Fabric dyeing process

A fabric and process technology, applied in the field of fabric dyeing technology, can solve problems such as inability to dye fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

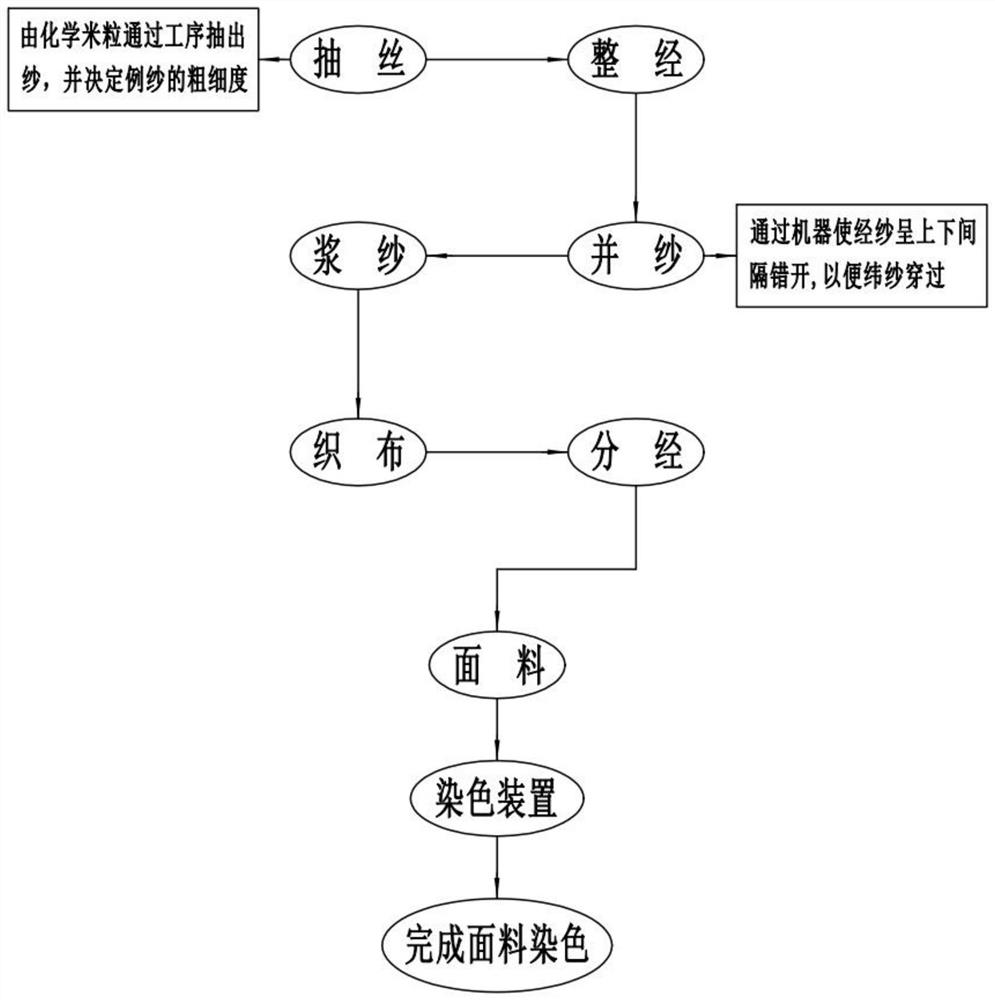

[0034] Attached below figure 1 In detail, a fabric dyeing process, the preparation process includes the following steps:

[0035] Step 1: Spinning, the chemical rice grains are used to extract the yarn through the process, and the thickness of the yarn is determined, and then the warping treatment is carried out;

[0036] Step 2, doubling the yarns, making the warp yarns staggered at the upper and lower intervals by the machine, so that the weft yarns can pass through, and sizing is carried out;

[0037] Step 3: Fabrics can be processed by weaving and dividing;

