Patents

Literature

43results about How to "Efficient Dyeing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

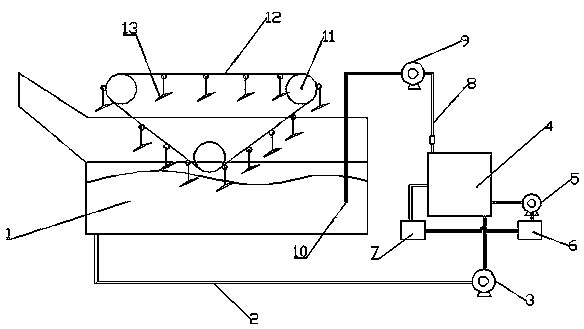

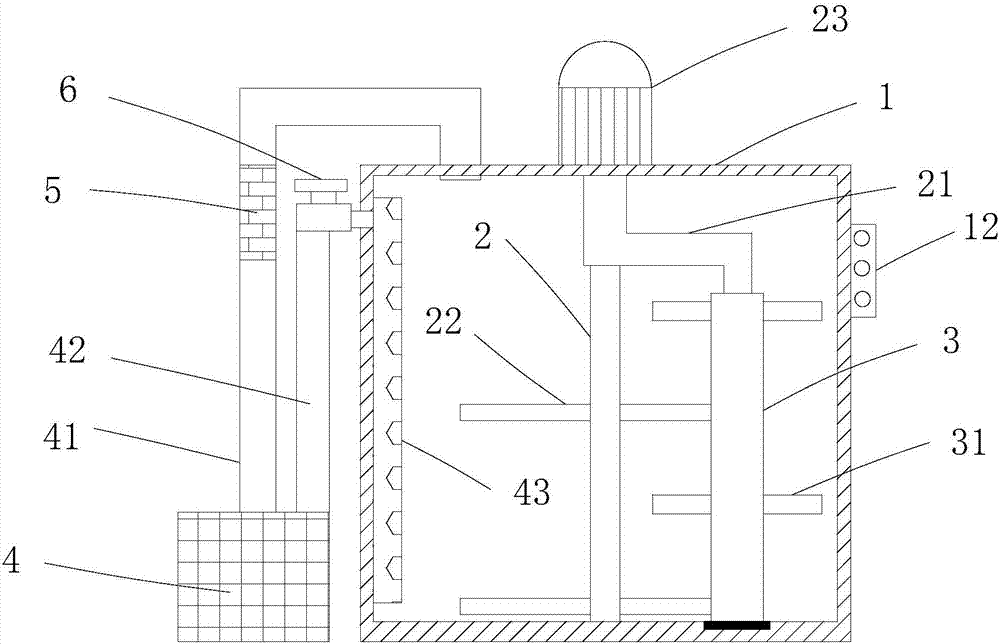

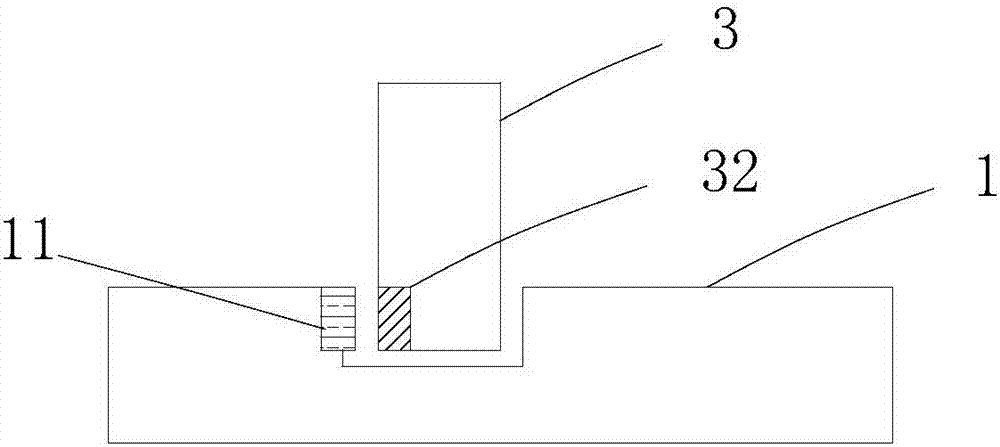

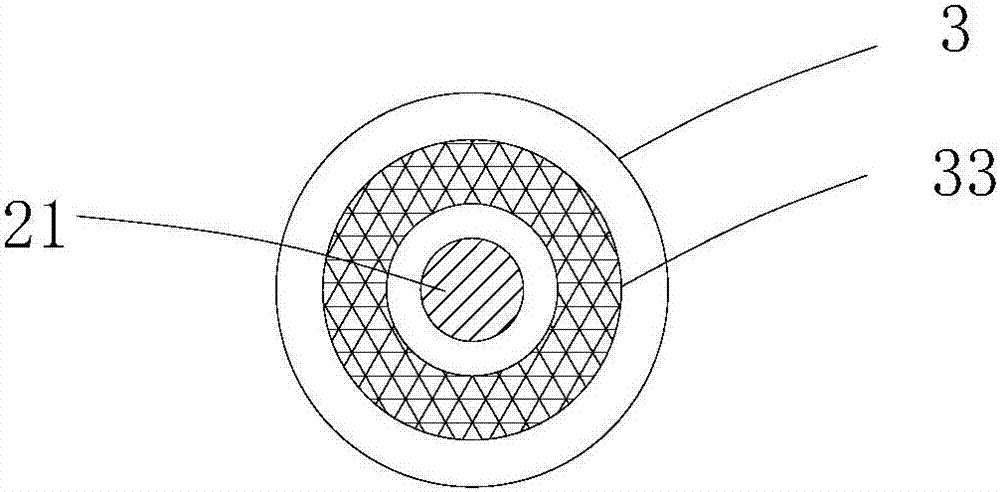

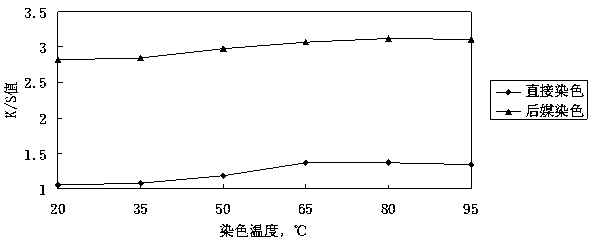

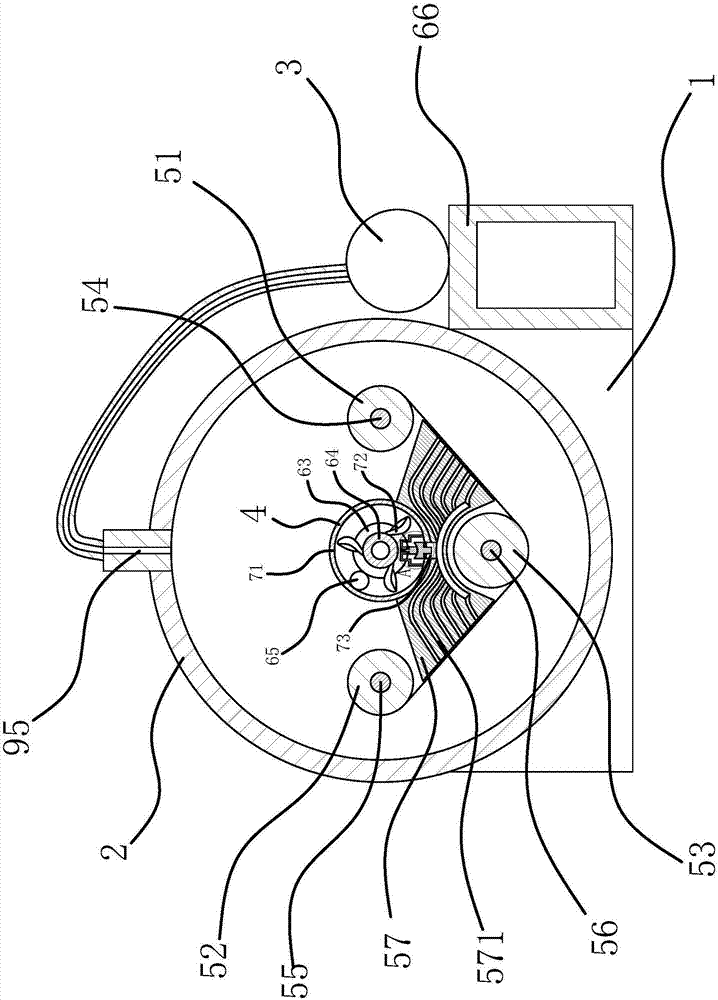

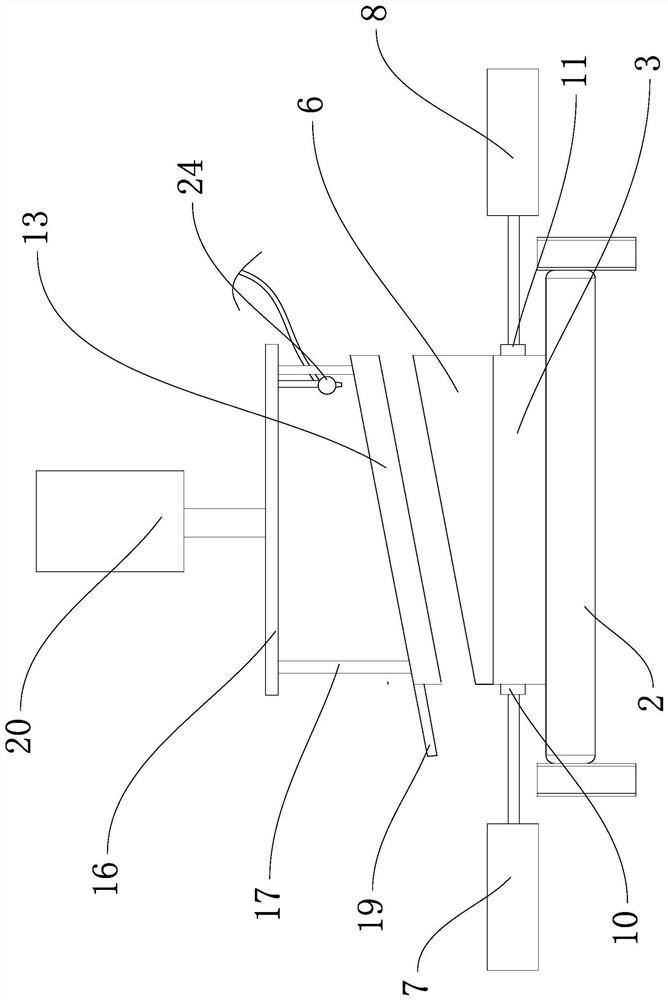

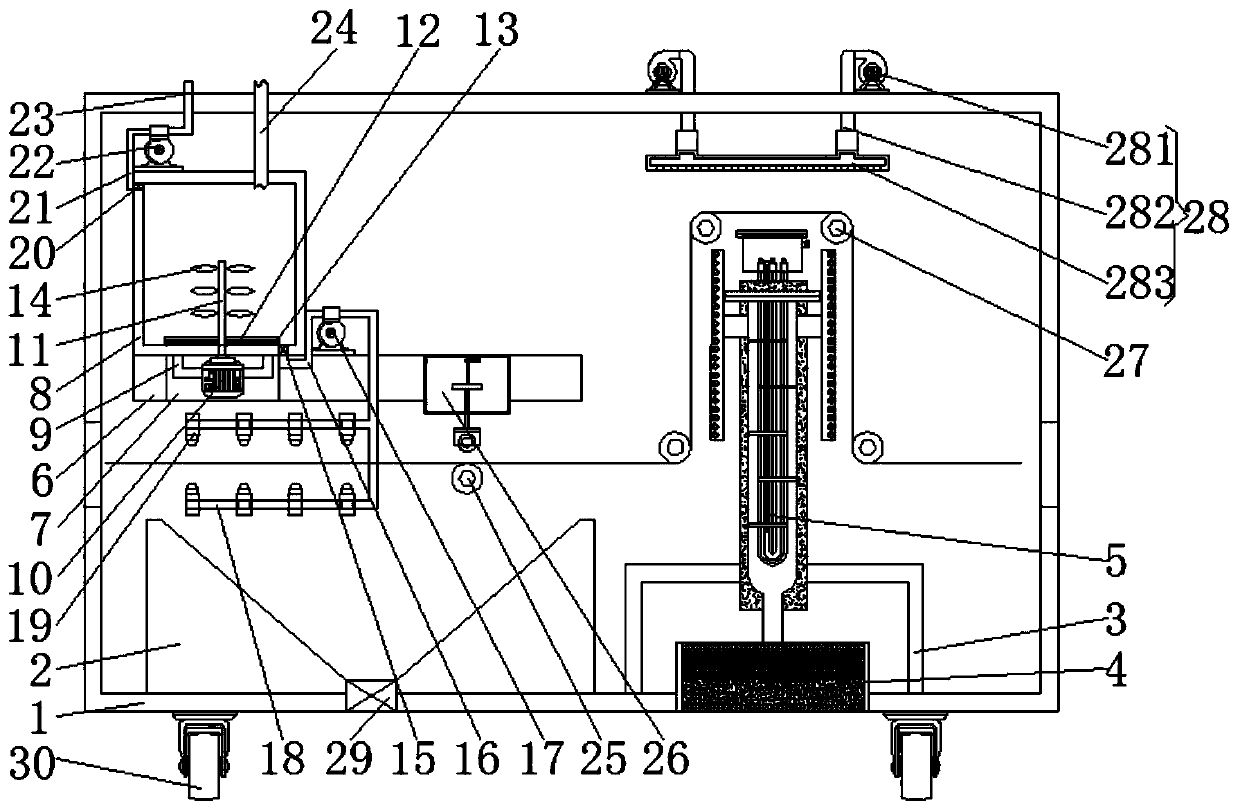

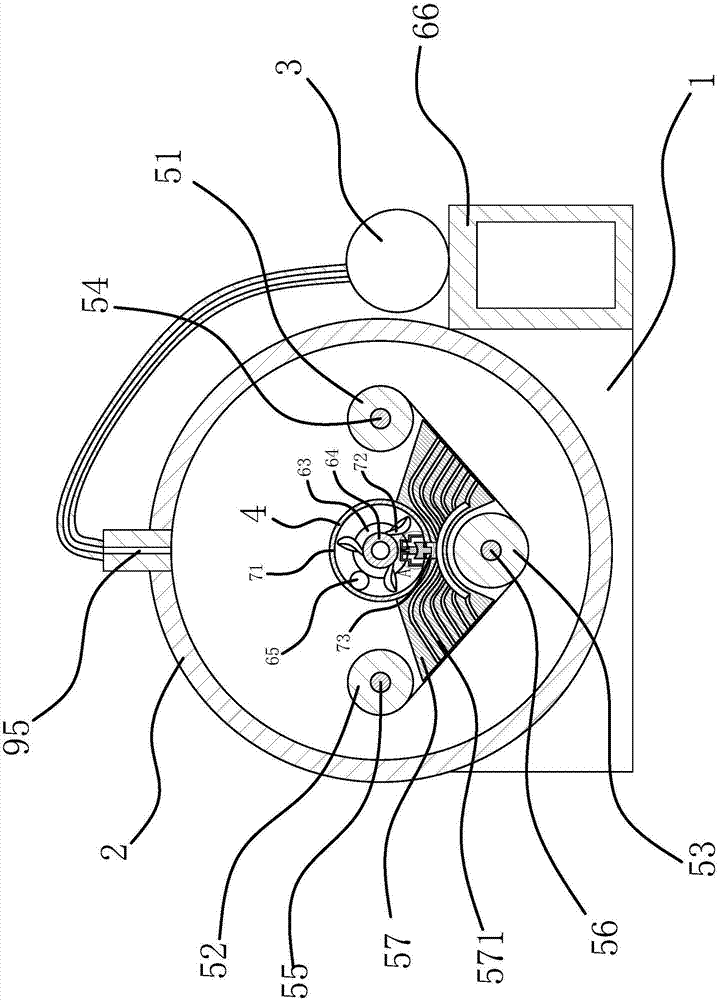

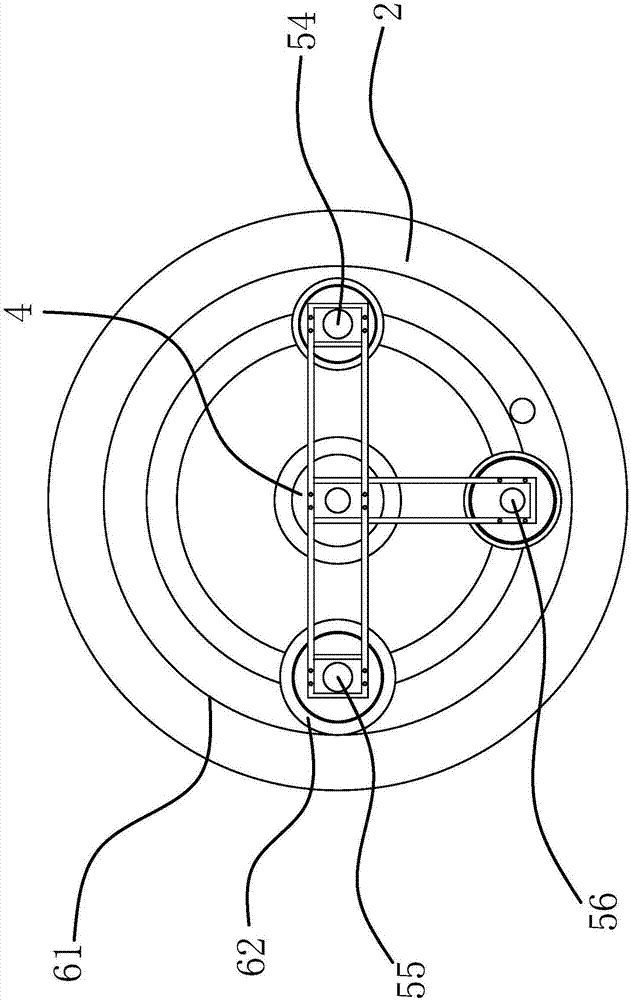

Circulating dyeing machine for garments

InactiveCN103643424AUniform dyeingGood dyeingLiquid/gas/vapor article treatmentTextile treatment machine arrangementsProcess engineeringClothes hanger

The invention provides a circulating dyeing machine for garments and belongs to the field of garment dyeing equipment. The circulating dyeing machine is formed by a dyeing tank, a garment suspension device and a color solution regulating device. The garment suspension device comprises at least two rotating shafts, and a conveyer belt is arranged on the rotating shafts. A plurality of clothes hangers are fixedly arranged on the conveyer belt. The color solution regulating device comprises a color blending tank, a color solution box and a detection device. The color blending tank is connected with the color solution box through a pump A. The color solution box is connected with the detection device through a pipeline and is connected with the detection device through a pipeline again. The lower end of the color blending tank is connected with a pump B. The pump B is connected with the lower end of the dyeing tank through a pipeline B. The upper end of the color blending tank is connected with a pump C through a pipeline C. The pump C is connected to the dyeing tank through a pipeline. A pipeline port is located on the lower portion in the dyeing tank. The circulating dyeing machine is provided with a color complementation device, can carry out continuous dyeing, and is uniform in dyeing and efficient in garment dyeing.

