Patents

Literature

96results about How to "Quick stain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reactive dye ultra-short rapid dyeing and fixation technology method

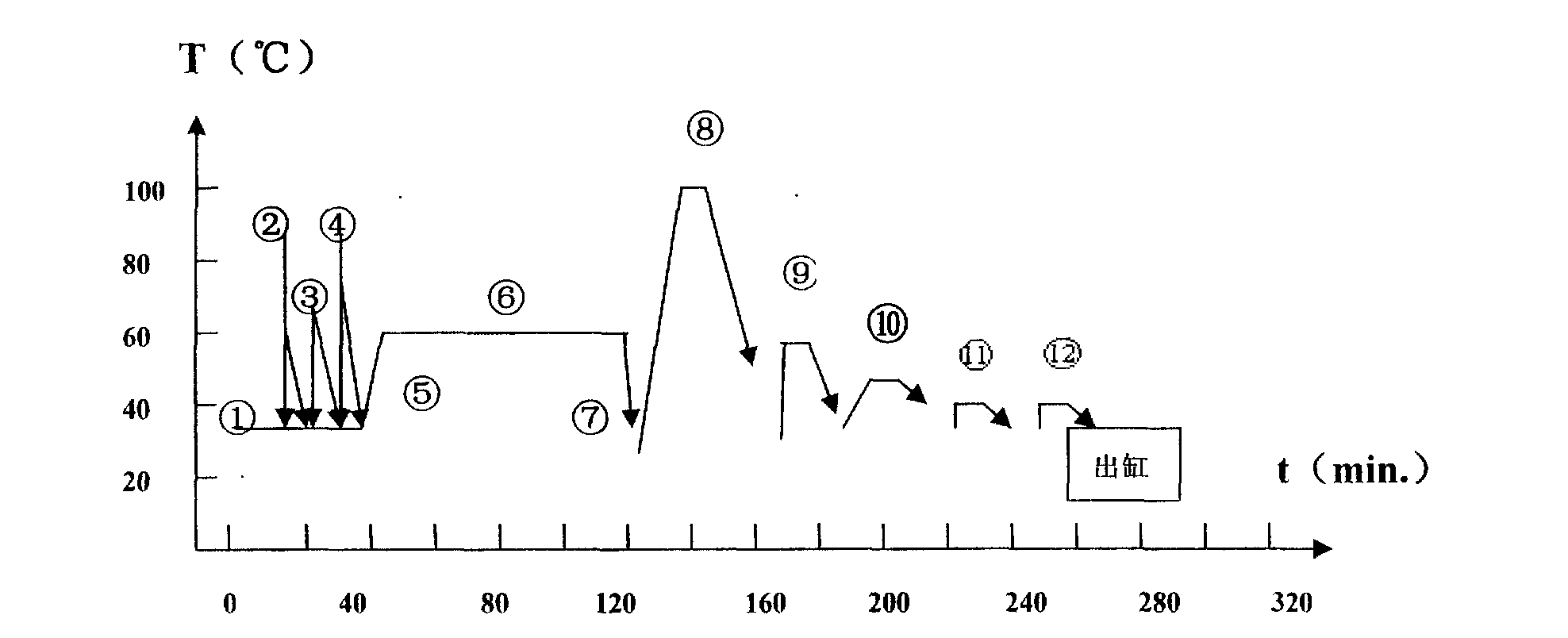

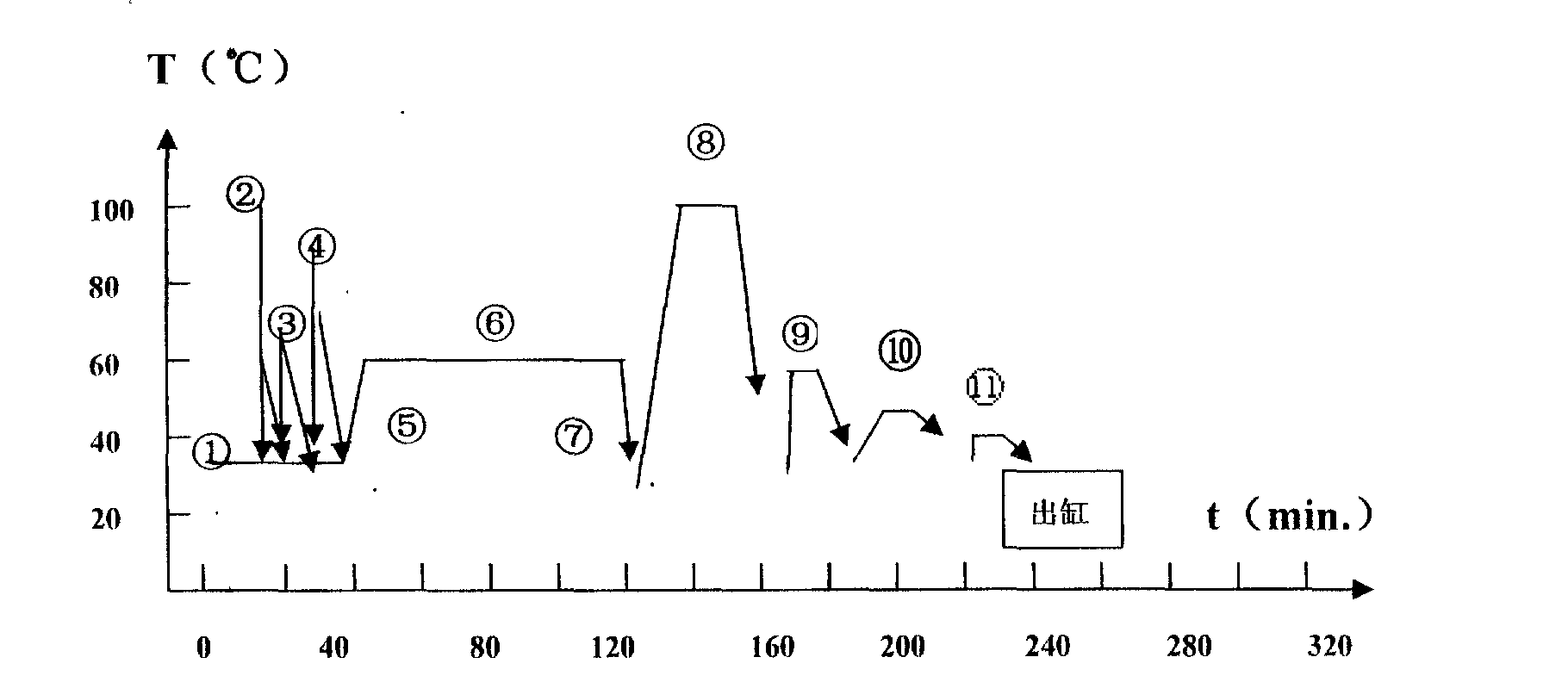

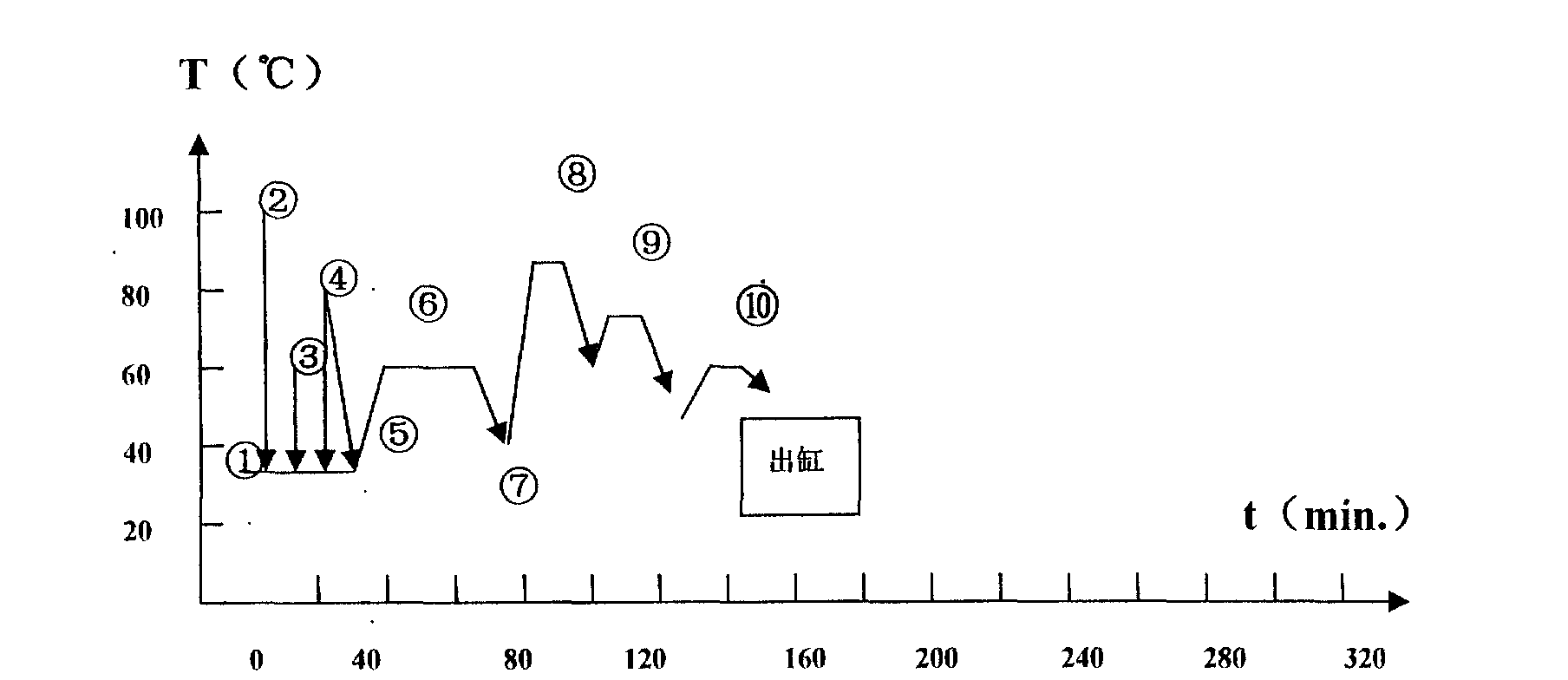

The invention relates to a reactive dye ultra-short rapid dyeing and fixation technology method. The method is realized by effectively minimizing auxiliary time such as feeding, shortening and optimizing post-processing processes, especially carrying soap boiling (one bath color mending) only once in advance to the greatest extend, merging washing, using less hot water and controlling the use of water aiming at various substances to be dyed according to dyeing requirements and the conditions of normal or abnormal and with the help of various accessory ingredients, thereby the reactive dye normal or abnormal dyeing conditions (especially mediate high color with a dye usage higher than 1percent of o. W. f) by the single one bath process, the multifunction composite one bath process, or the like, comprising pre-processing, dyeing, polishing with enzyme, and color mending, and even the pre-processing and the whole dyeing procedure in conventional equipment in an ultra-low bath ratio limit state can be completed well within 2.5-8h. The effects of thorough energy saving and emission reduction, efficiency increasing and consumption reduction, cleaner production and environmental protection are achieved.

Owner:罗海航 +1

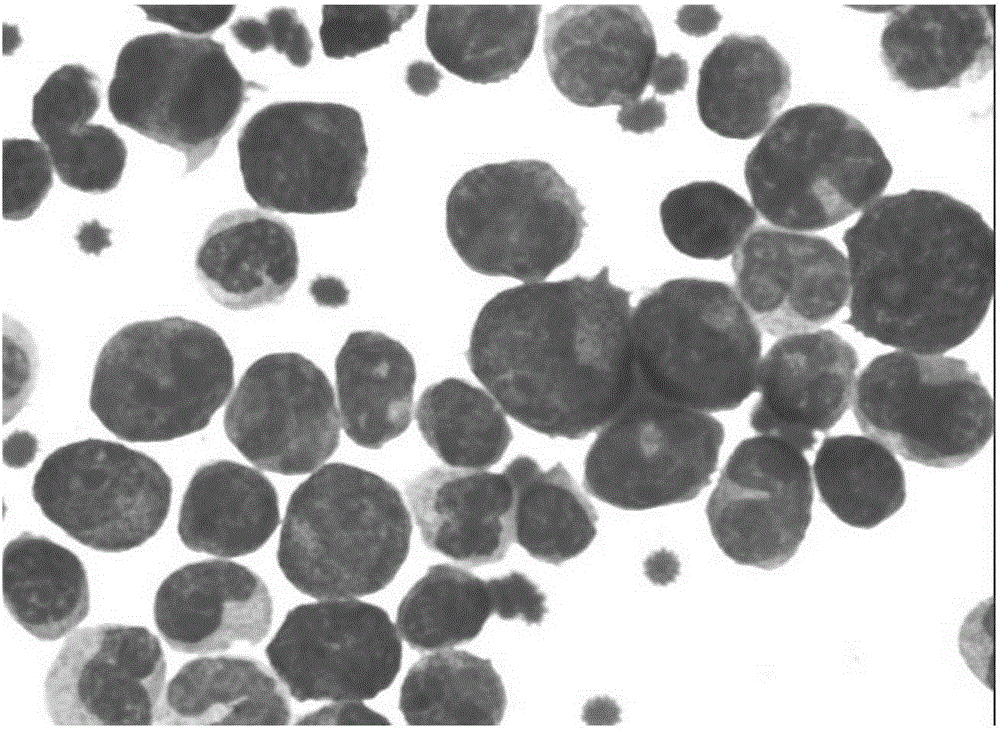

Wright-Giemsa compound staining solution and preparation method thereof

InactiveCN105300772AReduce formulation costsClear dyeing effectPreparing sample for investigationStainingGlycerol

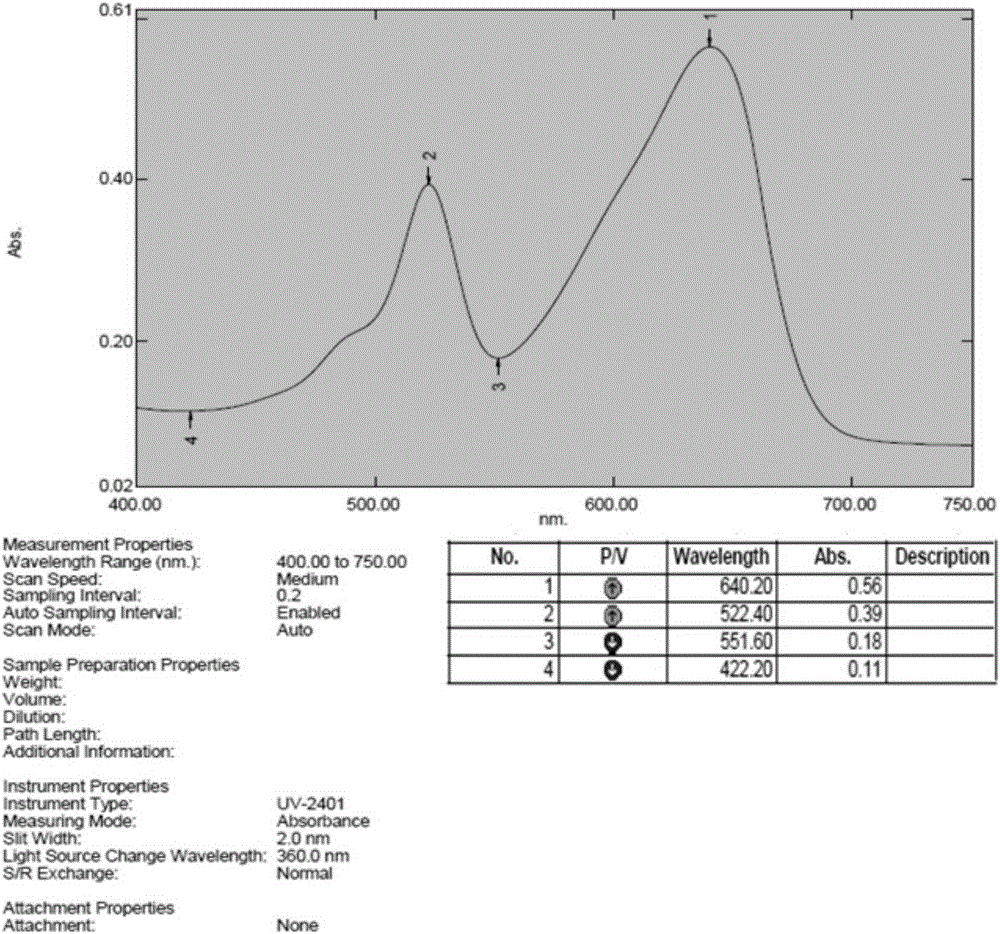

The invention provides a Wright-Giemsa compound staining solution. The Wright-Giemsa compound staining solution is prepared from the following raw materials according to the following proportion: 15 to 17 parts of Wright staining powder in weight, 3 to 4 parts of Giemsa staining powder in weight, 33 to 35 parts of glycerinum in volume and 5000 parts of methanol in volume. The invention further provides a preparation method and application of the compound staining solution. The Wright-Giemsa compound staining solution has the advantages of high staining speed and good staining effect on human sources and animal cells, simple formula, low preparation cost and simplicity in operation during staining and is favorable for popularization.

Owner:成都华西海圻医药科技有限公司

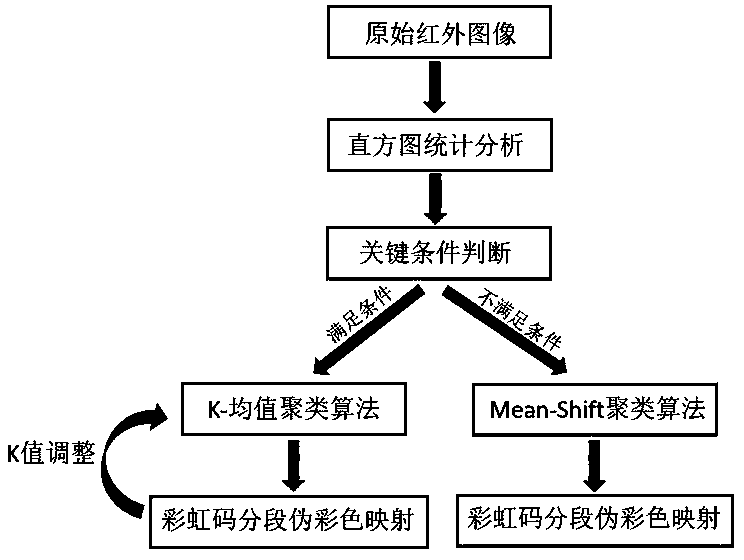

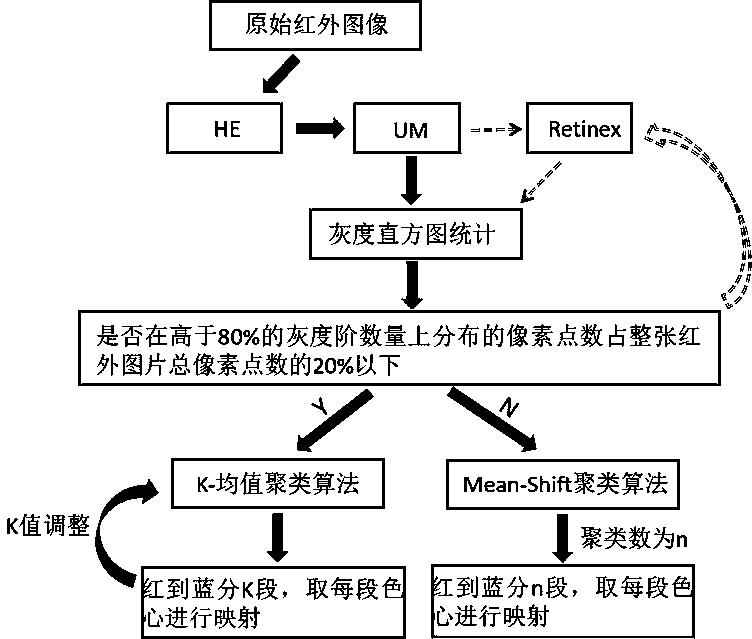

Adaptive coloring method, system, storage medium, terminal for infrared image

ActiveCN109147005AGood visual perceptionGood clustering effectImage enhancementImage analysisMean-shiftRainbow

The invention discloses an adaptive dyeing method for an infrared image, a system, a storage medium and a terminal. The method comprises the following steps: gray histogram statistics: calculating theproportion of pixel points of each gray value of the infrared image to the total pixel points; condition Judgment and Selection: judging whether the number of pixel points distributed on the number of gray scale above X% accounts for less than Y% of the total pixel points of the whole infrared picture, if so, entering K-Means clustering; Pseudocolor Discrete Transform of Rainbow Codes: the numberof clusters completed by K-Means clustering or Mean-Shift clustering is used as discrete color segments to divide the rainbow color from red to blue into several segments, and the center color of each segment is used for pseudo-color mapping. The invention adopts different clustering methods for images of different qualities and adopts interval adaptive rainbow code pseudocolor transformation, which has good effect on infrared pictures with low thermal contrast which need to obviously distinguish layers.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

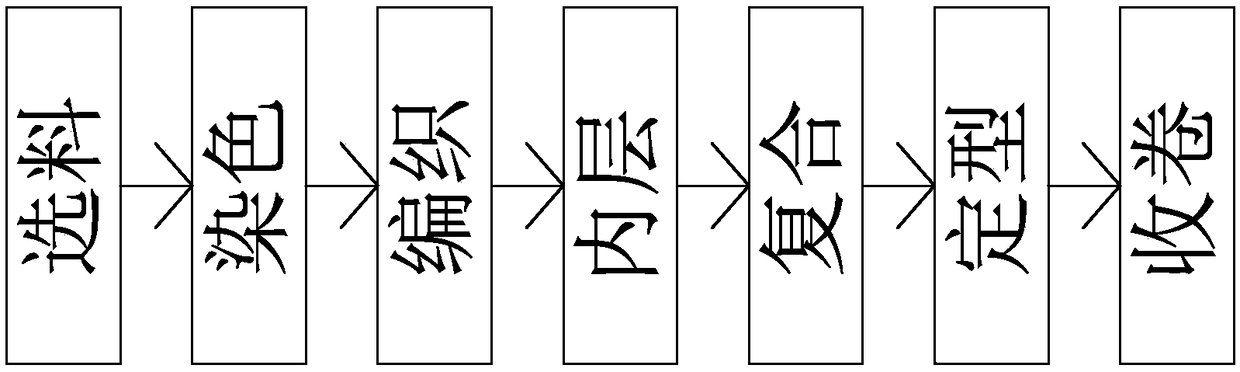

Dyeing method of environmentally-friendly bamboo fiber bath towel

The invention relates to a dyeing method of a bamboo fiber bath towel, and especially relates to a dyeing method of an environmentally-friendly bamboo fiber bath towel. The method comprises the following steps: 1, extracting a plant color fixing agent; 2, drying the plant color fixing agent; 3, extracting a plant dyeing agent; 4, pre-processing; 5, carrying out primary color fixation; 5, dyeing; 7, carrying out secondary color fixation; and 8, dehydrating, and drying. Primary color fixation, dyeing and secondary color fixation are combined to dye the bamboo fiber bath towel, so the process is simple, the color is fastened, and a color fixation solution can be repeatedly used to save the cost; the above ultrasonic dyeing method realizes fast and uniform dyeing and softens the bamboo fiber bath towel; and plant extract products are adopted as the color fixation agent and the dyeing agent, have the characteristics of no heavy metal ions, natural plants, environmentally-friendly dyeing, weed removal, production facilitation and low cost, can clear heat, detoxify and prevent bacteria, and has a very good protection effect on skins.

