICS CO LTD

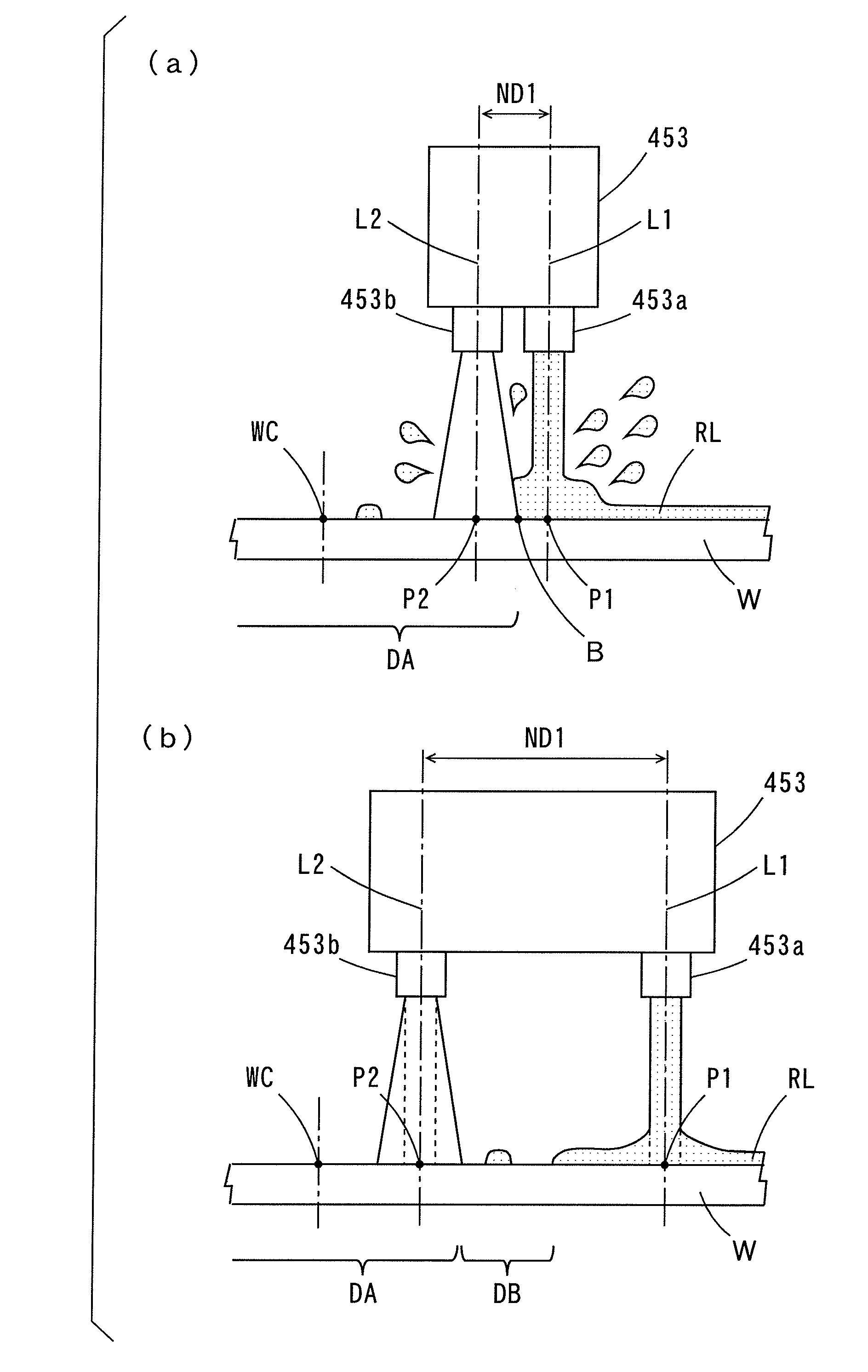

Substrate processing apparatus and substrate processing method

InactiveUS20070130716A1Avoid processing defectsMechanical cleaningPressure cleaningCompound (substance)Waste management

A substrate processing apparatus comprises a multifunctional nozzle having a double-pipe structure. An inner flow path of the multifunctional nozzle is connected to a first supply suction system through a supply suction pipe. An outer flow path is connected to a second supply suction system through the supply suction pipe. The first supply suction system and the second supply suction system have respectively chemical liquid supply sources, rinse liquid supply sources, inert gas supply sources, and ejectors. Such a configuration makes it possible to selectively supply the chemical liquid, supply the rinse liquid, and supply the inert gas and suck in through the inner flow path and the outer flow path of the multifunctional nozzle.