Owner:DALIAN UNIVERSITY

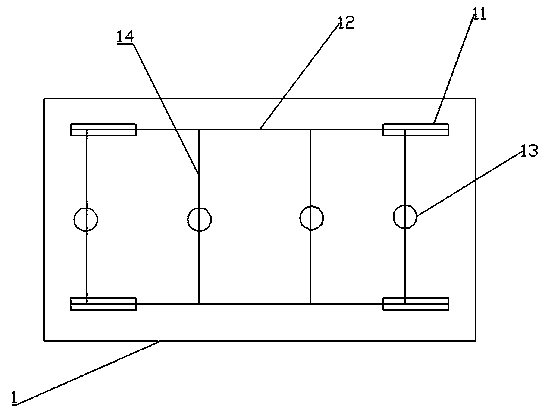

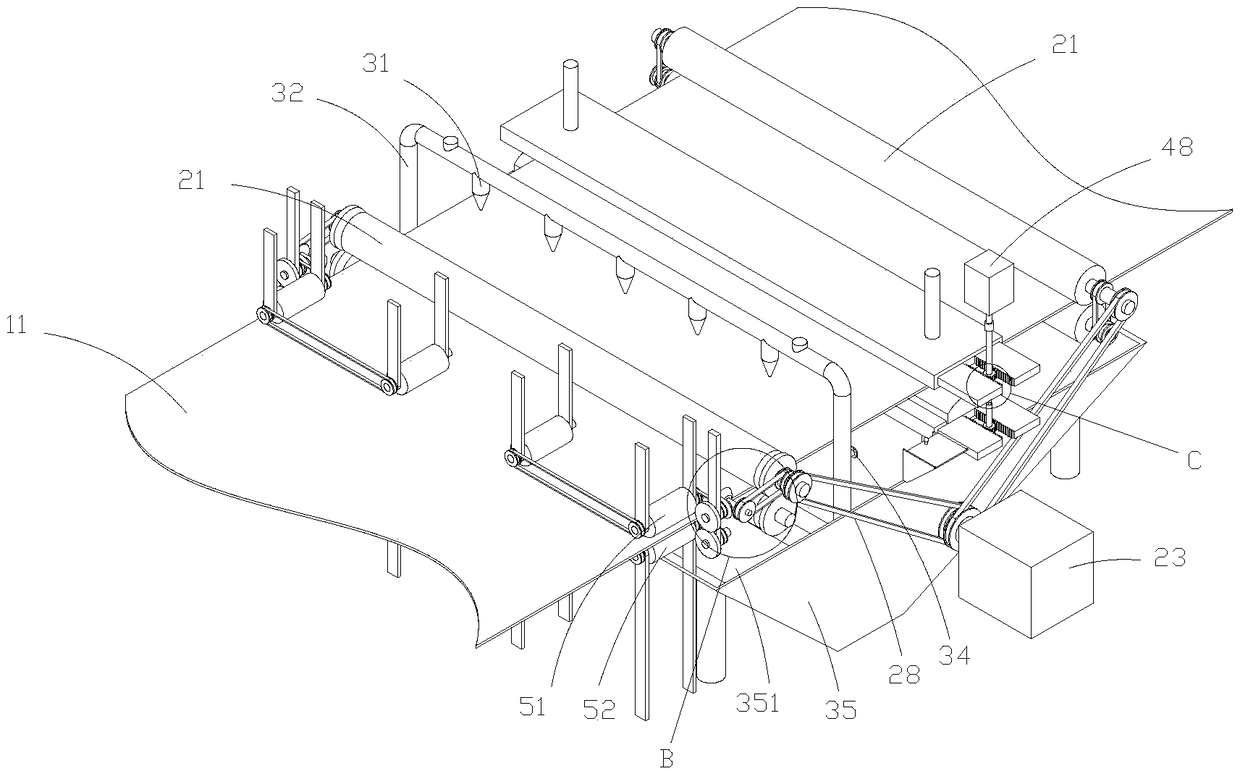

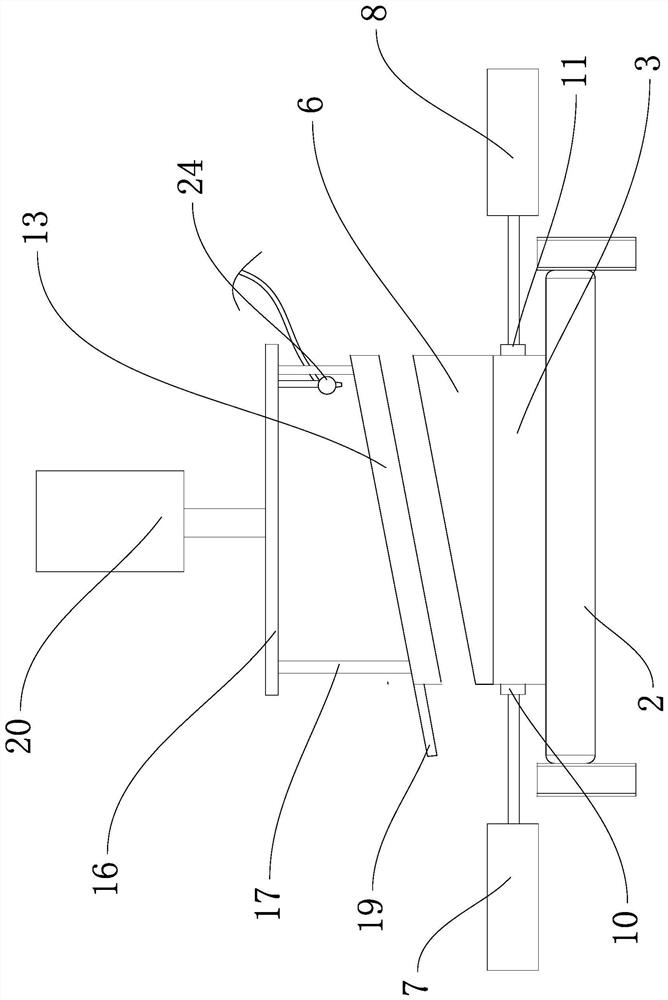

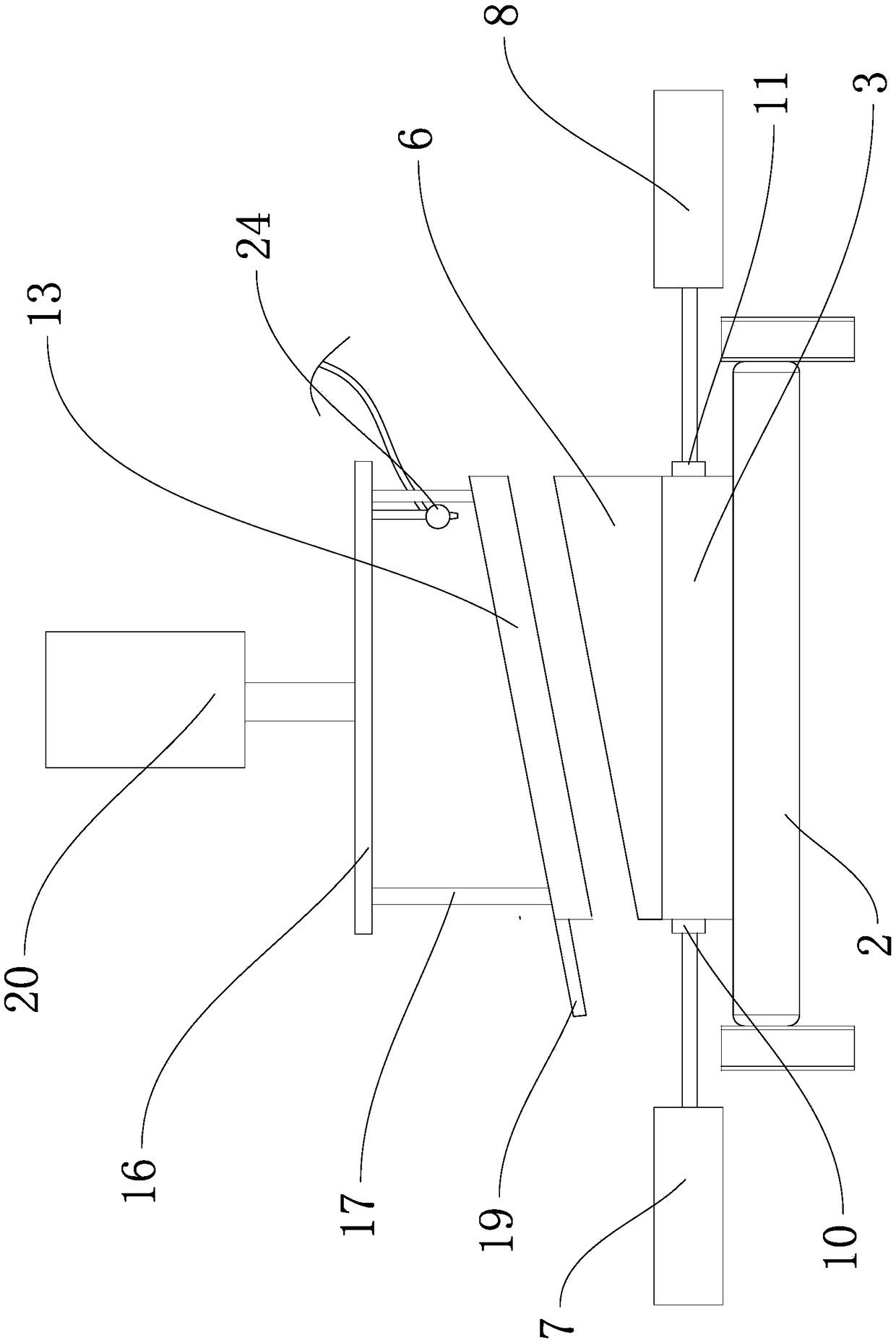

Spray-dyeing device with good dyeing effect

ActiveCN109295629AAvoid damageGuaranteed synchronous rotationTextile treatment by spraying/projectingTextile treatment carriersEngineeringRaw material

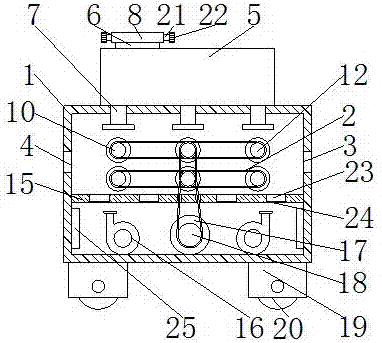

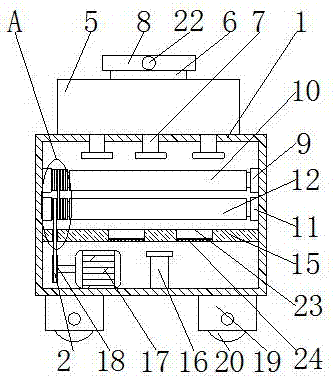

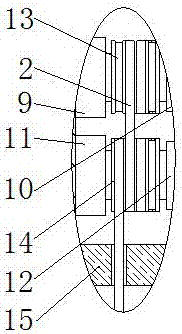

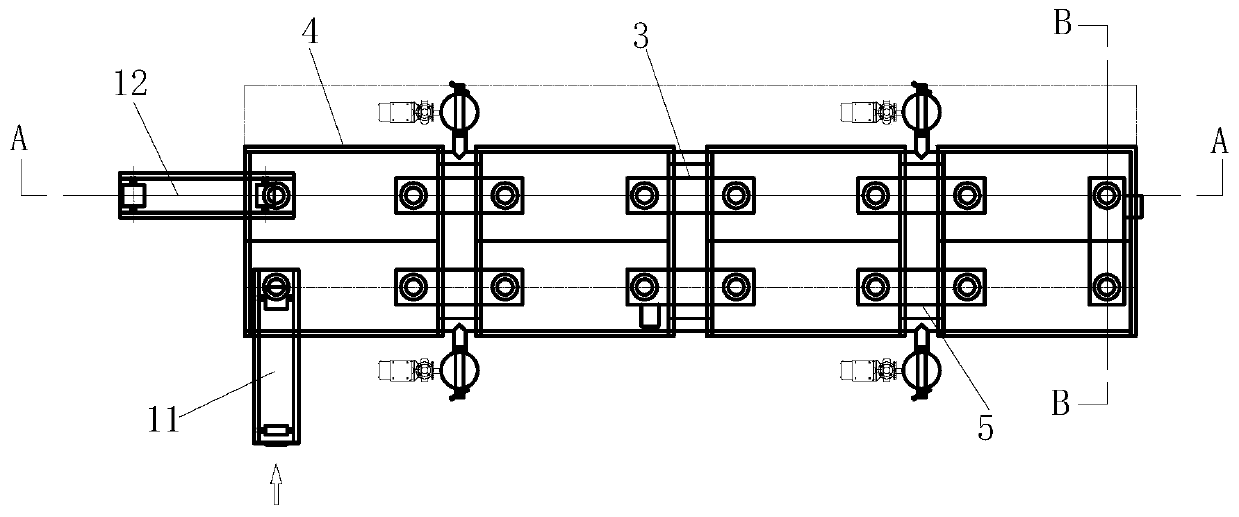

The invention discloses a spray-dyeing device with a good dyeing effect. The device comprises a frame, a raw material roller movably connected with the frame, a receiving roller movably connected withthe frame, a driving device for driving the movement of a fabric, an applicator for smearing evenly the dyeing liquid on the fabric and a flattening device for flattening the fabric; the flattening device comprises a left roller shaft set, a right roller shaft set matched with the left roller shaft set, a left transmission structure for being in drive connection with the left roller shaft set andthe driving device and a right transmission structure for being in driving connection with the right roller shaft set and the driving device; the device pulls the two edges of the fabric to the sidesby the arrangement of the left and right roller shaft sets, so that the surface of the fabric is kept flat, and the appearance of wrinkles is avoided so that the dyeing liquid can be evenly sprayed on the fabric to ensure uniform dyeing of the fabric.

Owner:SHAOXING UNIVERSITY

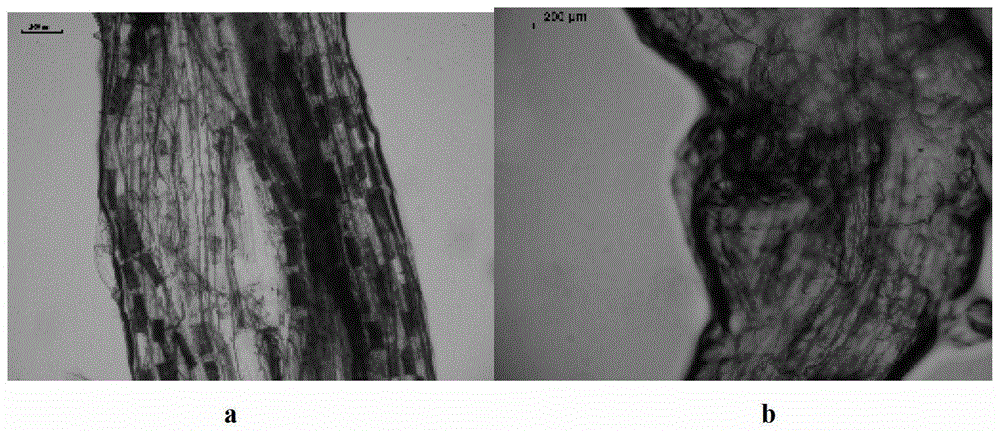

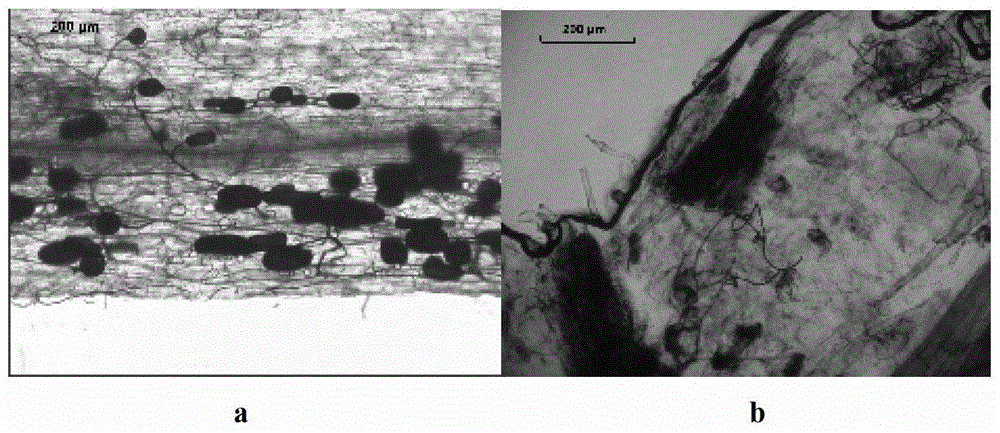

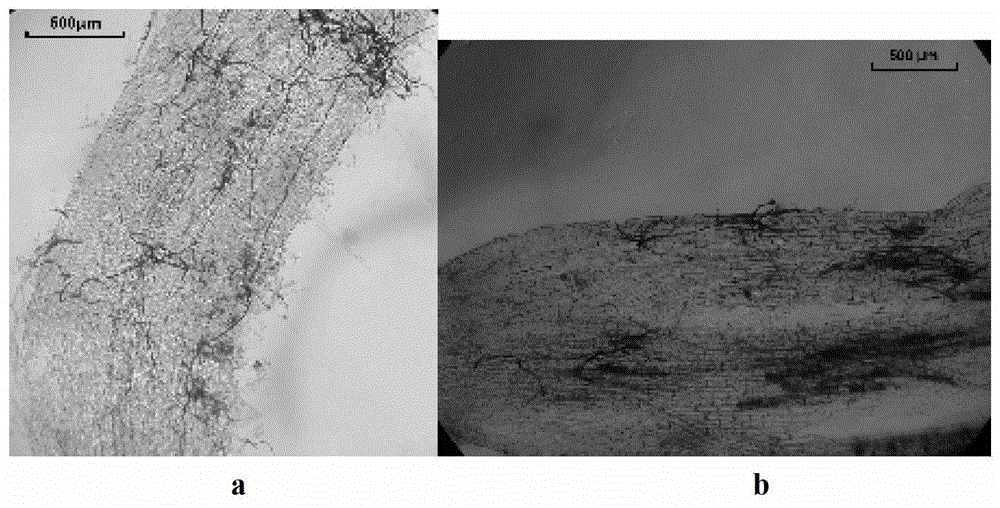

Method for rapidly and efficiently dyeing arbuscular mycorrhizal fungi

InactiveCN103411813AEfficient DyeingAdaptablePreparing sample for investigationBiotechnologyArbuscular mycorrhizal fungi

The invention relates to a method for rapidly and efficiently dyeing arbuscular mycorrhizal fungi, belonging to the field of application microbiology, and being capable of rapidly and efficiently dyeing and observing the arbuscular mycorrhizal fungi at the root of a plant. The method comprises the following steps of: firstly, carrying out transparency treatment on a root tissue by using a KOH (Potassium Hydroxide) solution with the concentration being 20% at high temperature, whitening the root tissue by using H2O2, subsequently dyeing by using trypan blue with the concentration being 0.1%, and observing the structure of the arbuscular mycorrhizal fungi after decoloration by using a decoloration liquid. The method has the characteristics of convenience, rapidness and efficiency, and has the characteristics that the decoloration is thorough, the dyeing effect is clear, the arbuscular structure and the vesicle structure are clear and discernable, and the coloring is long-lasting. The roots of most plants can be dyed by using the method, the arbuscule and the vesicle of the arbuscular mycorrhizal fungi are clearly observed, and the method has good application prospects as the mycorrhiza research is gradually taken seriously.