Owner:JIESHOU SHUANGXIN TEXTILE

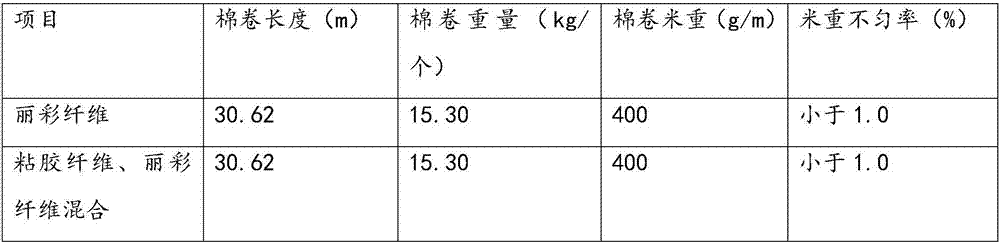

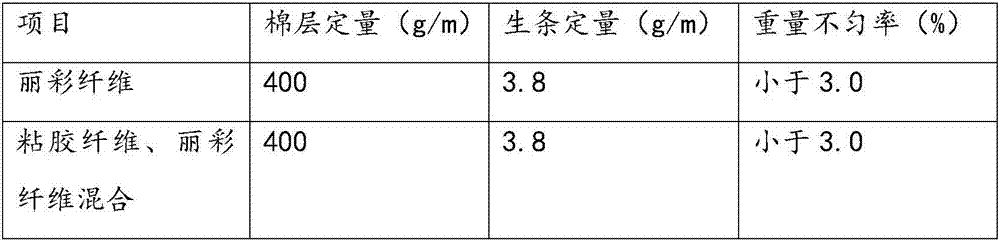

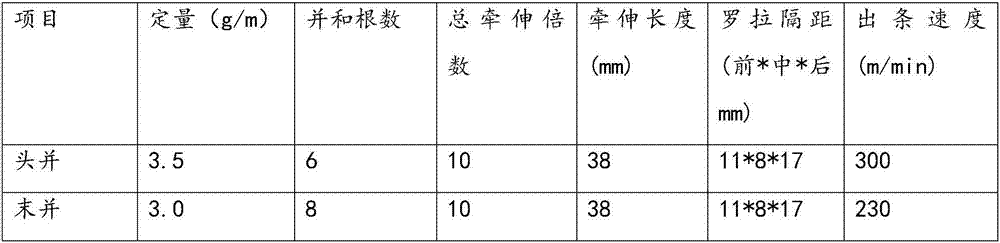

Viscose fiber and leecy fiber blended yarn and spinning technology thereof

The invention discloses a viscose fiber and leecy fiber blended yarn and a spinning technology thereof. The blended yarn comprises viscose fibers with the fiber content blending ratio of 60-70%, and leecy fibers with the fiber content blending ratio of 30-40%. The fibers are woven into the yarn through the spinning technology. Firstly, after the leecy fibers are subjected to opening and picking and cotton carding, the leecy fibers and the viscose fibers are mixed, then opening and picking and cotton carding are carried out, and the leecy fibers and the viscose fibers can be mixed to be uniform; due to the fact that the leecy fibers with the durable physical bacteriostasis function are added, the viscose fiber finished products can be prepared into the yarn with the antibacterial function directly through the following spinning technology, it is not needed to independently carry out antibacterial treatment on the viscose fiber finished products, the technology is simplified while the antibacterial effect is guaranteed, the production cost is reduced, fabric woven from the viscose fiber and leecy fiber blended yarn can be rapidly dyed, the colors are gorgeous, gradually varied and rich in layering sense after the fabric is colored, and multiple colors can be obtained through one time of dyeing.

