Dyeing method for improving dyeing performance of polyester fibers

A polyester fiber and dyeing performance technology, applied in the field of polyester fiber dyeing, can solve the problems of low color fastness and low dye uptake, and achieve the effects of enhancing color fastness, efficient dyeing, and reducing costs

Pending Publication Date: 2022-06-10

QINGDAO UNIV OF SCI & TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved is to provide an excellent polyester fiber pretreatment process and dyeing process to overcome the shortcomings of low dyeing rate and low color fastness in the polyester fiber dyeing process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| soaping fastness | aaaaa | aaaaa |

| soaping fastness | aaaaa | aaaaa |

Login to View More

Abstract

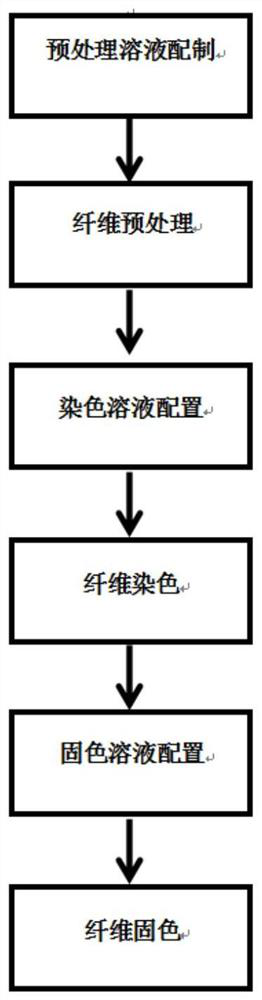

The invention belongs to the technical field of polyester fiber dyeing, and particularly relates to a dyeing method for improving the dyeing performance of polyester fibers, which comprises the steps of pretreatment solution preparation, fiber pretreatment, fiber dyeing and fiber fixation and reduction. According to the dyeing method disclosed by the invention, the dyeing performance of the polyester fiber can be remarkably improved, wherein the performance comprises the dyeing rate, the fixation rate, the color fastness and the rubbing fastness of the fiber; the process steps are relatively simple, the dyeing effect is excellent, the used raw materials are green and environment-friendly, the harm to the environment is reduced, the concept of green chemistry and sustainable development is met, and the method is suitable for industrial large-scale production. Compared with the prior art, the mechanical strength of the polyester fiber after dyeing and the mechanical strength of the polyester fiber before dyeing show that the difference between the mechanical strength of the polyester fiber after dyeing and the mechanical strength of the polyester fiber before dyeing is small, the practicability of the fiber is greatly improved, and a foundation is laid for wide application of the polyester fiber fabric in the field of daily use.

Description

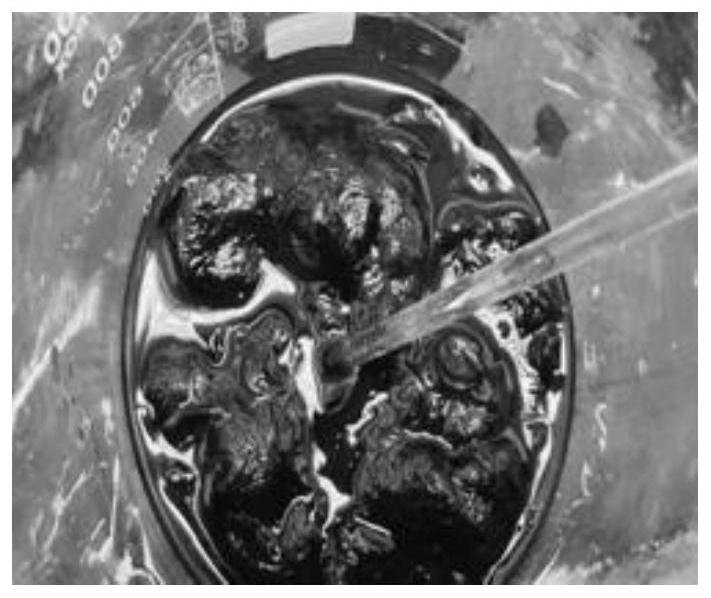

technical field [0001] The invention belongs to the technical field of polyester fiber dyeing, and in particular relates to a dyeing method for improving the dyeing performance of polyester fiber. Background technique [0002] Polyester fiber, commonly known as polyester, is a polyester material synthesized by polycondensation of dibasic alcohols and dibasic acids, and synthetic fibers are obtained after spinning, referred to as PET fibers. Polyester fiber was invented in 1941 and was the first synthetic fiber variety at that time. Polyester fiber has the advantages of good shape retention and wrinkle resistance, high elastic recovery ability and strength, non-lint, wrinkle-free ironing, and durability. In recent years, in the world, the polyester fiber industry has developed very rapidly and has always maintained a relatively fast growth rate. [0003] Polyester fiber has high strength, high modulus, and low water absorption, and it has a wide range of uses as civil fabri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D06P1/16D06P1/62D06P1/651D06P3/54D06P5/10

CPCD06P1/16D06P3/54D06P1/65131D06P1/623D06P5/10

Inventor 金岩冯柏成候玉辉张磊郑婕

Owner QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com