High-performance carbon nano tube yarn and preparation method thereof

A carbon nanotube, carbon nanotube fiber technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. The problem of low strength utilization rate, etc., can achieve the effect of promoting recombination and structural remodeling, improving fiber strength utilization rate, and improving strength utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

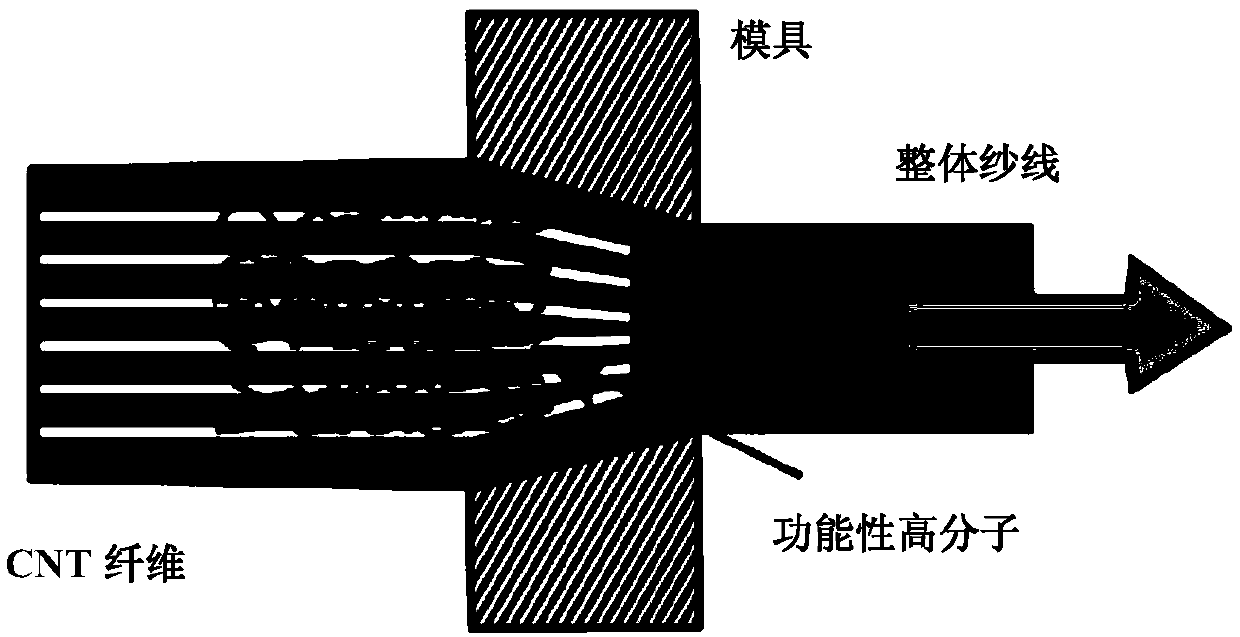

[0024] An aspect of the embodiments of the present invention provides a method for preparing a high-performance carbon nanotube yarn, which includes:

[0025] Make two or more carbon nanotube fibers enter a through hole, and make the two or more carbon nanotube fibers be fully infiltrated by the functional polymer solution in the through hole, and pull the two or more carbon nanotube fibers along the length direction , allowing the two or more carbon nanotube fibers to pass continuously through the through hole, so that the two or more carbon nanotube fibers are stretched straight and squeezed and shrunk by the through hole while fully infiltrating the functional polymer solution to form a whole yarn.

[0026] In some embodiments, the two or more carbon nanotube fibers enter the through hole in parallel.

[0027] In some embodiments, the preparation method further includes: pulling the two or more carbon nanotube fibers from both ends, making the two or more carbon nanotube f...

Embodiment 1

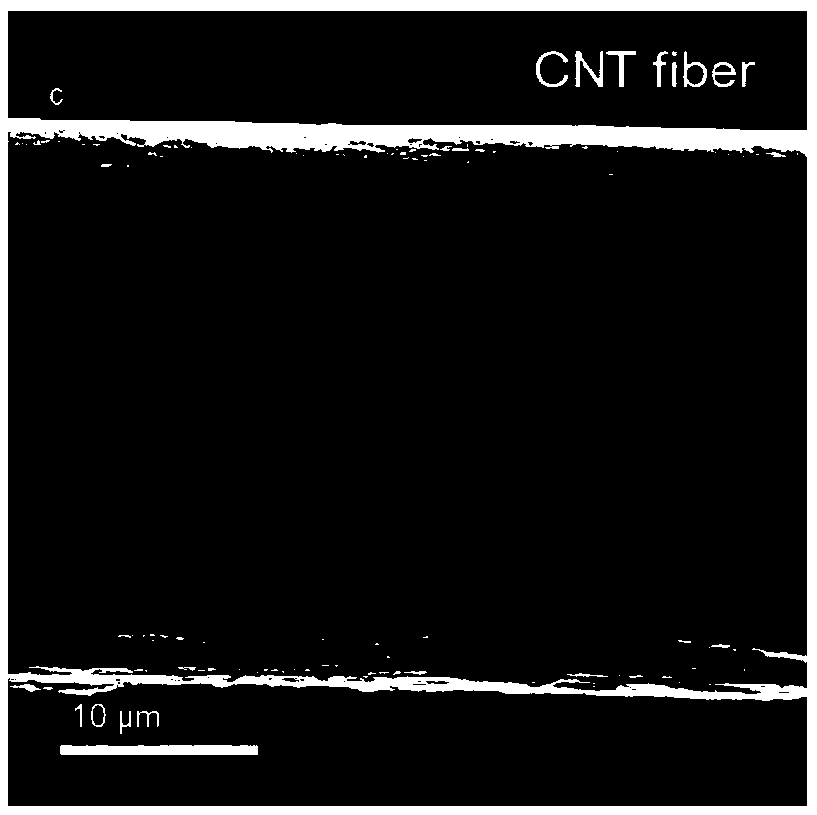

[0056] Taking two single carbon nanotube fibers with a diameter of about 50 μm as an example: introduce the two single fibers into the through hole of the drawing die with a diameter of 80 μm, and drop a polyethyleneimine / ethanol solution with a mass volume fraction of 5.5% into the In the hole, pull the fiber through the drawing hole at a pulling speed of 0.5m / min. The fiber is contracted by the drawing die and soaked in polyethyleneimine polymer quickly, and the two fibers form a whole yarn.

[0057] The diameter of the carbon nanotube yarn obtained in this embodiment is about 70-80 μm, the load can reach 1.2-2.0 N, and the tensile strain is 8%-20%.

Embodiment 2

[0059] Taking 6 carbon nanotube fibers with a diameter of about 50 μm as an example: introduce 6 single fibers into the through holes of the drawing die with a diameter of 130 μm, and drop a polyethyleneimine / ethanol solution with a mass volume fraction of 8% into the holes Inside, the fiber is pulled through the drawing hole at a pulling speed of 1m / min. The fiber is contracted by the drawing die and quickly infiltrated with polyethyleneimine polymer, and 6 fibers form a whole yarn.

[0060] The diameter of the carbon nanotube yarn obtained in this embodiment is about 100-120 μm, the load can reach 4.5-6.5 N, and the tensile strain is 6%-8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com