Owner:宜宾恒丰丽雅纺织科技有限公司

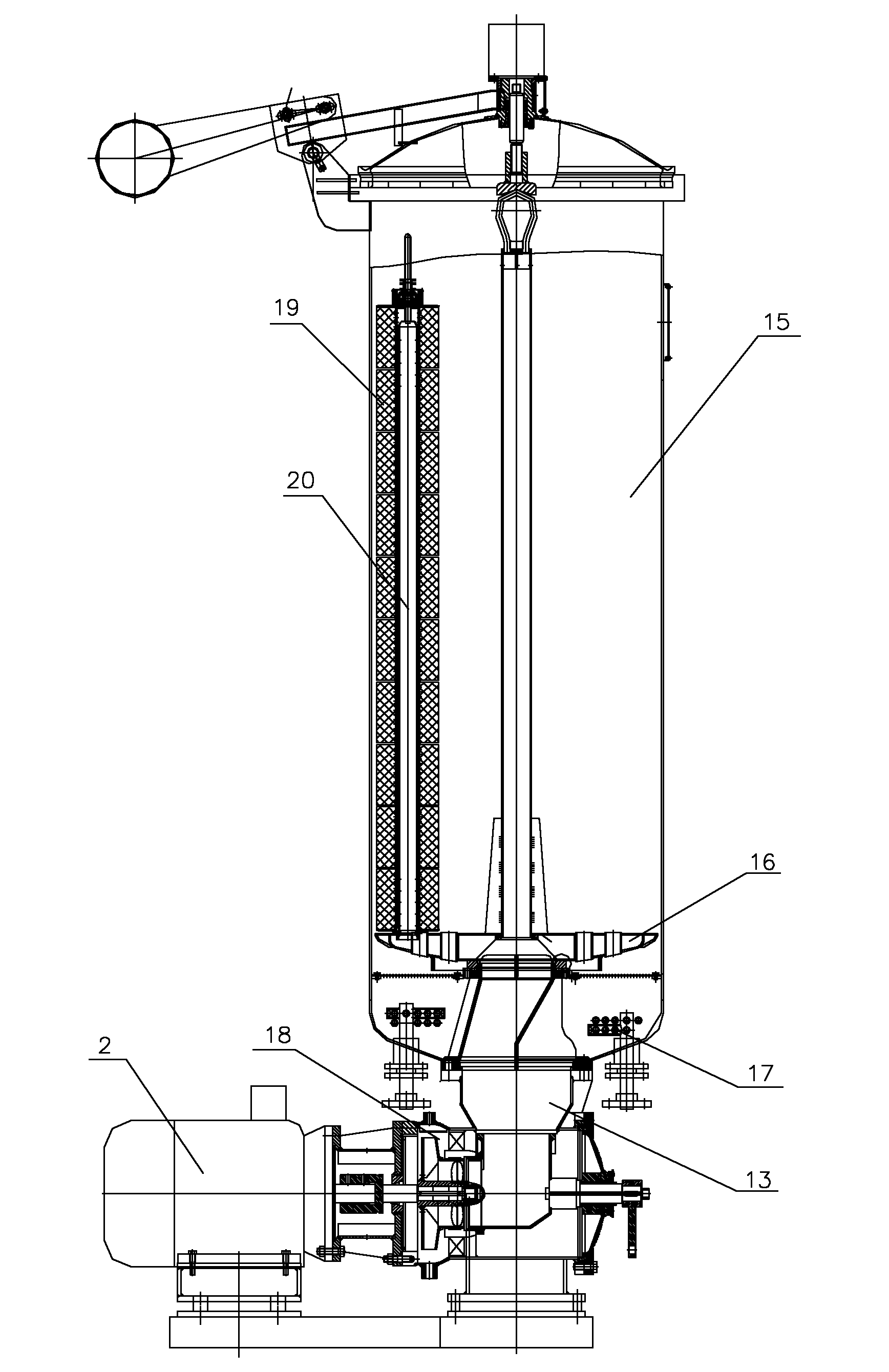

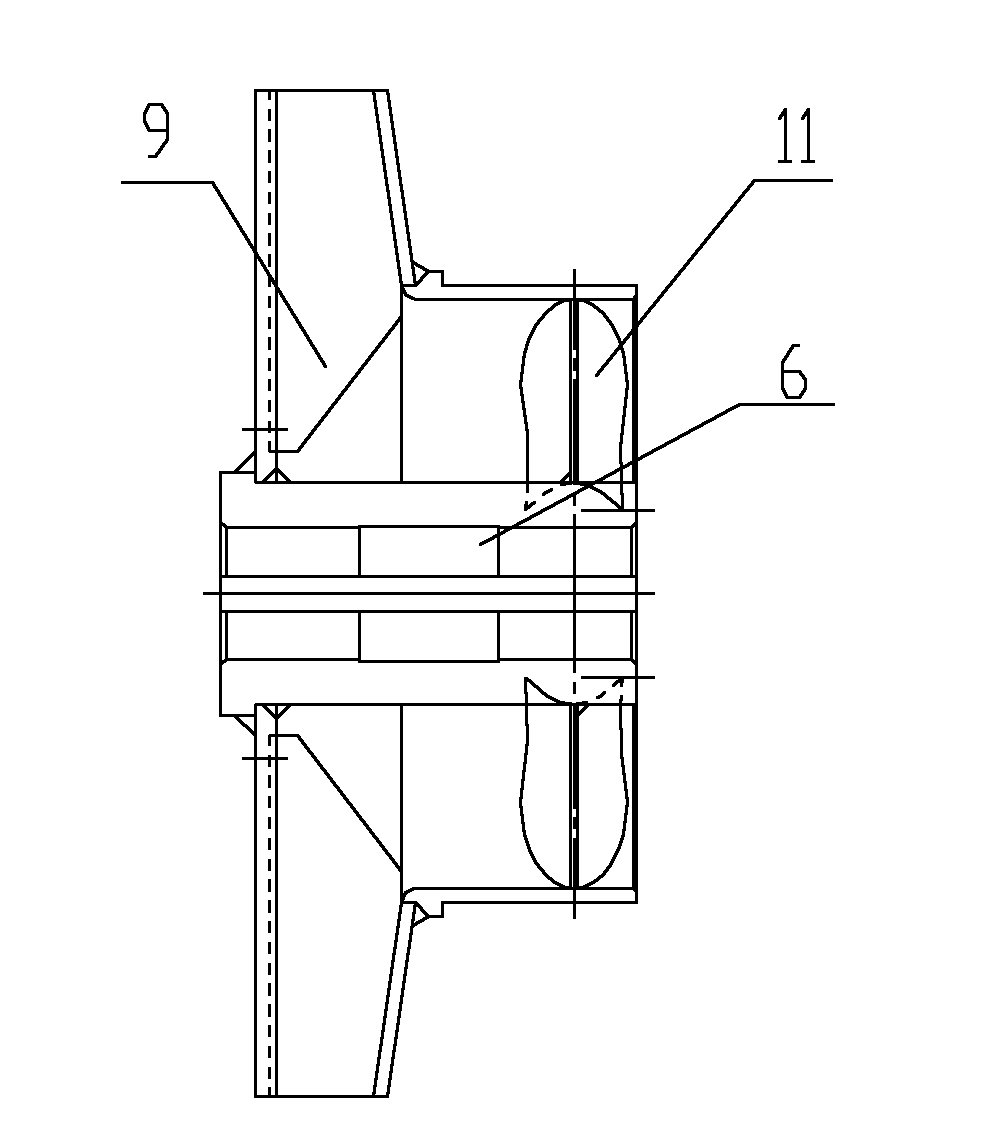

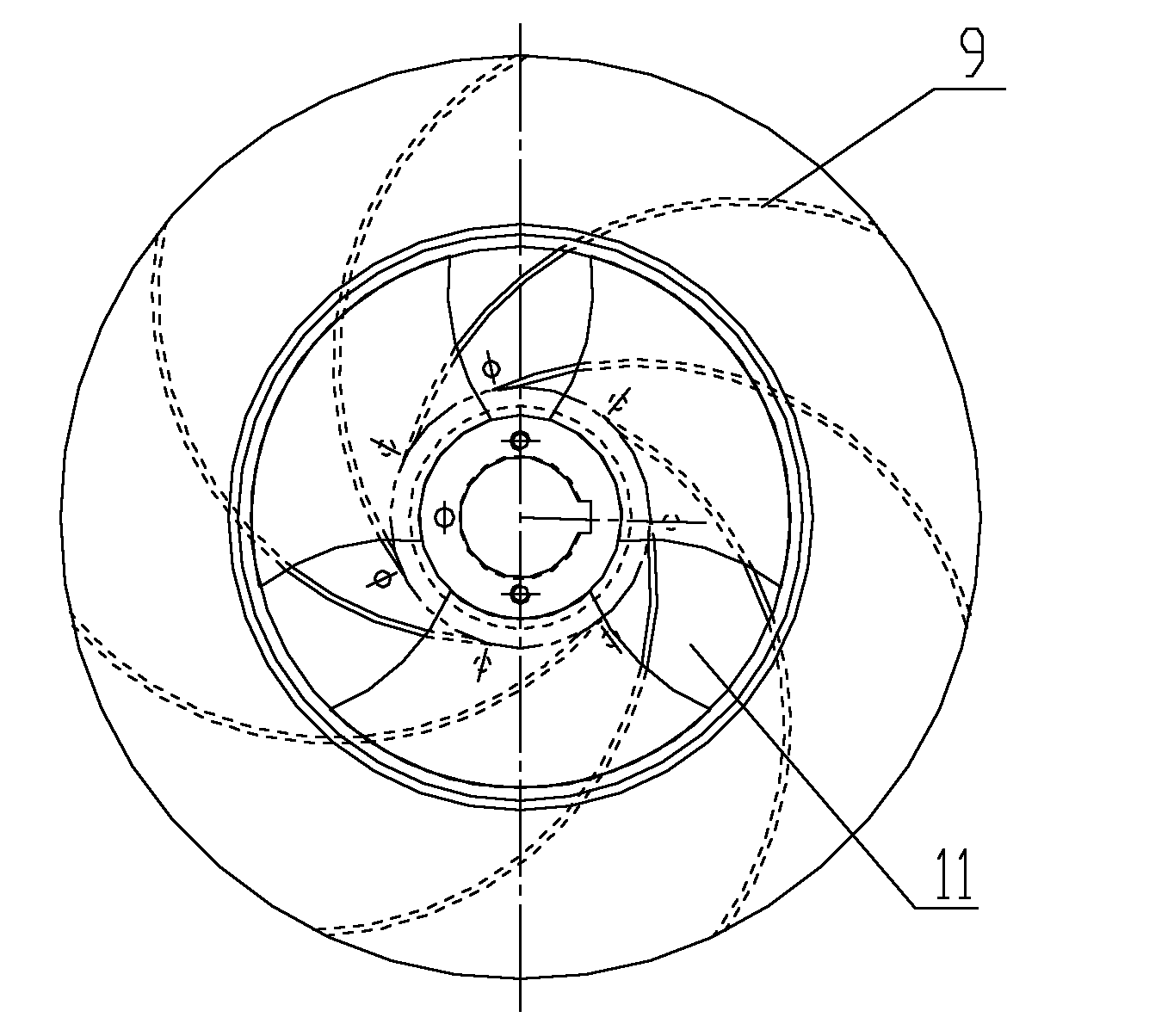

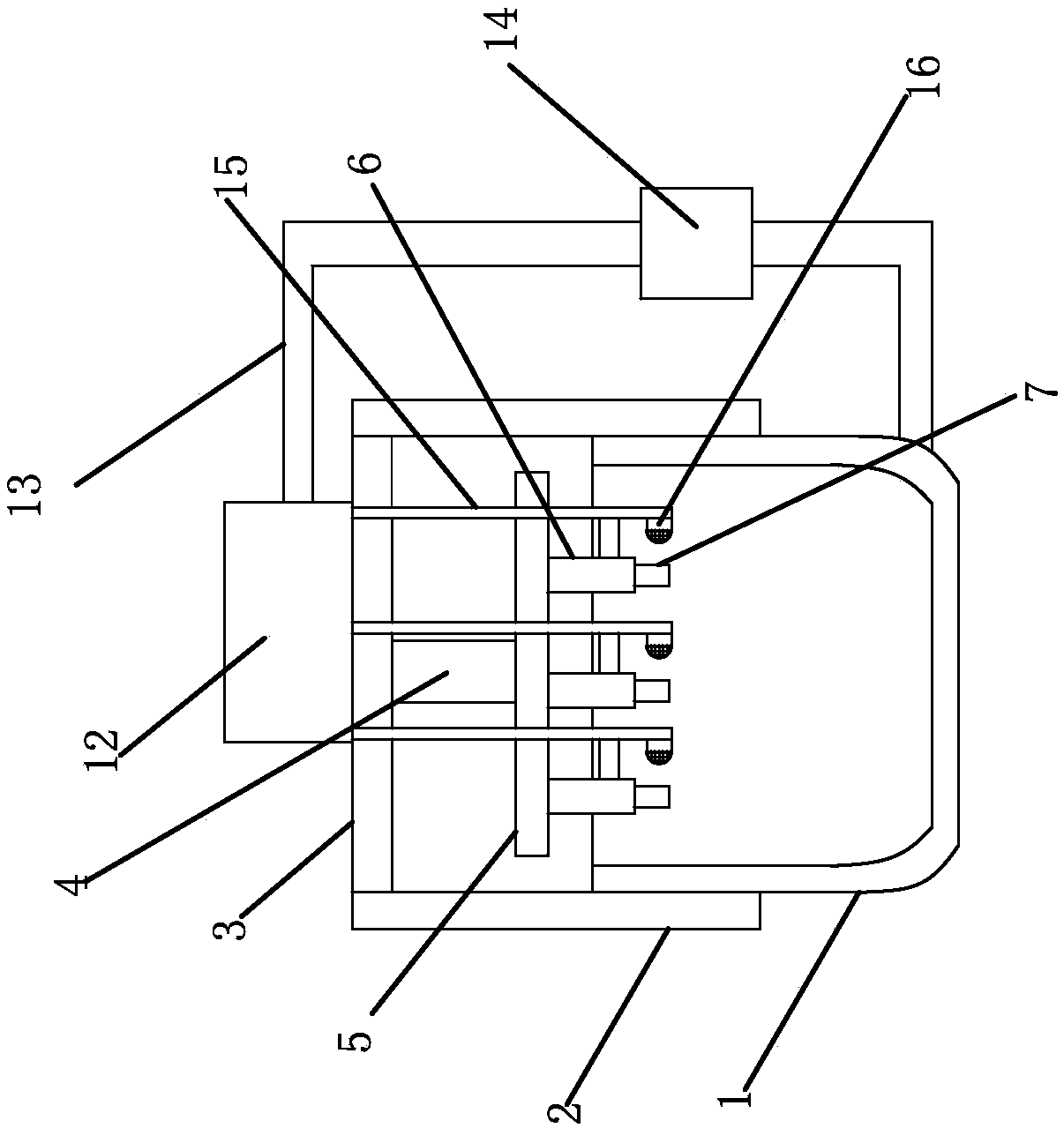

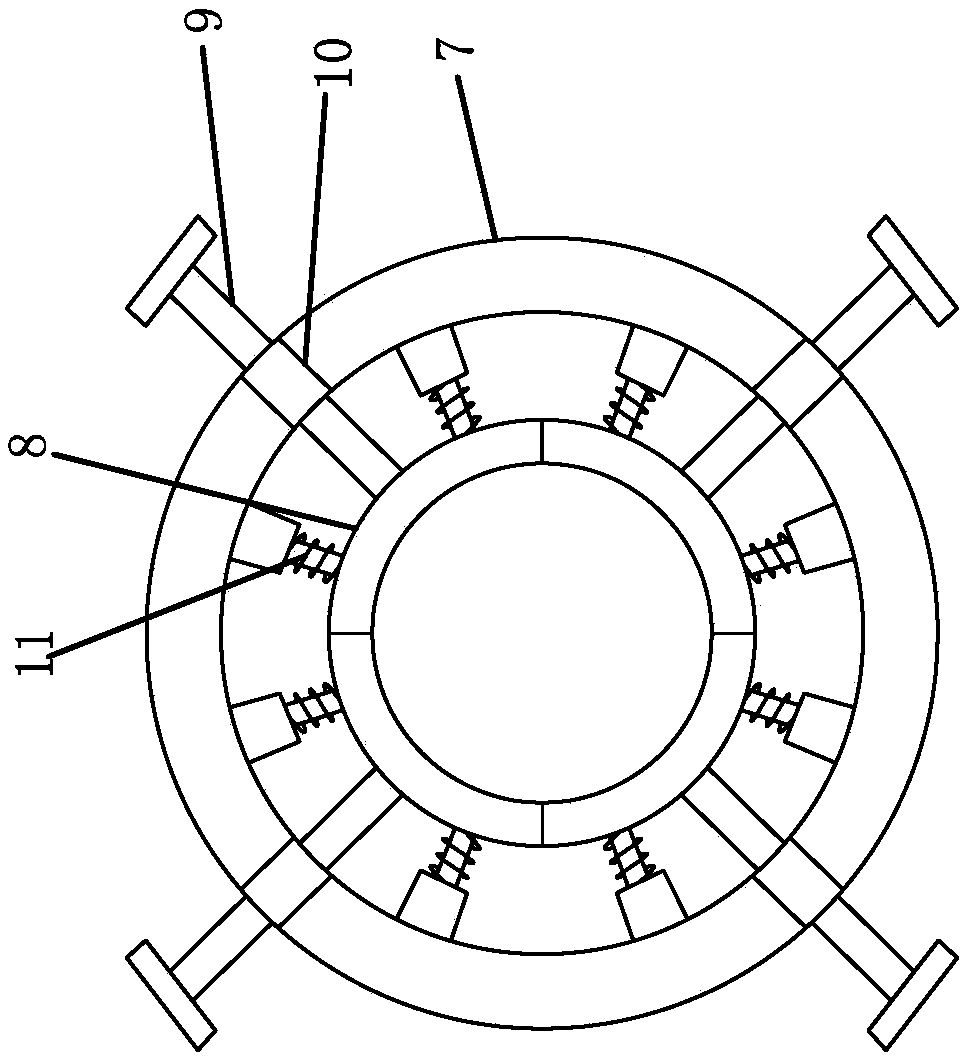

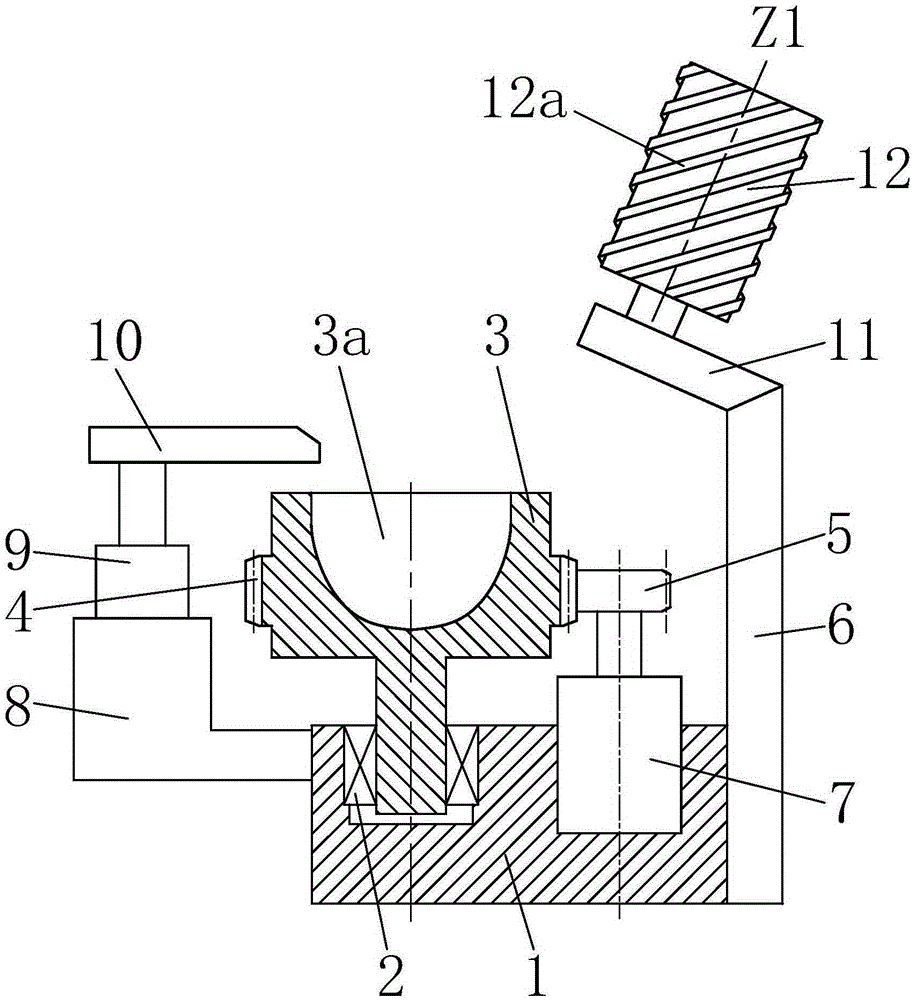

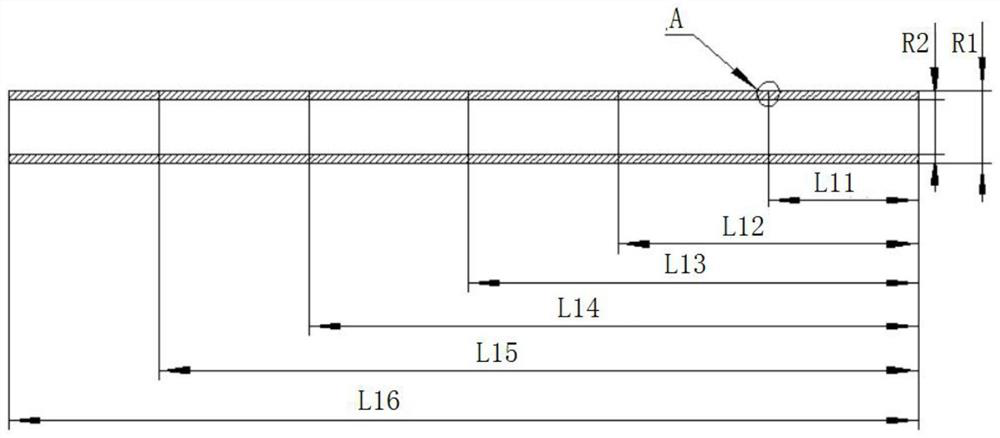

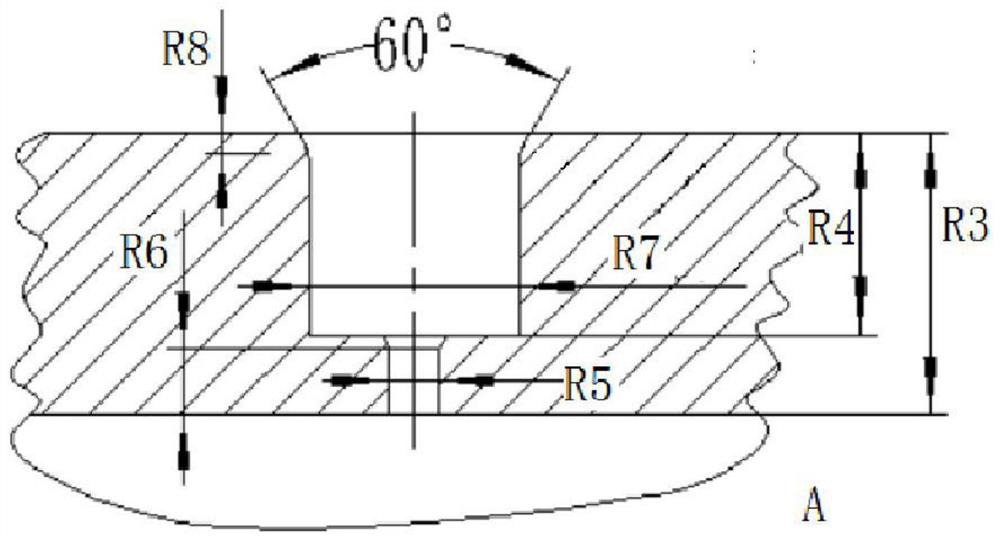

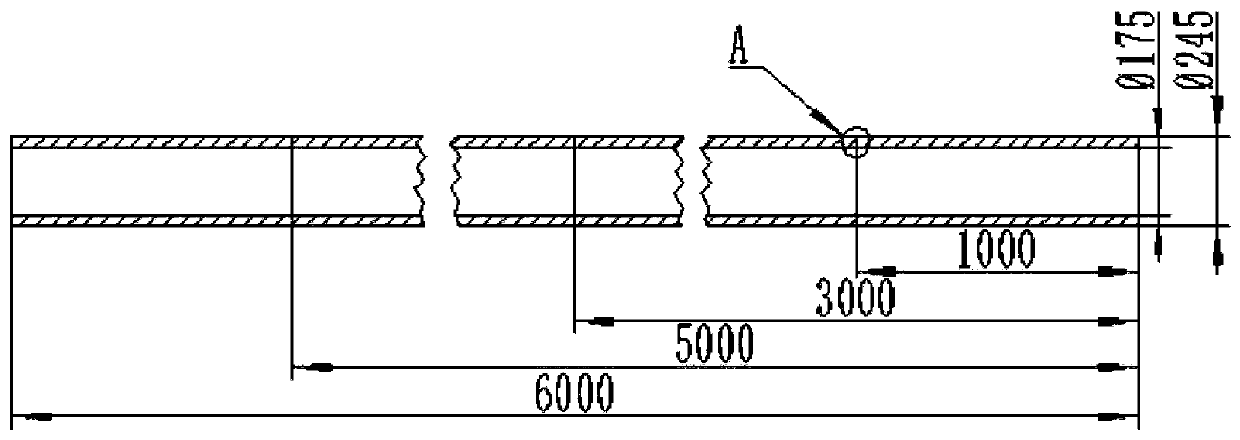

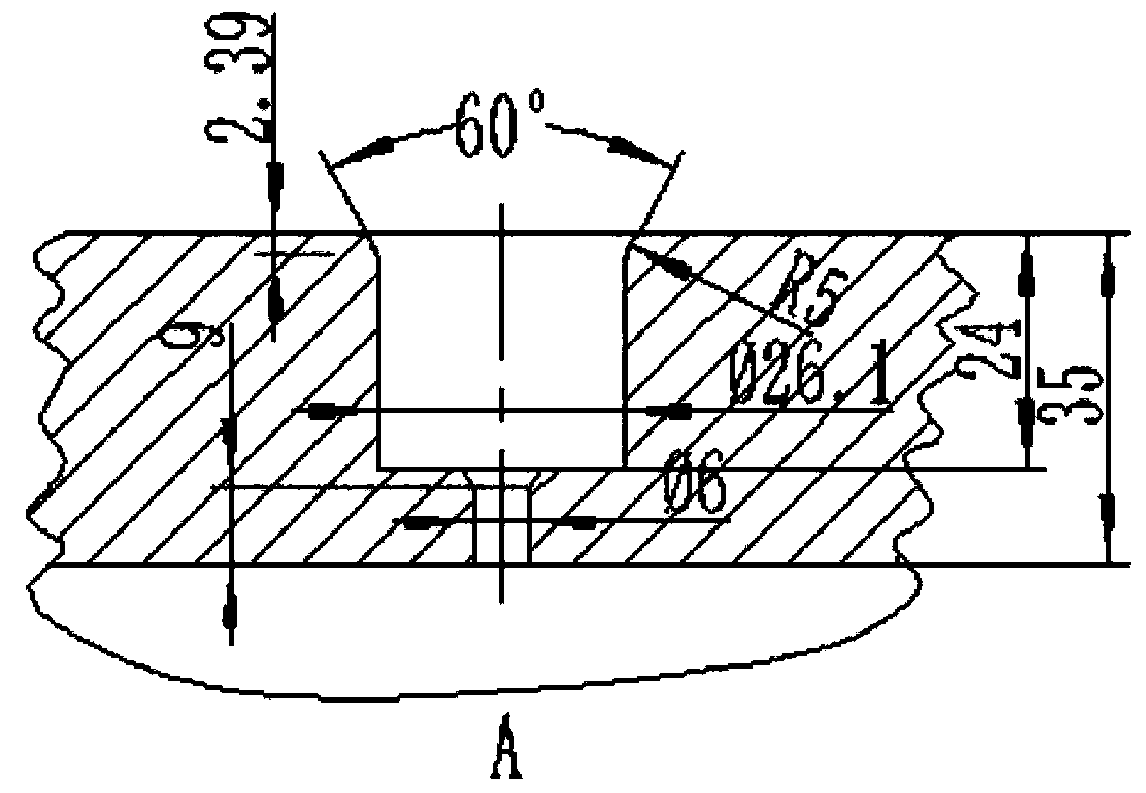

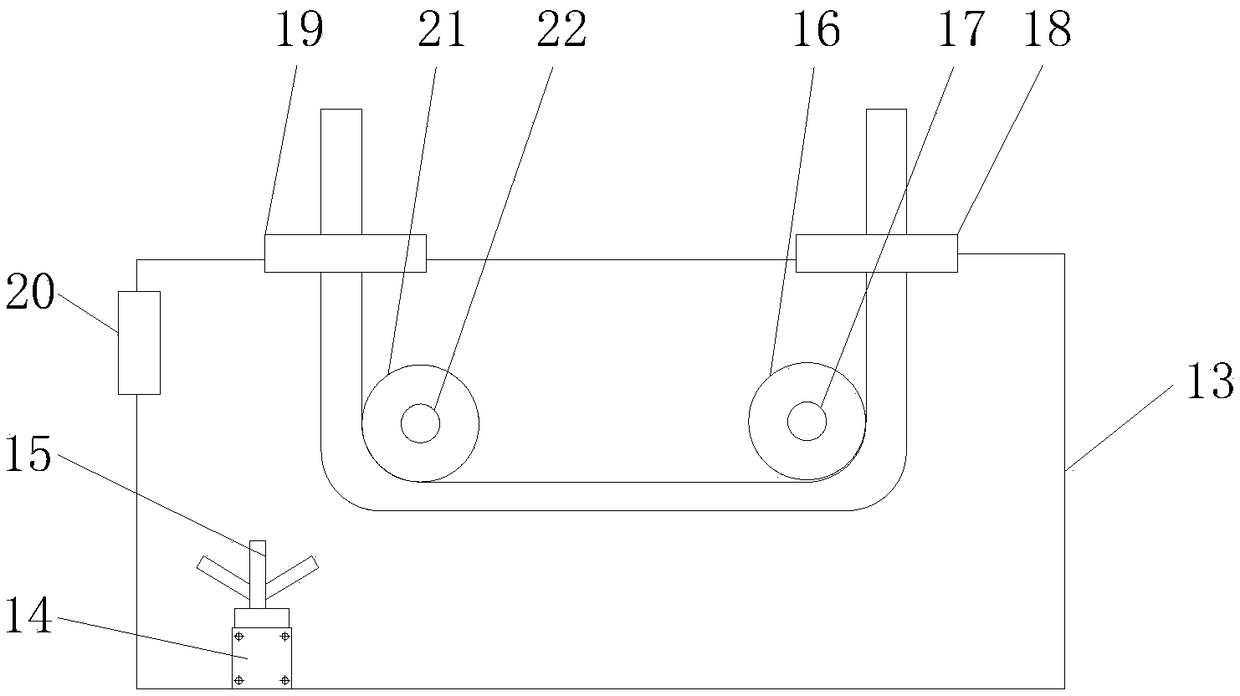

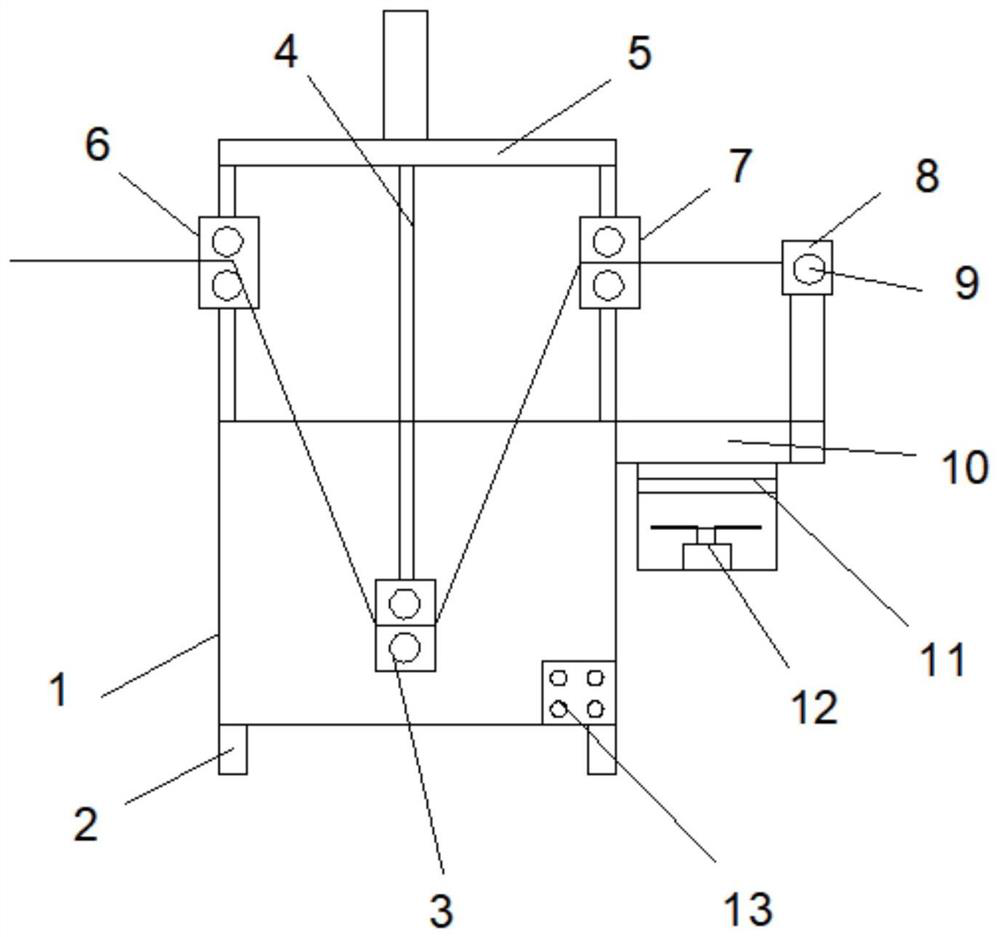

High-temperature pulse flow yarn dyeing machine with ultra low bath ratio and control method thereof

InactiveCN102140743AIncrease exchange frequencyQuick responseTextile treatment machine arrangementsTextile/flexible product manufactureYarnThree level

The invention discloses a high-temperature pulse flow yarn dyeing machine with an ultra low bath ratio and a control method thereof. The yarn dyeing machine comprises a dye vat, a creel, a heat exchange coiler, an adaptive water level monitoring device, a variable frequency motor, a three-level vane pump with an ultra low bath ratio and a dyeing computer. The method comprises the following steps: a time pulse generator in the dyeing computer gives out pulse flow data to a variable frequency motor controller to control the revolving rate of the variable frequency motor according to the set technological process; the variable frequency motor drives the three-level vane pump with an ultra low bath ratio to output dyeing flow in pulse flow type fluctuation; the output dyeing flow carries out adaptive adjustment according to an ideal reference model in the dyeing computer; the adaptive water level monitoring device gives out water-level reference identification information; and according to the information, a water level regulator and the variable frequency motor controller respectively regulate the water level and the variable frequency motor to reach the water level and the pulse flow required by the set technological process. The pulse flow dyeing technology in the invention conforms to the requirement of the minimum consumption of four factors, namely, water, energy, accessory ingredient and time for economical dyeing of ecological environment protection.

Owner:高勋绿色智能装备(广州)有限公司

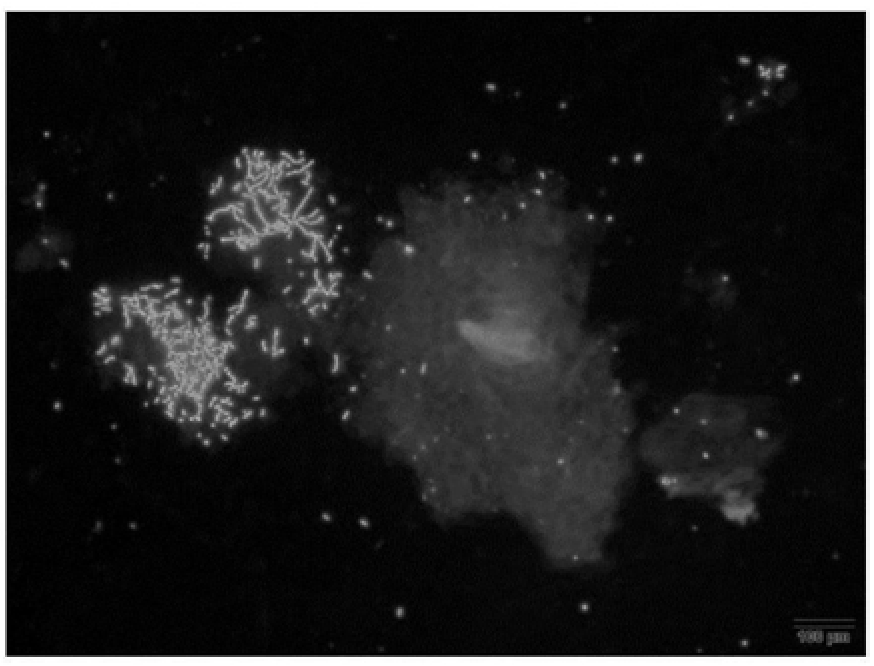

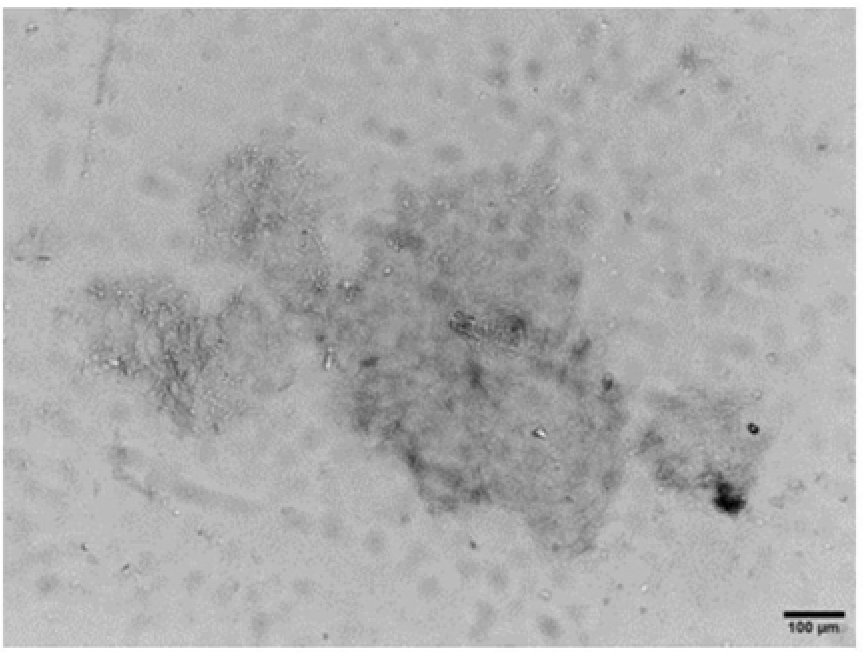

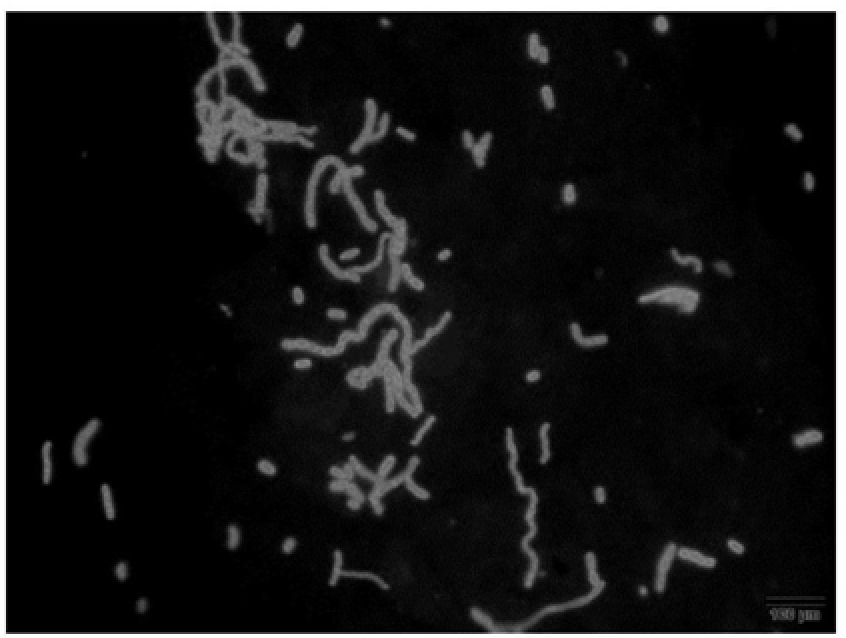

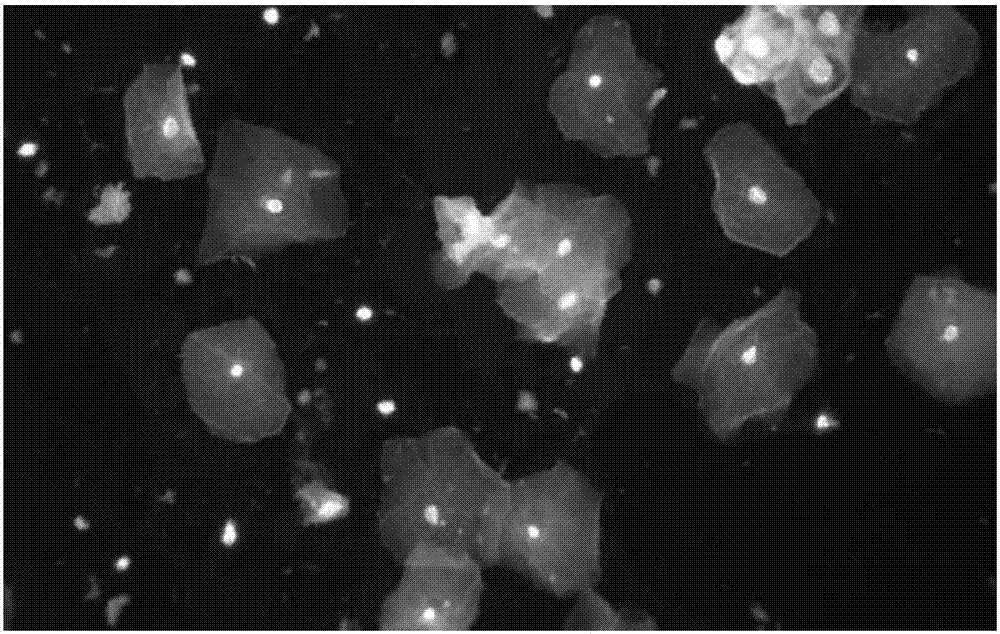

Anti-attenuation fungal fluorescent dyeing liquid and preparation method thereof

InactiveCN109100201APenetrate fastQuick stainPreparing sample for investigationLuminescent compositionsUltrasound attenuationCellulose

