Substrate processing apparatus and substrate processing method

a processing apparatus and substrate technology, applied in lighting and heating apparatus, cleaning equipment, combustion types, etc., can solve the problems of chemical liquid supply conditions changing, and the drop of chemical liquid on the substrate, so as to prevent the formation of chemical liquid deposits on the substrate. , the effect of processing defects in substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

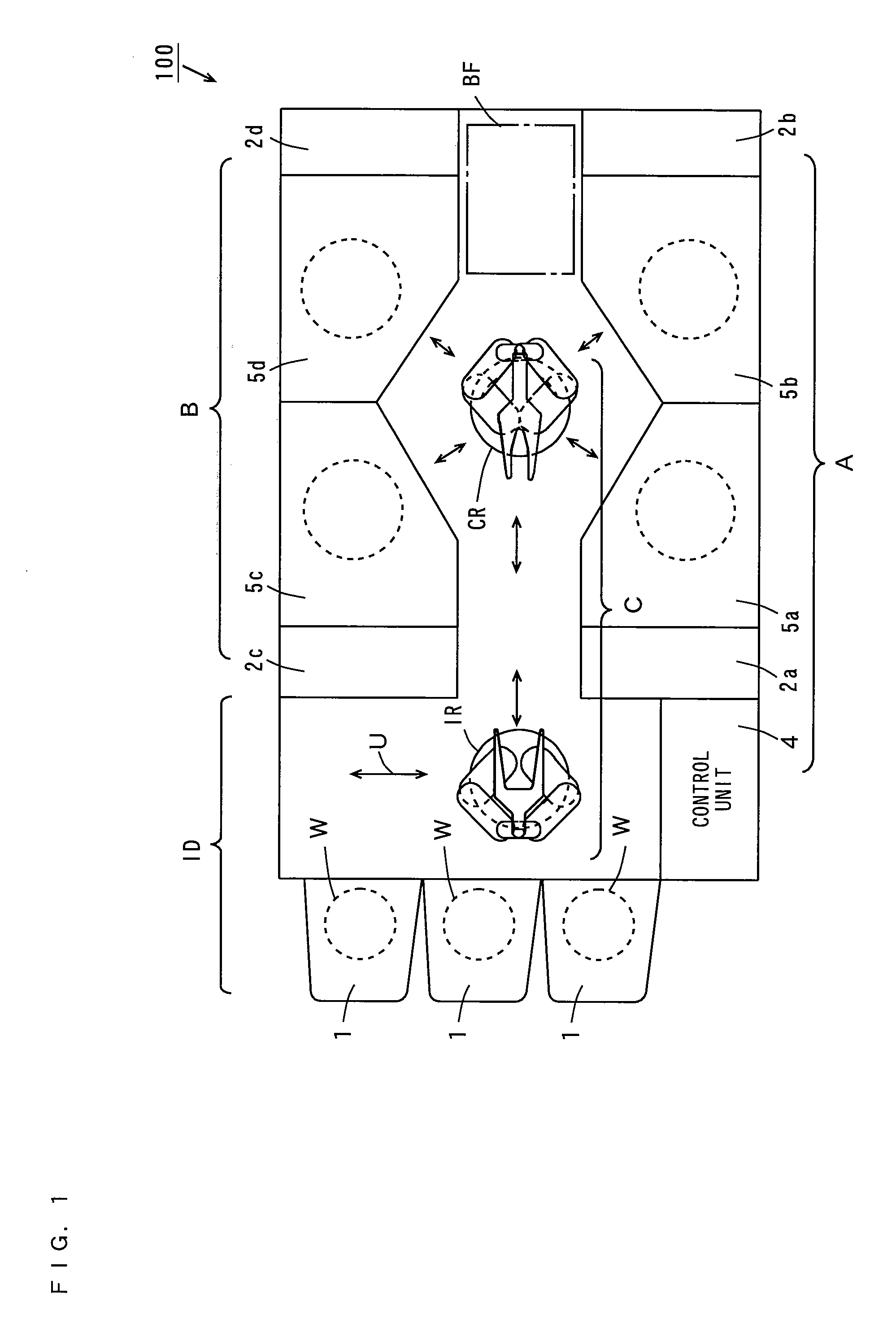

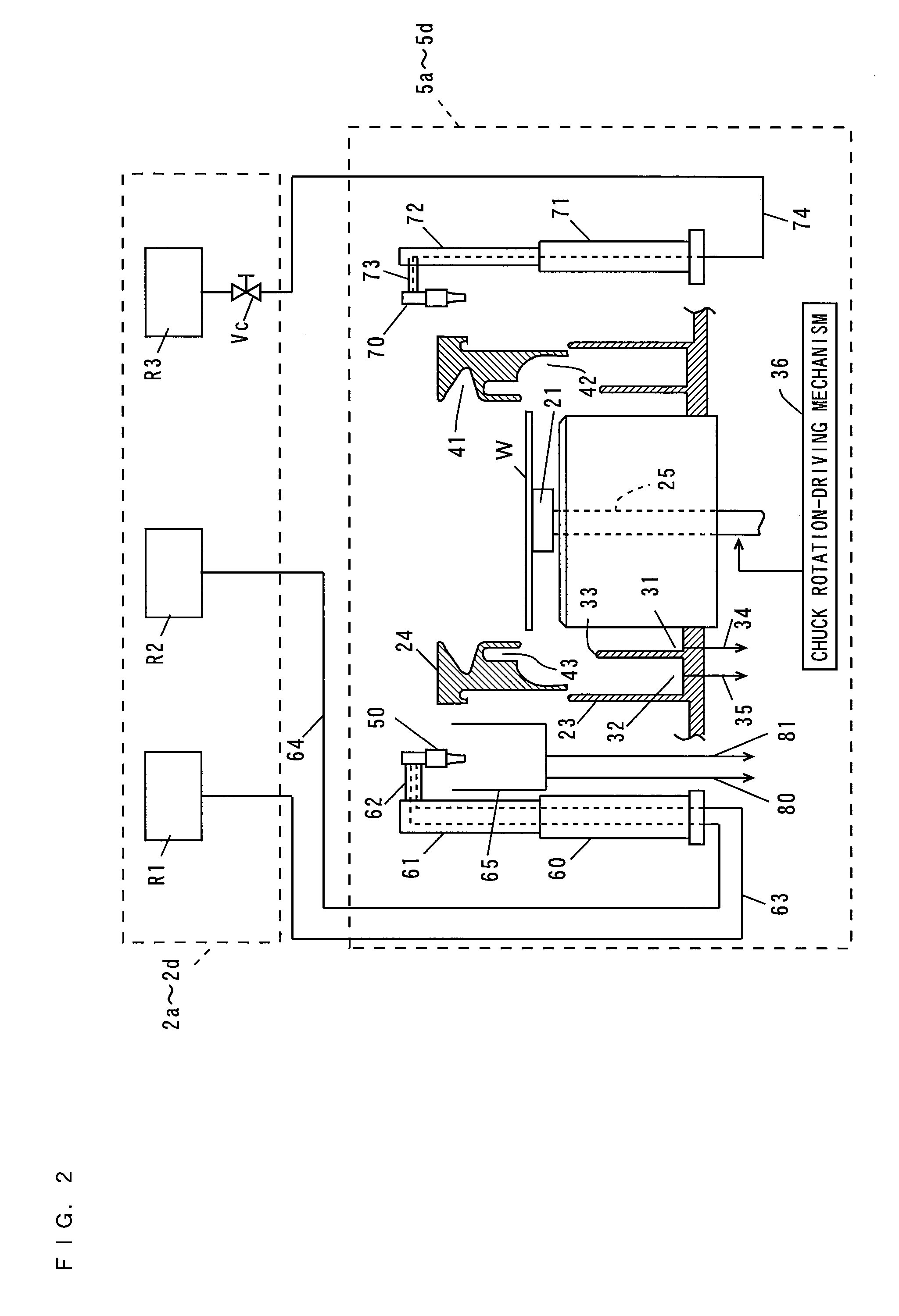

[0112] A substrate processing apparatus according to embodiments of the present invention will be now described with reference to the drawings.

[0113] In the following description, a substrate refers to a semiconductor wafer, a glass substrate for a liquid crystal display, a glass substrate for a PDP (Plasma Display Panel), a glass substrate for a photo mask, a glass substrate for an optical disk, or the like.