Owner:JIANGSU UNIV

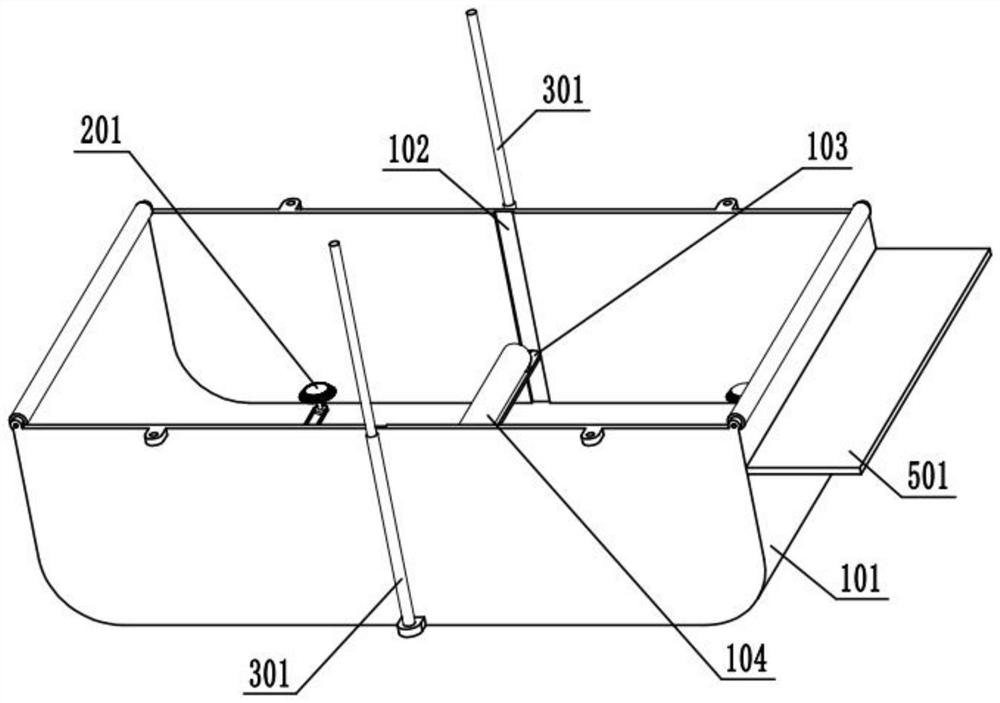

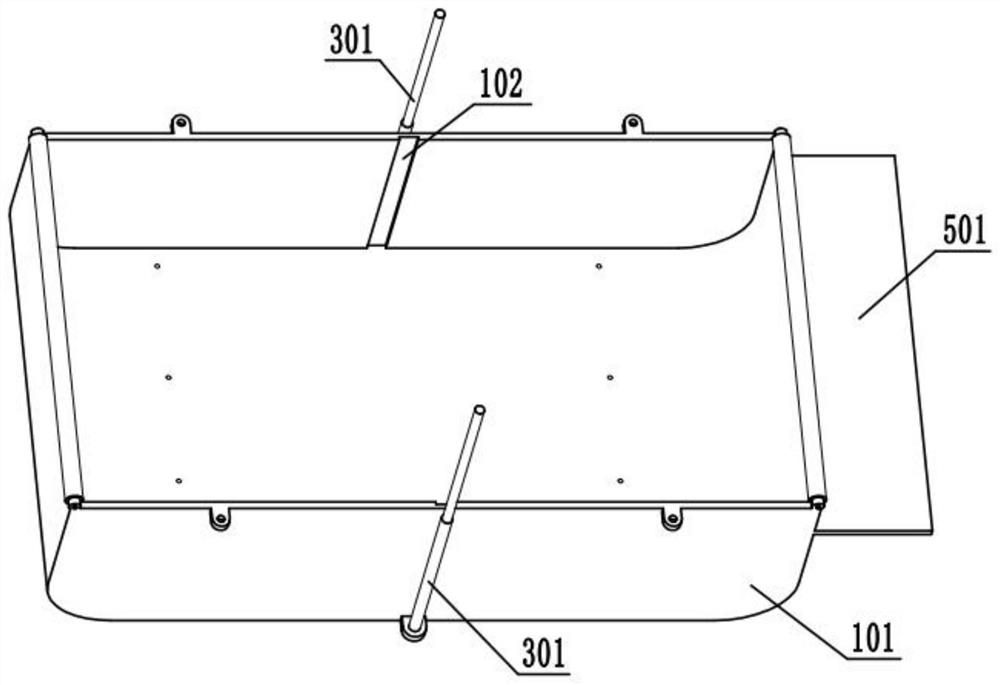

Dyeing device for textile fabric

InactiveCN107142632AEfficient DyeingUniform dyeingTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsElectricityEngineering

The invention discloses a dyeing device for textile fabric. The dyeing device comprises a work box and a belt, an inlet and an outlet are formed in the two sides of the work box respectively, a dyeing vessel is fixedly connected to the top of the work box, a feeding pipe is communicated with the top of the dyeing vessel, a spray head is fixedly connected to the bottom of the dyeing vessel, the bottom of the spray head penetrates through the top of the work box and extends to an inner cavity of the work box, a cap is connected to the top of the feeding pipe in a threaded mode, first bearings are fixedly connected to the front end and the rear end of the inner cavity of the work box, and a first roll shaft is movably connected between the two first bearings. Accordingly, by using the work box, the belt, the inlet, the outlet, the dyeing vessel, the spray head, the first roll shaft, a second roll shaft, an air heater and a motor cooperatively, the textile fabric can be dyed efficiently, follow-up work is conducted more conveniently, by means of matching of the first roll shaft and the second roll shaft, dyeing can be more uniform, water and electricity are saved, and less waste water is generated.

Owner:SUZHOU COMFORT TEXTILE NEW MATERIALS TECH CO LTD

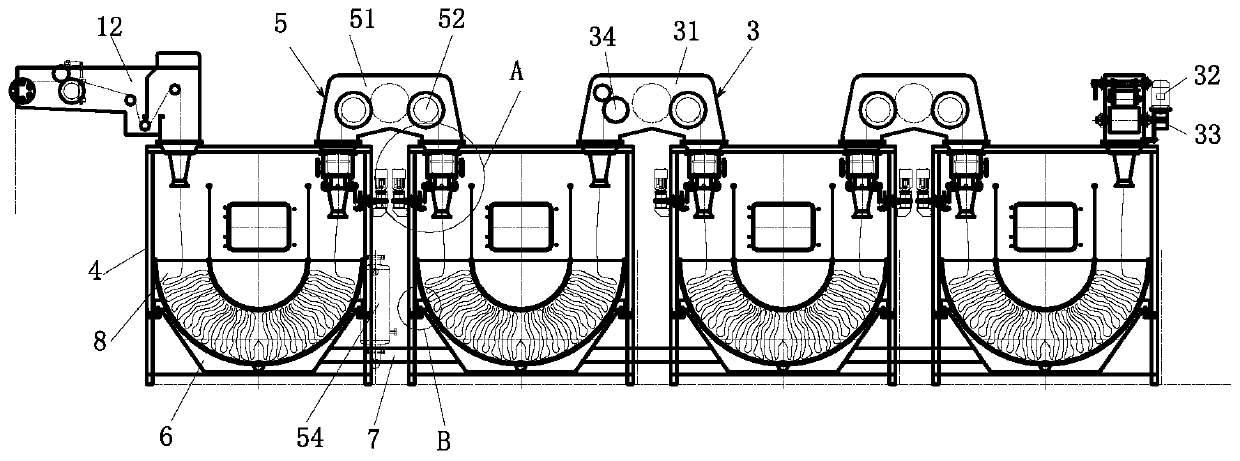

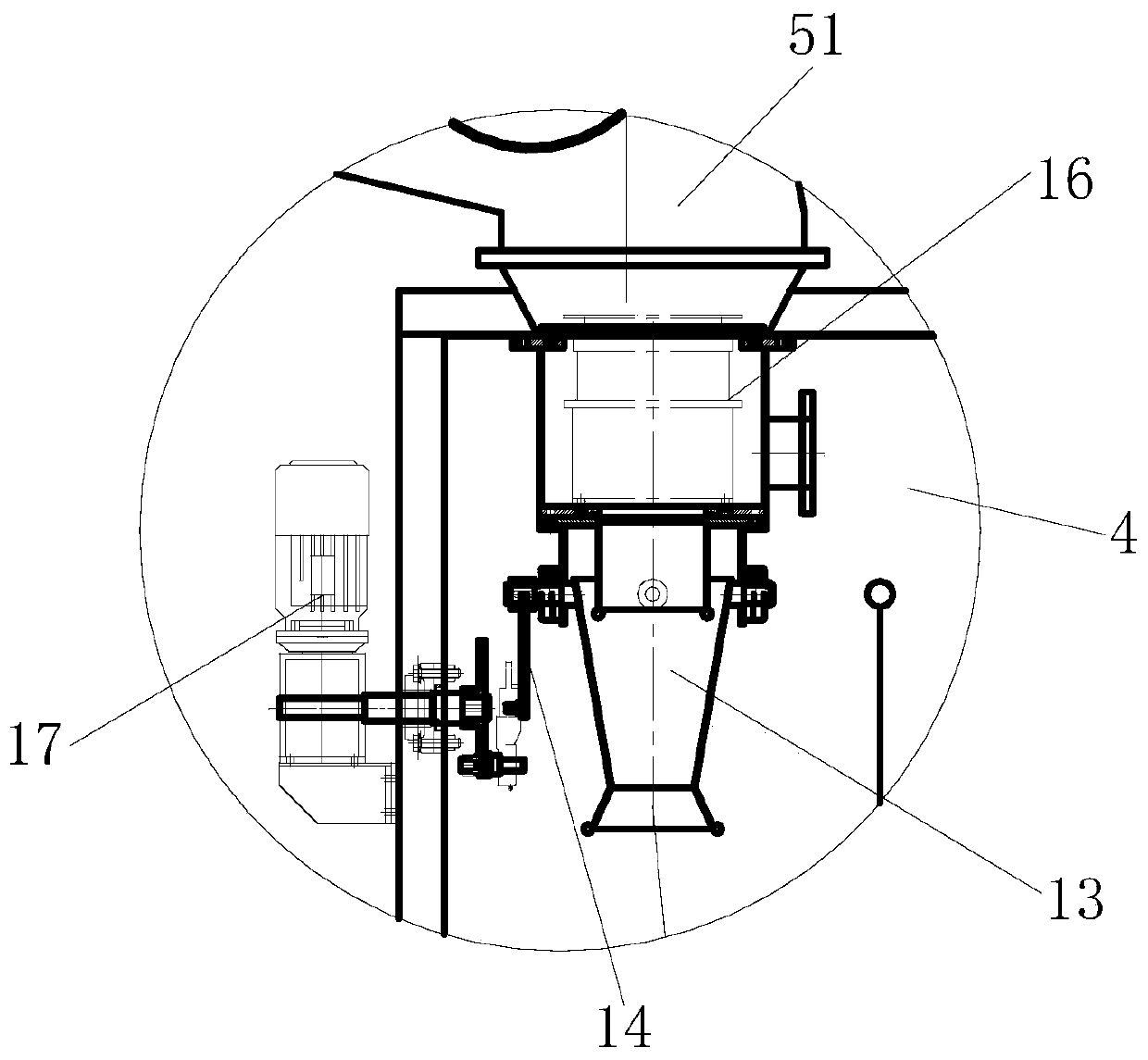

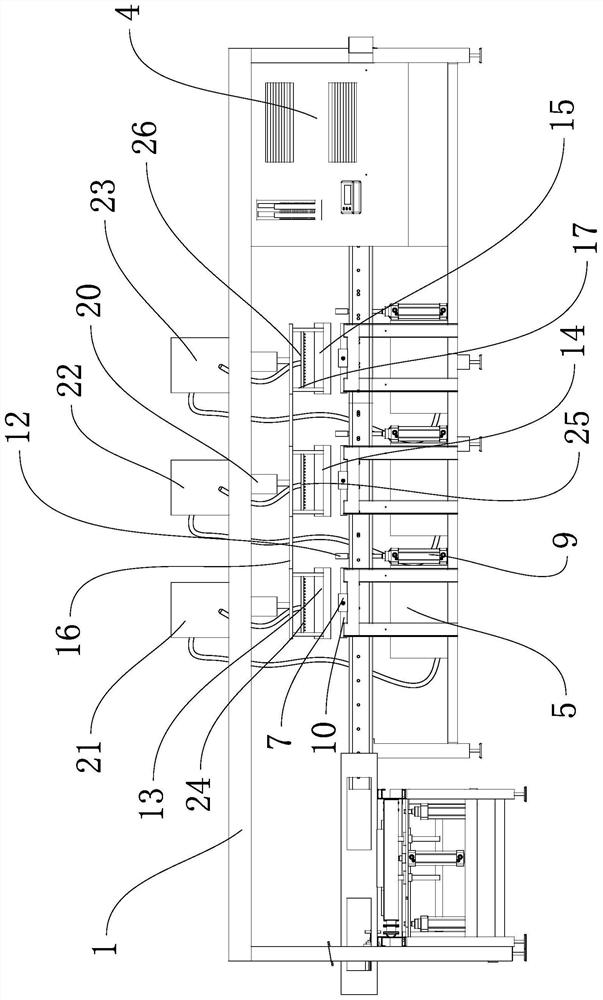

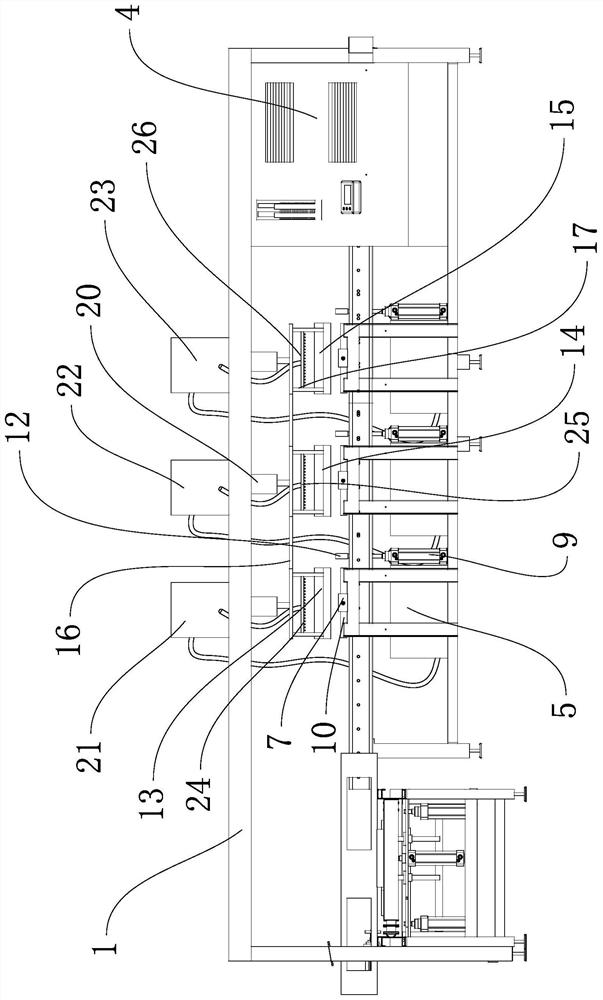

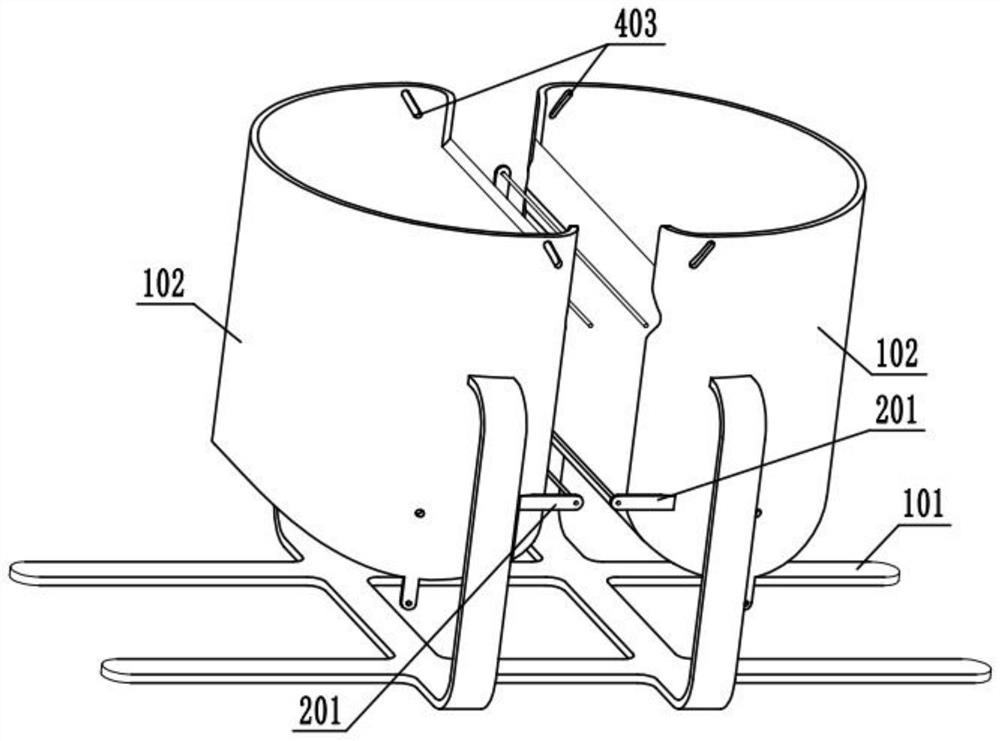

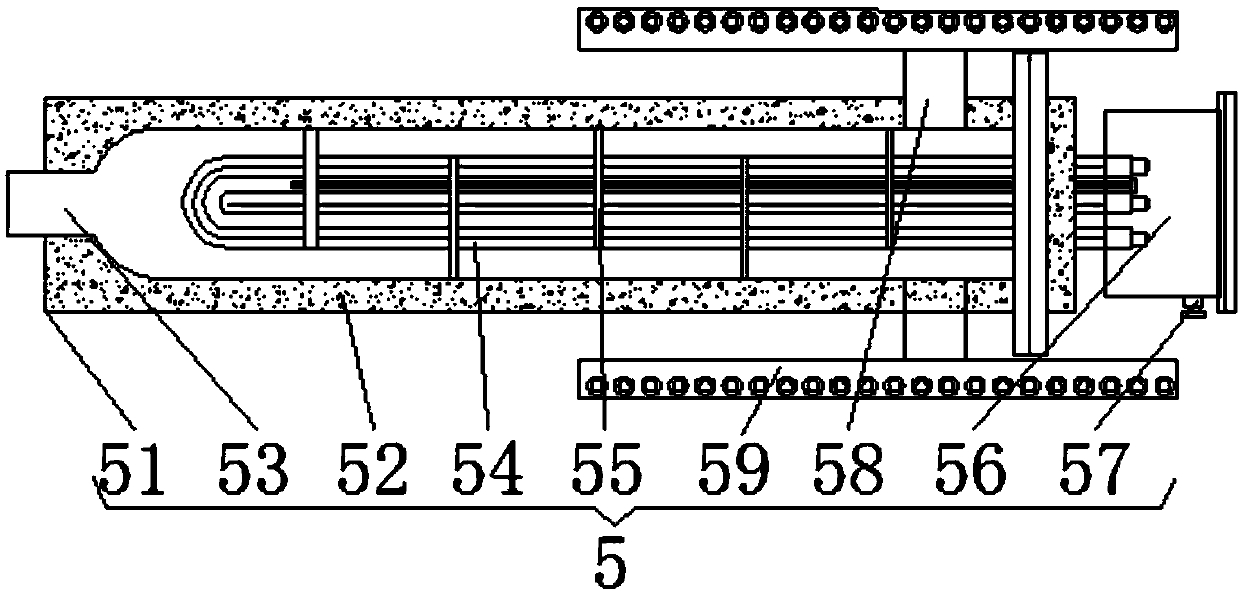

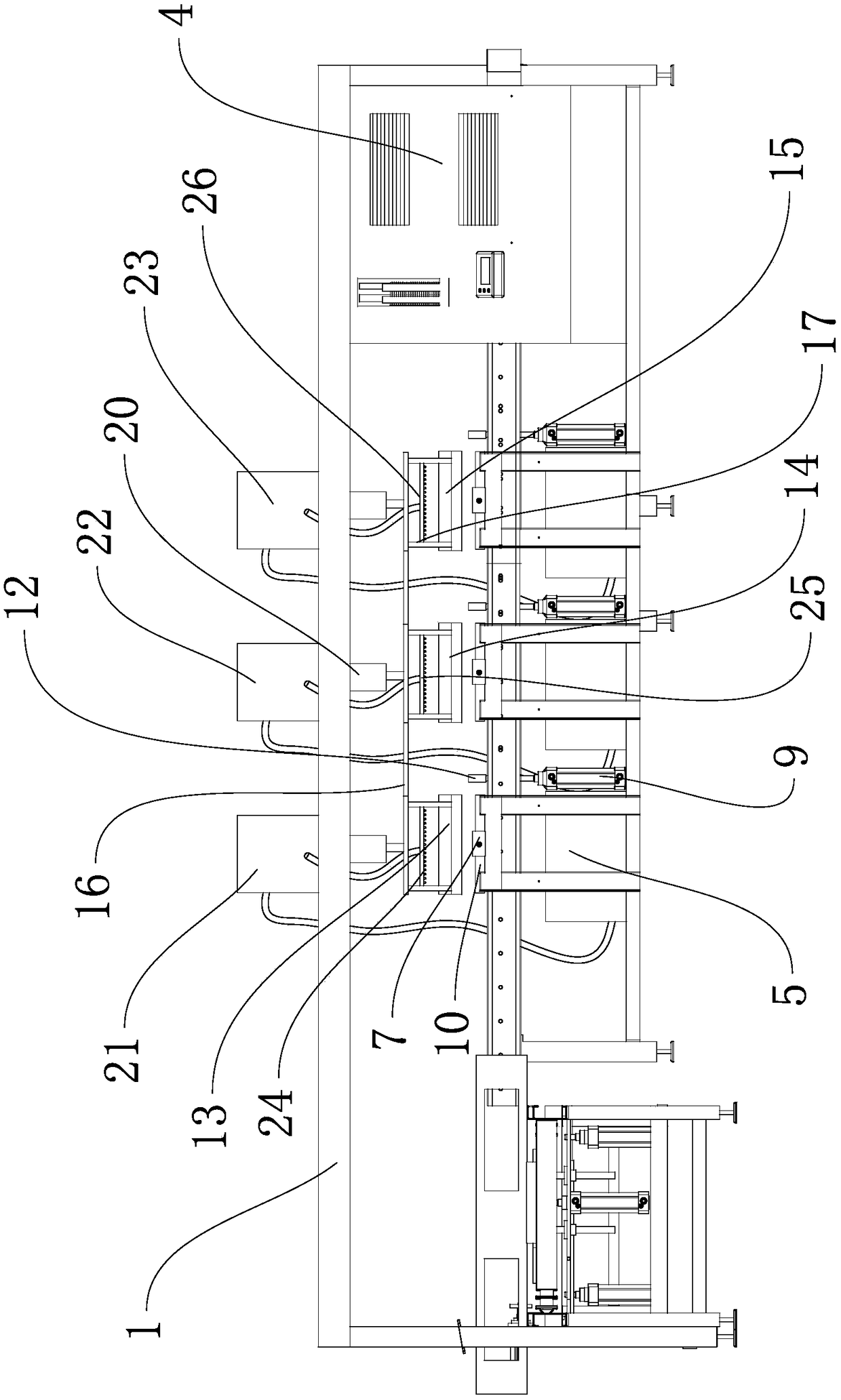

Intelligent jet airflow overflow combination machine

ActiveCN111088624AIntelligent operationIncrease productivityTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsReciprocating motionEngineering

The invention belongs to the technical field of printing and dyeing equipment, and discloses an intelligent jet airflow overflow combination machine. The intelligent jet airflow overflow combination machine comprises a combination machine body composed of a plurality of sets of airflow overflow nozzles which achieve high-speed reciprocating motion of fabric between cloth containing cylinders through a high-pressure water pump, the front part of a combination body has a cloth feeding function, and the rear part of the combination body has a cloth discharging function. According to the intelligent jet airflow overflow combination machine, a plurality of sets of U-shaped cloth containing cylinder bodies are connected in series, the fabric is driven to reciprocate through the high-speed large-flow water pump between the cylinder bodies, and the fabric continuously runs from a cloth feeding direction to a cloth discharging direction at the production process speed of 20-100 m / min; the clothcontaining amount of each cloth containing cylinder is about 1200 m (according to the difference of fabric gram amounts), the cloth containing amount of each cloth containing cylinder is detected bya gravity sensor in the production operation process, signals generated by the gravity sensor are processed by a PLC, the flow speed and the flow direction of water are controlled by controlling the pump and a valve, the equipment operates intelligently, and the production efficiency is greatly improved.