The invention discloses an anti-attenuation fungal fluorescent dyeing liquid and a preparation method thereof. Wherein the components of the anti-attenuation fungal fluorescent dyeing liquid include:a fluorescent agent, a solubilizing agent, a penetrating agent, a background dye, an anti-fluorescent attenuation agent, a stabilizer, and deionized water. According to the anti-attenuation fungal fluorescent dyeing liquid and the preparation method thereof, each component is stabilized in a solution system, and filtered by a cellulose membrane, all kinds of minute impurities are effectively removed, thereby having an effect of long-term storage without crystallization and having the advantages that the fungal fluorescence mark and the background dyeing are synchronously carried out in a few seconds; the anti-attenuation fungal fluorescent dyeing liquid does not need to be operated in a dark room, the performance is relatively stable, and has the characteristics of convenient operation, short dyeing time, long attenuation time, high efficiency, comprehensive use range, high observation clarity, good specificity and accurate detection result, and has a good clinical application prospect.

Owner:THE THIRD AFFILIATED HOSPITAL INST OF FIELD SURGERY OF PLA ARMY MEDICAL UNIV

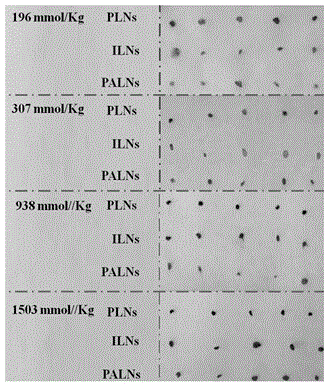

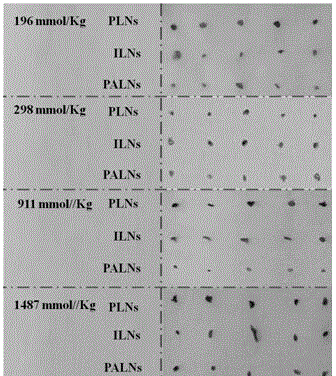

Isosulfan blue injection for lymphatic tracing and preparation method thereof

ActiveCN106267240AQuick stainPrecise positioningIn-vivo testing preparationsWater solubleTissue space

The invention provides an isosulfan blue injection having efficient lymphaffinity and a preparation method thereof. Accordingly, the effects of efficient lymphatic drainage and uptake are achieved by adopting different types and dosages of osmotic pressure adjusting agents. The osmotic pressure adjusting agents are one or combinations of sodium chloride and glucose. The isosulfan blue injection has the advantages that the defects of tissue space dispersion, low lymph uptake ratio and poor dyeing effect after water soluble dyes undergo hypodermic injection of a clinic tumor sentinel lymphatic positioning operation are overcome, the lymph gland can be accurately positioned without other auxiliary equipment, the isosulfan blue injection is non-radioactive, simple, convenient and visual, can achieve the purpose of lymphatic tracing and is a technical method having development prospect and a clinical application value.

Owner:SHENYANG PHARMA UNIVERSITY

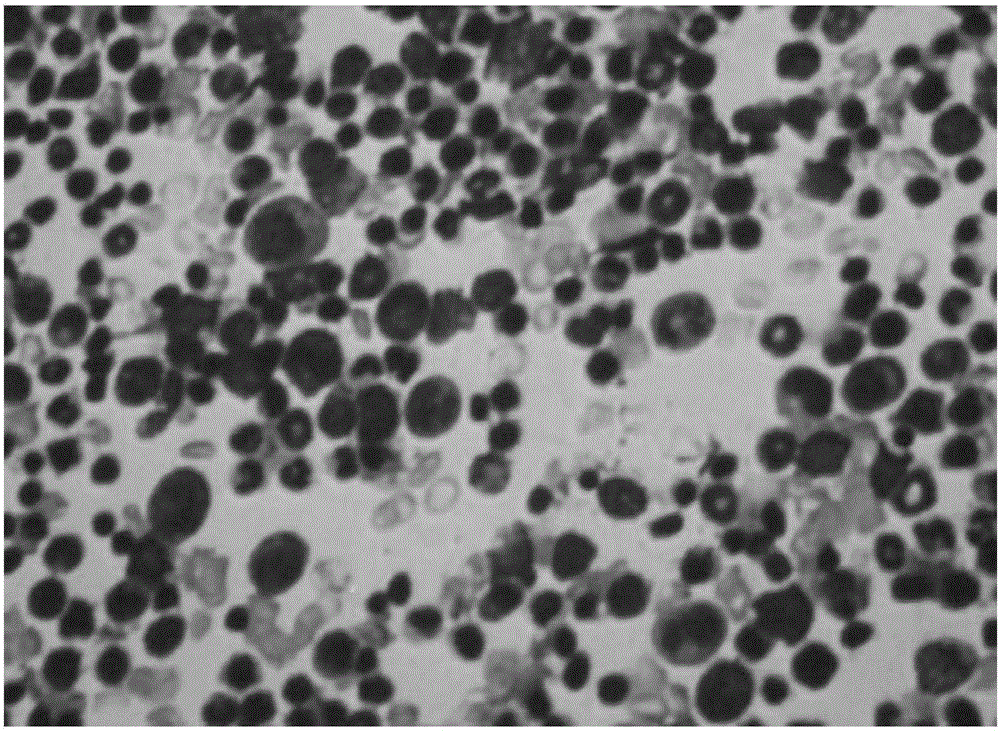

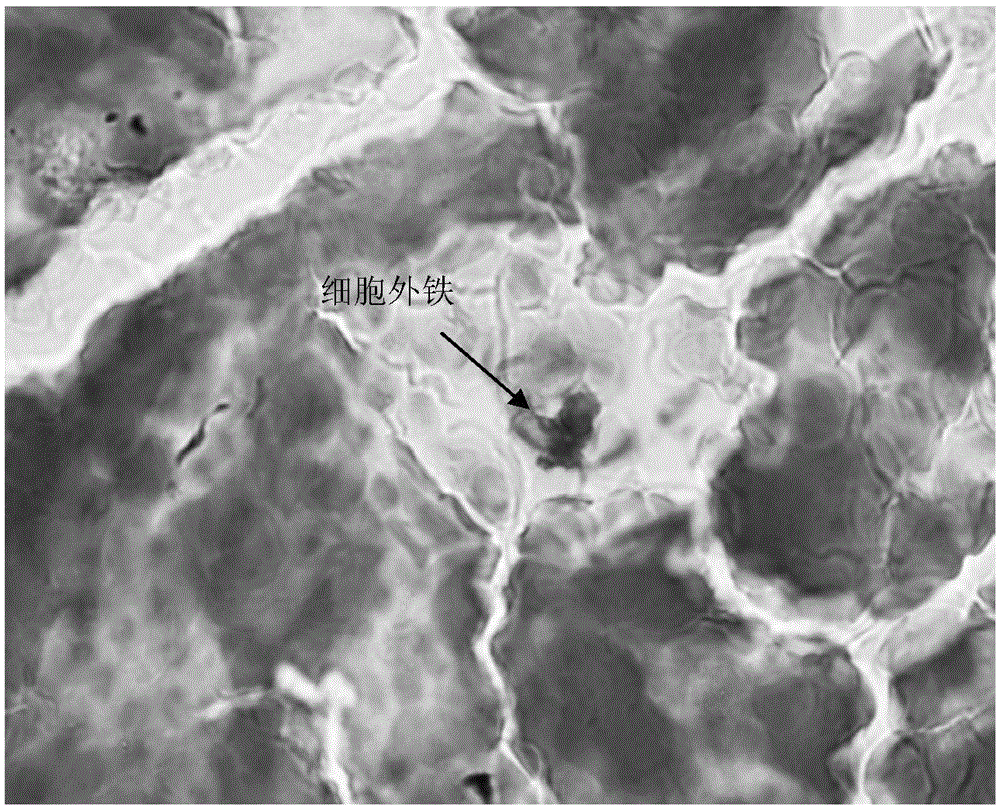

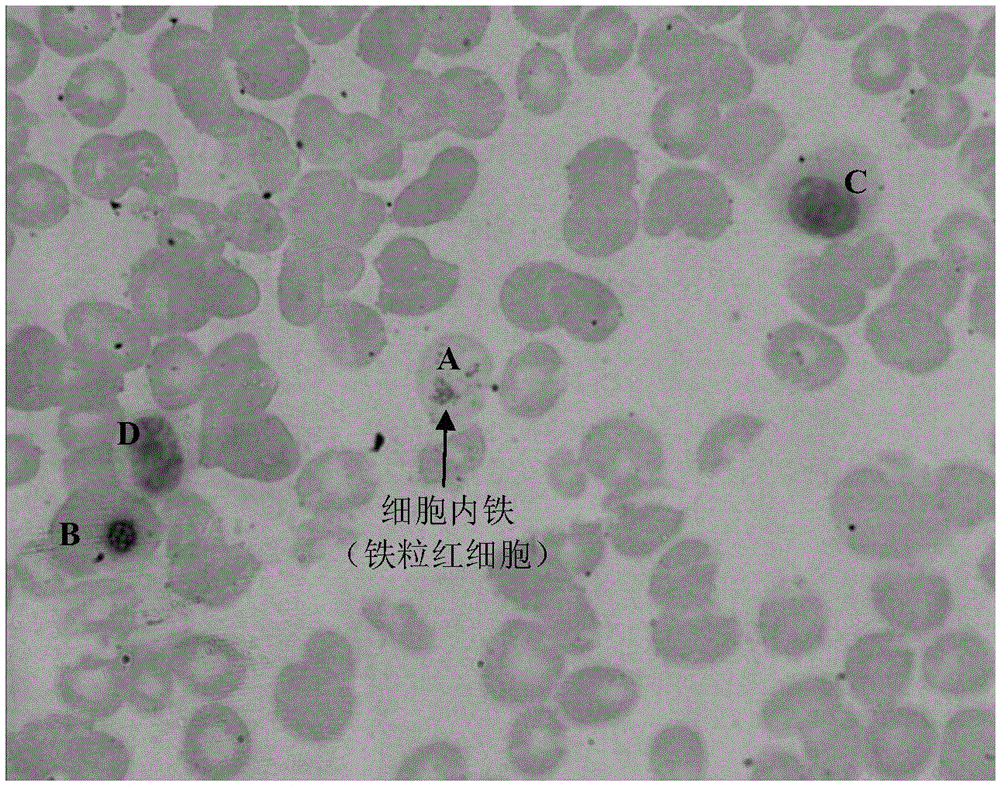

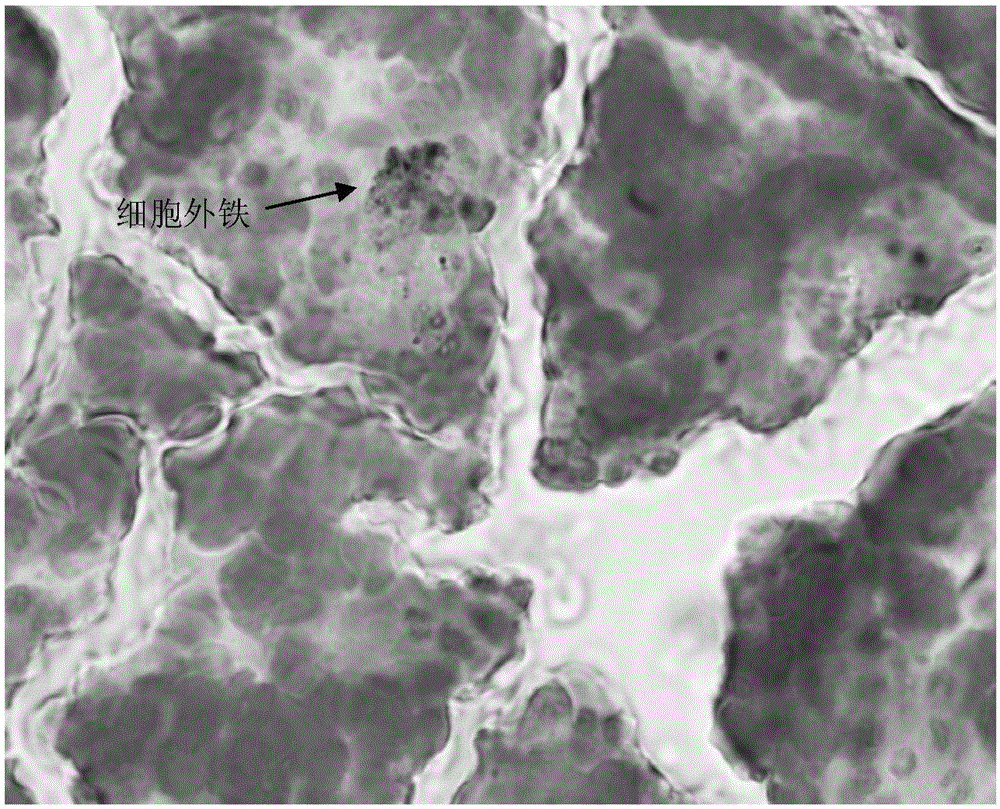

Iron staining (IS) fluid (chemical staining method)

ActiveCN105136549AClear structureAccurate judgmentPreparing sample for investigationWater bathsStaining

The invention relates to the technical field of biology, and discloses an iron staining kit containing nucleus fast red counter staining fluid and a staining method thereof. The nucleus fast red counter staining fluid in the iron staining kit includes a decontamination agent TritonX-100. The ingredient composition of the nucleus fast red counter staining fluid is adjusted, the decontamination agent TritonX-100 is added, hence, the types of cells can be distinguished more easily in the iron staining process of bone marrow cells compared with conventional nucleus fast red counter staining fluid, the cell structure is clear and iron inside the cells can be determined more accurately. Meanwhile, in the staining method, a microwave mode is used for replacing a conventional water bath mode, and thus the overall staining time is greatly shortened.

Owner:SHANGHAI SUNBIO TECH

Method for rapid Wright-giemsa stain

PendingCN109799123AImprove dyeing effectShorten dyeing timePreparing sample for investigationGiemsa stainWorking fluid

The invention discloses a method for rapid Wright-giemsa stain. The method includes: preparing Wright-giemsa working fluid, PBS (polybutylene succinate), a stain-fixative, appropriate ionized water and experimental apparatuses; dropping a solution to be tested on a glass slide with a pipette, spreading the solution evenly on a smear and drying in the shade naturally; fixing the glass slide for 1-3minutes with the stain-fixative and placing the glass slide on a stain frame; dropwise adding the Wright-giemsa working fluid to the smear to have the same evenly covered, wherein the operation environment is controlled at room temperature, and time is controlled at 10-15 minutes; after stain is completed, placing the smear in the PBS, and shaking the smear slightly for standby for 5-10 minutes;taking out the standby smear and performing rinsing from one end of the smear with deionized water; performing microscopic examination after drying. Through combined utilization of giemsa stain and Wright-giemsa stain, good stain effect can be obtained, stain time can be shortened, rapid stain and microscopic examination can be performed, and clinical diagnosis is assisted.

Owner:广州和能生物科技有限公司

Production process of antibacterial environment-friendly denim composite fabric

InactiveCN108527963AThe production process is simpleIncrease productivityTextile treatment containersSynthetic resin layered productsCotton fibreDyeing

The invention provides a production process of an antibacterial environment-friendly denim composite fabric, which belongs to the technical field of fabrics, and solves the problem in the prior art that the production quality is poor. The production process of the antibacterial environment-friendly denim composite fabric comprises the following steps: a, selecting materials: blending spandex fiberand cotton fiber into a warp yarn, and blending jute fiber and regenerated fibers into a weft yarn; b, dyeing: dyeing the warp yarn and the weft yarn by virtue of a dye vat for dyeing the yarn; c, weaving: weaving the warp yarn and the weft yarn in step b to form base cloth by virtue of a weaving machine; d, forming an inner layer: weaving the warp yarn and the weft yarn to form the inner layer,and coating the inner layer with antibacterial coating; e, compounding: compounding the inner layer and the base cloth by virtue of a compositing machine, and forming a semi-finished product fabric after the compounding; f, stereotyping: stereotyping the semi-finished product fabric by virtue of a stereotyping machine; and g, rolling: rolling the stereotyped fabric by virtue of a rolling apparatus. The production process has the advantage that the production quality can be improved.

Owner:海宁市金义服饰有限公司

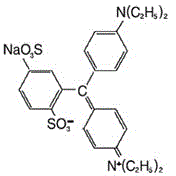

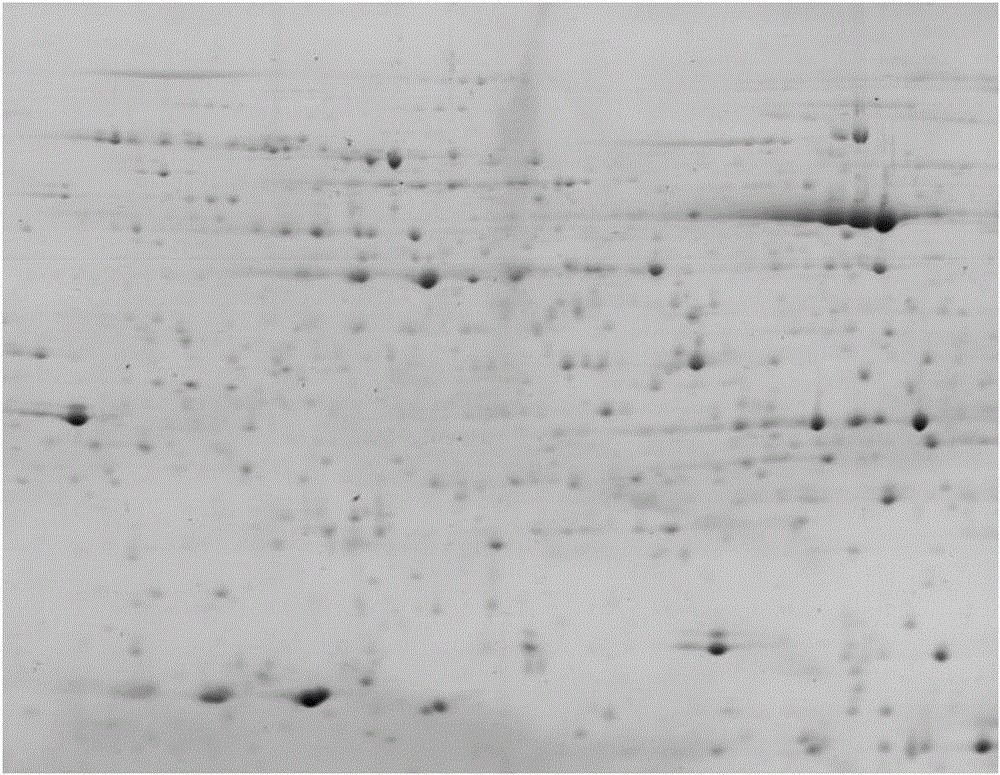

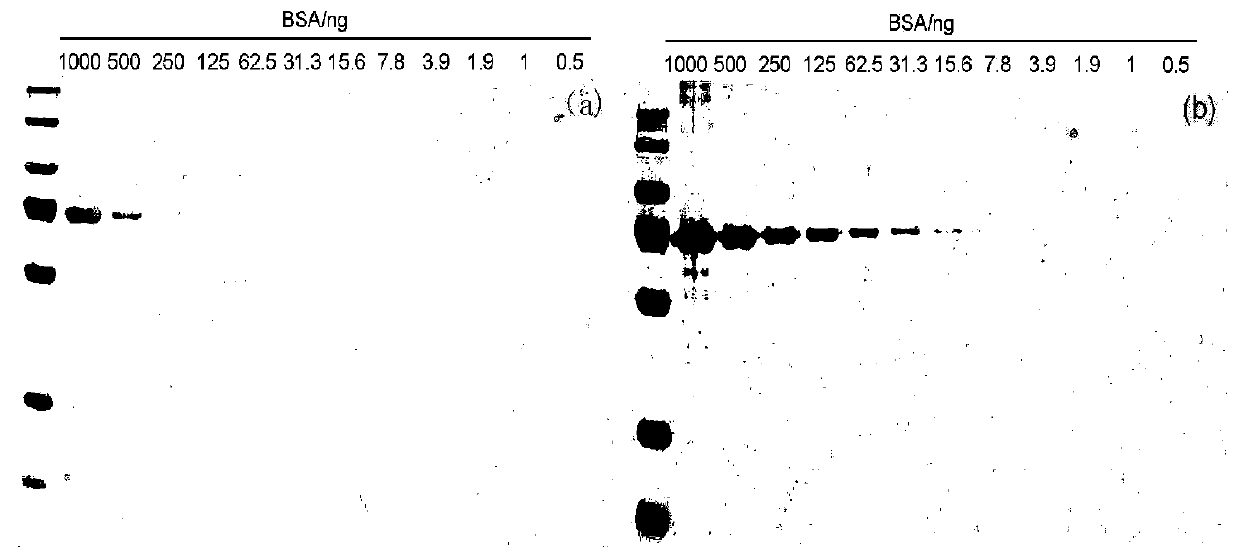

Dyeing and decoloration method of two-dimensional electrophoresis gel Coomassie brilliant blue for screening saline-alkaline resistant plant material

InactiveCN106596233AWide range of trialsGood effectPreparing sample for investigationAcetic acidAlcohol

The invention discloses a dyeing and decoloration method of two-dimensinal electrophoresis gel Coomassie brilliant blue for screening a saline-alkaline resistant plant material. The method comprises the first step of preparing a staining solution containing Coomassie brilliant blueR250, methyl alcohol, acetic acid and distilled water with a constant volume, uniformly blending the staining solution and still standing for 0.5-1.5 hours, filtering the staining solution and then storing the staining solution at a normal temperature for use; the second step of preparing a destaining solution containing ethyl alcohol, acetic acid and distilled water with a constant volume; the third step of using distilled water to wash two-dimensional SDS gel for 2-3 times, putting the two-dimensional SDS gel in a dyeing box, adding the staining solution into the dyeing box, using a preservative film to seal the dyeing box, and conducting dyeing on the two-dimensional SDS gel on a table concentrator for 2-3 hours at the normal temperature; the fourth step of conducting decoloration, wherein the decoloration comprises the procedures of pouring out the staining solution, using the distilled water to wash the gel for 2-4 times, adding the destaining solution, wherein the dosage of the destaining solution is 1-2 times that of the staining solution, conducting decoloration on the gel on the table concentrator for 2-3 hours at the normal temperature, and using the distilled water to wash the gel for 2-4 times. According to the dyeing and decoloration method, the method is further optimized on the basis of a routine technique method, procedures of pre-immobilization and the like are omitted, the speed of the dyeing and the decoloration is fast, and the effects of the dyeing and the decoloration are good.