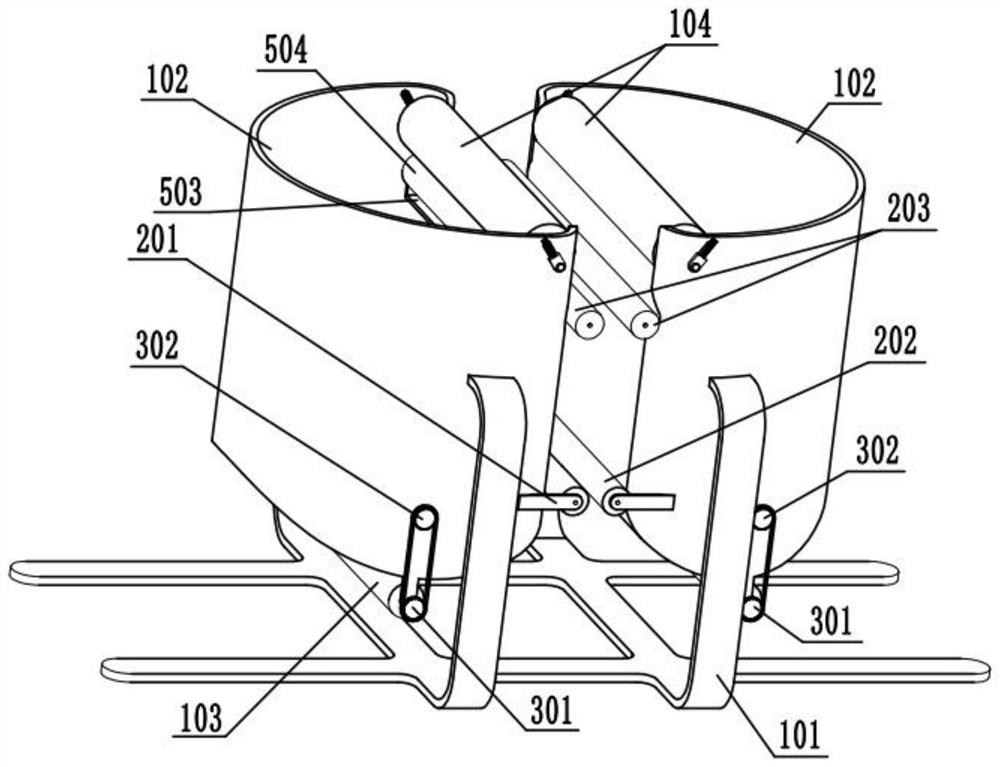

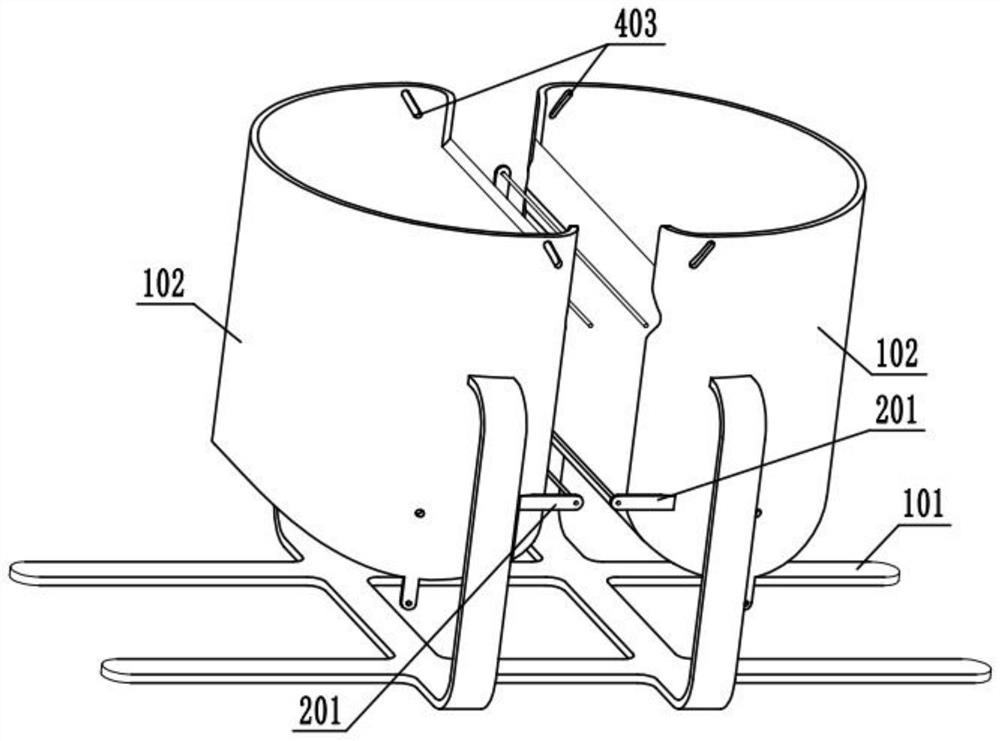

[0038] Step 4: The dyeing process of the fabric can be completed by passing the processed double-layer fabric through a dyeing device.

[0039] Attached below figure 1 In detail, the warping is to gather the scattered yarn cakes on the pan head, and the number of the pan head is related to the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com