Owner:DAINIPPON SCREEN MTG CO LTD

Substrate processing apparatus

InactiveUS20100129526A1Operation is troublesomeAvoid processing defectsSemiconductor/solid-state device manufacturingPhotosensitive material processingEngineeringTreatment unit

Owner:SCREEN SEMICON SOLUTIONS CO LTD

Tapered roller bearing and method of designing the same

ActiveUS8858088B2Convenience to workImprove machine efficiencyRoller bearingsShaftsCircular coneEngineering

In a tapered roller bearing assembly, a crowning profile formed portion of the roller rolling surface is made up of a contact area crowned portion, which is held in contact with an inner ring raceway surface, and a non-contact area crowned portion which is held in non-contact with the inner ring raceway surface. The contact area crowned portion and the non-contact area crowned portion have their generatrices extending in an axial direction of a roller, which generatrices are represented by corresponding continuous lines represented by different functions and continued smoothly at a point of connection, and the curvature of the generatrix of the non-contact area crowned portion in the vicinity of the connection point is chosen to be smaller than the curvature of the generatrix of the contact area crowned portion.

Owner:NTN CORP

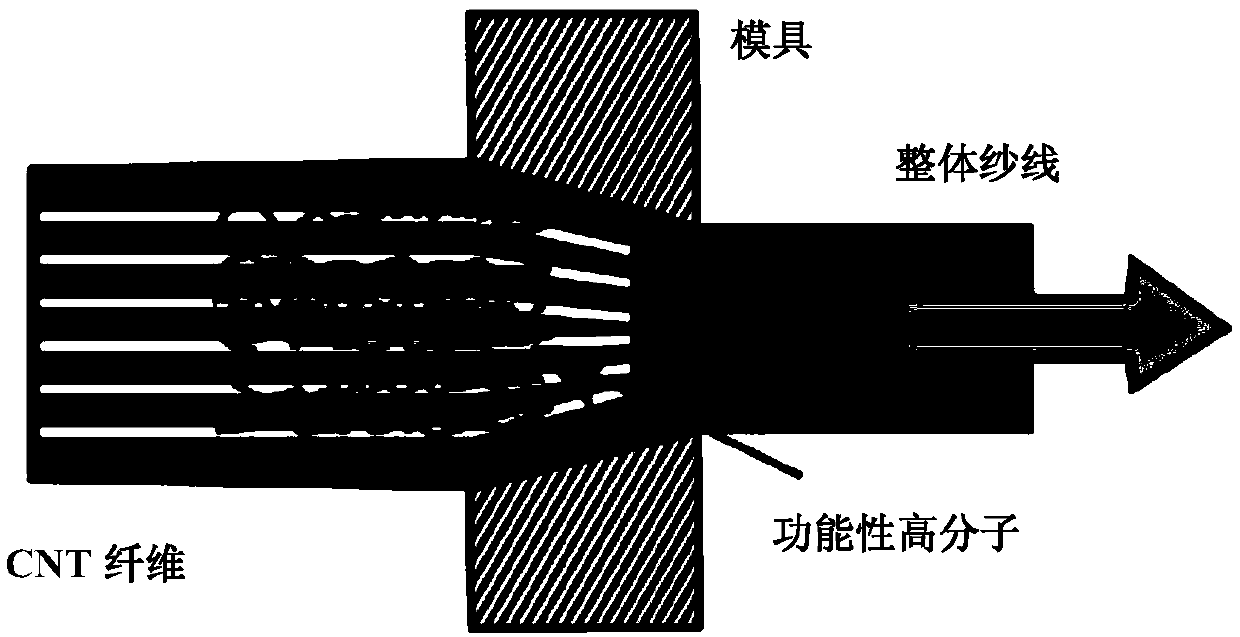

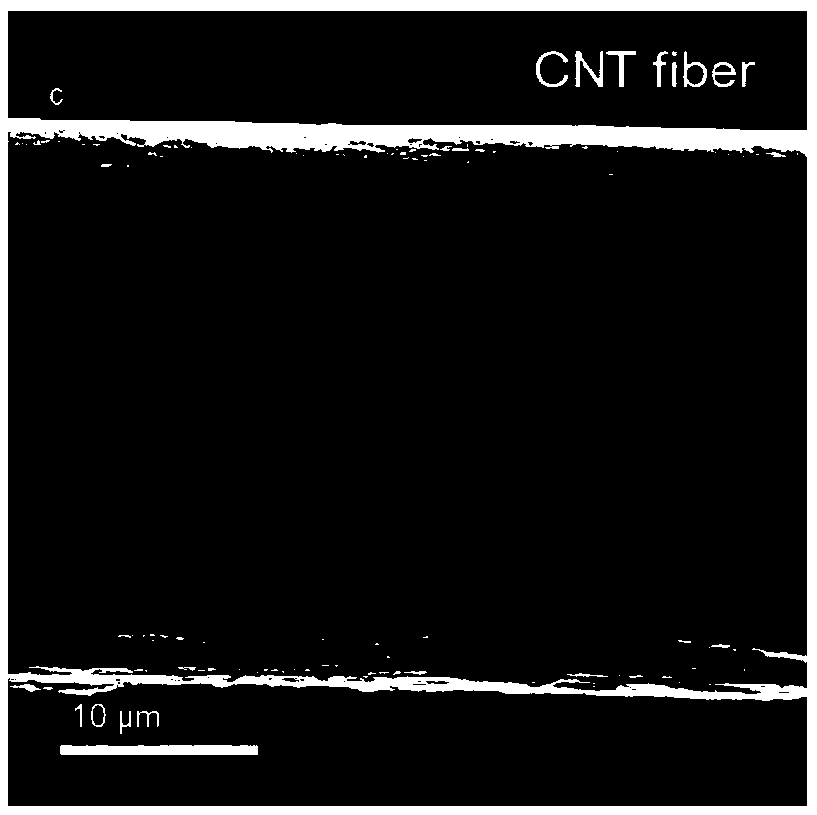

High-performance carbon nano tube yarn and preparation method thereof

InactiveCN110857478AReduce strong and weak linksAvoid strong damageMaterial nanotechnologyAdhesivesCarbon nanotube yarnFiber strength

The invention discloses a high-performance carbon nano tube yarn and a preparation method thereof. The preparation method includes introducing at least two carbon nano tube fibers into a through hole,and pulling the carbon nano tube fibers along the length direction to thread the through hole with the carbon nano tube fibers continuously, thereby straightening the carbon nano tube fibers by pulling, and squeezing to allow the carbon nano tube fibers to shrink by the through hole; meanwhile, fully soaking the carbon nano tube fibers with a functional polymer solution, so as to obtain an integral yarn. Without adoption of the conventional yarn twisting method, strength loss of the carbon nano tube fibers in the early stage and unevenness of the yarn structure both caused by twisting are avoided, and weak links of strength of the yarn are decreased; the yarn prepared by the method has the advantages that interference bonding strength of fibers of the yarn is enhanced, breakage simultaneity of the fibers is improved, utilization rate of fiber strength is increased, and the yarn has high strength and good flexibility, thermal stability and wear-resistance performance.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