Owner:DAQING BRANCH OF HEILONGJIANG ACAD OF SCI

Fungus fluorescent staining solution and preparation method thereof

ActiveCN111289336AImprove dyeing effectImprove color durabilityPreparing sample for investigationFluorescence/phosphorescenceFluorescent stainingWhitening Agents

The invention belongs to the technical field of biological examination of pathogenic bacteria in medical clinical examination, and particularly relates to a fungus fluorescent staining solution and apreparation method thereof. The fungus fluorescent staining solution is prepared from the following components in parts by weight: 0.5 to 1.5 parts of a fluorescent whitening agent, 0.07 to 0.15 partof a background pressure preparation, 10 to 15 parts of a dissolution promoter, 1 to 2.5 parts of an anti-fluorescence decay agent, 0.3 to 0.8 part of a surfactant and 0.5 to 1.5 parts of sodium chloride. The fluorescent whitening agent and the background dye are mixed and prepared; according to the staining solution, the anti-fluorescence decay agent, the surfactant, the dissolution promoter andthe sodium chloride are added, so that the staining effect and the staining durability of the staining solution are remarkably improved, the staining solution can be stably placed for a long time, specimen staining steps are simplified, and the staining solution has the advantages of high staining speed and good effects.

Owner:山东源科生物科技股份有限公司

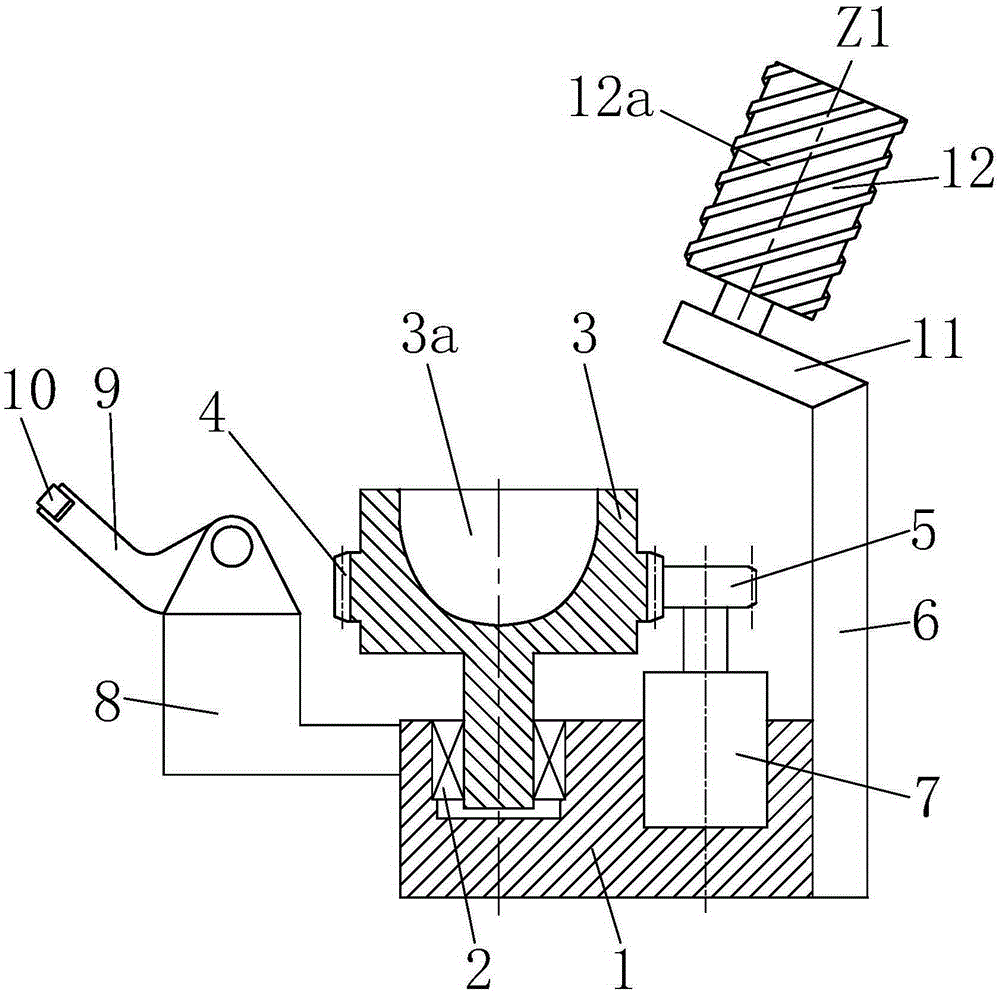

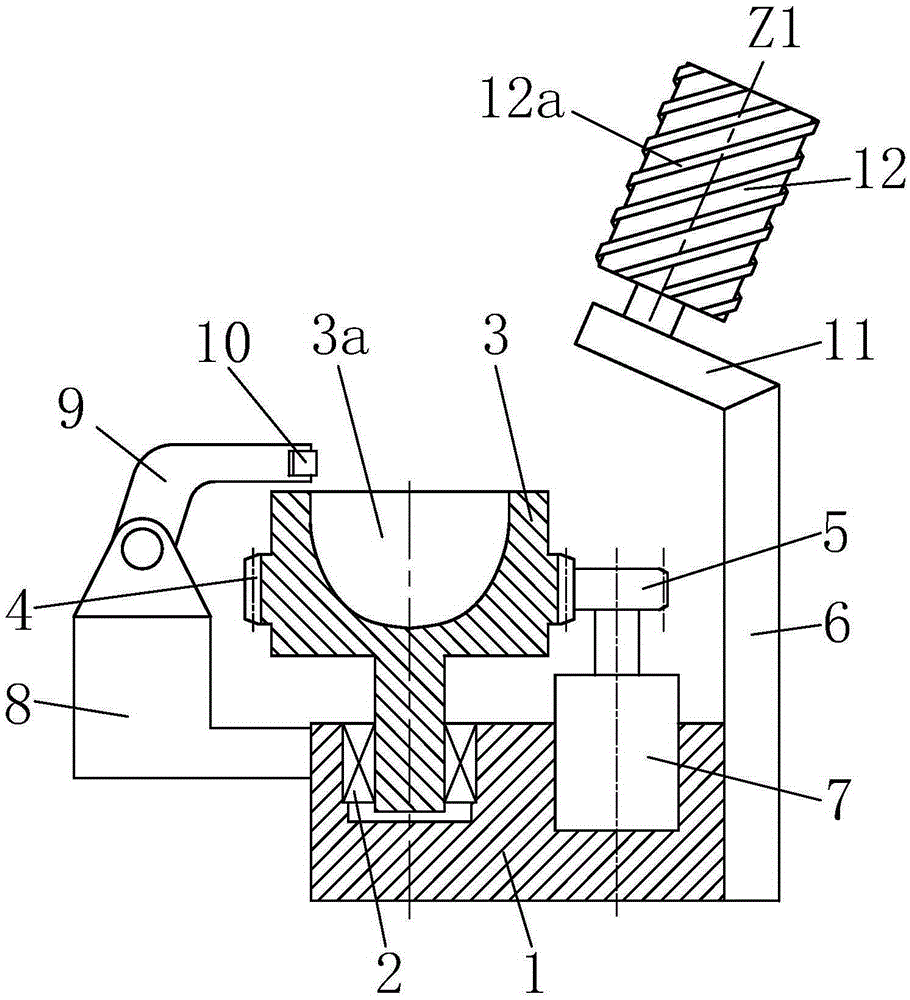

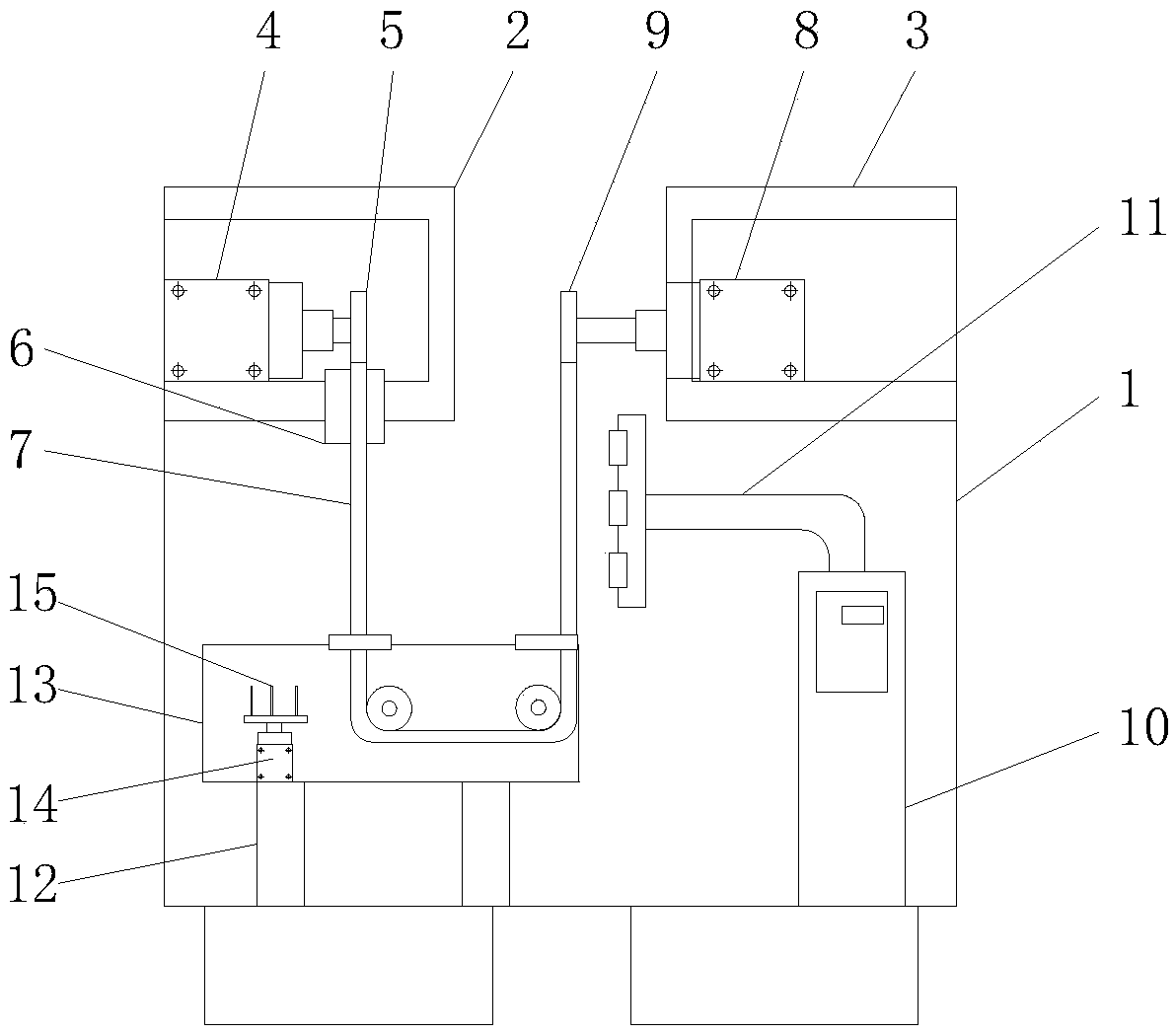

Shuttlecock coloring machine

The invention relates to a shuttlecock coloring machine which comprises a base. The left of the base is connected with a shuttlecock holder positioning seat through a bearing, the upper portion of the shuttlecock holder positioning seat is of a cylindrical structure, an outer gear is arranged on the cylindrical excircle surface of the shuttlecock holder positioning seat, a motor is mounted on the right of the base, a gear meshed with the outer gear is fixed at the upper end of the motor, an L-shaped bracket is fixed on the left end of the base, a limiting device is fixed at the upper end of the L-shaped bracket, a fixing board is fixed on the right end of the base, a dyeing supporting board is obliquely arranged at the upper end of the fixing board, and a dyeing roller is mounted on the dyeing supporting board. The shuttlecock coloring machine has the advantages of reasonable structure design, high automation level and low production cost, attractiveness of shuttlecocks is improved, quick dyeing of feathers of shuttlecocks can be realized, and the shuttlecock coloring machine is orderly in dyeing, high in dyeing efficiency and suitable for batched processing treatment.

Owner:安徽省无为县奥宇体育用品有限公司

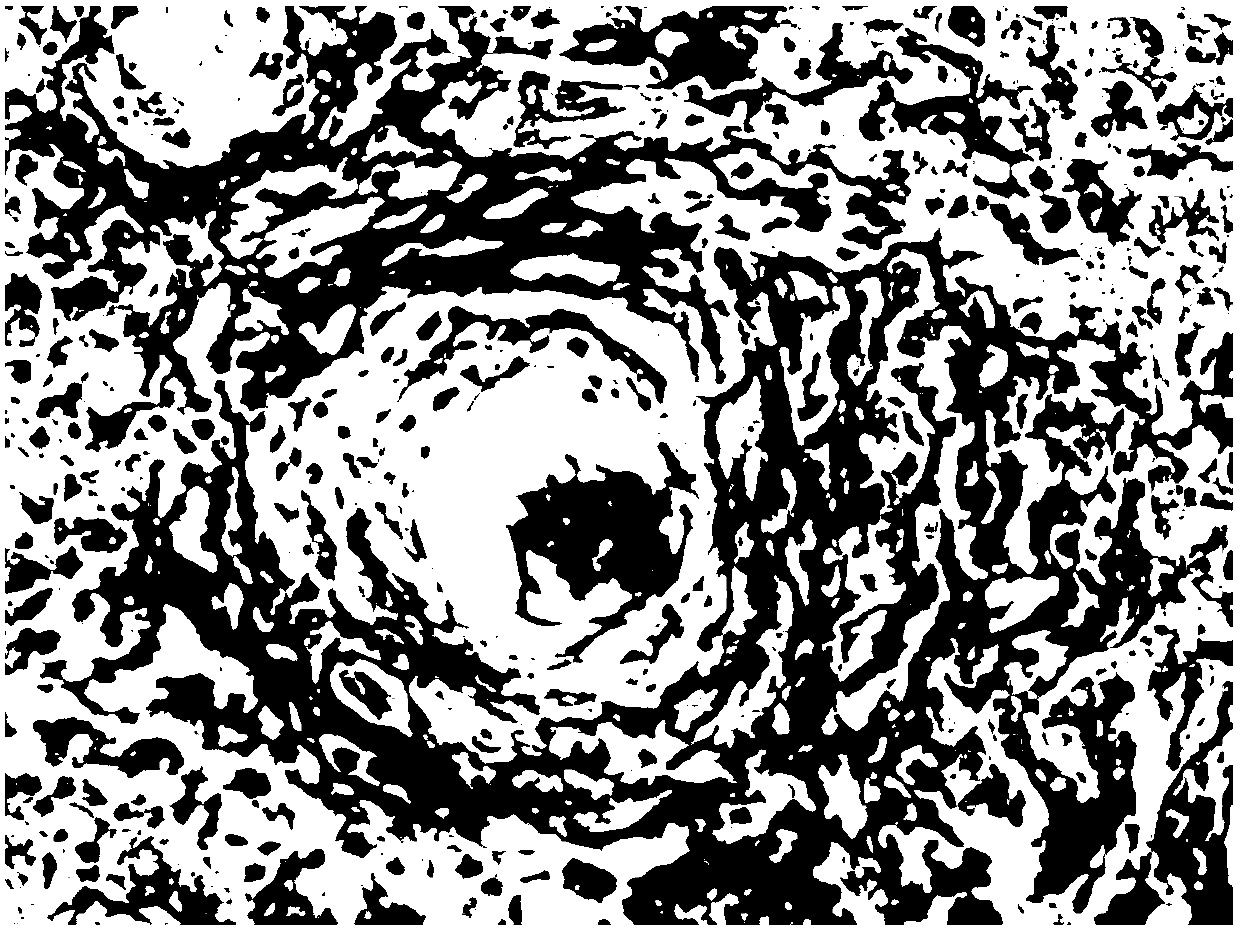

Collagenous fiber Masson trichrome stain kit, preparation method thereof and staining method

InactiveCN107907397AQuick stainBreaking down the dyeing barriers of dyeing vatsPreparing sample for investigationFiberPhosphomolybdic acid

The invention relates to a collagenous fiber Masson trichrome stain kit, a preparation method thereof and a staining method. The stain kit comprises a kit body, wherein 6 dropping bottles are contained in the kit body; different reagents are respectively contained in the 6 dropping bottles; the volumes of the dropping bottles are 5ml or 10ml; the reagents in the 6 dropping bottles are hematoxylinstaining solution, hydrochloric acid differentiation solution, back-to-blue solution, ponceau acid fuchsin solution, phosphomolybdic acid solution and aniline blue solution separately. The kit performs optimization in terms of the packaging of the kit, formulas of reagents and a staining process, further a collagenous fiber Masson trichrome stain kit based on instillation is assembled, and the kitcan be directly applied to rapid staining of small-scale tissue slices, and has the characteristics of economical efficiency, practicability, special effect and speediness.