Owner:江苏赛格纺织机械有限公司

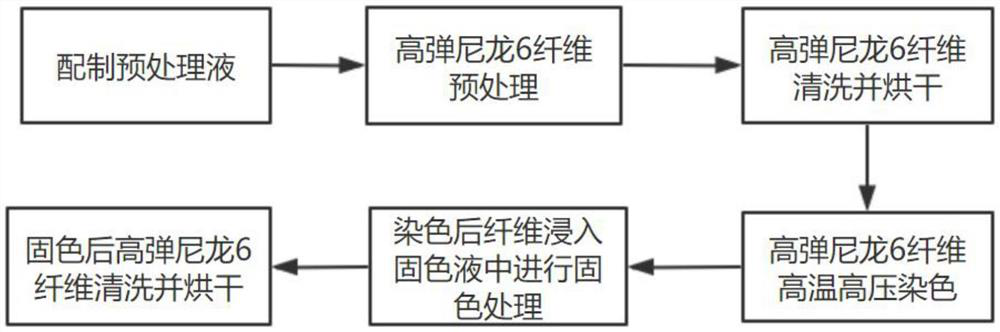

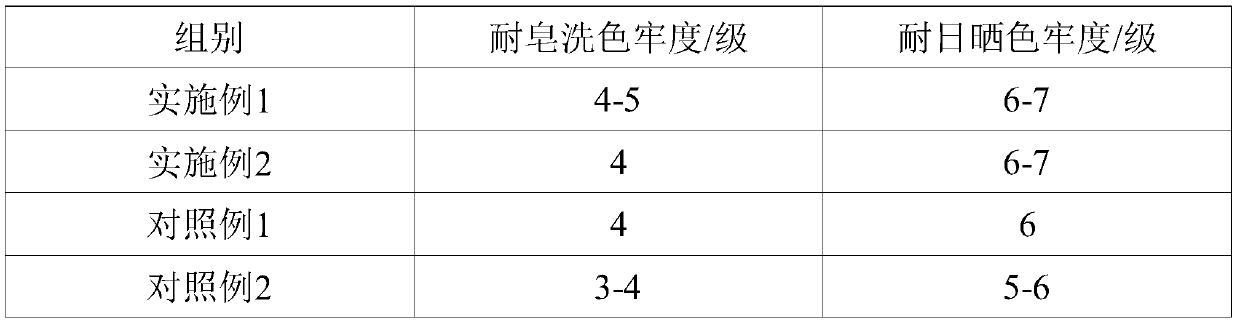

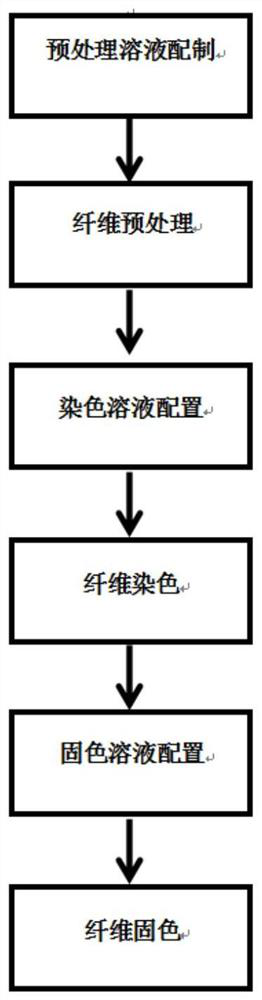

Dyeing method capable of improving dyeing performance of high-elastic nylon 6 fibers

PendingCN113073482AFully dyedImprove color fixationDyeing processColour fastnessEnvironmentally friendly

The invention discloses a dyeing method capable of improving the dyeing performance of high-elastic nylon 6 fibers. The method comprises the steps of dyeing pretreatment, a dyeing process and a color fixing process. According to the dyeing method, the dyeing performance of the high-elastic nylon 6 fibers can be effectively improved, the dyeing rate, the fixation rate, the K / S value and the level dyeing performance of the fibers are remarkably improved, and the washing color fastness, the rubbing color fastness and the light color fastness of fabric are improved. The process is simple and efficient, the usage amount of dye can be remarkably reduced, the method is environmentally friendly, the adopted reagent is efficient in dyeing, bright in color and not prone to fading, and the efficient and lasting dyeing effect can be achieved. On the basis that the dyeing performance of the high-elastic nylon 6 fibers is enhanced, the simplicity, high efficiency and environmental friendliness of the dyeing process are further improved, and wide application of the high-elastic nylon 6 fibers and fabric can be promoted.

Owner:绍兴市柯桥区东纺纺织产业创新研究院

High-precision flat shade cloth dyeing process

The invention discloses a high-precision flat shade cloth dyeing process, and relates to the technical field of textile dyeing. The dyeing process comprises the following steps of (1) dye liquor preparation; (2) dyeing; (3) water washing; and (4) fabric weaving. A polyester-cotton blended yarn is dyed by utilizing a disperse dye and an reactive dye, efficient dyeing of polyester fibers and cottonfibers is achieved, and the dyeing uniformity is ensured through the cooperative use of a leveling agent; the adhesive force of the dyes on the polyester-cotton fibers is enhanced through the additionof a color fixing agent, so that the color fastness of the prepared polyester-cotton fabric is improved; and the prepared high-precision flat shade cloth is suitable for being used as a processing fabric of middle and high-grade curtains, the shading rate is close to 100%, the soaping color fastness and the light fastness to sunlight are high, and the use quality of the curtains is guaranteed.

Owner:LANGXI YUANHUA TEXTILE

A multifunctional textile dyeing device

InactiveCN105603659BEfficient DyeingMaximize contact areaTextile treatment machine arrangementsLiquid/gas/vapor fabric treatmentCollision rateTextile dyeing

The invention discloses a multifunctional textile dyeing device comprising a body. A motor is mounted in the middle of the top end of the body, a center shaft of the motor penetrates the top end of the body to be fixedly connected with a center shaft, a second gear tooth is arranged at the bottom end of an eccentric shaft, the eccentric shaft is connected with the body in a meshed manner through a gear, the top end of the body is connected with a steam generator through a first circulating pipe, and an air outlet pipe is arranged on the side wall of an inner cavity of the body. The multifunctional textile dyeing device has the advantages that a blender on the center shaft is used for blending dyes, the eccentric shaft is provided with power to be capable of rotating and revolving, and accordingly maximum contact area between textile and the dyes and adjustable collision rate can be provided, and the textile on storage racks can be dyed highly efficiently; under the action of the first circulating pipe and a second circulating pipe, steam circulates, so that resources are saved to a great extent, and working efficiency is improved.

Owner:广州市信森服饰有限公司

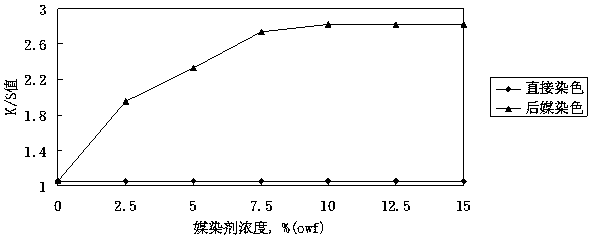

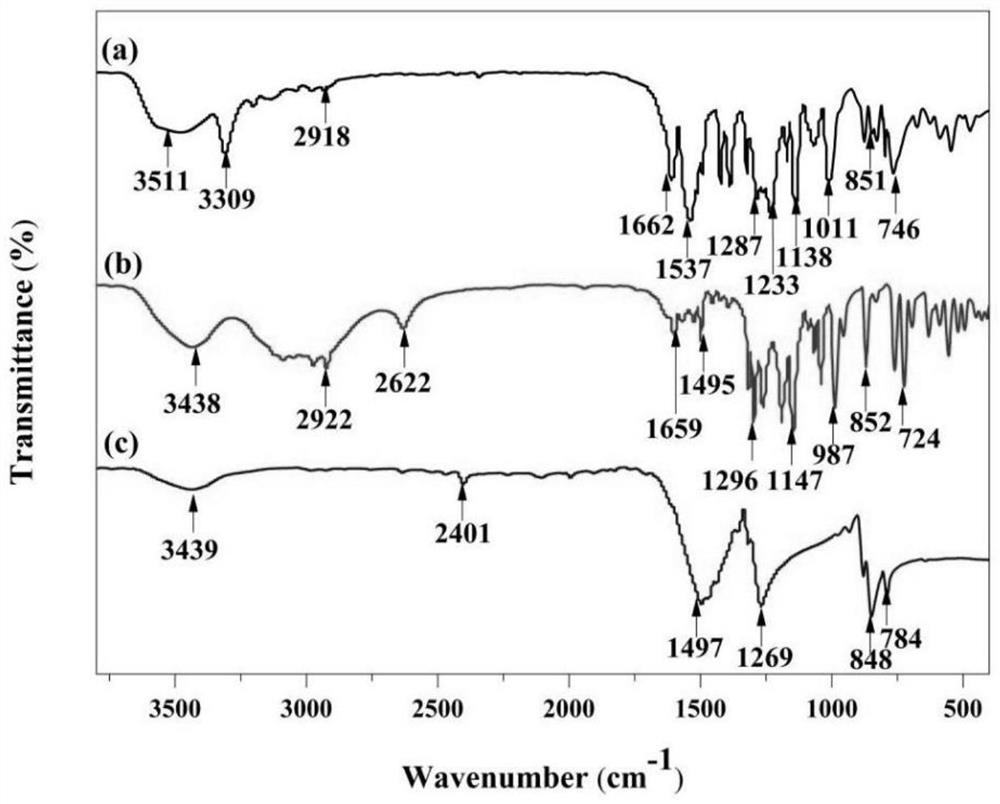

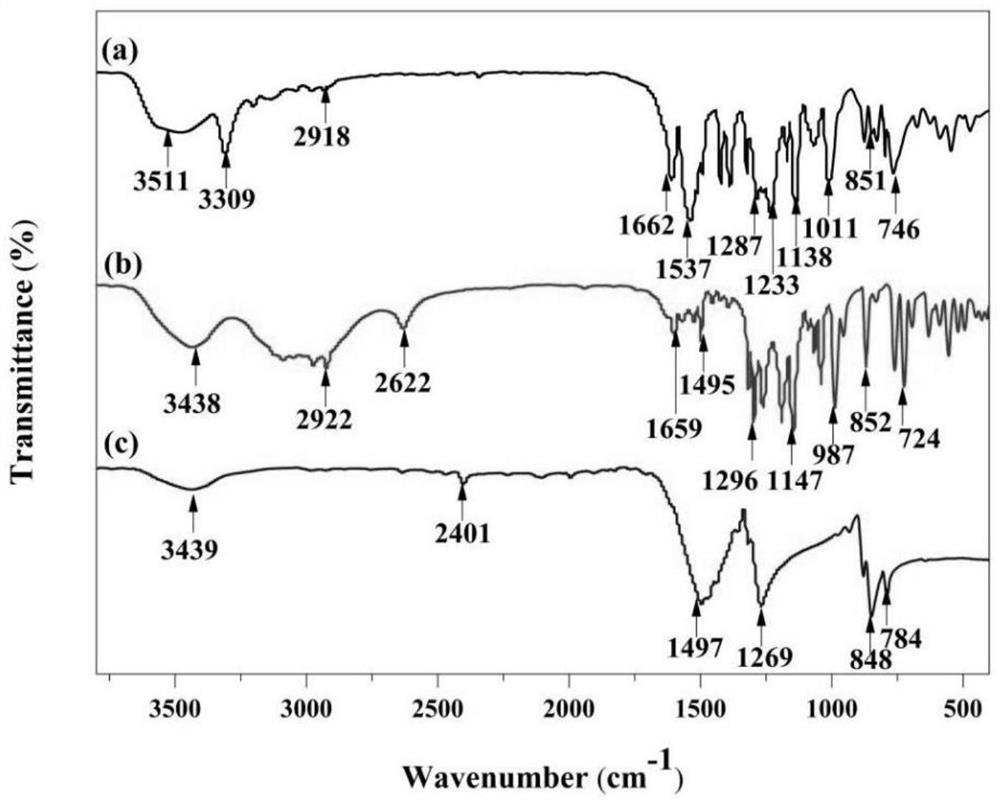

Application of folium artemisiae argyi pigment dye to cellulose fiber one-bath mordant dyeing process

ActiveCN106835769AAvoid destructionFully extractedNatural dyesDyeing processCellulose fiberColor changes

The invention provides application of folium artemisiae argyi pigment dye to a cellulose fiber one-bath mordant dyeing process. Cellulose fiber is dyed with the dye through a one-bath mordant dyeing method, so folium artemisiae argyi pigment can serve as plant dye of the cotton fiber; moreover, a dyeing process which applies the folium artemisiae argyi pigment dye to cellulose fiber dyeing and has an industrialized application value is provided; and by the one-bath mordant dyeing method of pure cotton fiber, the color depth K / S value of cotton fabric reaches 3.625, unlubricated friction reaches level 4 to 5, wet friction reaches level 4, color change reaches level 4, staining (cotton) reaches level 4 and hand feeling reaches level 4, the actual industrial production requirements are met, and the technological gap of folium artemisiae argyi pigment plant dye in the prior art is filled.

Owner:HUNAN INSTITUTE OF ENGINEERING

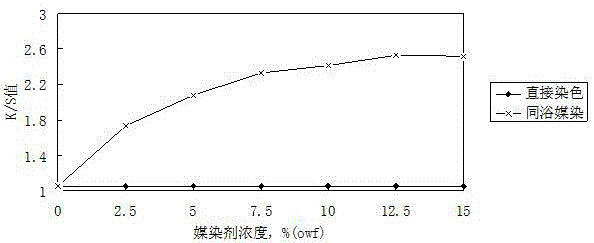

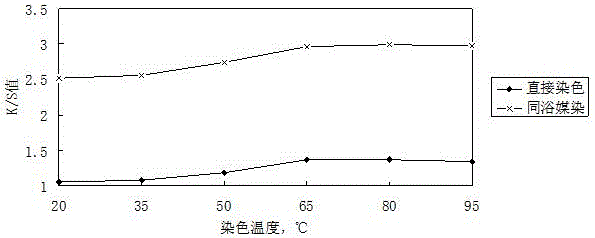

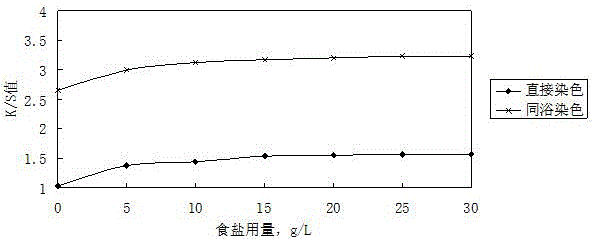

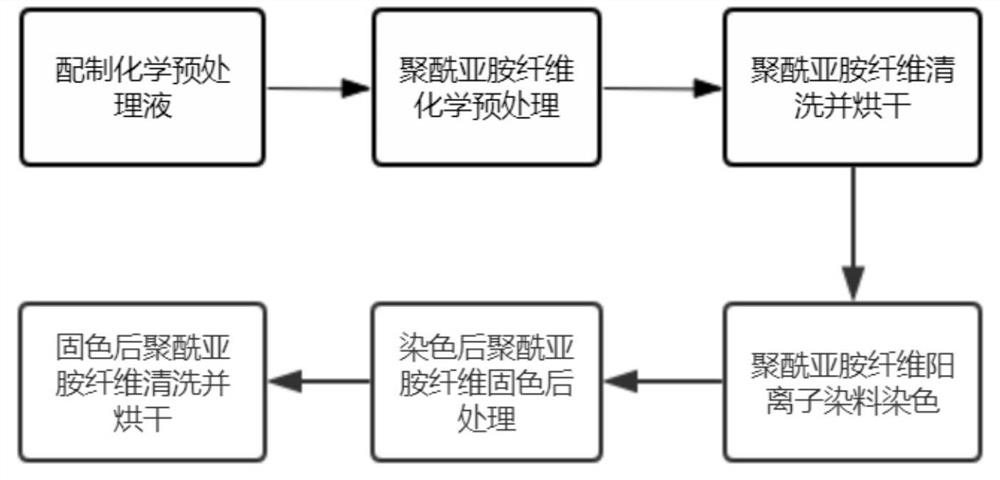

Dyeing method for improving dyeing performance of polyimide fibers

PendingCN113445331AGood leveling effectGood color fastness to washingDyeing processColour fastnessFiber

The invention discloses a dyeing method for improving the dyeing performance of polyimide fibers. The method comprises the steps of pretreatment liquid preparation, fiber pretreatment, fiber dyeing and fiber color fixation. According to the dyeing method provided by the invention, the dyeing performance of the polyimide fibers can be effectively improved, the fiber dye uptake, the fixation rate and the K / S value of the fabric are remarkably improved, and the wet color fastness and the rubbing color fastness of the fabric are improved. The process disclosed by the invention is simple in steps, high in dyeing efficiency, capable of remarkably reducing the use amount of cationic dyes and reducing environmental pollution, green and friendly; the adopted chemical pretreatment process is simple and efficient, and the dyeing performance of the polyimide fibers can be remarkably improved; and the cationic dyes are bright in color and not prone to fading, and the efficient and lasting dyeing effect can be achieved. According to the dyeing method for improving the dyeing performance of the polyimide fibers provided by the invention, on the basis that simple and efficient chemical pretreatment is carried out on the polyimide fibers, the dyeing performance of the polyimide fibers is enhanced, the dyeing efficiency of the dyeing process is further improved, the influence on the mechanical performance of the fibers is small, the environmental friendliness is improved, and wide application of the polyimide fibers and fabrics in the field of clothing can be promoted.