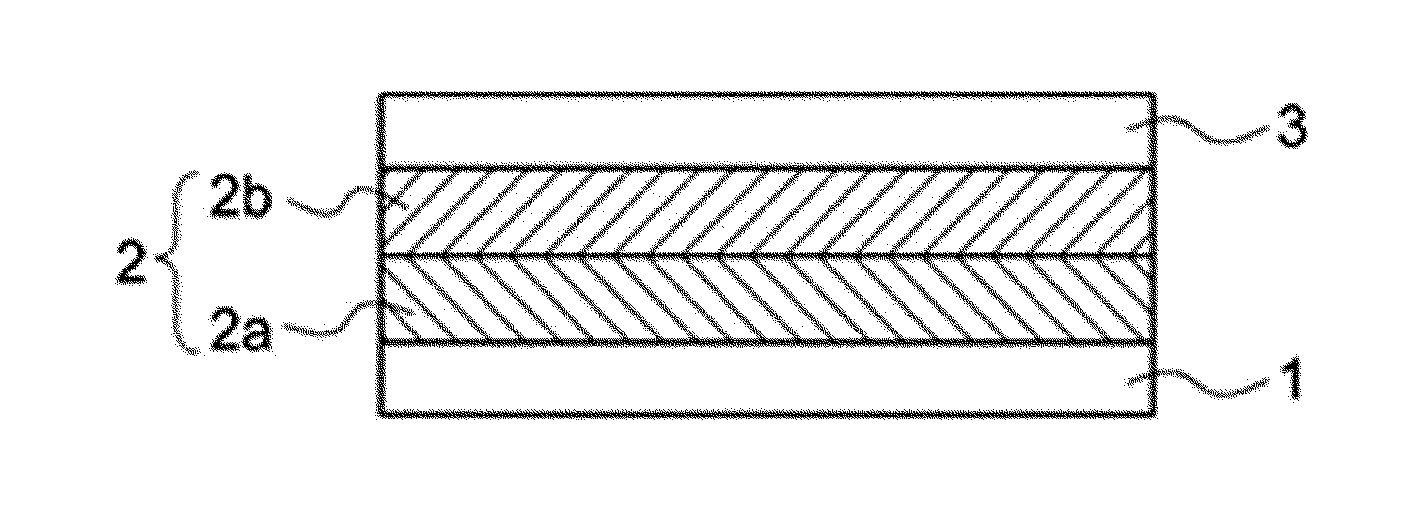

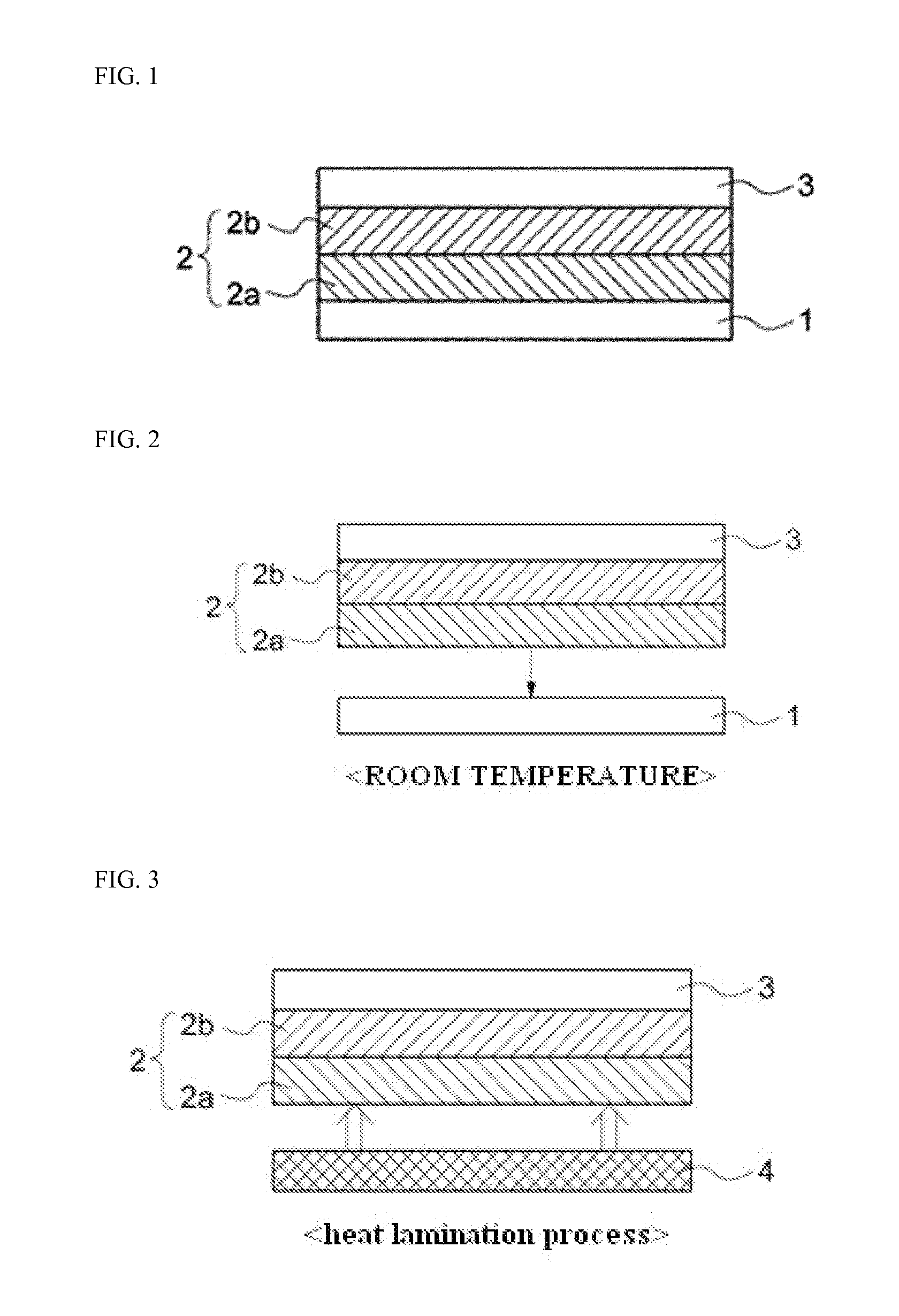

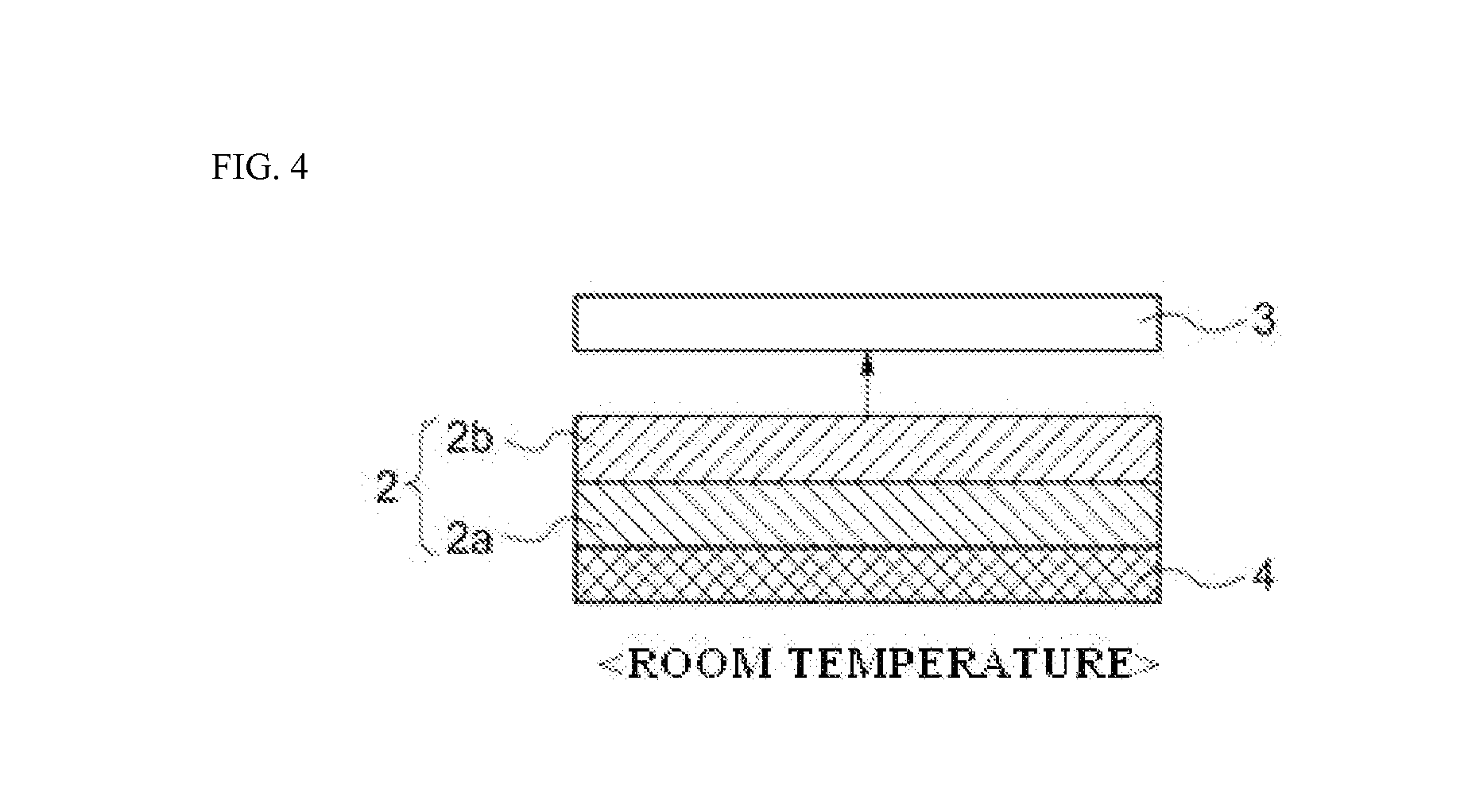

Adhesive film and method for encapsulating organic electronic device using same

ActiveUS20150144932A1Avoid processing defectsSolid-state devicesSemiconductor/solid-state device manufacturingElectronChemistry

The present invention relates to an adhesive film, to an encapsulated product of an organic electronic device using same and to a method for encapsulating an organic electronic device using same. More particularly, an adhesive film for encapsulating an organic electronic device comprises: a protective film layer, a first adhesive layer, a second adhesive layer and a release film layer sequentially arranged. The peel strength (A) between the first adhesive layer and the protective film layer is lower than the peel strength (B) between the second adhesive layer and the release film layer, and the peel strength (B) between the second adhesive layer and the release film layer is lower than the peel strength (C) between the first adhesive layer and an encapsulation substrate, thus improving faults during a peeling process.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com