(1) CONFIGURATION OF SUBSTRATE PROCESSING APPARATUS

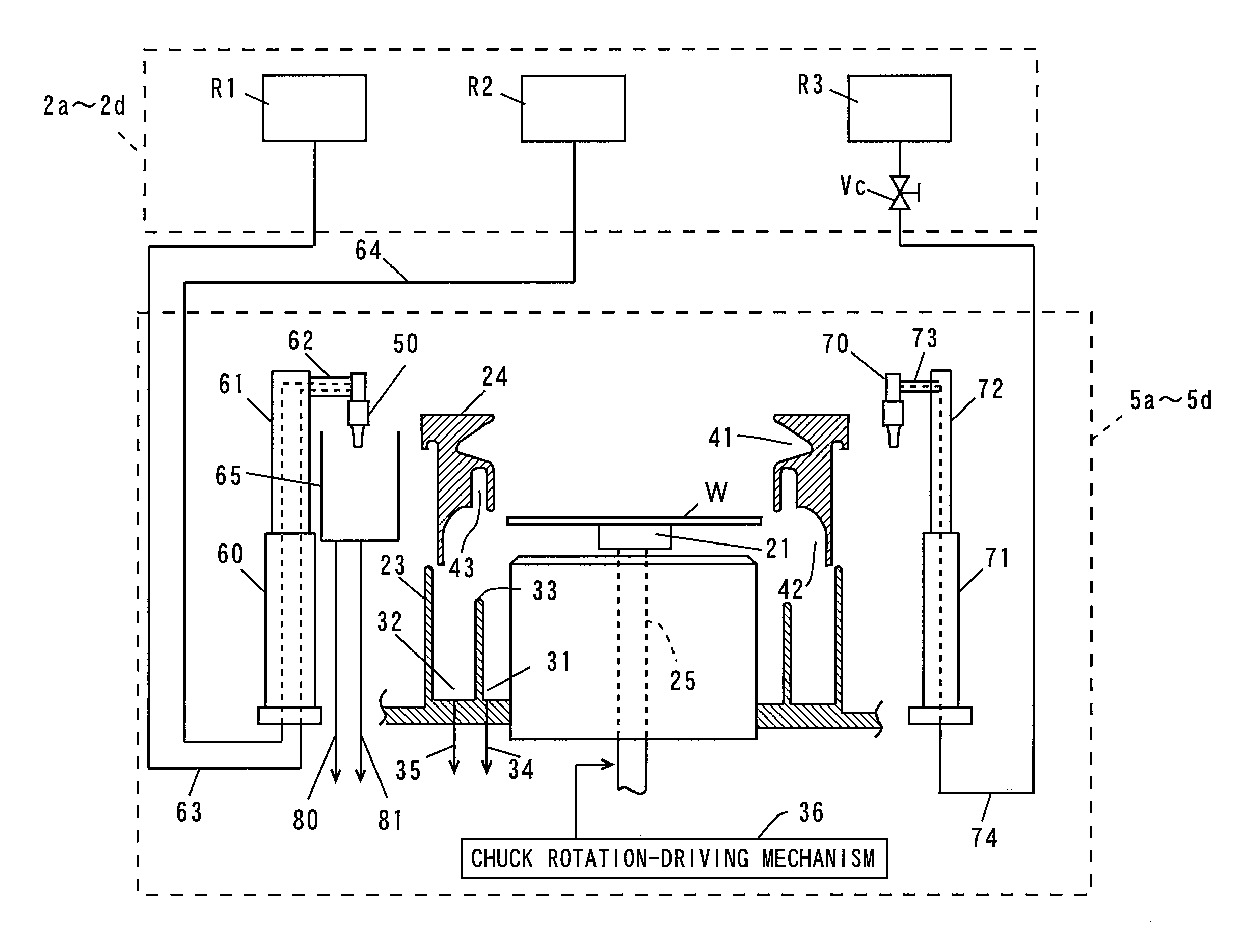

[0114]FIG. 1 is a plan view of a substrate processing apparatus according to an embodiment of the present invention. As shown in FIG. 1, a substrate processing apparatus 100 has processing regions A and B, and a transport region C between the processing regions A and B.

[0115] A control unit 4, fluid boxes 2a and 2b, a cleaning processing units 5a and 5b are arranged in the processing region A.

[0116] Each of the fluid boxes 2a and 2b shown in FIG. 1 stores fluid-related equipment such as pipes, joints, valves, flow meters, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com