Sand washing finishing process of chenille fabric

A chenille and sand washing technology, which is applied in fiber treatment, textiles and papermaking, can solve the problems of internal dye damage, internal damage of chenille fabrics, and poor antibacterial properties of chenille fabrics, so as to achieve less environmental pollution and increase Soft performance, the effect of avoiding strong damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

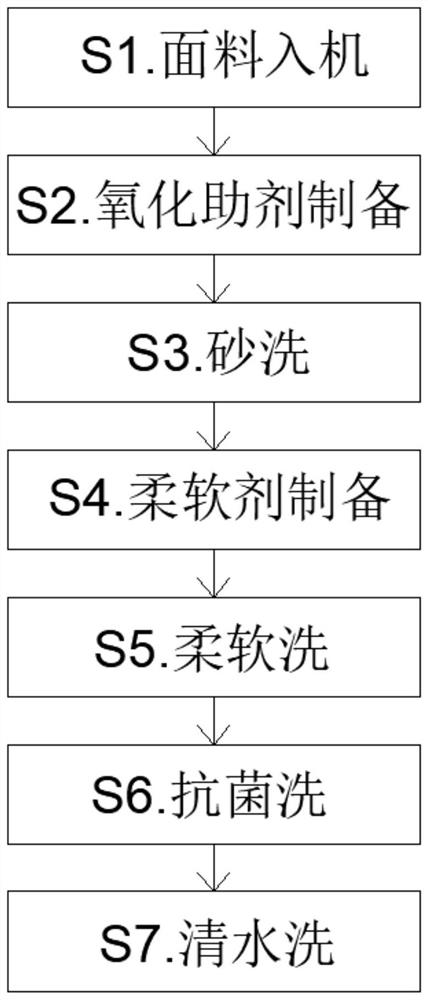

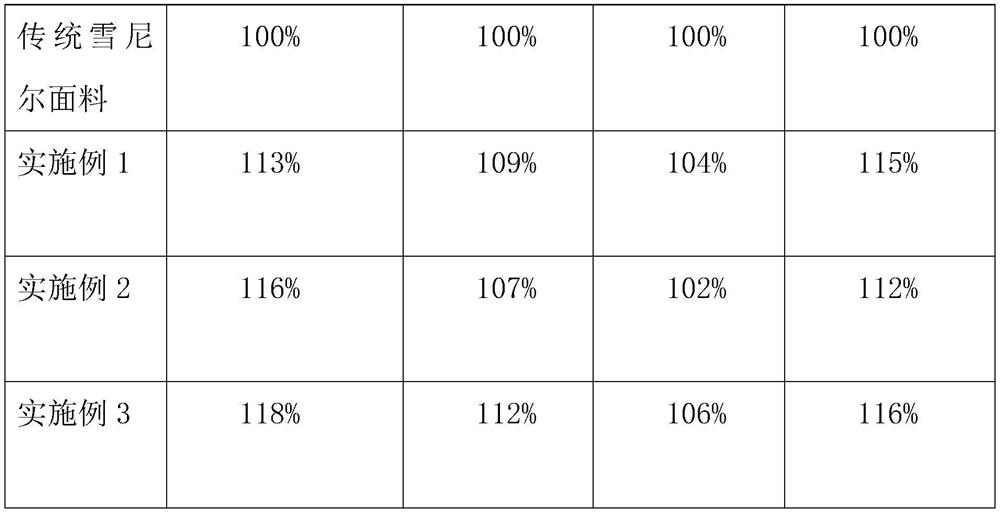

[0038] see figure 1 , the present invention provides a technical solution: a sand washing finishing process for chenille fabrics, comprising the following steps:

[0039] S1. Fabric into the machine: Put the dyed chenille fabric into the acid-resistant and oxidation-resistant polyester mesh bag, and then put it into the special sand washing machine. The liquor ratio is controlled at 1:20, and the pH buffer system is added at room temperature. Control pH value at 4.0;

[0040] S2. Oxidation auxiliary preparation: described oxidation auxiliary is selected from potassium permanganate slow-release agent;

[0041] S3. Sand washing: the temperature of the special machine for sand washing is raised to 50℃, and S2 is added to the special machine for sand washing to prepare an oxidation aid for sand washing, and the sand washing time is 40 minutes;

[0042] S4. Preparation of softener: the softener includes the following raw materials in parts by weight: 100 parts of octamethyltetras...

Embodiment 2

[0064] see figure 1 , the present invention provides a technical solution: a sand washing finishing process for chenille fabrics, comprising the following steps:

[0065] S1. Fabric into the machine: Put the dyed chenille fabric into the acid-resistant and oxidation-resistant polyester mesh bag, and then put it into the special sand washing machine. The liquor ratio is controlled at 1:60, and the pH buffer system is added at room temperature. Control the pH value at 5.8;

[0066] S2. Oxidation auxiliary preparation: described oxidation auxiliary is selected from potassium permanganate slow-release agent;

[0067] S3. Sand washing: raise the temperature in the special sand washing machine to 90℃, add S2 to the special sand washing machine to prepare the oxidation assistant for sand washing, and the sand washing time is 60 minutes;

[0068] S4. Preparation of softener: the softener includes the following raw materials in parts by weight: 140 parts of octamethyltetrasiloxane, 6...

Embodiment 3

[0090] see figure 1 , the present invention provides a technical solution: a sand washing finishing process for chenille fabrics, comprising the following steps:

[0091] S1. Fabric into the machine: Put the dyed chenille fabric into an acid-resistant and oxidation-resistant polyester mesh bag, and then put it into a special sand washing machine. The liquor ratio is controlled at 1:40, and the pH buffer system is added at room temperature. Control the pH value at 4.8;

[0092] S2. Oxidation auxiliary preparation: described oxidation auxiliary is selected from potassium permanganate slow-release agent;

[0093] S3. Sand washing: the temperature of the special machine for sand washing is raised to 70℃, and S2 is added to the special machine for sand washing to prepare an oxidation aid for sand washing, and the sand washing time is 50 minutes;

[0094] S4. Preparation of softener: the softener includes the following raw materials in parts by weight: 120 parts of octamethyltetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com