Reeling device on vacuum dyeing machine

A technology for vacuuming devices and dyeing machines, which is applied to the processing of textile materials, accessories of textile processing machines, and equipment configuration for processing textile materials. Less air corrodes parts, reduces air pollution dyes, and reduces air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

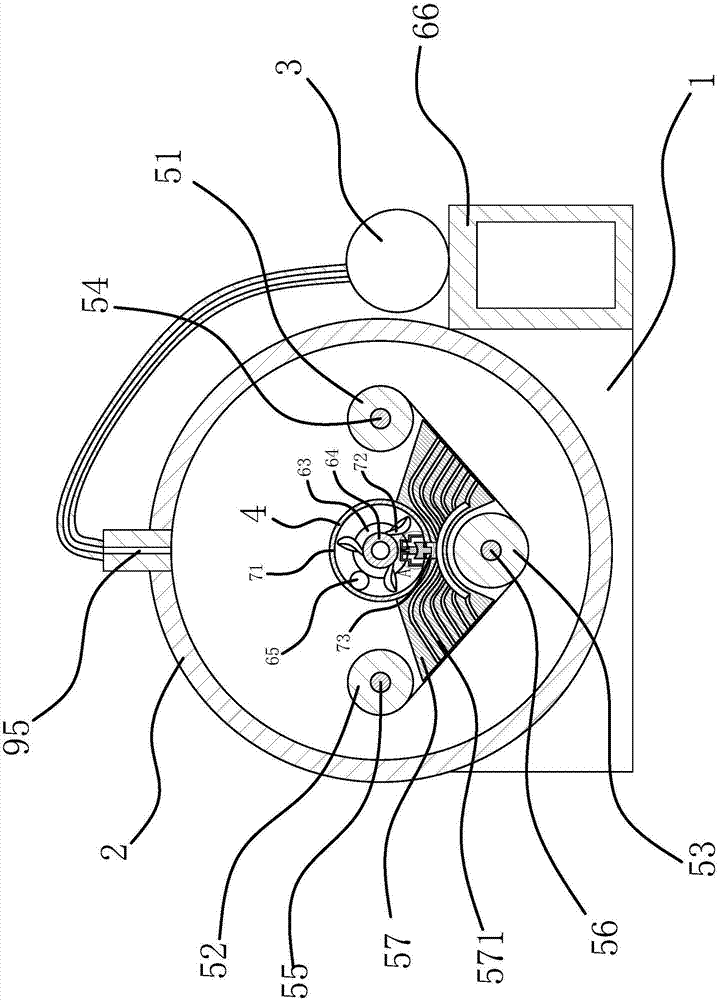

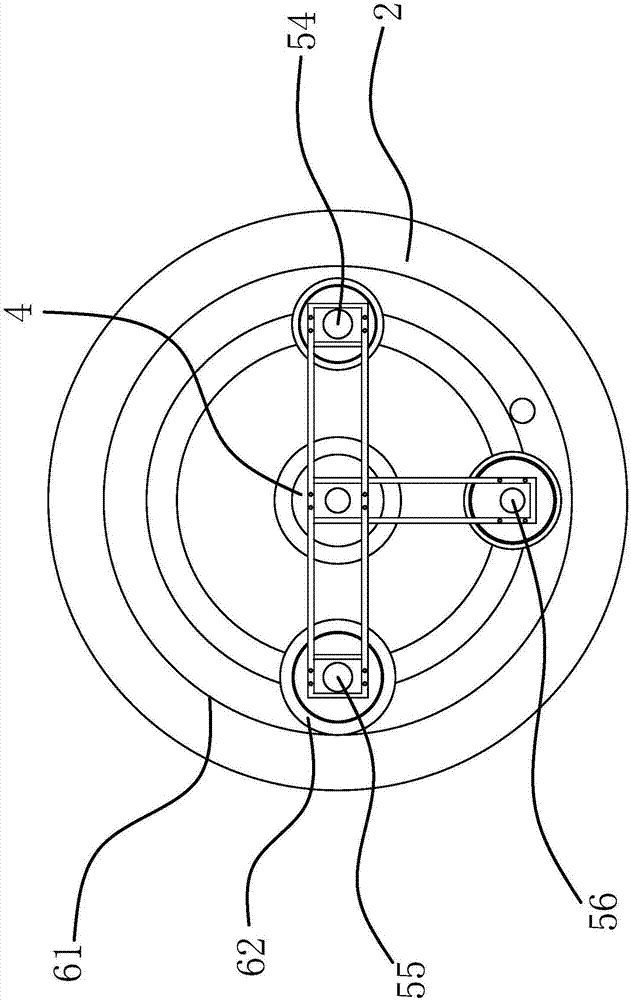

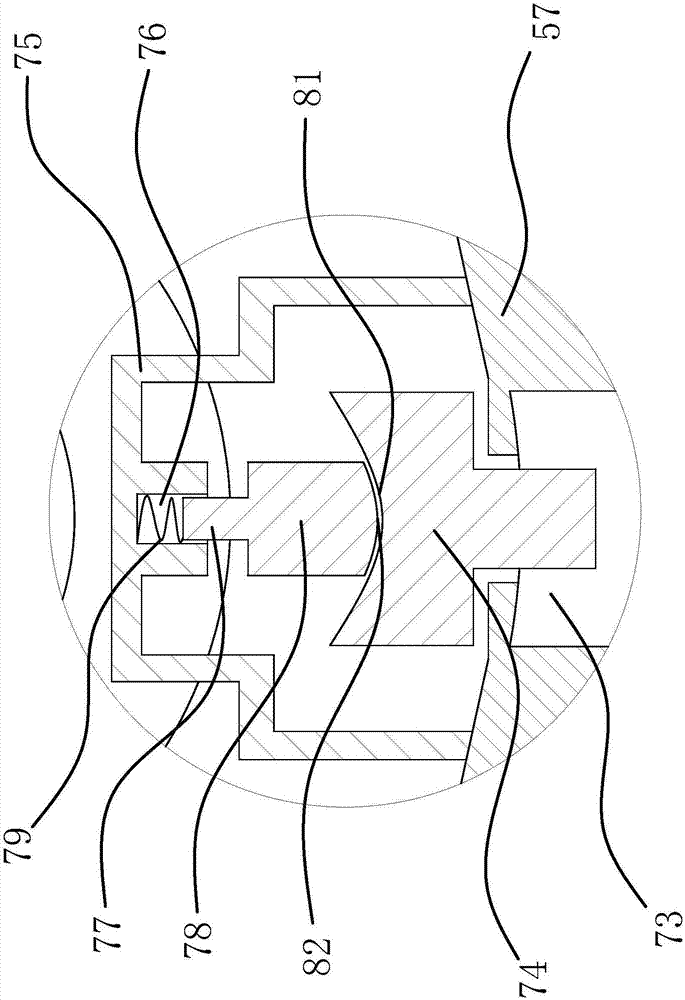

[0027] Such as figure 1 As shown, the dyeing machine includes a base 1, a barrel-shaped dyeing vat 2, a dye pool 66, a drip dyeing pump 3 and a main shaft 4. The dyeing vat 2 is fixed on the base 1, the main shaft 4 is a hollow structure, and the main shaft 4 is connected to a motor. The dyeing vat 2 is rotatably connected with a discharge drum 51, a receiving drum 52 and a tensioning drum 53, and the discharging drum 51, the receiving drum 52 and the tensioning drum 53 are connected to the dyeing vat through the first rotating shaft 54, the second rotating shaft 55 and the third rotating shaft 56 respectively. 2 are connected, rotating shaft 1 54, rotating shaft 2 55 and rotating shaft 3 56 are all fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com