Owner:苏州泽科生物科技有限公司

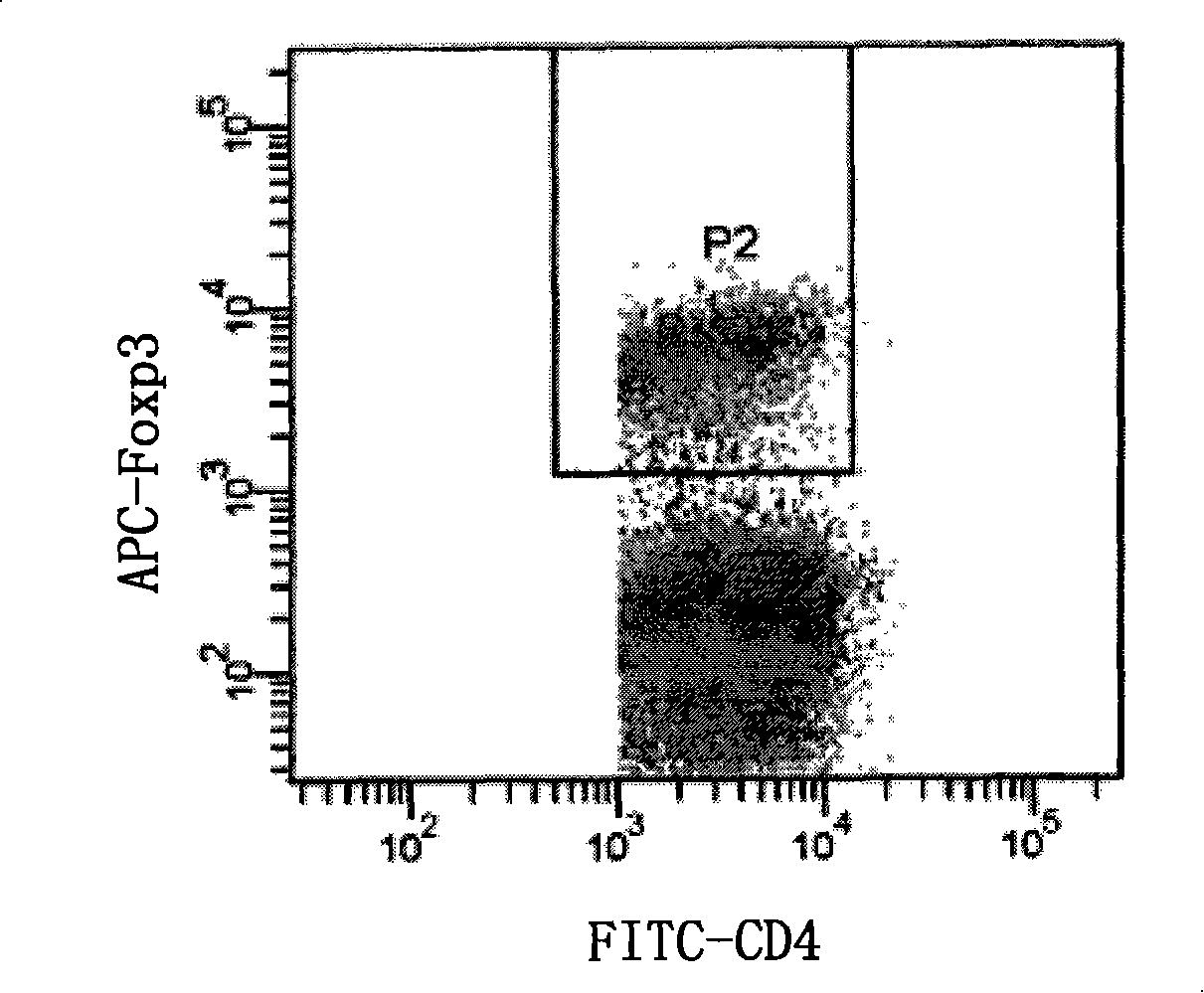

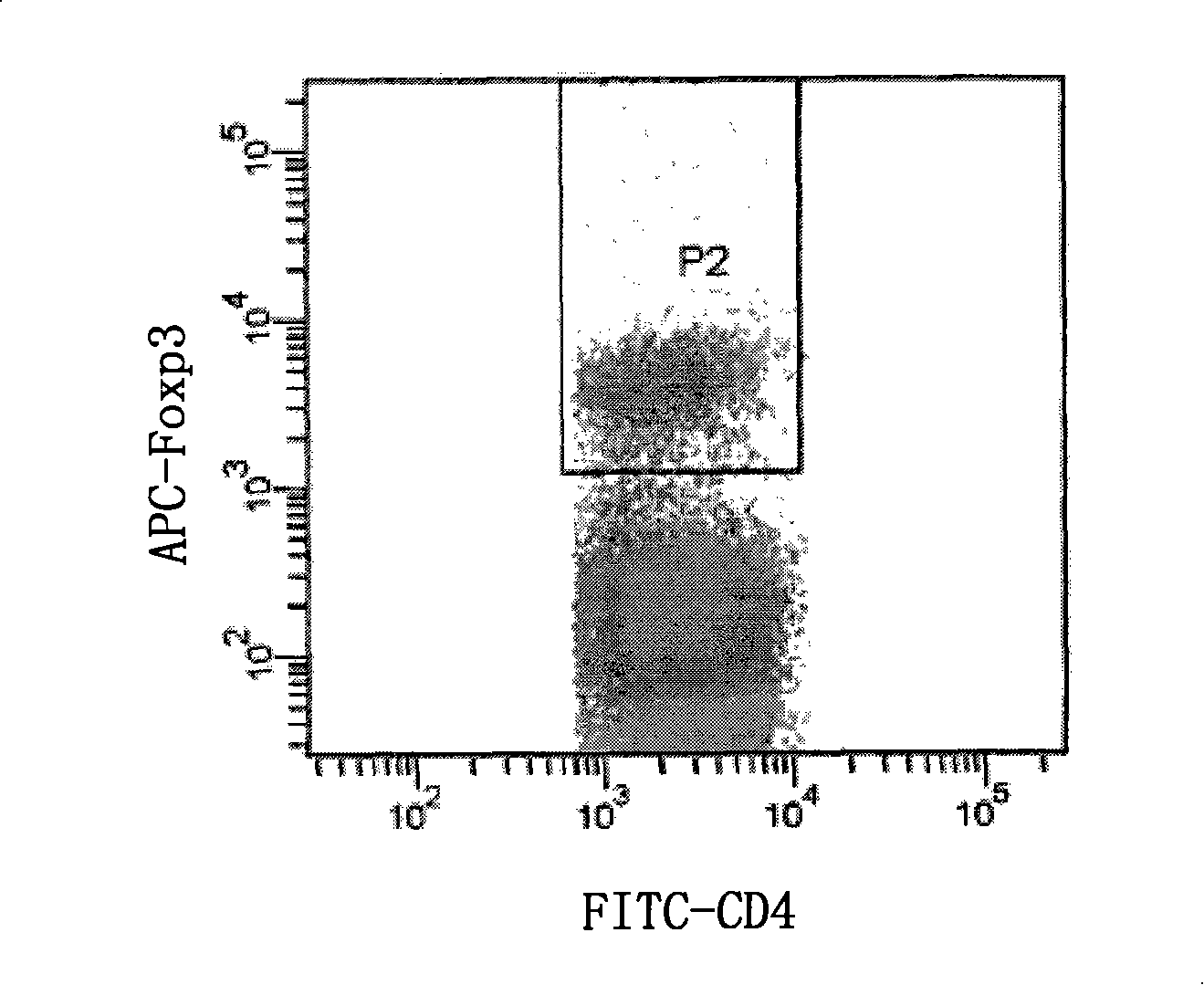

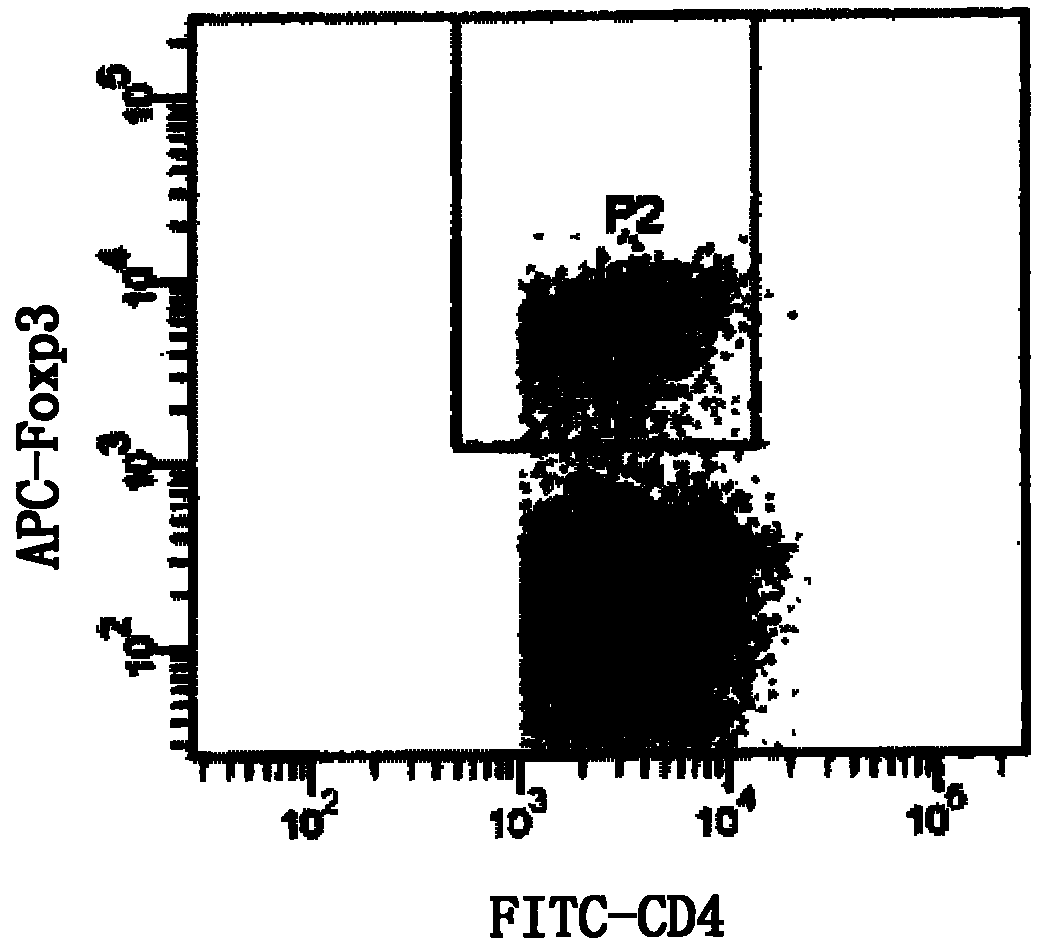

Improved method for dyeing immunofluorescence cell

InactiveCN101329230BReduce usageReduce stainsPreparing sample for investigationImmunofluorescenceStaining

The invention discloses an improved immune fluorescyte staining method, comprising 5 steps: fixing / permeating, permeating, surface staining, staining in nucleus, washing and weight dropping; the method of the invention is an improvement to the Foxp3 immune fluorescyte staining method of eBioscience Company, changes a two-step multiple staining method into a one-step multiple staining method, and carries out the staining on the surface of the cell and in the nucleus simultaneously, thus having the advantages of simple and convenient operation, quick staining, saving reagent, and reducing the cost, etc. The research shows that the method of the invention has no remarkable difference with the method of that of the eBioscience Company, can be used for the staining on the surface of the cell and in the nucleus simultaneously and has extremely good application prospect and promotional value.

Owner:ARMY MEDICAL UNIV

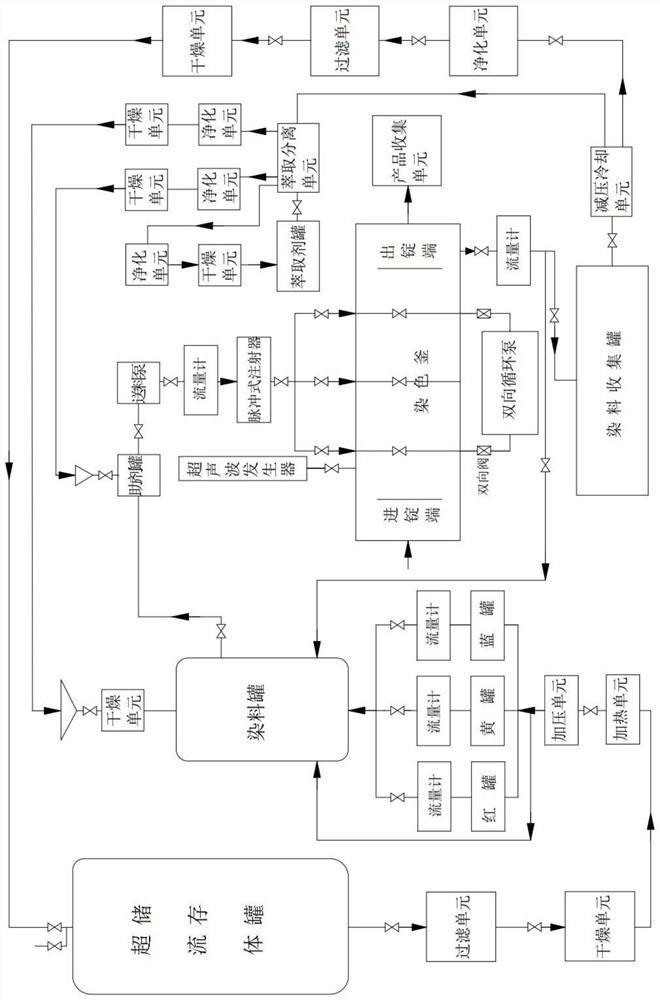

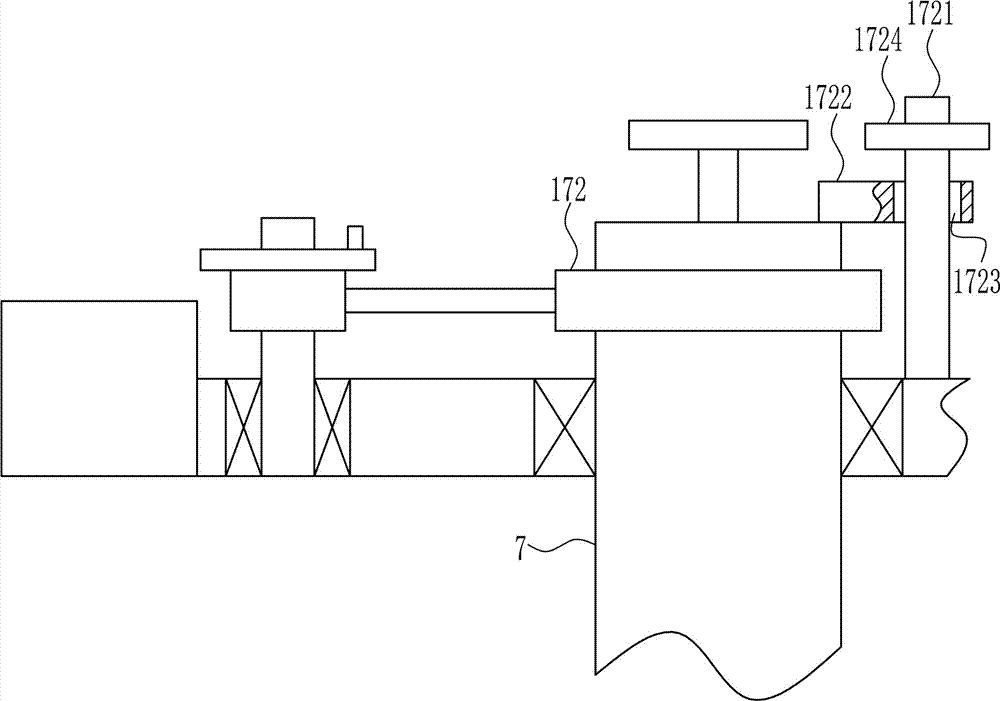

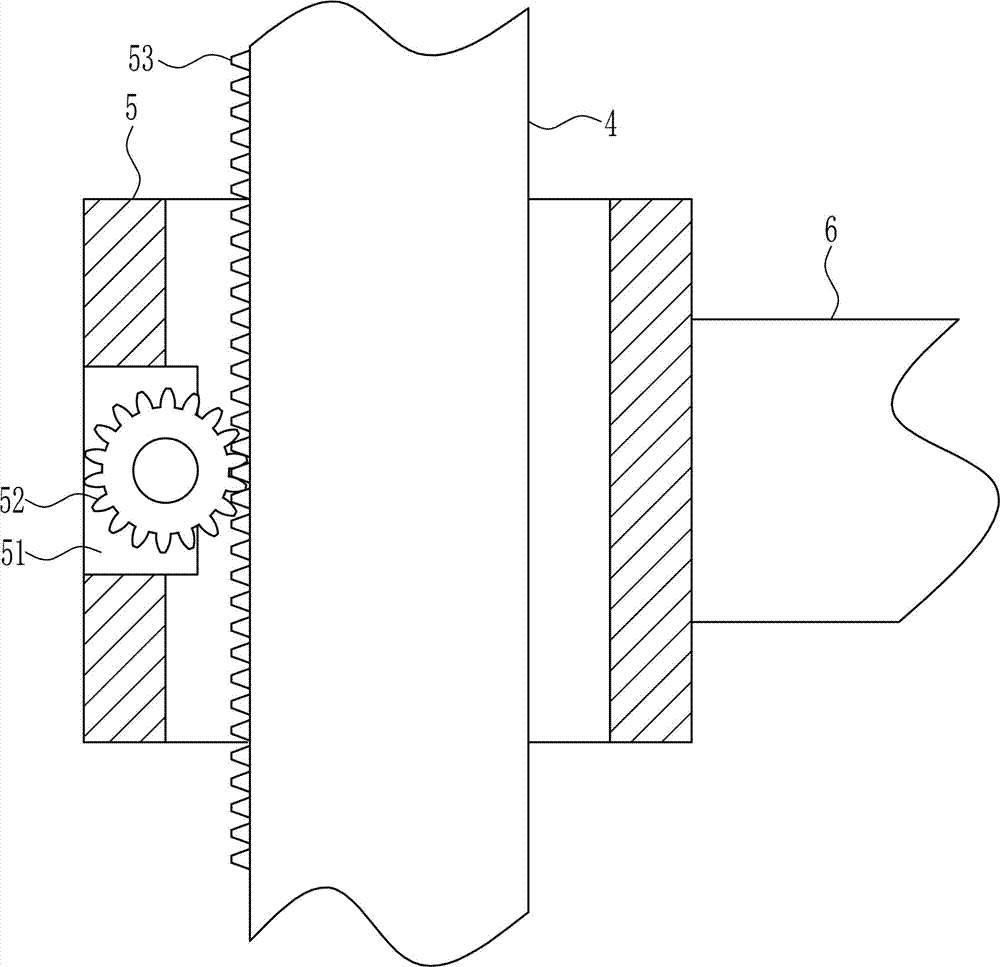

Pulse type supercritical fluid printing and dyeing process and device

InactiveCN111826846AHigh activityFacilitated DiffusionTextile treatment containersSolvent treatment with solvent recoveryLiquid stateProcess engineering

The invention discloses a pulse type supercritical fluid printing and dyeing process and device. The printing and dyeing process comprises the following steps: (1) converting liquid-state superfluid into supercritical fluid; (2) mixing the supercritical fluid with a three-primary-color dye to form dye liquor; (3) injecting the dye liquor into a dyeing kettle by adopting pulse type injectors, dyeing spindles from a spindle inlet end under the action of ultrasonic generators and bidirectional circulating pumps, and sending out the spindles from a spindle outlet end after the dyeing is mature; and (4) enabling the dye liquor discharged from the dyeing kettle to flow back to a dye tank for cyclic utilization, or separating and purifying the discharged dye liquor into liquid fluid and dye to berecycled or stored for later use. According to the pulse type supercritical fluid printing and dyeing process and device, the optimal dye liquor conveying condition can be realized through pulse typeconveying, and then the printing and dyeing uniformity and printing and dyeing efficiency are improved; and the printing and dyeing process is green and environmentally friendly, and is clean in production, good in economic benefit and remarkable in environmental benefit.

Owner:SHANGHAI FULUDI FLUID TECH CO LTD

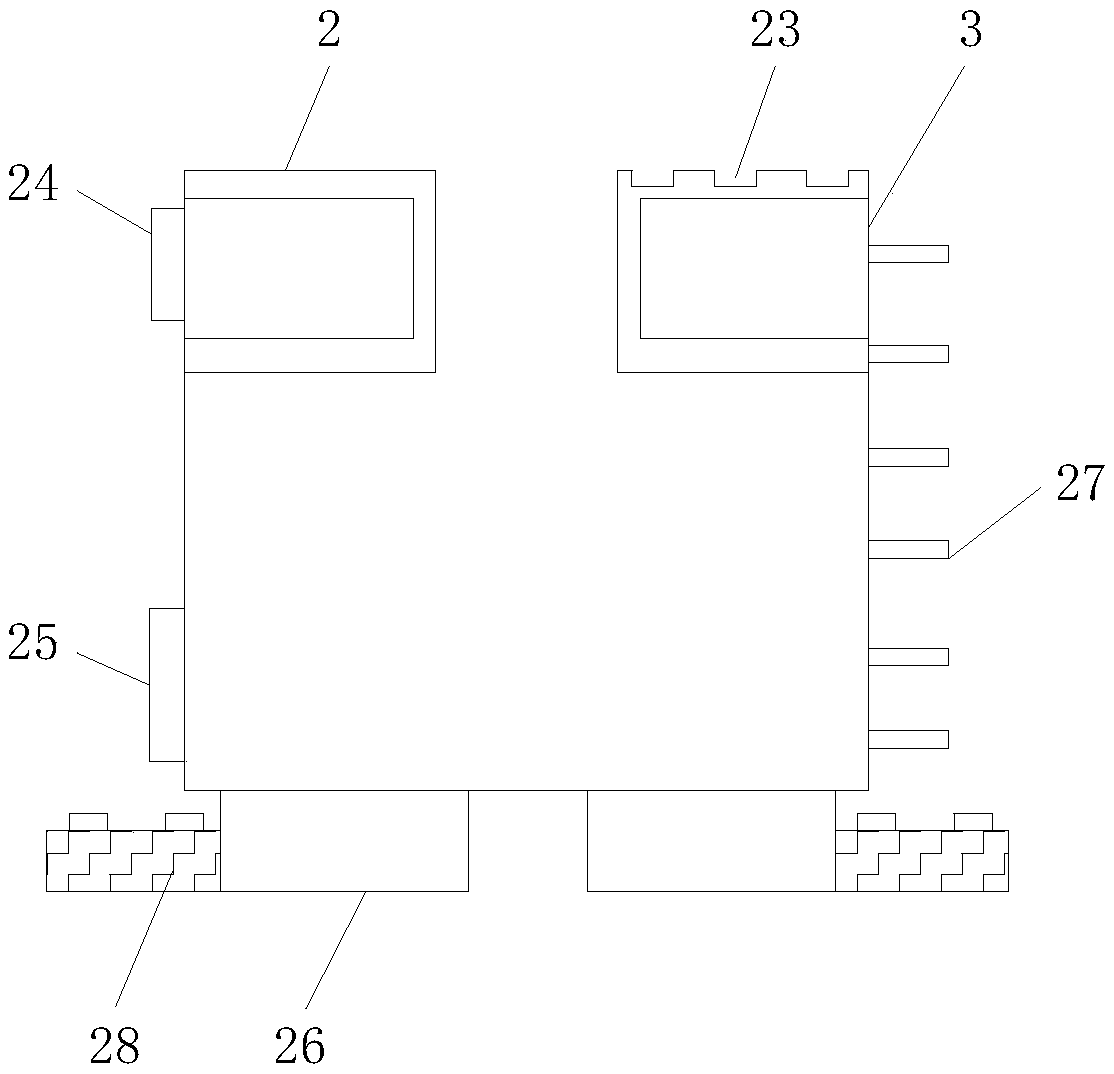

Coloring and belt wrapping integrated machine for shuttlecocks

The invention relates to a coloring and belt wrapping integrated machine for shuttlecocks. The coloring and belt wrapping integrated machine comprises a base, wherein a cork base positioning base is connected to the left side of the base through a bearing, and the upper portion of the cork base positioning base is of a cylindrical structure. A circle of outer gear is arranged on the outer cylindrical outer circle face of the shuttlecock positioning base. A motor is arranged on the right portion of the base. A gear meshed with the outer gear is fixed to the upper end of the motor. An L-shaped bracket is fixed to the left end of the base. A belt wrapping device is fixed to the upper end of the L-shaped bracket. A fixing plate is fixed to the right end of the base. A dyeing supporting plate arranged in an inclined mode is arranged at the upper end of the fixing plate. A dyeing roller is arranged on the dyeing supporting plate. The coloring and belt wrapping integrated machine has the advantages of being reasonable in structural design, high in automation degree, convenient to operate and control and the like, rapid dyeing of feather of shuttlecocks can be achieved, shuttlecocks can be more attractive in appearance, belt wrapping is completed at the same time, and the processing efficiency of shuttlecocks is improved.