Owner:绍兴市柯桥区东纺纺织产业创新研究院

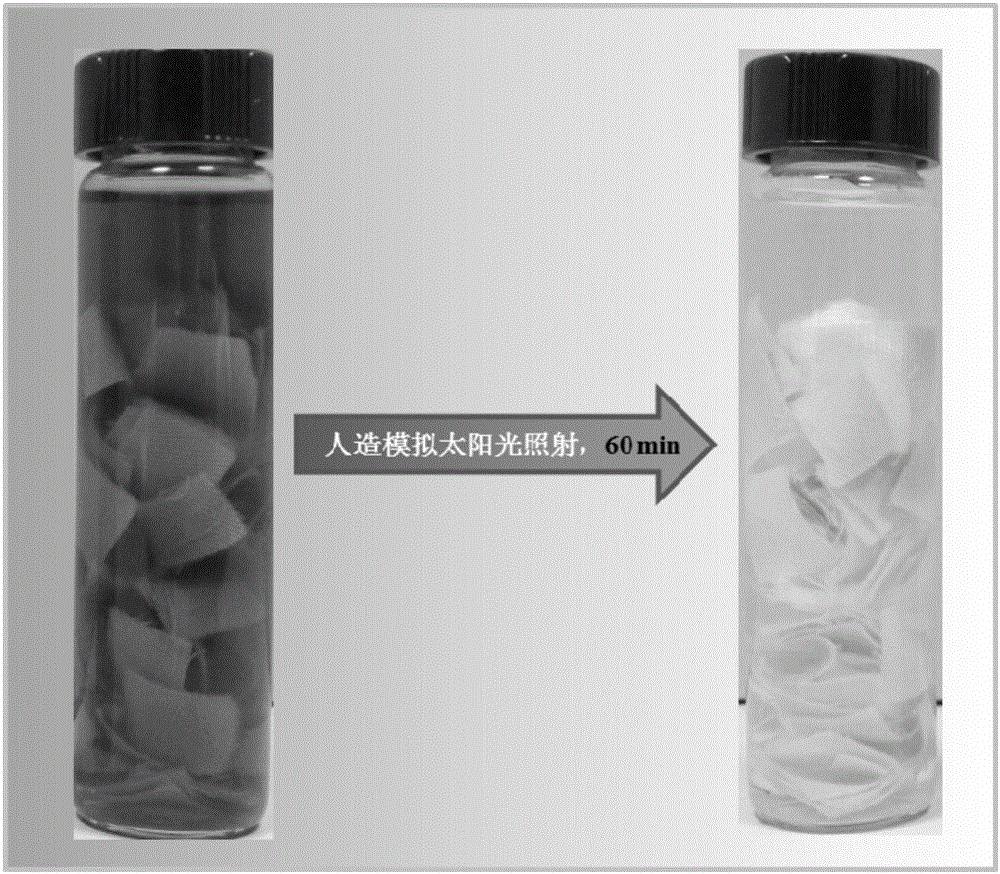

Photocatalysis treating method for dyeing wastewater of polyester/cotton one bath process dyeing

InactiveCN106219664AEasy to handleRealize low carbon and zero emissionWater/sewage treatment by irradiationWater treatment compoundsPolyesterDyeing wastewater

The invention discloses a photocatalysis treating method for dyeing wastewater of polyester / cotton one bath process dyeing. The method comprises the steps that 1, titanium alkoxide is dropwise added into an acid water solution under a violent stirring effect, the temperature is increased to 45-65 DEG C, continuous and violent stirring is carried out for 10-25 h, and prepared titanium dioxide nanometer hydrosol is used as a modified coating of cotton fabric; 2, cotton machine woven fabric is coated with the titanium dioxide nanometer hydrosol through dipping, roller pressing and curing; 3, the titanium dioxide modified fabric is shorn into multiple blocks, and the blocks are placed into bath liquid left after dyeing; processing liquid is exposed under sunlight. The cotton fabric with photocatalysis activity is prepared, the surface of the fabric is coated with a layer of nano TiO2 photocatalyst, and residual dye wastewater can be effectively photocatalyzed and degraded under irradiation of sunlight.

Owner:FOSHAN UNIVERSITY

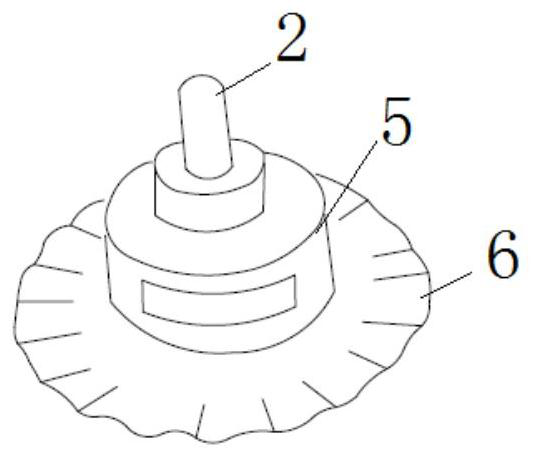

Button dyeing machine

InactiveCN108080210AStir wellEfficient DyeingLiquid surface applicatorsCoatingsPulp and paper industryScrew thread

The invention relates to the technical field of button machinery, in particular to a button dyeing machine. The button dyeing machine comprises supporting legs, and further comprises an operating boxclamped with the upper ends of the supporting legs, a feeding part clamped with the side edge of the upper end of the operating box, a dye adding part clamped with the middle part of the upper end ofthe operating box, a motor, a stirring part which penetrates through the operating box and the end part of which is rotataly connected to the motor, a first supporting frame and a discharge hole clamped with the lower end of the operating box; the first supporting frame comprises a connecting base, an outer clamping plate clamped with the outer wall of the connecting base, a first rotary rod clamped with the outer clamping plate, and a first spherical rotary part which is rotatably connected to one end, away from the external clamping plate, of the first rotary rod through screw threads. The button dyeing machine can be used for uniformly stirring buttons through the stirring part and the first supporting frame, and realizes high-efficient dyeing.

Owner:嘉善奇瑞达服饰辅料厂(普通合伙)

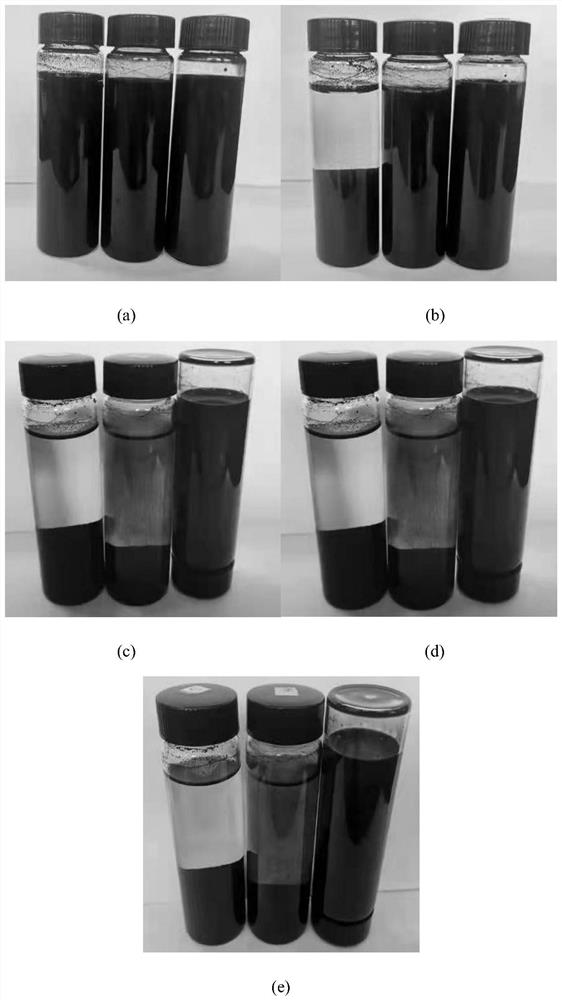

Preparation method of antibacterial graphene slurry

PendingCN111809418AHas antibacterial propertiesIncrease profitDyeing processEngineeringCellulose fiber

The invention discloses a preparation method of antibacterial graphene slurry, and relates to the technical field of textile processing. According to the invention, the antibacterial graphene slurry with antibacterial performance and good adsorption to anionic dyes is prepared through two-step chemical modification treatment of graphene oxide; after an anionic dye is added into the antibacterial graphene slurry, the cellulosic fiber fabric can be efficiently dyed, so that the utilization rate of the dye is remarkably improved, and the cellulosic fiber fabric is endowed with excellent antibacterial performance.

Owner:合肥克拉伦斯科技有限公司

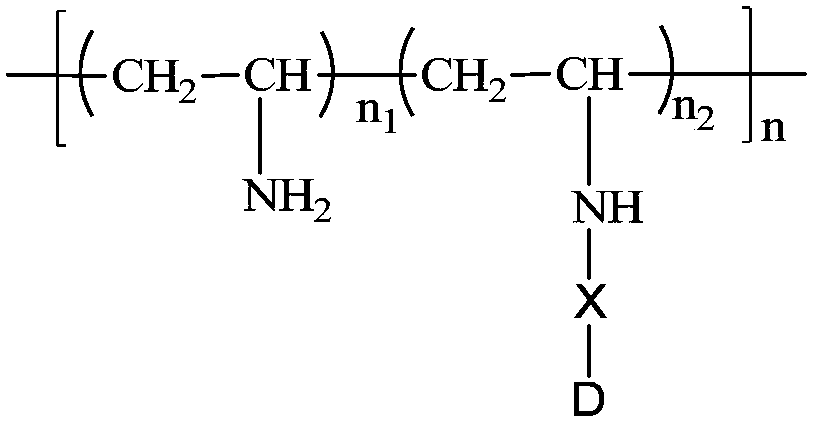

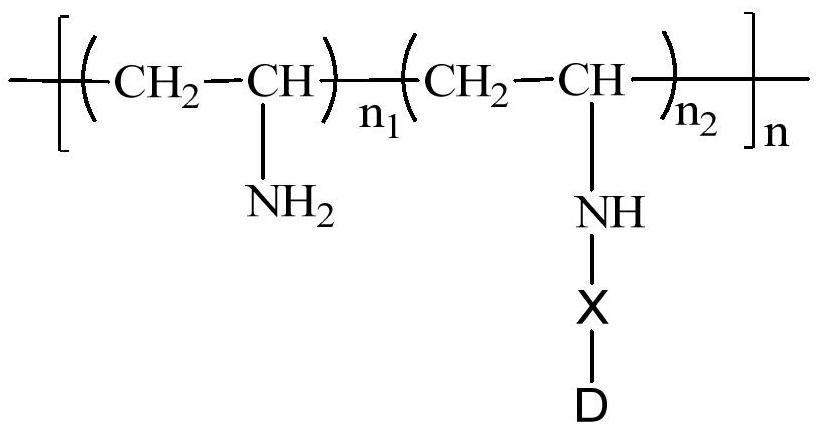

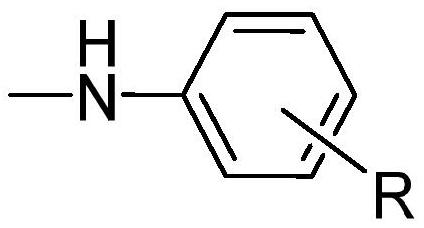

Method for dyeing calcium alginate fiber/silk fiber blend fabric by macromolecular dye containing polyethylene amine molecular chain

The invention belongs to the technical field of fiber dyeing, and particularly relates to a method for dyeing a calcium alginate fiber / silk fiber blend fabric by a macromolecular dye containing a polyethylene amine molecular chain. The method utilizes a macromolecular dye containing a polyvinylamine molecular chain and seaweed fiber to form a complex bond under alkaline conditions, and a polyvinylamine macromolecular dye forms a hydrogen bond and intermolecular interaction with the silk fiber under alkaline conditions, which can achieve the dyeing of calcium alginate fiber / silica fiber blend fabric by the macromolecular dye containing the polyethylene amine molecular chain. The dye of the invention has high dye uptake rate, low dyeing temperature, short dyeing time, and good energy savingand emission reduction effect, can save a lot of cost for enterprises, and has very good industrialization prospect.

Owner:SHANDONG UNIV OF TECH +1

Application of Artemisia argyi Pigment Dyestuff in Cotton Fiber Post-mordant Dyeing Process

The invention provides application of folium artemisiae argyi pigment dye to a cotton fiber post-mordant dyeing process. Cotton fiber is dyed with the dye through a post-mordant dyeing method, so folium artemisiae argyi pigment can serve as plant dye of the cotton fiber; moreover, a dyeing process which applies the folium artemisiae argyi pigment dye to cotton fiber dyeing and has an industrialized application value is provided; and by the post-mordant dyeing method of pure cotton fiber, the color depth K / S value of cotton fabric reaches 4.215, unlubricated friction reaches level 4 to 5, wet friction reaches level 4, color change reaches level 4, staining (cotton) reaches level 4 to 5 and hand feeling reaches level 4, the actual industrial production requirements are met, and the technological gap of folium artemisiae argyi pigment plant dye in the prior art is filled.

