Method and die for processing bolt

A processing method and technology of bolts, applied in the direction of bolts, manufacturing tools, metal processing equipment, etc., can solve the problems of low dimensional accuracy, low productivity, and low screw straightness of light screws, so as to avoid processing defects, easy installation and positioning, and easy operation. The effect of simple mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

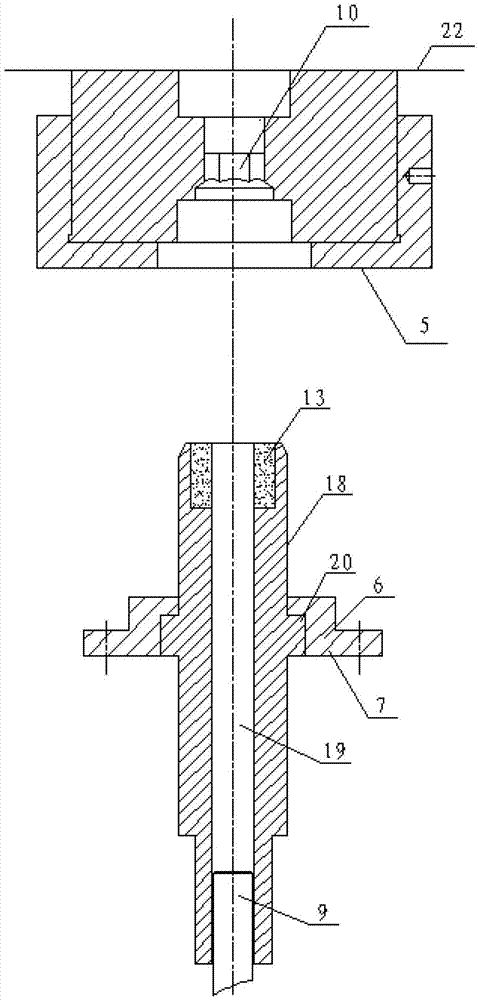

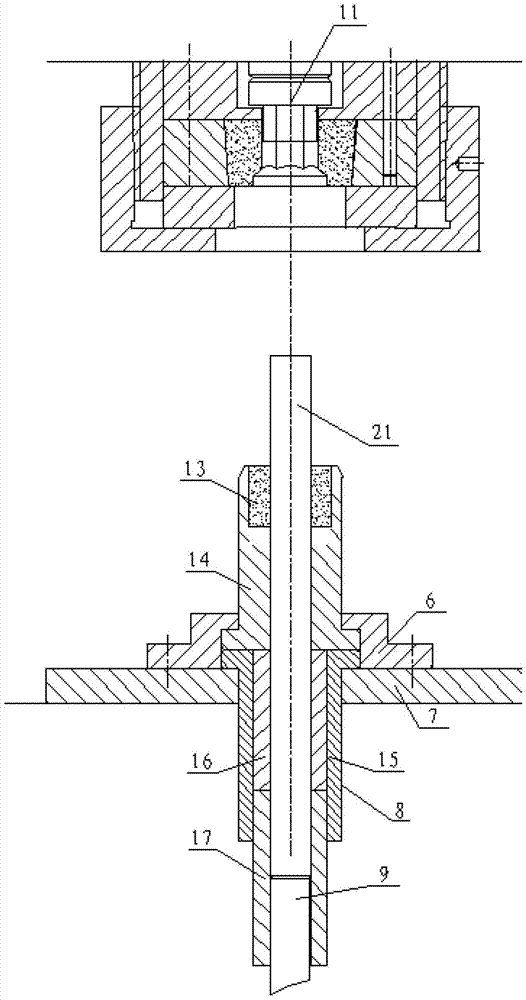

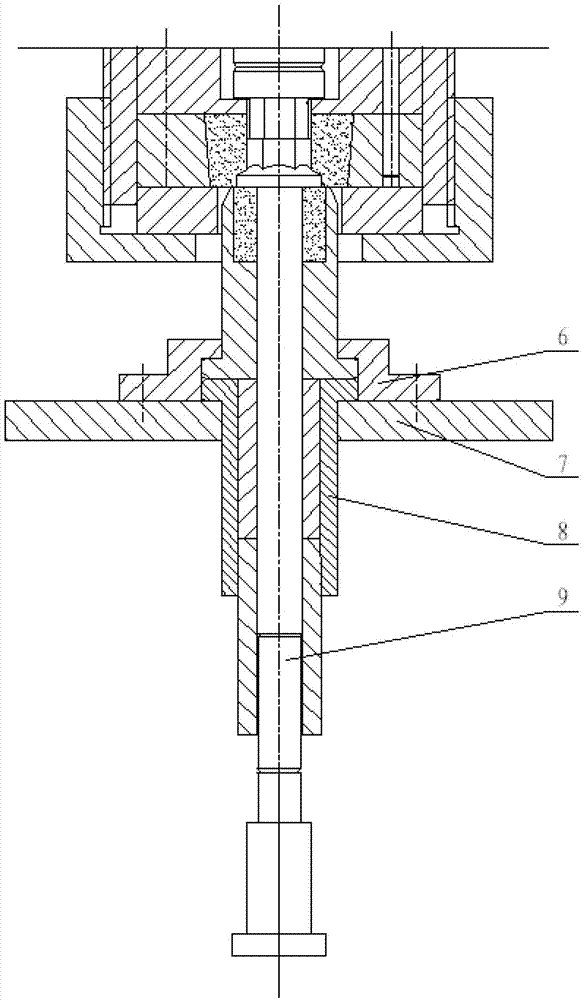

[0044] Take the bolt of processing a concrete elongated screw rod as example below, the present invention is described in detail.

[0045] The dimensions of the desired finished bolts are as follows: Image 6 As shown, the diameter of its elongated screw is The elongated screw has a length of 320 mm.

[0046] 1. Cutting according to the length of a single piece of material - the diameter is obtained by through-grinding rod member 21;

[0047] 2. According to Image 6 Select the appropriate upper die 5 for the bolt head size shown;

[0048] Select the extended mold cover 8 with a height of 270mm and put it into the through hole of the lower template 7, then place the lower mold pad 14 with a height of 70mm on the extended mold cover 8, and put the cushion block 9 into the axis hole 19 Inside, adjust the length of the rod 21 in the axial hole 19 with the spacer 9, the length of the rod 21 in the axial hole is 320 mm, press the gland 6 on the shoulder 20 and use the bolts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com