Owner:安徽省无为县奥宇体育用品有限公司

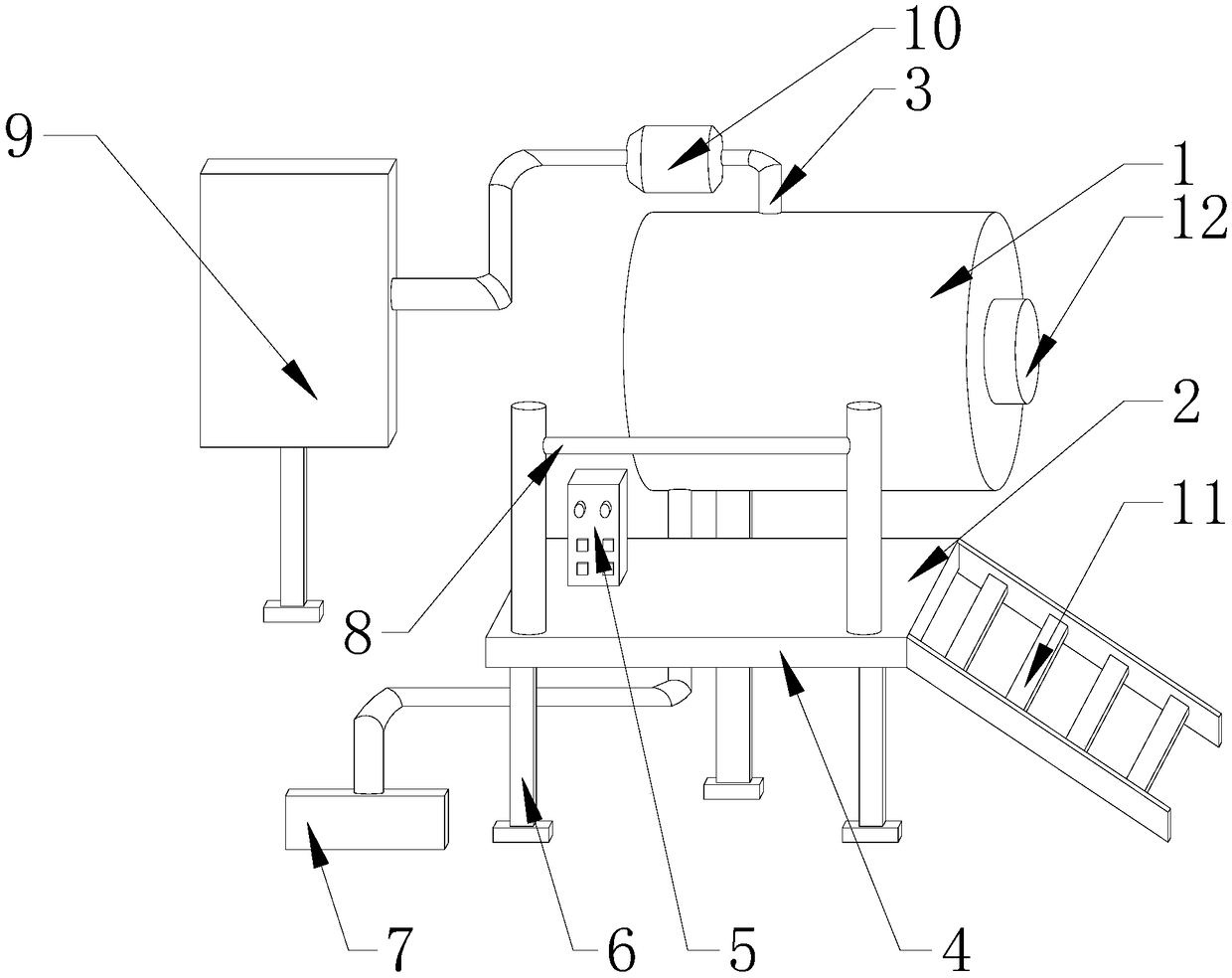

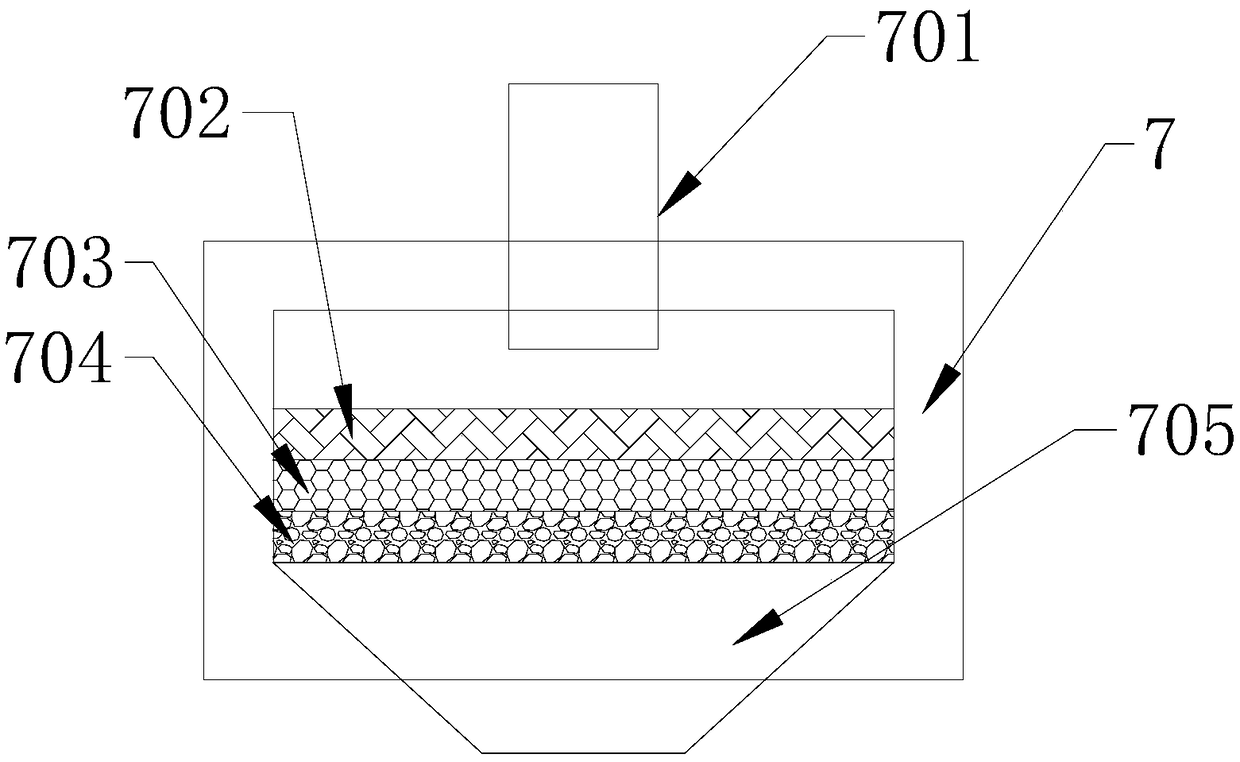

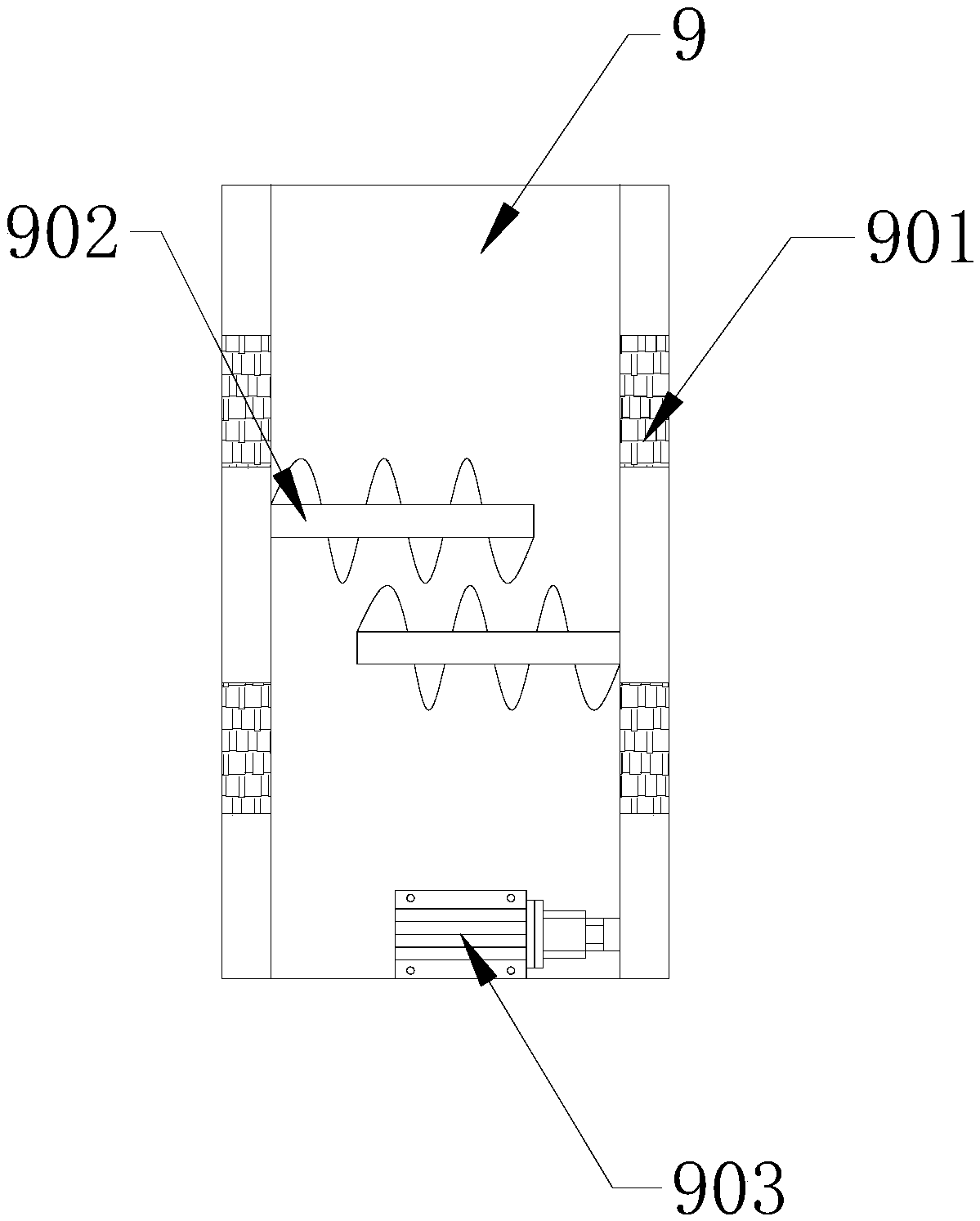

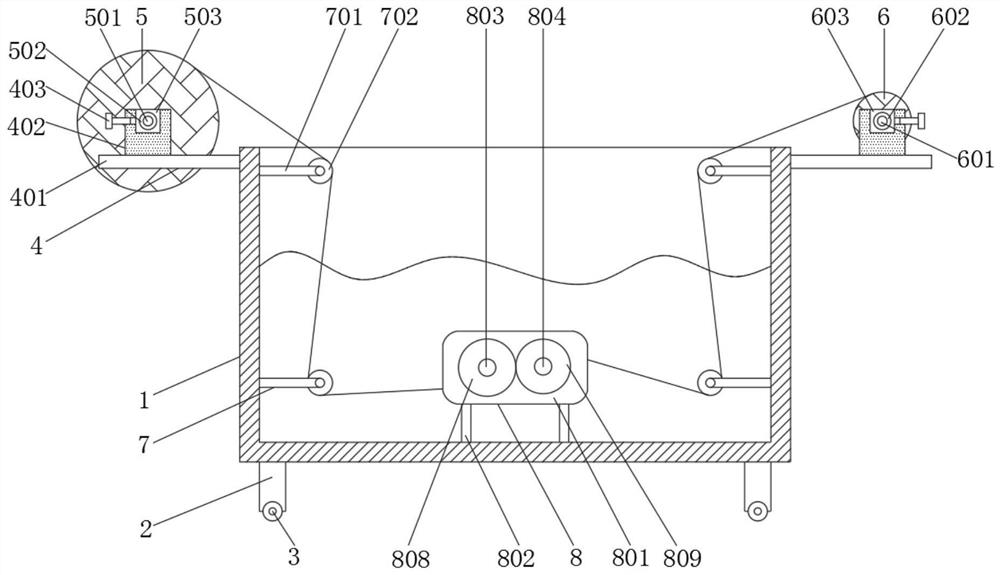

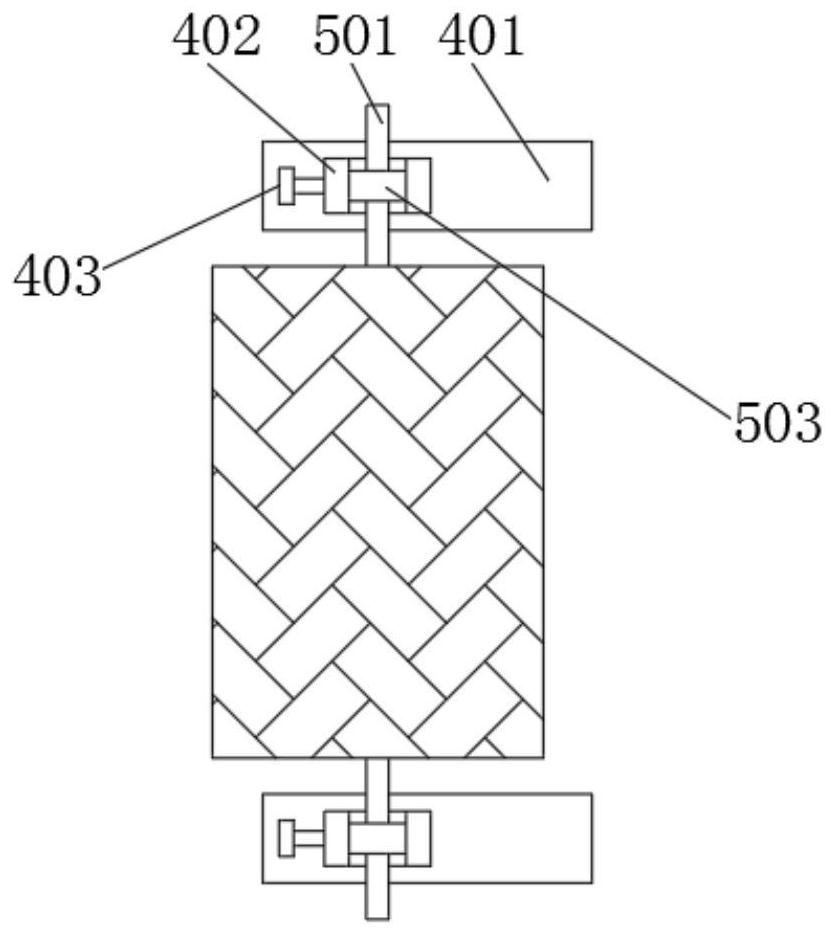

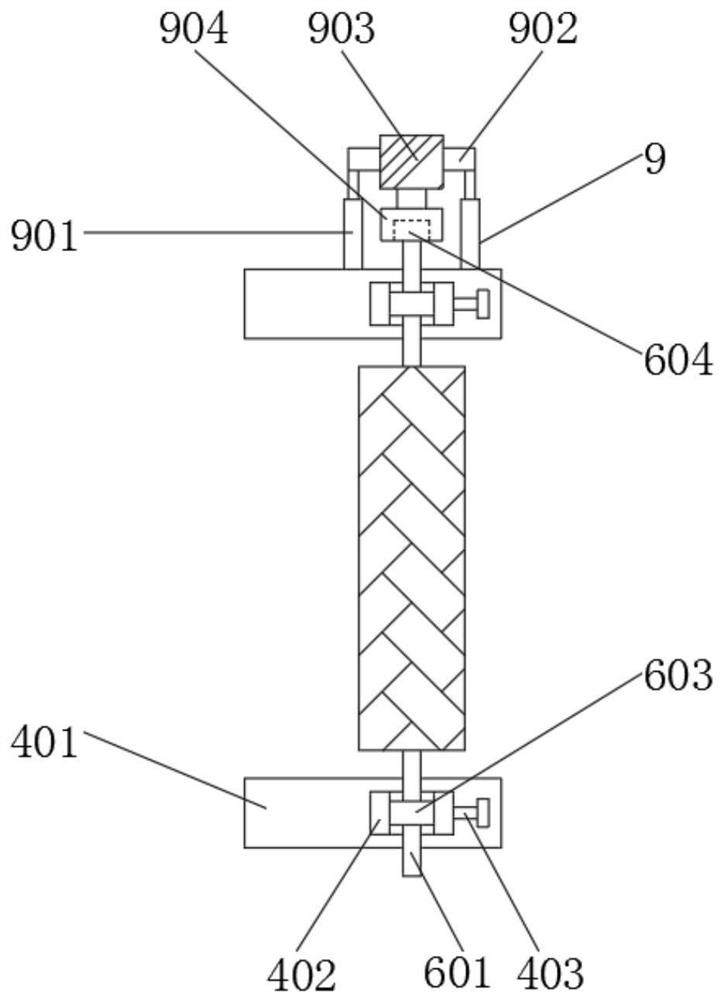

Rapid cow leather dyeing equipment for leather processing plant

ActiveCN106868236AShort dyeing timeQuick stainLeather/skins/hides/pelt chemical treatment apparatusProcessing plantsWaste management

The invention relates to leather dyeing and processing equipment, in particular to rapid cow leather dyeing equipment for a leather processing plant. In order to solve the technical problems, the invention provides the rapid cow leather dyeing equipment for the leather processing plant, and the rapid cow leather dyeing equipment is relatively short in dyeing time and is relatively uniform in adsorption. The rapid cow leather dyeing equipment for the leather processing plant comprises a bottom plate, supporting columns, material boxes, a guide rail, a guide sleeve, a supporting plate, a connecting rod, a slide rail and the like, wherein the two supporting columns are mounted at the left side and the right side of the bottom plate in a welding mode; the material boxes are mounted at the upper ends of the supporting columns in a welding mode; the guide rail is mounted at the left side of the bottom plate in the welding mode; and the guide rail is connected on the guide rail in a sliding mode. The rapid cow leather dyeing equipment achieves the effects of being short in dyeing time and relatively uniform in dyeing; and a mode of arranging a filter box and cow leather on the connecting rod with a relatively great gap is adopted, so that a plurality of pieces of cow leather can be dyed once.

Owner:温州市依恋典鞋业有限公司

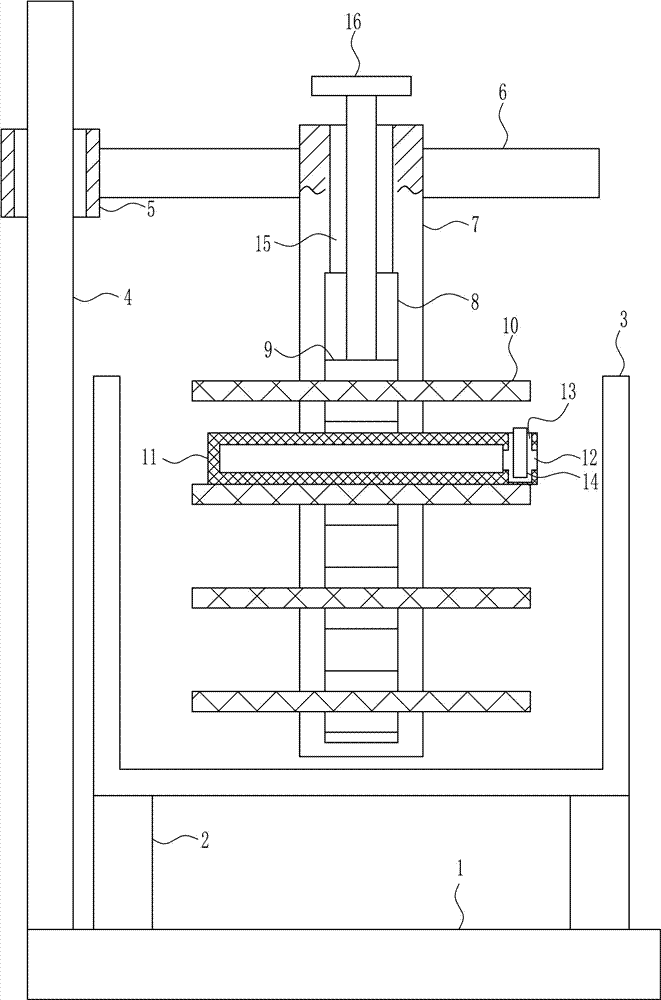

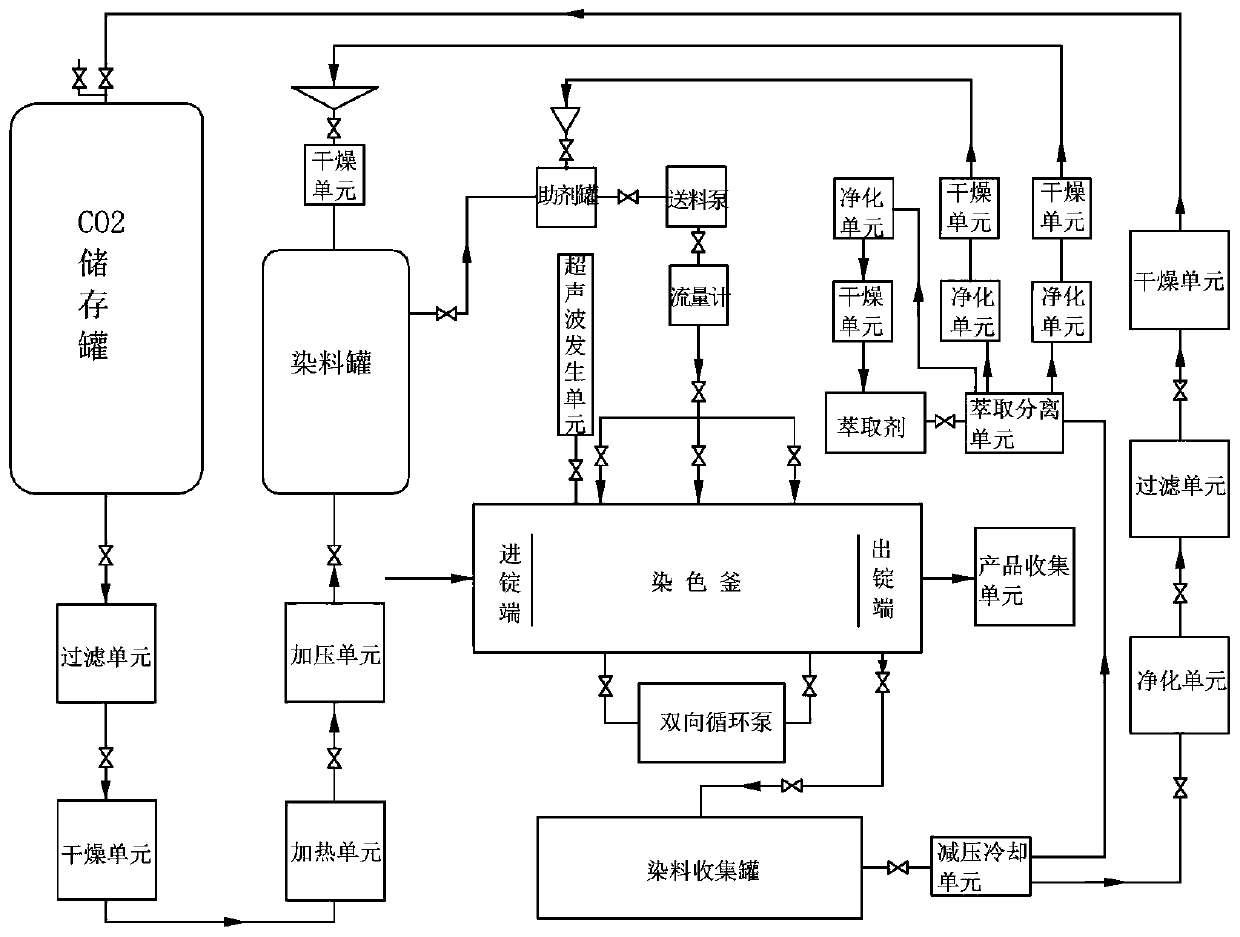

Supercritical carbon dioxide printing and dyeing technology and system

PendingCN110565415AHigh activityFacilitated DiffusionSolvent treatment with solvent recoveryTextile treatment machine arrangementsWastewaterEconomic benefits

The invention discloses a supercritical carbon dioxide printing and dyeing technology and system. The supercritical carbon dioxide printing and dyeing technology comprises the steps that (1), liquid carbon dioxide is transformed into supercritical carbon dioxide; (2), the supercritical carbon dioxide is mixed with dye to form dye liquor; (3), the dye liquor is introduced into a dyeing kettle, andspindles from a spindle feeding end are dyed under the action of ultrasonic waves and bidirectional circulation; (4), the remaining dye liquor obtained after dyeing is collected, decompressed and separated, and the dye and the supercritical carbon dioxide which are obtained after separation are separately purified and dried to be recycled. The printing and dyeing technology and system have the advantages that no waste dyeing water or other wastes are generated, environment-friendly and clean production can be achieved, the economic benefits are high, and the environmental benefits are significant, and the aims of recycling, flowline production, improvement of the yield and reduction of industrial cost can be achieved.