Owner:HUNAN INSTITUTE OF ENGINEERING

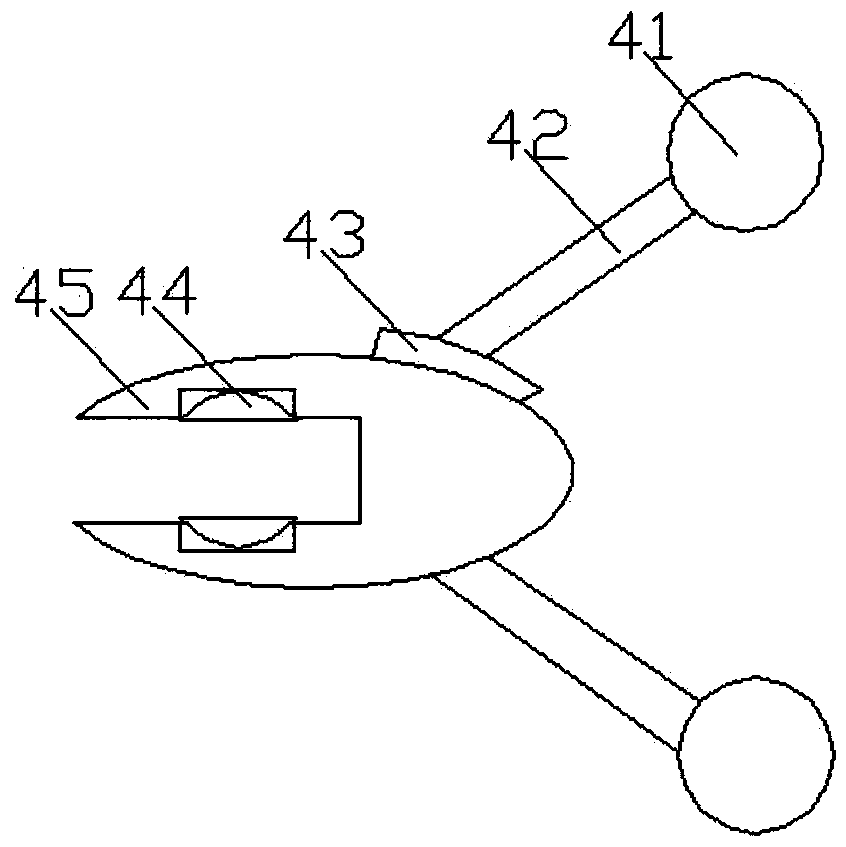

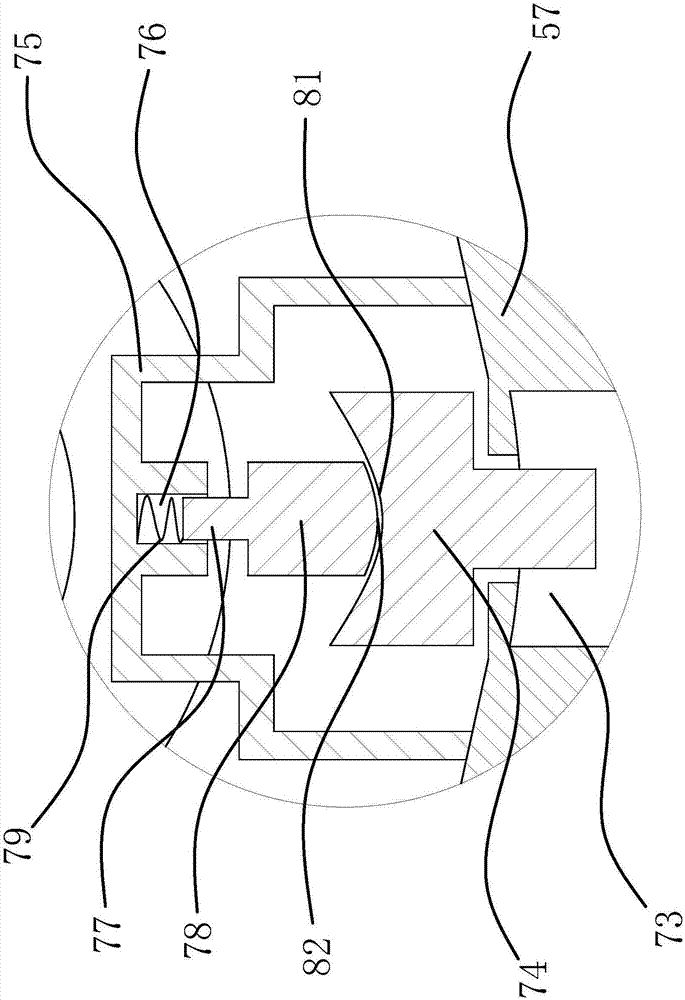

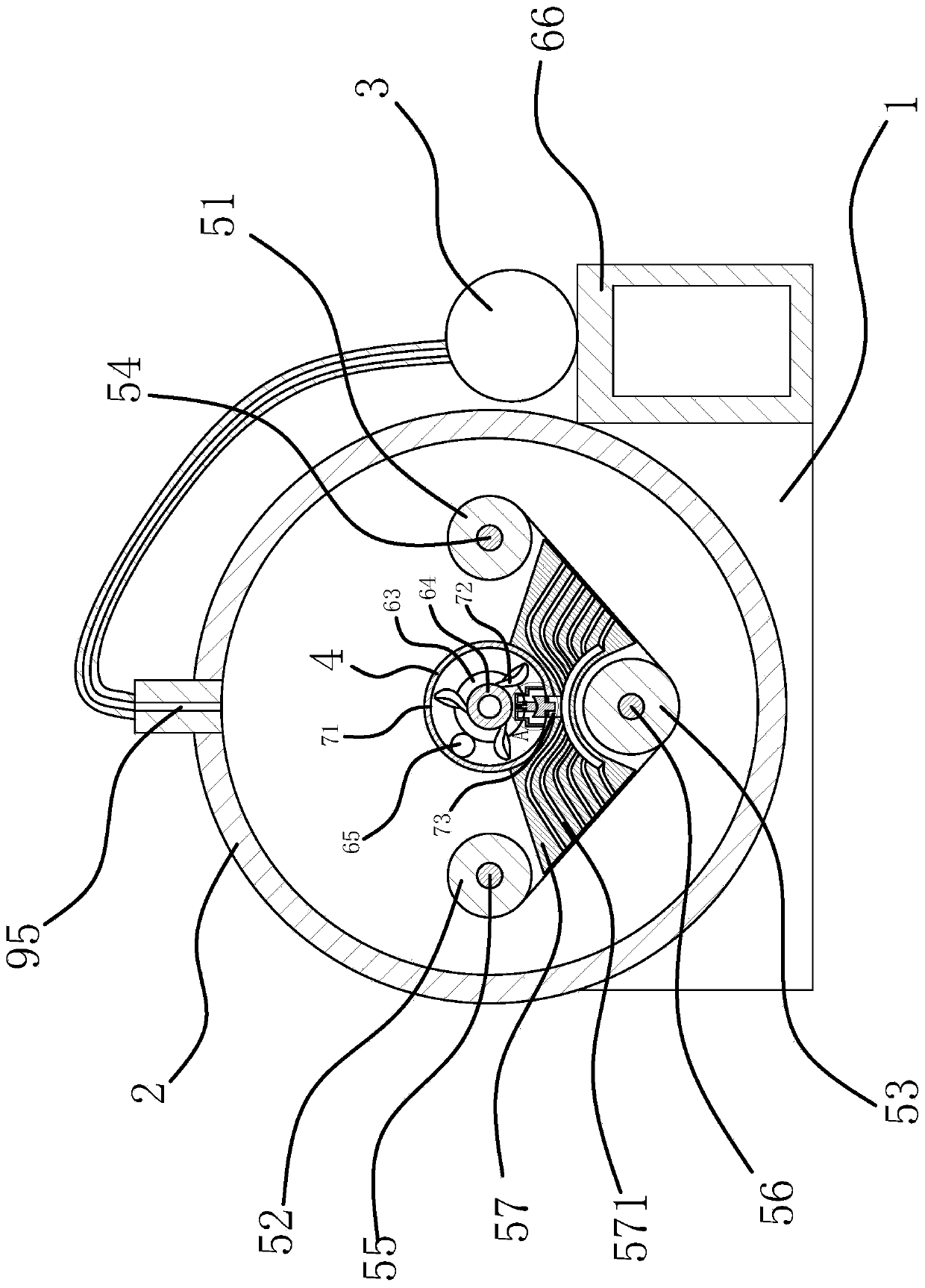

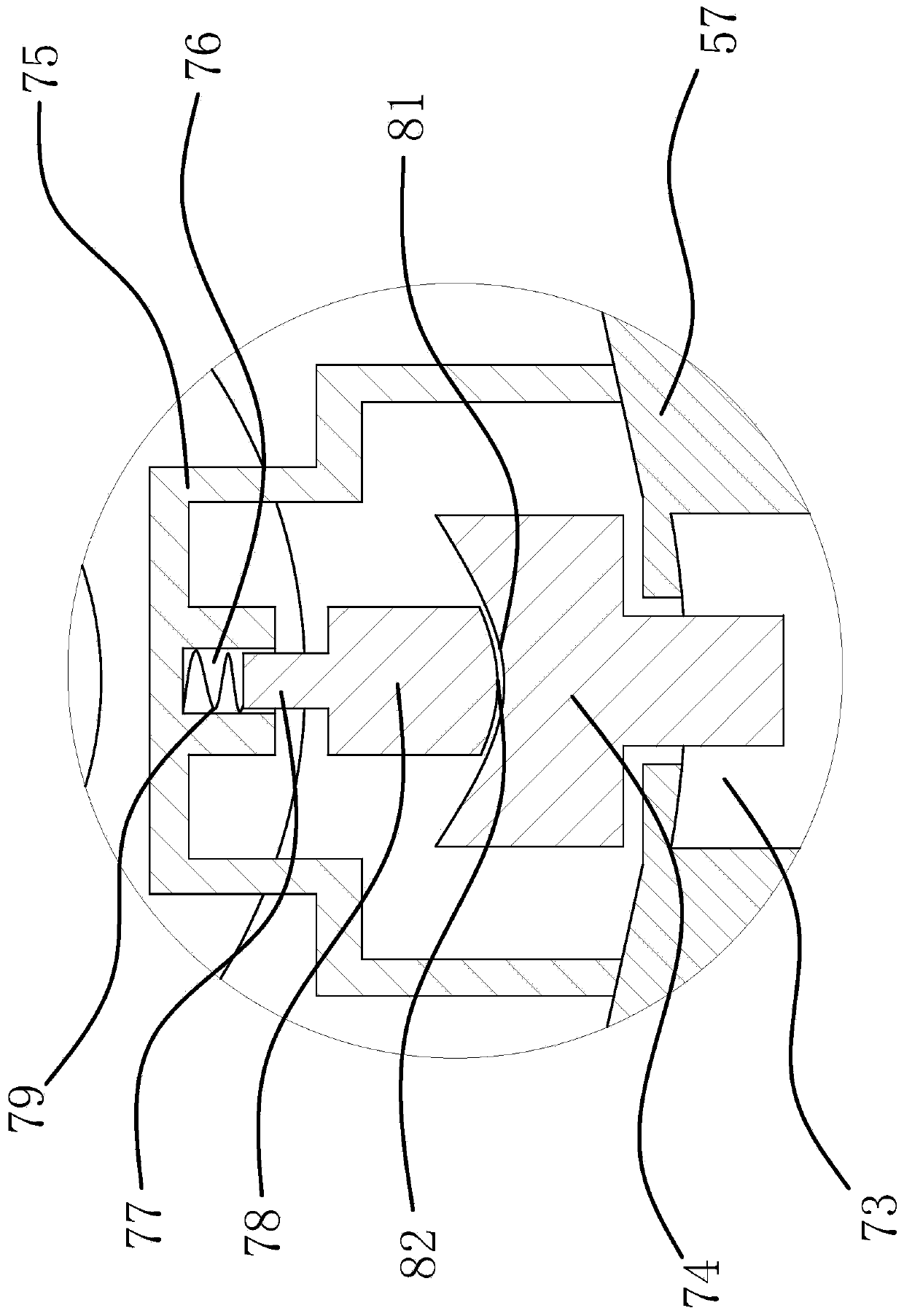

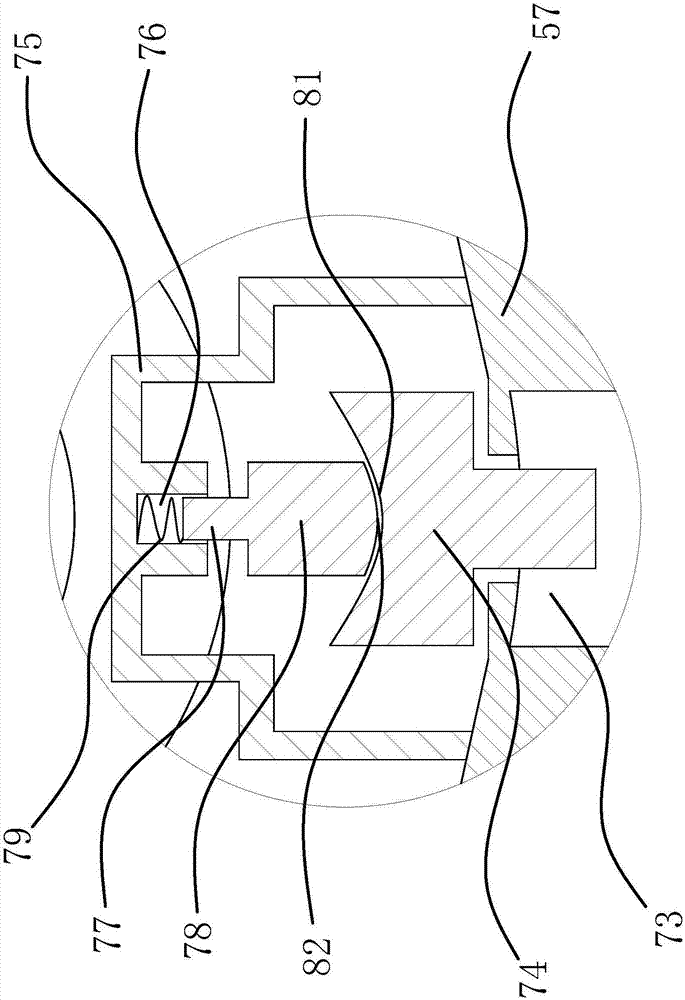

Interception device on vacuum dyeing machine

ActiveCN107385738AGood dyeingReduce air resistanceTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentDyeingTextile

The invention provides an interception device on a vacuum dyeing machine, belongs to the technical field of textile, and solves the technical problems that dyestuff blocks a ventilating channel and the like. The dyeing machine comprises a base, a barrel-shaped dyeing cylinder, a dyestuff pond, a dripping dyeing pump and a spindle; the dyeing cylinder is fixedly arranged on the base; and the spindle has a hollow structure. The interception device comprises a T-shaped valve; a small-diameter end of the valve is inserted in a through hole; a valve seat is fixedly arranged on the inner wall of the spindle; a guiding hole which faces the outer side of the spindle is formed in the valve seat; the inside of the guiding hole is movably connected with a guiding column; a push block is arranged on the guiding column and can be propped against a large-diameter end of the valve body; and the small-diameter end of the valve can be inserted in the through hole by the push plate under the effect of gravity. The interception device on the vacuum dyeing machine has the advantages that the dyestuff can be prevented from blocking a ventilating channel, and is saved, and the like.

Owner:浙江深梦皮革科技有限公司

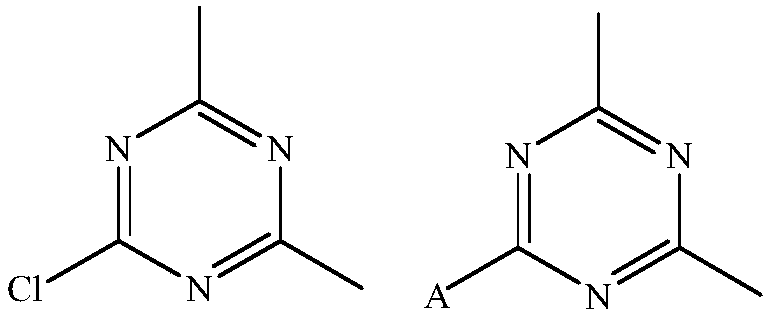

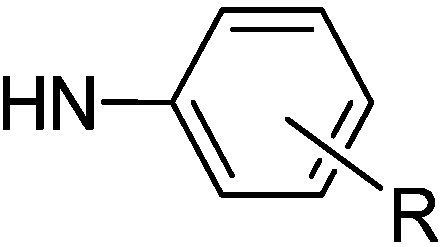

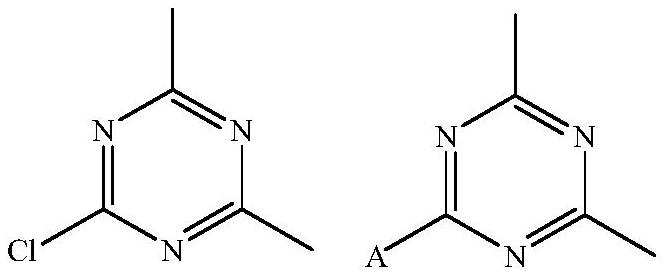

Preparation of self-dispersing reactive nano carbon powder and method for dyeing cotton fabric by using self-dispersing reactive nano carbon powder

The invention provides a preparation and dyeing method of self-dispersing nano carbon powder. The preparation and dyeing method comprises the following steps: preparing a compound A, preparing a compound B, preparing a compound C, preparing amino modified CB, preparing the self-dispersing nano carbon powder, and preparing a dyed CB dyed cotton fabric finished product. According to the preparation and dyeing method of the self-dispersing nano carbon powder, on the basis of ensuring the performance, the advantages of small environmental harm and low energy consumption rate are realized.

Owner:YANCHENG INST OF TECH

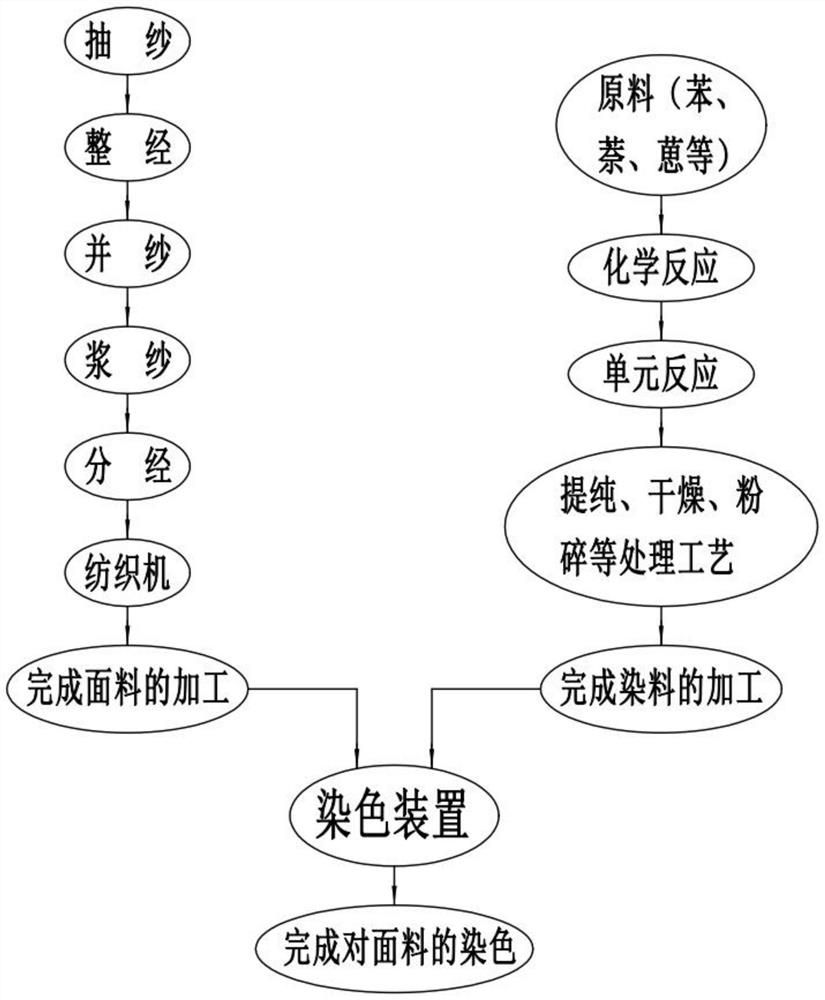

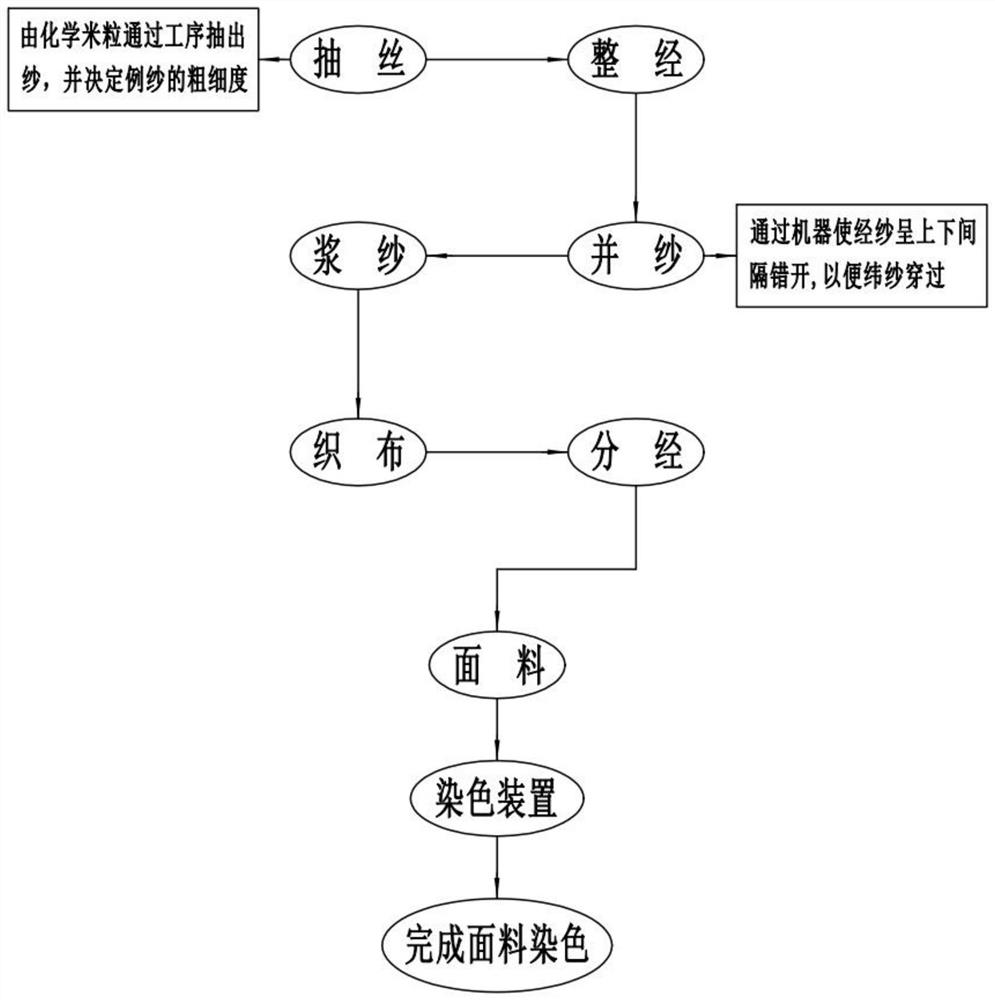

Fabric dyeing process

InactiveCN114561762AEfficient DyeingLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsChemistryProcess engineering

The invention relates to the technical field of fabric dyeing, in particular to a fabric dyeing process which comprises the following steps: step 1, screening preparation raw materials of a fabric and preparation raw materials of dye; 2, raw materials for preparing the fabric are subjected to yarn drawing, warping, doubling, slashing and leasing treatment and placed in a textile machine, and fabric processing is completed; step 3, performing chemical reaction and unit reaction on the preparation raw materials of the dye, and performing purification, drying, crushing and other treatment processes to complete the processing of the dye; step 4, adding dye into the dyeing device, and enabling the fabric to pass through the dyeing device, so as to finish dyeing of the fabric.

Owner:张爱荣

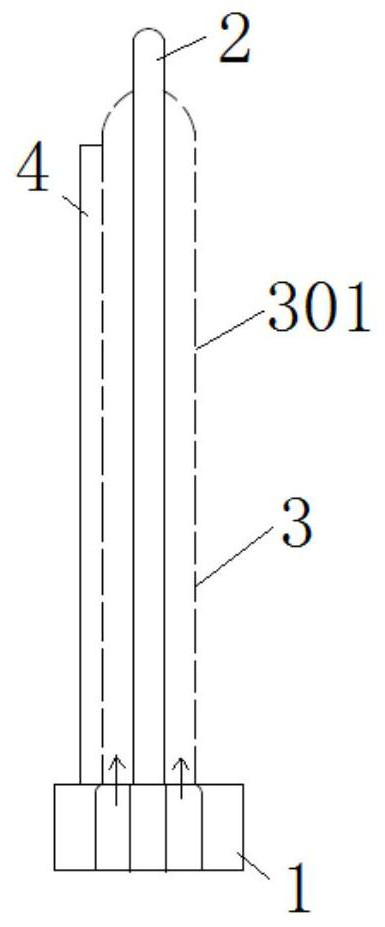

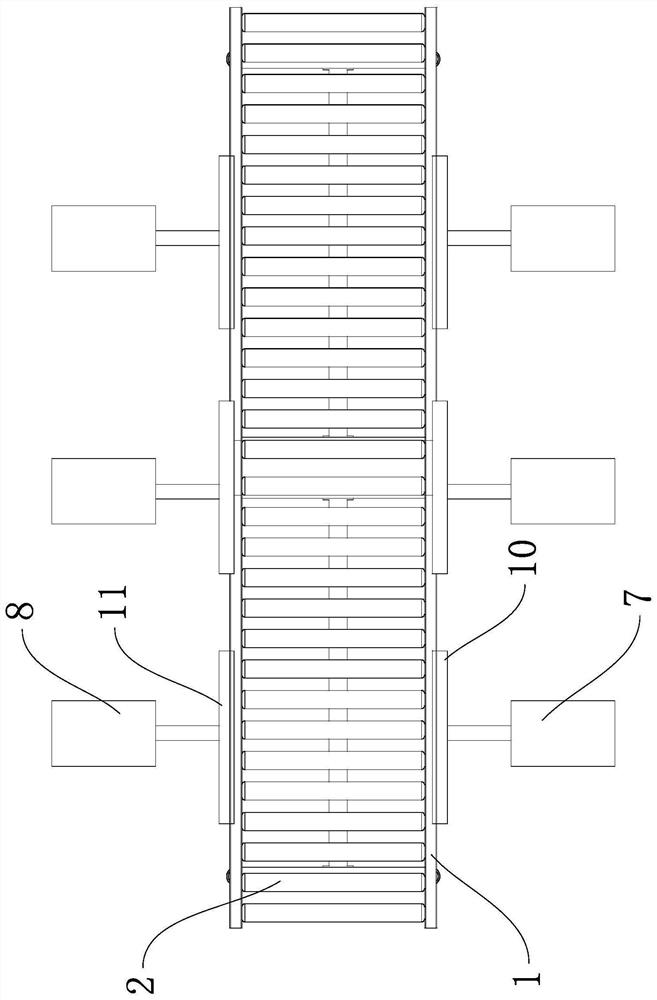

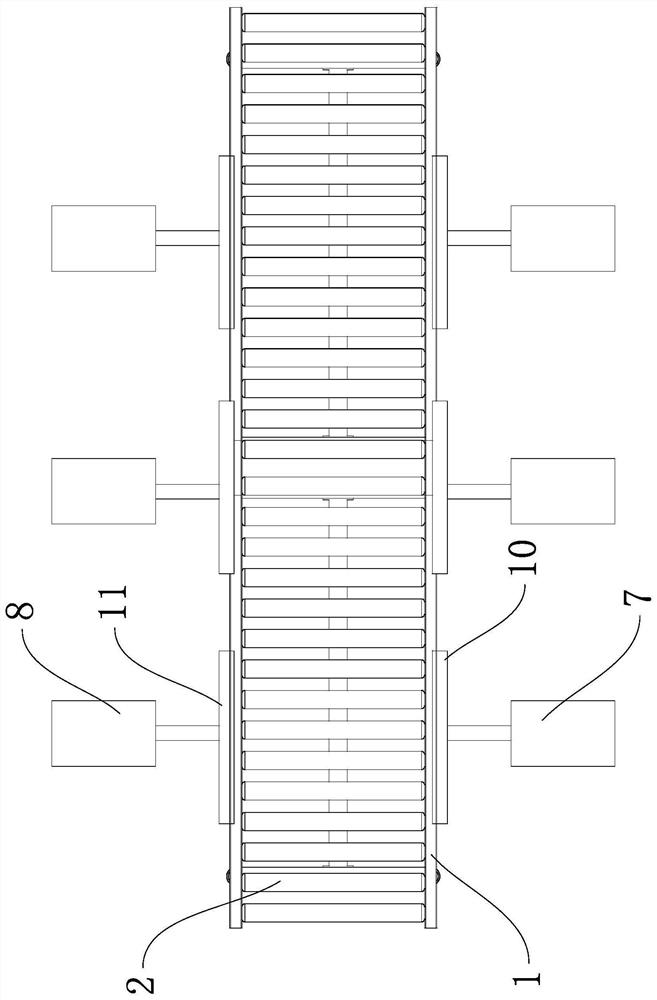

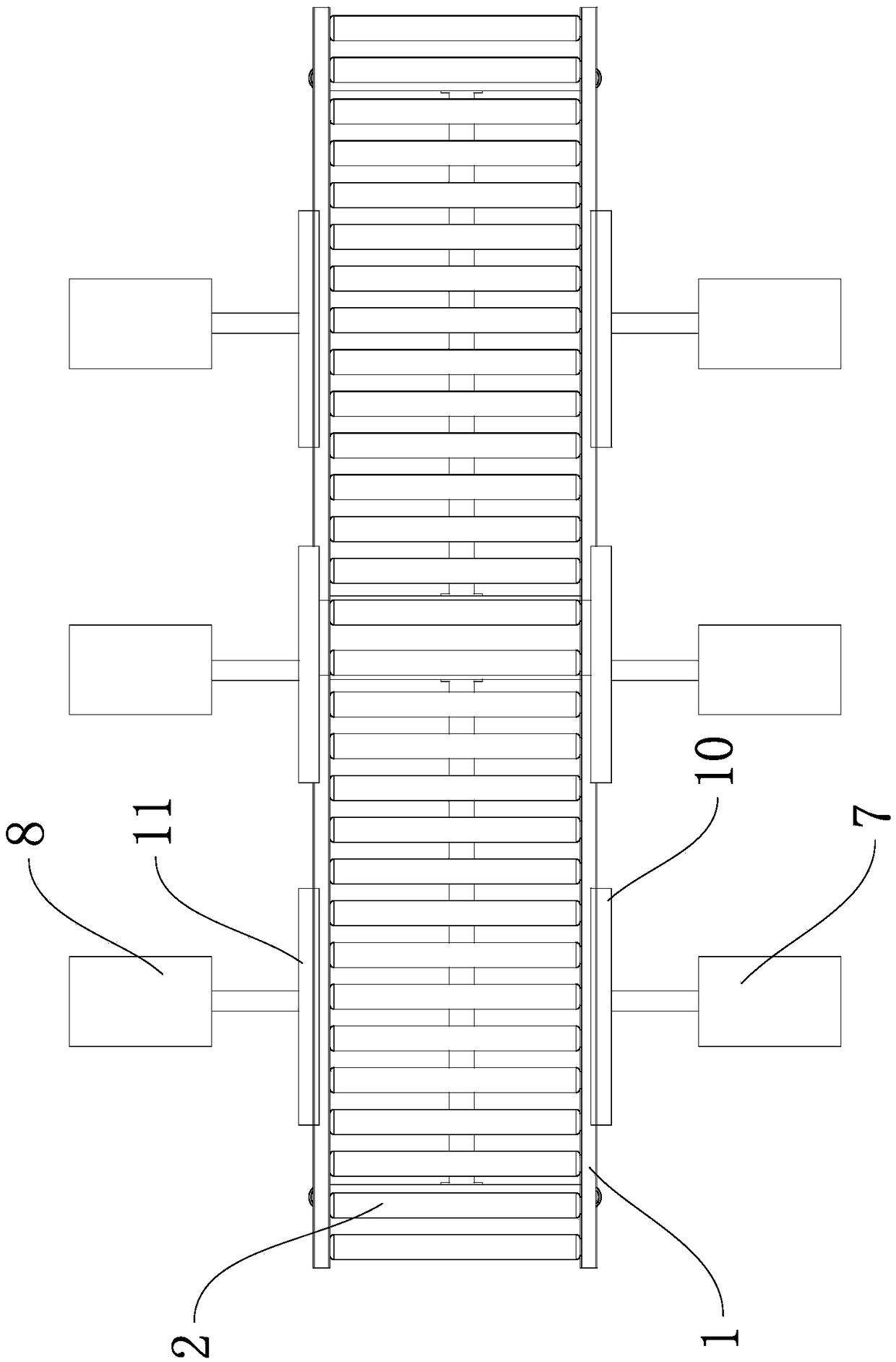

Bobbin structure for cheese dyeing

PendingCN113584781AReasonable structural designUniform dyeingTextile treatment carriersLiquid/gas/vapor yarns/filaments treatmentPolymer scienceEngineering

The invention discloses a bobbin structure for cheese dyeing. The bobbin structure comprises a fixing seat and a supporting rod arranged on the fixing seat; the bobbin structure further comprises a hollow bobbin; the supporting rod is sleeved with the hollow bobbin; an empty groove for dye liquor to enter is formed in the fixing seat; the bottom end of the hollow bobbin is communicated with the empty groove; and the hollow bobbin is provided with a group of liquid outlet holes for dye liquid to flow out. The bobbin for cheese dyeing is reasonable in structural design, a set of cheese is arranged on the hollow bobbin in a sleeving mode, dye liquor enters the hollow bobbin from the empty groove of the fixing seat, then enters the bobbin through the through holes in the bobbin and finally penetrates through the cheese to be discharged, dyeing is uniform, the dye liquor can be pressurized, and dyeing is efficient.

Owner:WUHU FUCHUN DYEING & WEAVING

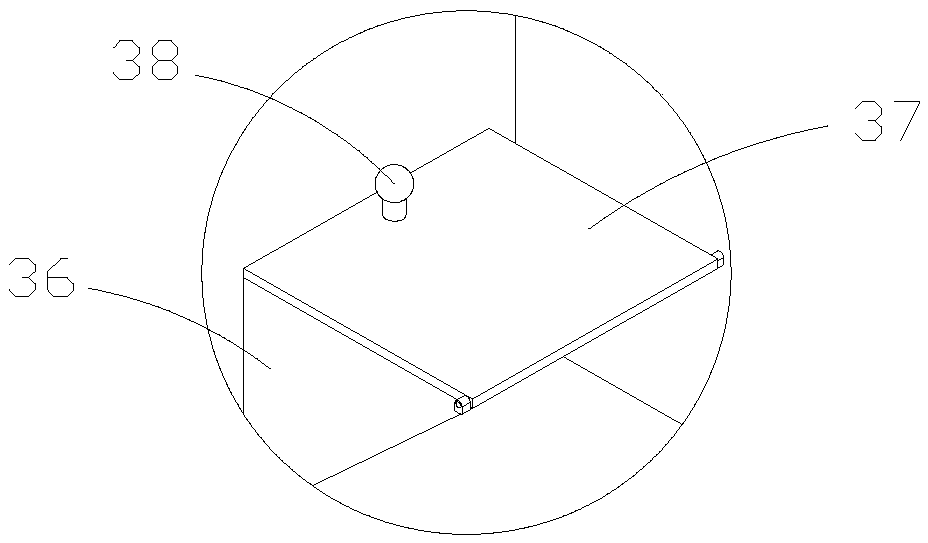

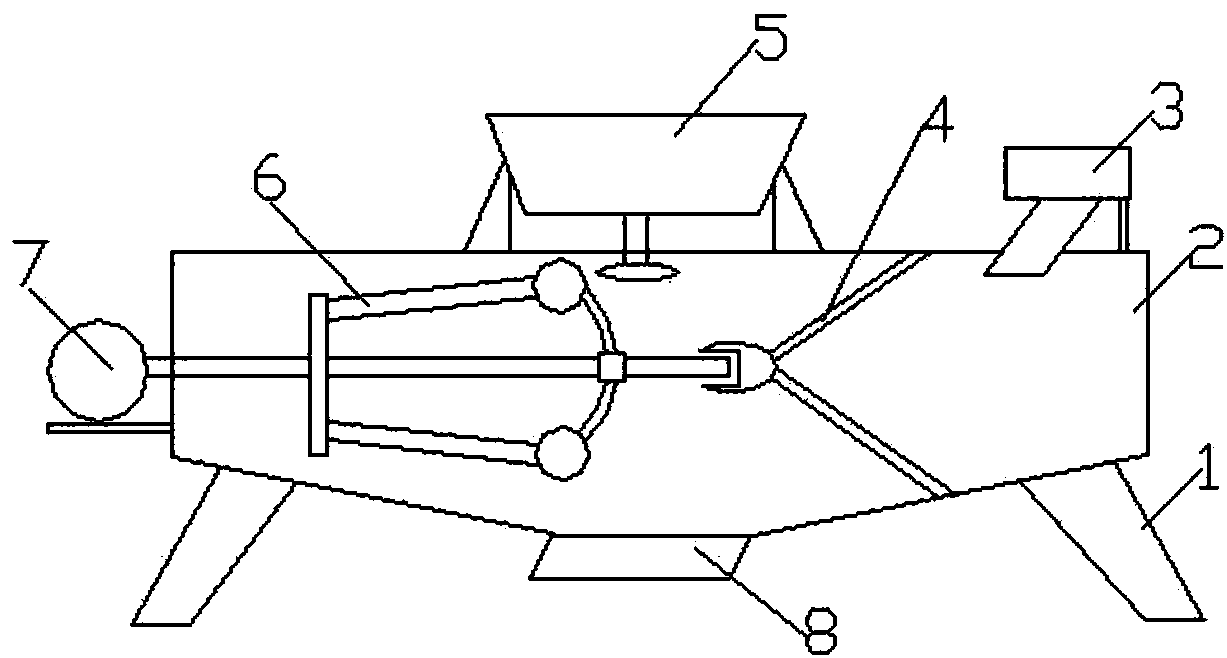

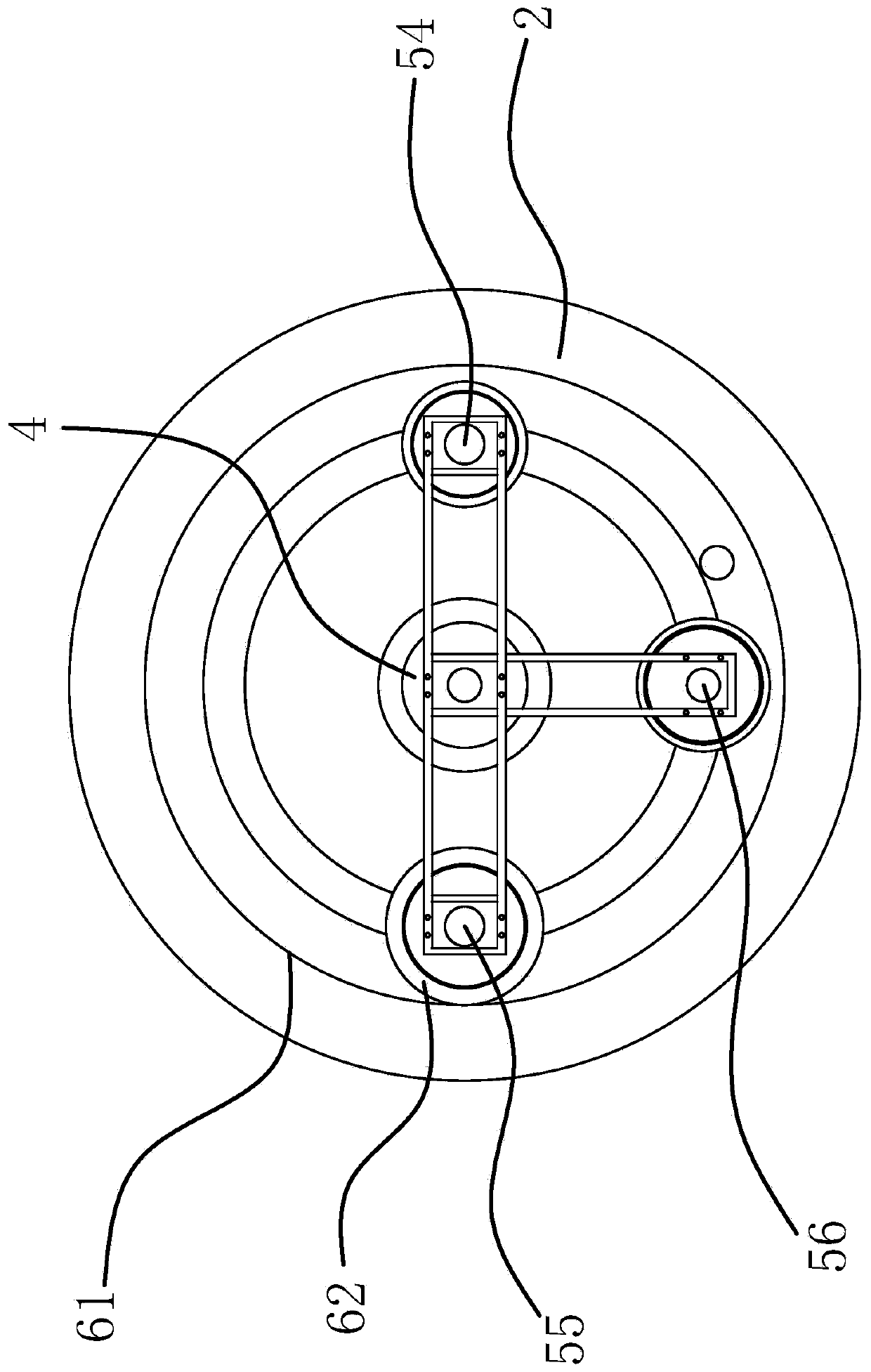

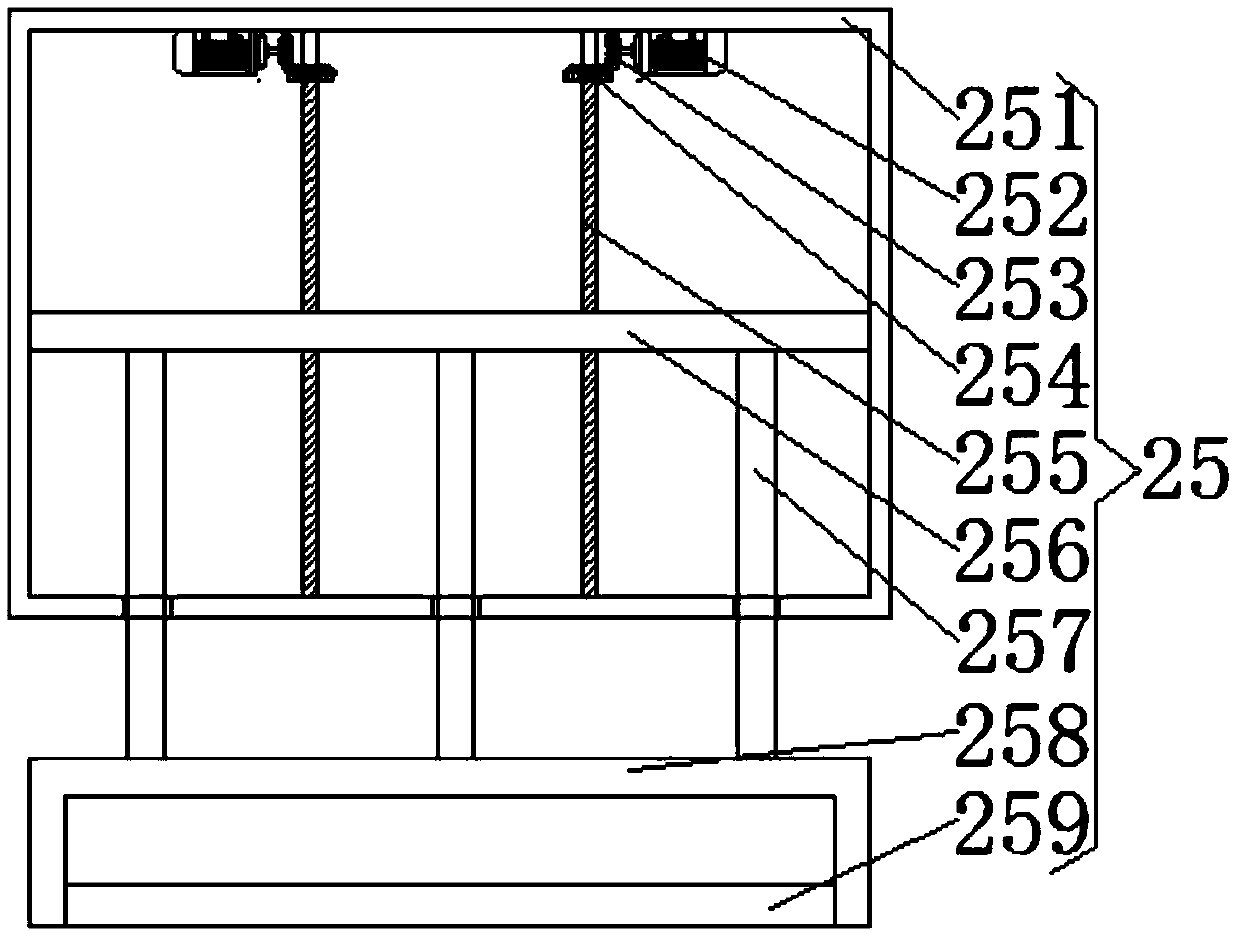

Vacuum dyeing machine

InactiveCN110629433AQuick stainEfficient DyeingLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removal by suctionPulp and paper industryDyeing

The invention belongs to the technical field of textiles, provides a vacuum dyeing machine and solves technical problems of procedure complexity, failure in drying and the like of an existing dyeing machine. The vacuum dyeing machine comprises a base, a cylindrical dye vat, a dye tank, a drip dyeing pump and a spindle. The dye vat is fixedly arranged on the base, the spindle is in a hollow structure, a discharging roller, a collection roller and a tensioning roller are rotationally connected to the dye vat through a first rotating shaft, a second rotating shaft and a third rotating shaft respectively, and the first rotating shaft, the second rotating shaft and the third rotating shaft are all fixedly connected with the spindle. An absorption block is arranged between the discharging rollerand the collection roller and provided with absorption holes aiming at to-be-dyed cloth. A vacuumizing device for vacuumizing the dye vat is arranged on the spindle, and a driving structure for driving the collection roller to rotate under the driving action of the spindle is arranged between the dye vat and the collection roller. The vacuum dyeing machine has the advantage that cloth drying canbe realized during dyeing.