Owner:SHANGHAI FULUDI FLUID TECH CO LTD

Dyeing composition comprising 4,5-diamino-1-(beta-hydroxyethyl)-1h-pyrazole or 4,5-diamino-1-(beta-methoxyethyl)-1h-pyrazole as oxidation base and 6-hydroxyindole as coupling agent

InactiveCN1589768ALow selectivityRenders natural shadesCosmetic preparationsHair cosmeticsFiberPyrazole

The present invention relates to a composition which is used for oxidizing the dyeing keratin fiber, especially the human keratin fiber such as curled hair, and the composition includes 4,5-diamino-1-( beta -hydroxyethyl) or ( beta -methoxyethyl)-1H-pyrazole as the oxidation base and 6- hydroxyindole as color coupler. The invention also relates to the application of the oxidizing dyeing composition for the dyeing keratin fiber, and a method for dyeing with the composition.

Owner:LOREAL SA

Novel printing and dyeing device for bed sheet fabric

InactiveCN108691123AQuick stainFully dyedLiquid/gas/vapor removalTextile treatment machine arrangementsSurface mountingEngineering

The invention discloses a novel printing and dyeing device for bed sheet fabric. The novel printing and dyeing device comprises a housing, a first frame and a second frame are sequentially arranged onthe outer surface of the housing from left to right, a first drum is installed on the right end surface of a first rotating motor arranged in the first frame, a second drum is installed on the left end surface of a second rotating motor arranged in the second frame, a bed sheet fabric strip is connected to the surface of the second drum, a storage box is welded to the top ends of supporting legsfixed to the inner lower surface of the housing, stirring rods are installed on the top end surface of a third rotating motor arranged in the storage box, and a first roller and a second roller are sequentially arranged in the storage box from right to left. By arranging the first frame, the second frame, the second rotating motor, the second drum, the third rotating motor, the stirring rods, thefirst roller, the second roller and metal steps, the problems that heavy fabric cannot be sufficiently soaked, and a horizontal laying installation mode wastes space are solved.

Owner:安徽省鼎立服饰有限公司

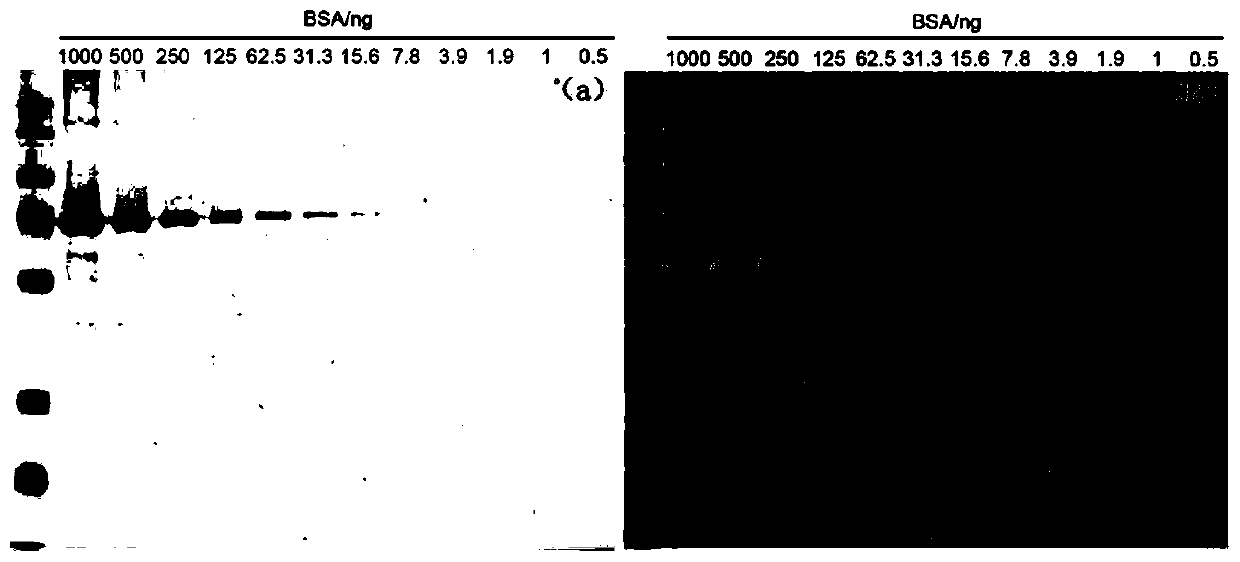

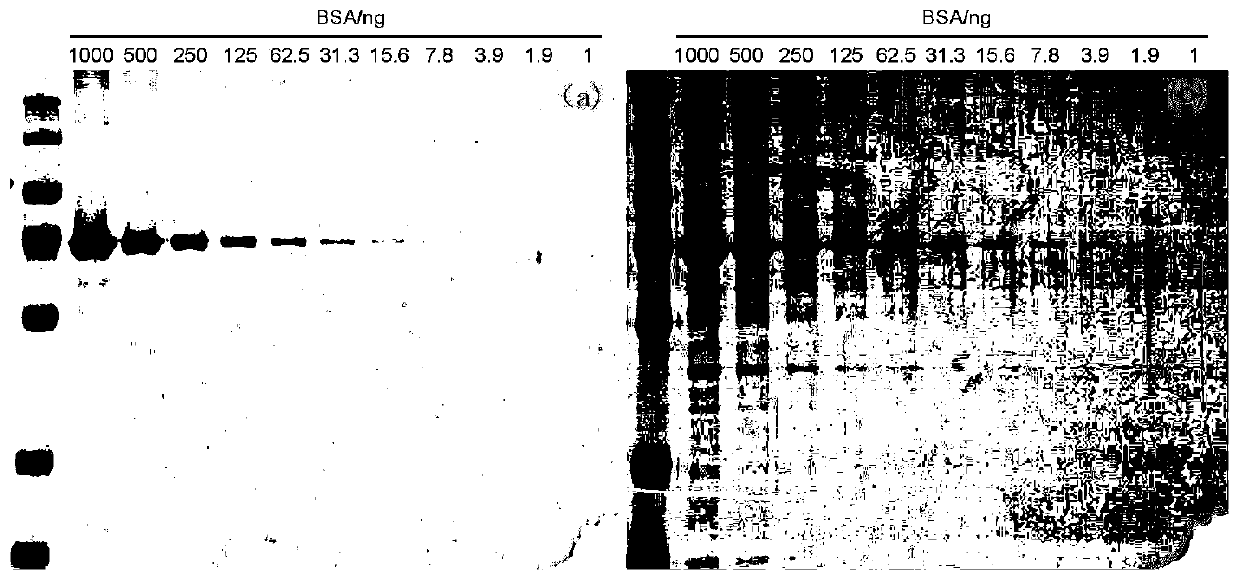

High sensitivity and low background Coomassie brilliant blue staining solution and using method thereof

InactiveCN110068491AAvoid generatingHigh detection sensitivityPreparing sample for investigationAmmonium sulfateChemistry

The present invention discloses a high sensitivity and low background Coomassie brilliant blue (CBB) staining solution and a using method thereof, and belongs to the technical field of protein staining reagents of SDS-PAGE. The staining solution is composed of CBB R250 with a mass volume concentration of 0.03%-0.05%, acetic acid with a volume percentage of 2%-6%, ammonium sulfate with a mass volume concentration of 8%-15%, and ethanol with a volume percentage of 12%-16%. The CBB staining solution provided by the present invention is optimized on the basis of the traditional staining solution,and a clearer background is obtained, so that the detection sensitivity is greatly improved and the staining sensitivity reaches the nanogram level. According to the method for using the CBB stainingsolution provided by the present invention, without elution after staining, deionized water is used to wash to destroy the colloid state to complete decolorization, so that the detection time is greatly shortened, the method can be used for rapid protein staining of SDS-PAGE, and work efficiency can be improved.

Owner:湖北擎科生物科技有限公司

Dyeing machine with eco-friendly effect

PendingCN108914436AImprove work efficiencyEmbody efficiencyTextile treatment machine arrangementsTextile treatment by spraying/projectingEnvironmental resistanceWater resources

The invention discloses a dyeing machine with eco-friendly effect. The machine comprises a body of the dyeing machine, a support board, an operation platform and a power box. The operation platform isfixedly connected right ahead of the body of the dyeing machine. The support board is fixedly connected with the top end of the operation platform. The other side of the operation platform is fixedlyconnected with a pedal. One end of the body of the dyeing machine is fixedly connected with a dye box. One side at the top of the support board is fixedly connected with the power box. A cloth guideroll is connected at the top end right ahead of the support board in an embedding manner. One side at the bottom end of the body of the dyeing machine is fixedly connected with a filtering box. The filtering box ensures that discharged waste water does not cause pollution to the environment, thereby protecting the nature. Meanwhile, waste of water resources is saved. The body of the dyeing machineis eco-friendly. The dye box can ensure that dyes can be more quickly put into use. Therefore, the body of the dyeing machine is efficient. A nozzle can uniformly spray dyes to cloth material when cloth is dyed so that uniformity of the body of the dyeing machine is ensured.

Owner:孝感市智强医疗器械有限公司

Method for identifying discharged live zooplanktons in blast water

InactiveCN102636487AQuick stainEasy to dyePreparing sample for investigationMaterial analysis by optical meansZooplanktonStaining

The invention provides a method for identifying discharged lived zooplanktons in blast water. The method includes steps: (1) dripping from 1.0 to 2.0ml of 1-2% zooplankton staining solution into every 60ml of acquired zooplankton water sample, and realizing staining; (2) further dripping formalin liquid into the water sample to fix the sample; and (3) realizing microscopic examination for the sample after the sample is uniformly mixed, and counting. Compared with the prior art, an integral staining process of the method is speedy and is simplified, cost is low, the effect is obvious, and whether the blast water contains the lived zooplanktons or not can be quite easily identified.

Owner:SHANGHAI OCEAN UNIV

Efficient dyeing device for textile production

InactiveCN112064258AEasy to disassembleImprove work efficiencyTextile treatment machine arrangementsTextile treatment carriersEngineeringTextile production

The invention discloses an efficient dyeing device for textile production. The efficient dyeing device comprises a box, bearing seats are arranged on the left side and the right side of the box, a discharging assembly is installed on the bearing seat on the left side, a collecting assembly is installed on the bearing seat on the right side, and a power mechanism is installed at the rear end of thebearing seat on the right side. A plurality of roller assemblies are arranged on the left side wall and the right side wall in the box, a friction mechanism is arranged at the bottom in the box, andto-be-dyed cloth sequentially passes through the roller assembly on the left side, the friction mechanism and the roller assembly on the right side from the discharging assembly and is wound to the collecting assembly. The friction mechanism is arranged, friction rollers in the friction mechanism rotate to rub the surface of cloth, so that the contact area between the cloth and dye is increased, and the cloth dyeing efficiency is improved; and meanwhile, the two friction rollers are arranged to rub the upper side face and the lower side face of the cloth, the uniformity degree of the dyed cloth can be increased, and the dyeing quality of the cloth is better.

Owner:丁帅飞

Cast-off cell one-step staining method, and dye combination and kit for cast-off cell one-step staining method

InactiveCN108007754AAvoid complexityQuick stainPreparing sample for investigationStainingUltraviolet lights

The invention belongs to the field of cytopathology, and particularly relates to a cast-off cell one-step staining method, and a dye combination and a kit for the cast-off cell one-step staining method, wherein one-step staining is the synchronous staining of the nucleus and the cytoplasm of cast-off cells, and comprises: carrying out one-step staining on cast-off cells by using a fluorescent dyecombination, and the fluorescent dye combination contains a nucleus fluorescent dye and a cytoplasm fluorescent dye. According to the present invention, the nucleus and the cytoplasm of cast-off cellsare synchronously stained with the fluorescent dye combination without the washing of the background fluorescence, such that the rapid staining and detection can be achieved; and excitation is performed with the single ultraviolet light source, and the good effect is achieved, such that the light source can be simplified, and the image forming complexity caused by the two irradiations can be avoided.

Owner:陈石磊

Textile fabric dyeing device with automatic drying function

InactiveCN111648067AQuick stainEasy to dryLiquid/gas/vapor removalTextile treatment machine arrangementsIndustrial engineeringCotton material

The invention discloses a textile fabric dyeing device with an automatic drying function. The textile fabric dyeing device comprises a dyeing jar, support legs, a first guide roller frame, an electrictelescopic rod, a top plate, a second guide roller frame, a third guide roller frame, a fourth guide roller frame, guide rollers, a drying box, an electric heating rod, a fan and a power switch, wherein the support legs are mounted at the bottom of the dyeing jar, the second guide roller frame is mounted on one side of the top of the dyeing jar, the third guide roller frame is mounted on the other side of the top of the dyeing jar, the top plate is mounted at the tops of the second guide roller frame and the third guide roller frame, the electric telescopic rod is mounted in the middle of thetop plate, the first guide roller frame is mounted at the bottom of the electric telescopic rod, the drying box is mounted on one side of the dyeing jar, and the electric heating rod is mounted in the drying box. The dyeing device can realize assembly line dyeing and dye fabrics quickly, is high in efficiency and high in speed, can rapidly dry the fabrics and improve the dyeing efficiency and drying efficiency, and is simple in structure and convenient to promote.

Owner:何翠凤

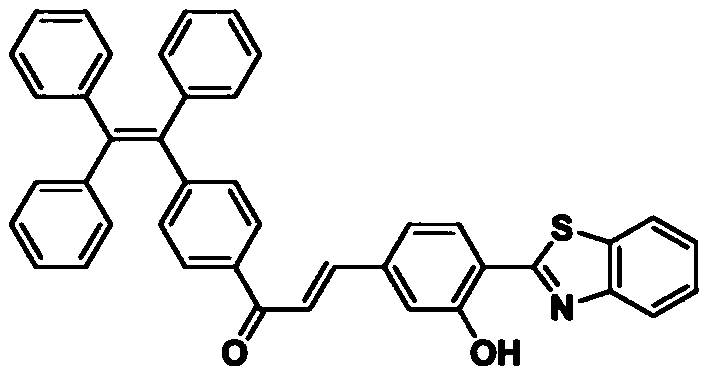

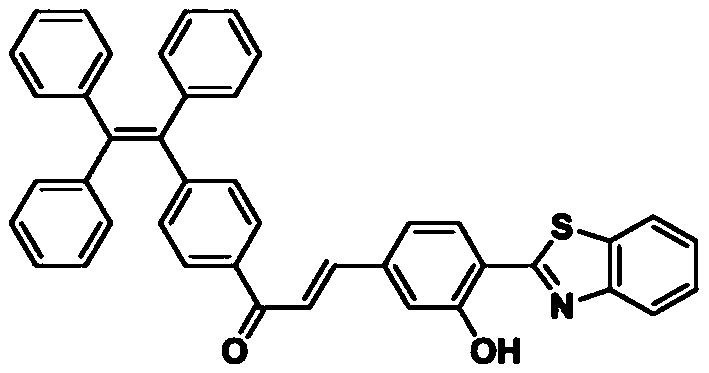

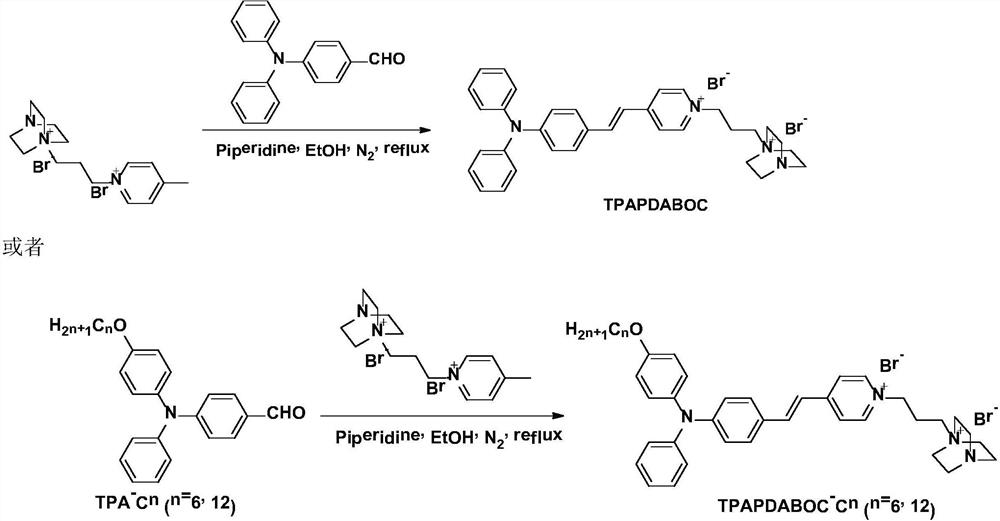

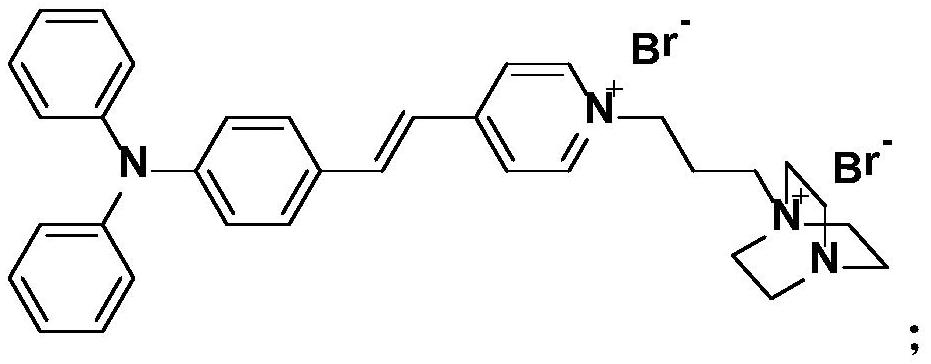

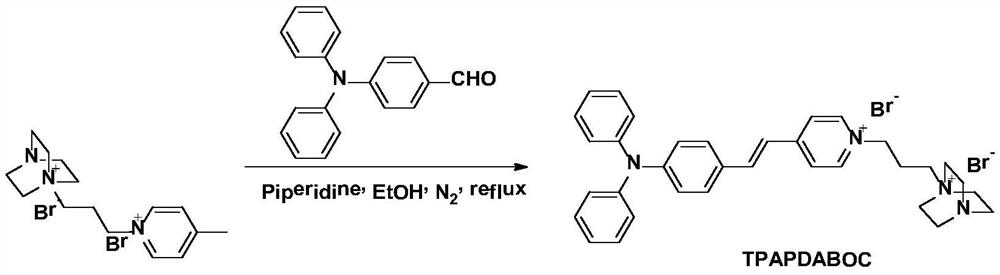

Near-infrared aggregation-induced emission membrane probe molecule, and preparation method and application thereof

ActiveCN113788836AGood water solubilityReduce dosageOrganic chemistryFluorescence/phosphorescenceCell membraneEthyl acetate

The invention discloses a near-infrared aggregation-induced emission membrane probe molecule, and also discloses a preparation method of the probe molecule. The preparation method comprises the following steps: S1, adding ethanol into a three-necked flask, conducting vacuumizing, filling nitrogen, sequentially adding two-charge large-steric-hindrance salt, a triphenylamine skeleton and piperidine, and conducting refluxing; S2, after a reaction is finished, subjecting a solution to spin-drying until a small amount of ethanol is left, adding a large amount of ethyl acetate into a formed system, separating red solids out, carrying out standing, and pouring an upper-layer solution away; S3, completely removing a triphenylamine skeleton; S4, washing a solid obtained in the step 3 with acetone to remove ethyl acetate with a high boiling point; and S5, performing reduced-pressure vacuum spin-drying on the solid obtained in the step S4, and carrying out sealing and storing to obtain red solid powder. According to the invention, a water-soluble near-infrared fluorescent molecular probe is synthesized by taking triphenylamine as a skeleton and is used for cell membrane imaging, and a group with relatively large steric hindrance and a long alkyl chain are introduced into the probe to prolong membrane retention time.

Owner:ZHEJIANG NORMAL UNIVERSITY

Composition dye formula for fiber fabric

PendingCN110983823AGood anti-static effectImprove coloring abilityFibre treatmentDyeing processComposite materialNitroso

The invention provides a composition dye formula for a fiber fabric, and belongs to the technical field of home textile printing and dyeing. The composition dye formula for the fiber fabric comprisesthe following ingredients in parts by weight: 10 to 15 parts of methylene blue, 1 to 2 parts of modified graphene oxide, 5 to 10 parts of nitroso dye, 1 to 3 parts of sodium thiosulfate, 1 to 2 partsof polytetrafluoroethylene, 2 to 5 parts of laurate polyoxyethylene ether, 15 to 20 parts of levelling agents, 10 to 20 parts of dyeing accelerators, 10 to 15 parts of a color fixing agent and 50 to 80 parts of water. The modified graphene oxide is prepared through the following steps of taking a nitrogen source; adding the nitrogen source into a graphene oxide solution; performing stirring and mixing; performing ultrasonic treatment for 3 to 4h; and performing centrifugal drying to finally obtain the modified graphene oxide. The composition dye formula has good effects of antistatic performance, fading-resistant performance and the like.

Owner:江苏中诚印染股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com