Owner:卢巧巧

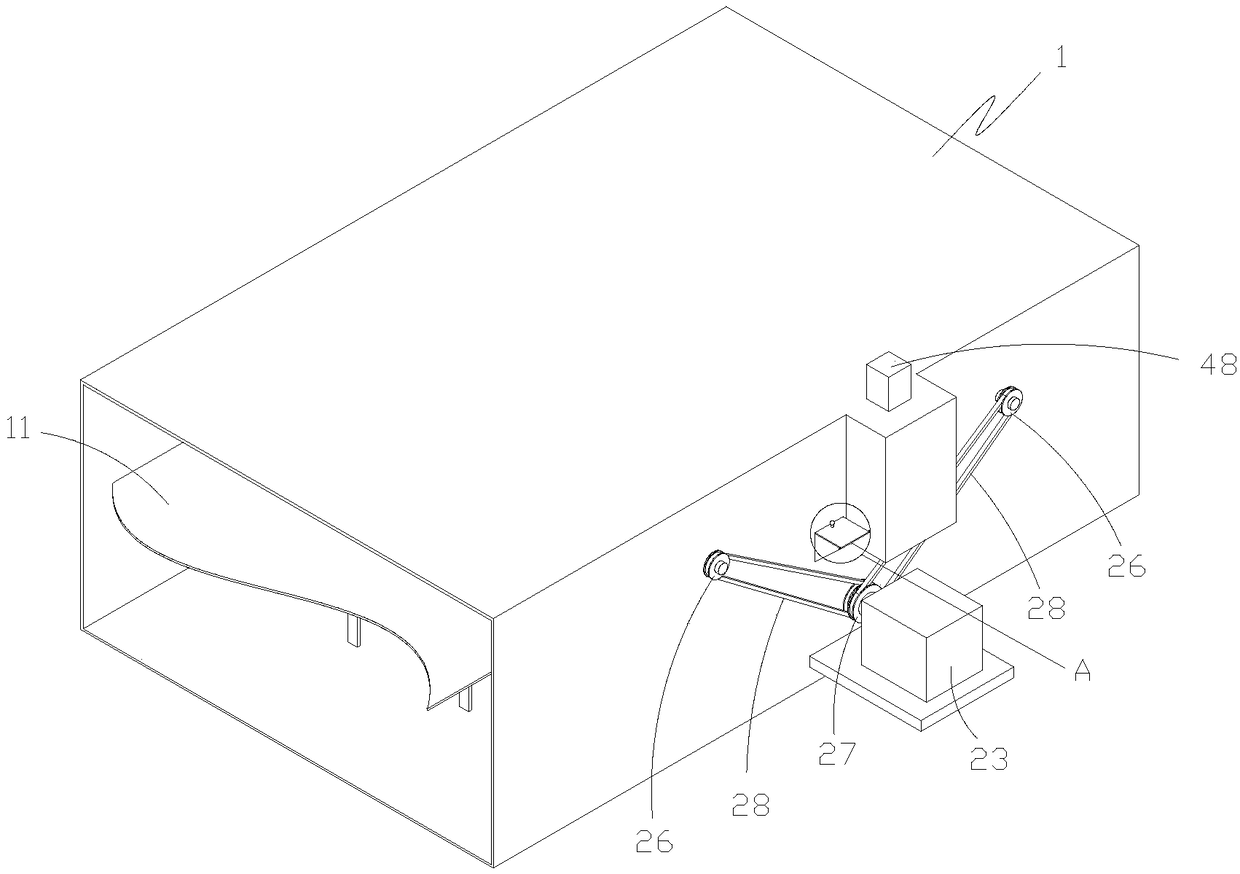

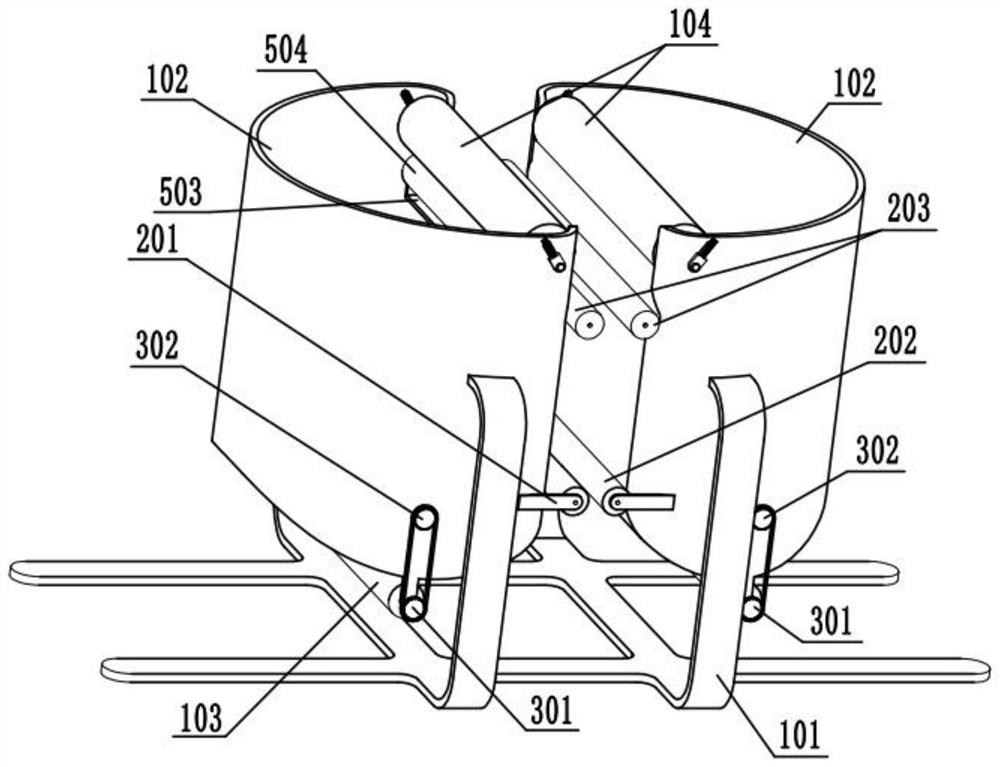

A mahjong coloring device

ActiveCN109203655BImprove efficiencyShorten the timeCylinder pressesIndoor gamesMechanical engineeringEngineering

The invention provides a mahjong coloring device, which belongs to the technical field of machinery. It is a coloring device for mahjong, which includes a frame, on which a number of conveying rollers are rotated, on which are provided boxes for placing mahjong, and on the frame, three conveying rollers are arranged The calibration mechanism for placing the calibration position of the box on the frame; there are three coloring mechanisms for spraying and coloring the mahjong surface on the frame; the coloring mechanism corresponds to the position of the calibration mechanism one by one, and a cleaning box is fixed on the frame. The cleaning box is provided with a cleaning mechanism for cleaning the excess dye on the mahjong surface; multiple recovery boxes are fixed at the lower part of the frame, and the recovery boxes are located below the coloring mechanism. The invention has the advantage of high coloring efficiency.

Owner:山东天成钢结构有限公司

A coloring mechanism in a mahjong coloring device

The invention provides a coloring mechanism in a mahjong coloring device, belonging to the technical field of machinery. A coloring mechanism in a mahjong coloring device, comprising a frame, on which a number of conveying rollers are rotated, on which are provided boxes for placing mahjong, and on the frame are provided three The calibration mechanism for the calibration position of the placement box on the conveying roller; there are three coloring mechanisms for coloring the mahjong surface on the frame; the coloring mechanism corresponds to the position of the calibration mechanism one by one, and the coloring mechanism includes a printing and dyeing board 1. Printing and dyeing board 2, printing and dyeing board 3 and the lifting board. The lifting board is connected and fixed on the upper part of the frame through the lifting mechanism. , printing and dyeing board two and printing and dyeing board three are located directly above the conveying roller. The invention has the advantage of high mahjong coloring efficiency.

Owner:山东天成钢结构有限公司

Fabric dyeing process

PendingCN114561758AEfficient DyeingTextile treatment containersDyeing processPolymer scienceEngineering

The invention relates to the technical field of fabric dyeing, in particular to a fabric dyeing process which comprises the following steps: step 1, drawing, namely drawing yarns from chemical grains through a procedure, determining the thickness of the yarns, and then performing warping treatment; step 2, doubling: staggering the warp yarns at intervals up and down through a machine so as to enable the weft yarns to pass through, and slashing; 3, the fabric can be processed through weaving and leasing treatment; 4, the processed double-layer fabric passes through a dyeing device, and dyeing processing of the fabric can be completed.

Owner:陈凤云

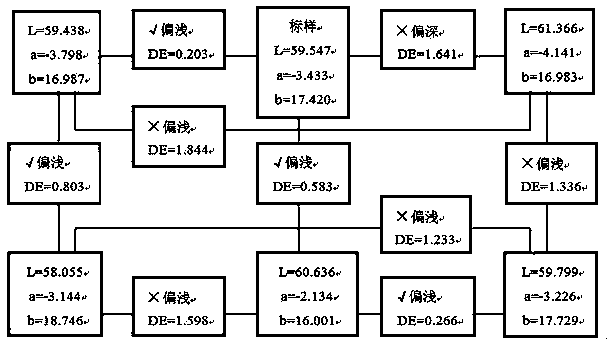

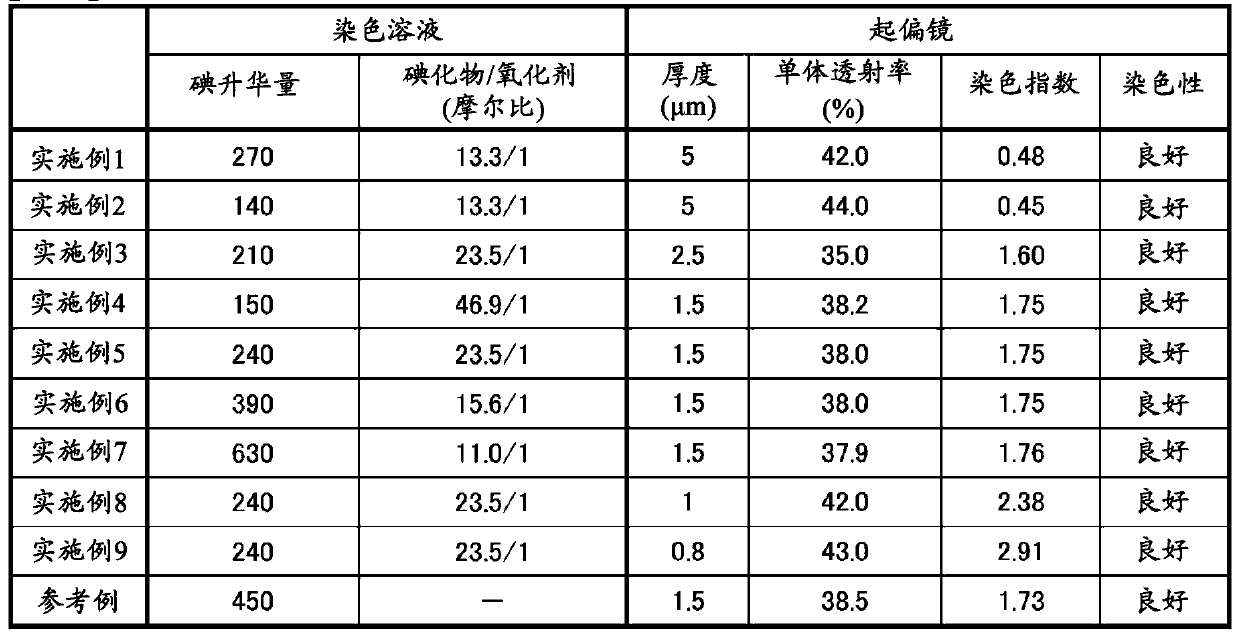

Polarizer production method

The purpose of the present invention is to provide a polarizer production method with which dyeing can be performed more efficiently. This polarizer production method includes a step in which a solution including an iodide and an oxidant of iodine ions is used to dye a polyvinyl alcohol resin film. The oxidant is an ionic compound which comprises a cation and an anion. The standard electrode potential of any one among the anion and the cation is greater than that of iodine ions. As a result of using such a solution to perform dyeing, the polyvinyl alcohol resin film can be dyed more efficiently.

Owner:NITTO DENKO CORP

A textile dyeing device with drying effect

ActiveCN107503051BEasy to dryColoring firmLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by suctionAir filterEngineering

A textile dyeing device having drying effect comprises a box, one side of the bottom of an inner cavity of the box is fixedly connected with a drainage tank, a position, below a supporting frame, of the bottom of the inner cavity of the box is fixedly connected with an air filtering device, the top of the supporting frame is fixedly connected with an air heating device, the top, positioned on one side of a through groove, of a supporting plate is fixedly connected with a dye box, a nozzle is positioned between the supporting plate and the drainage tank, one side, away from the through groove, of the bottom of the supporting plate is fixedly connected with a water extruding device, and an exhaust device is fixedly connected at a position, right above the air heating device, of the top of the box. The invention relates to the technical field of textile processing. The textile dyeing device can quickly dry and dye cloth for the convenience of the next process, product quality is ensured, quick and efficient dyeing is realized, uniformity and thoroughness in dyeing are guaranteed, no flaw is about to be generated, and redundant water and dye are enabled to leave the cloth and can be recycled, so that resources are saved, and environment is protected.

Owner:天龙数码印染科技有限公司

Method for dyeing calcium alginate fiber/silk fiber blended fabric with macromolecular dye containing polyvinylamine molecular chain

The invention belongs to the technical field of fiber dyeing, and in particular relates to a method for dyeing calcium alginate fiber / silk fiber blended fabrics with macromolecular dyes containing polyvinylamine molecular chains. The present invention utilizes macromolecular dyes containing polyvinylamine molecular chains to form complex bonds with seaweed fibers under alkaline conditions, and at the same time polyvinylamine macromolecular dyes form hydrogen bonds and intermolecular interactions with silk fibers under alkaline conditions To achieve the dyeing of calcium alginate fiber / silk fiber blended fabrics with macromolecular dyes containing polyvinylamine molecular chains. The invention has high dye uptake rate, low dyeing temperature and short dyeing time, has good energy saving and emission reduction effects, can save a large amount of cost for enterprises, and has very good industrialization prospects.

Owner:SHANDONG UNIV OF TECH +1

Dyeing method for improving dyeing performance of polyester fibers

The invention belongs to the technical field of polyester fiber dyeing, and particularly relates to a dyeing method for improving the dyeing performance of polyester fibers, which comprises the steps of pretreatment solution preparation, fiber pretreatment, fiber dyeing and fiber fixation and reduction. According to the dyeing method disclosed by the invention, the dyeing performance of the polyester fiber can be remarkably improved, wherein the performance comprises the dyeing rate, the fixation rate, the color fastness and the rubbing fastness of the fiber; the process steps are relatively simple, the dyeing effect is excellent, the used raw materials are green and environment-friendly, the harm to the environment is reduced, the concept of green chemistry and sustainable development is met, and the method is suitable for industrial large-scale production. Compared with the prior art, the mechanical strength of the polyester fiber after dyeing and the mechanical strength of the polyester fiber before dyeing show that the difference between the mechanical strength of the polyester fiber after dyeing and the mechanical strength of the polyester fiber before dyeing is small, the practicability of the fiber is greatly improved, and a foundation is laid for wide application of the polyester fiber fabric in the field of daily use.

Owner:QINGDAO UNIV OF SCI & TECH

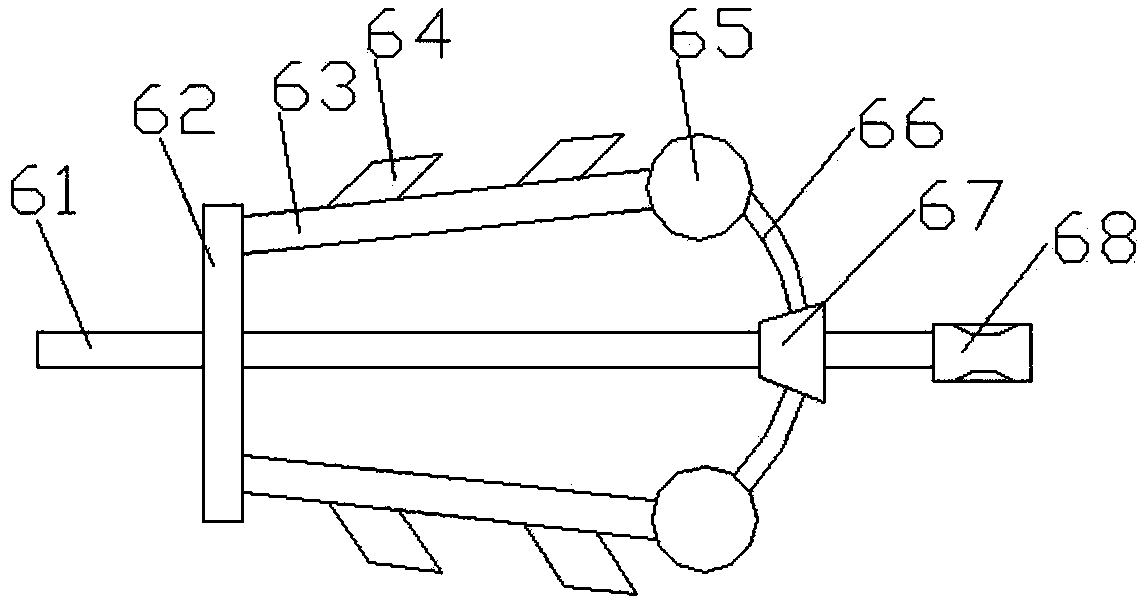

Reeling device on vacuum dyeing machine

ActiveCN107385740AGood dyeingReduce air resistanceTextile treatment containersTextile treatment machine arrangementsDyeingTextile

The invention provides a reeling device on a vacuum dyeing machine, belongs to the technical field of textile, and solves the technical problems that existing cloth is difficult to reel in a dyeing cylinder and the like. The dyeing machine comprises a base, a barrel-shaped dyeing cylinder, a dyestuff pond, a dripping dyeing pump and a spindle; the dyeing cylinder is fixedly arranged on the base; a first rotating shaft, a second rotating shaft and a third rotating shaft are fixedly connected with the spindle; a suction block is arranged between a discharging drum and a collecting drum; a suction hole for cloth to be dyed is formed in the suction block; the spindle is provided with a vacuumizing device which is used for vacuumizing the inside of the dyeing cylinder; a driving structure which is driven by the spindle to drive the collecting drum to rotate is arranged between the dyeing cylinder and the collecting drum; the drying structure comprises a second inner gear ring arranged on the dyeing cylinder; and a transmission gear which is engaged with the second inner gear ring is arranged on the second rotating shaft. The reeling device on the vacuum dyeing machine has the advantages of simple structure, reliable and synchronous reeling and the like.

Owner:浙江深梦皮革科技有限公司

A Fast and Efficient Method for Staining Arbuscular Mycorrhizal Fungi

InactiveCN103411813BEfficient DyeingAdaptablePreparing sample for investigationArbuscular mycorrhizal fungiStaining

The invention relates to a method for rapidly and efficiently dyeing arbuscular mycorrhizal fungi, belonging to the field of application microbiology, and being capable of rapidly and efficiently dyeing and observing the arbuscular mycorrhizal fungi at the root of a plant. The method comprises the following steps of: firstly, carrying out transparency treatment on a root tissue by using a KOH (Potassium Hydroxide) solution with the concentration being 20% at high temperature, whitening the root tissue by using H2O2, subsequently dyeing by using trypan blue with the concentration being 0.1%, and observing the structure of the arbuscular mycorrhizal fungi after decoloration by using a decoloration liquid. The method has the characteristics of convenience, rapidness and efficiency, and has the characteristics that the decoloration is thorough, the dyeing effect is clear, the arbuscular structure and the vesicle structure are clear and discernable, and the coloring is long-lasting. The roots of most plants can be dyed by using the method, the arbuscule and the vesicle of the arbuscular mycorrhizal fungi are clearly observed, and the method has good application prospects as the mycorrhiza research is gradually taken seriously.

Owner:JIANGSU UNIV

Coloring mechanism in mahjong tile coloring device

The invention provides a coloring mechanism in a mahjong tile coloring device and belongs to the technical field of machines. The coloring mechanism in the mahjong tile coloring device comprises a rack, multiple conveying rollers are rotatably arranged on the rack, placement boxes for placing mahjong tiles are arranged on the conveying rollers, and three calibration mechanisms for calibrating thepositions of the placement boxes on the conveying rollers are arranged on the rack; three coloring mechanisms for painting and coloring the surfaces of the mahjong tiles are arranged on the rack; thecoloring mechanisms correspond to the calibration mechanisms one to one, each coloring mechanism comprises a first printing and dyeing plate, a second printing and dyeing plate, a third printing and dyeing plate and a lifting plate, and the lifting plate is fixedly connected to the upper portion of the rack through a lifting mechanism; the first printing and dyeing plate, the second printing and dyeing plate and the third printing and dyeing plate are fixedly connected with the lifting plate through fixing supporting rods in sequence and located over the conveying rollers. The coloring mechanism has the advantage of high mahjong tile coloring efficiency.

Owner:山东天成钢结构有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com