Production process of antibacterial environment-friendly denim composite fabric

A manufacturing process and composite fabric technology, applied in the direction of processing textile material carriers, textile material containers, synthetic resin layered products, etc., can solve the problems of poor dyeing effect, etc., to improve production quality, good dyeing effect, and simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

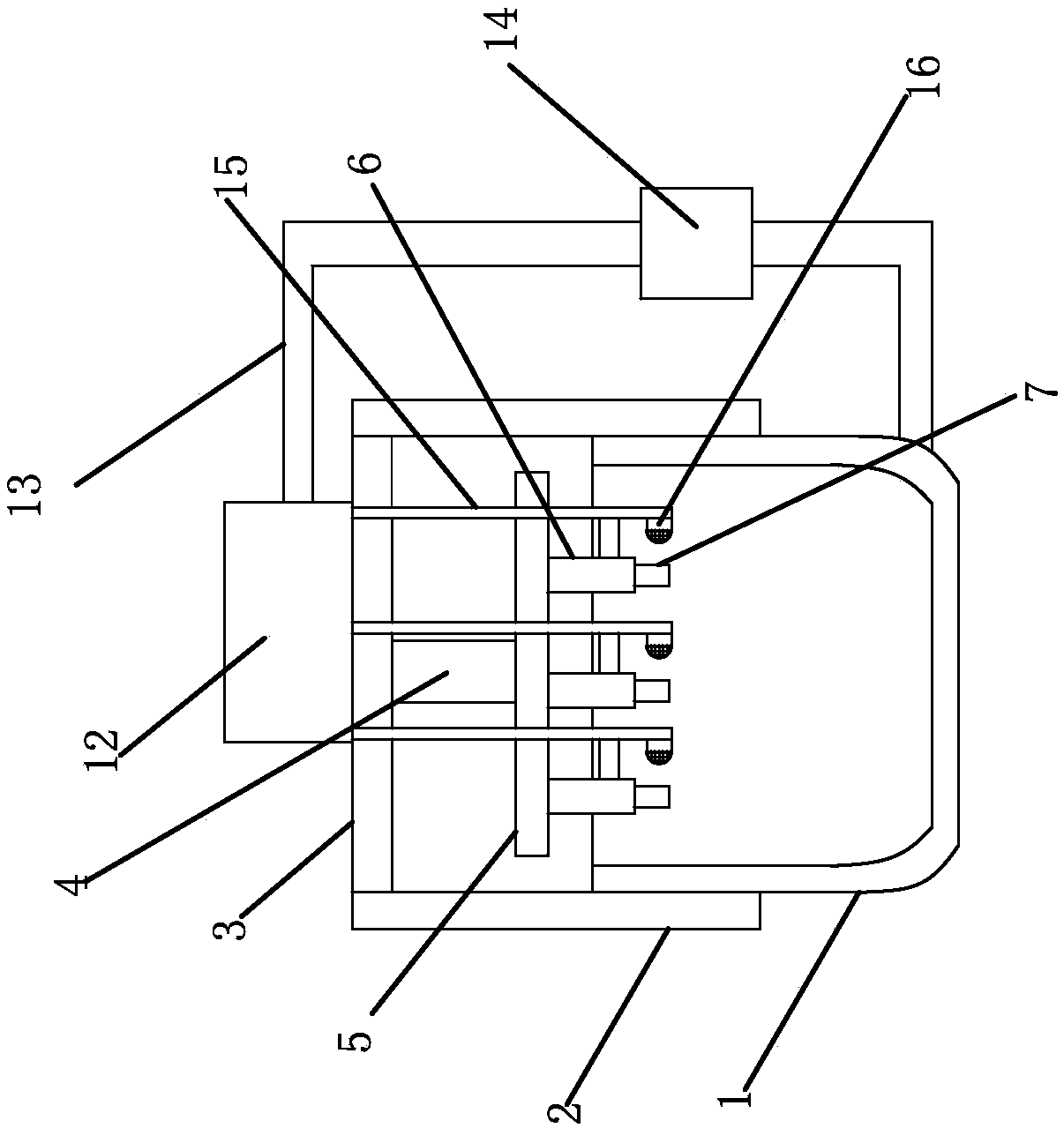

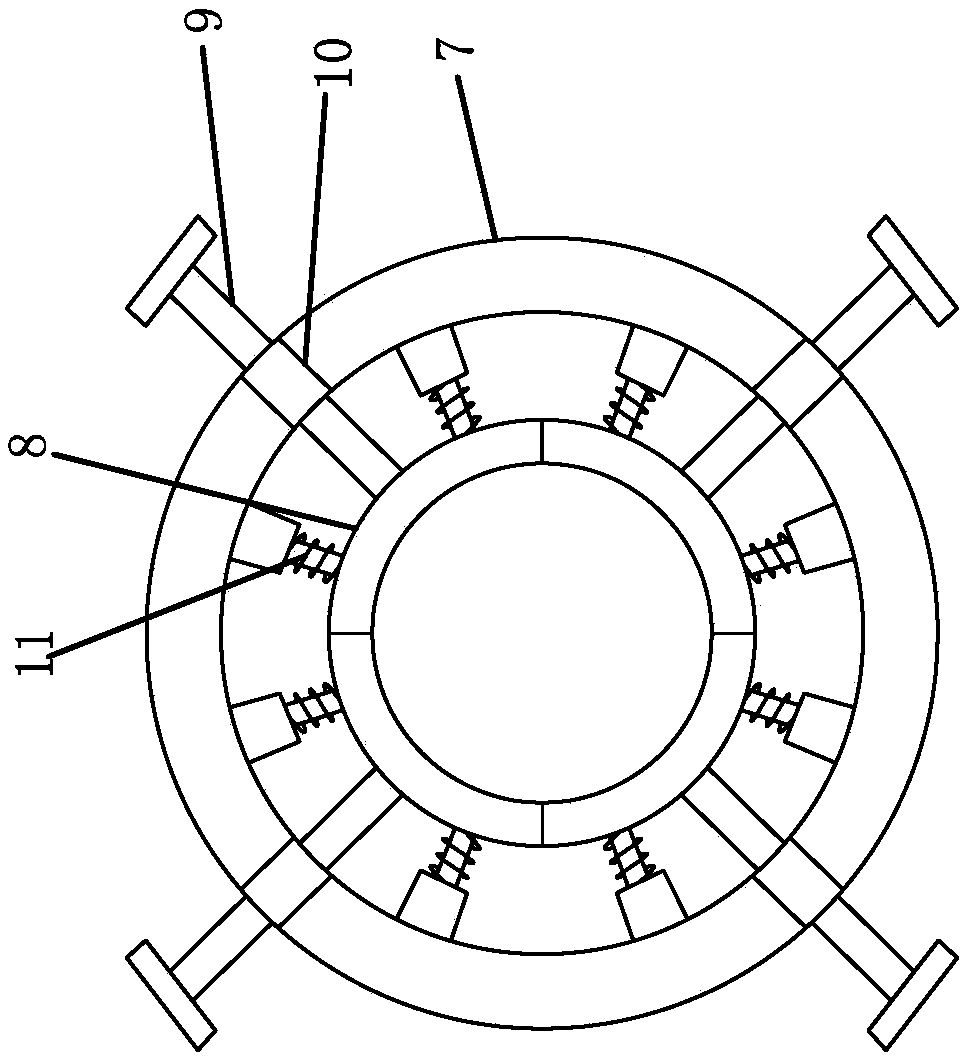

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

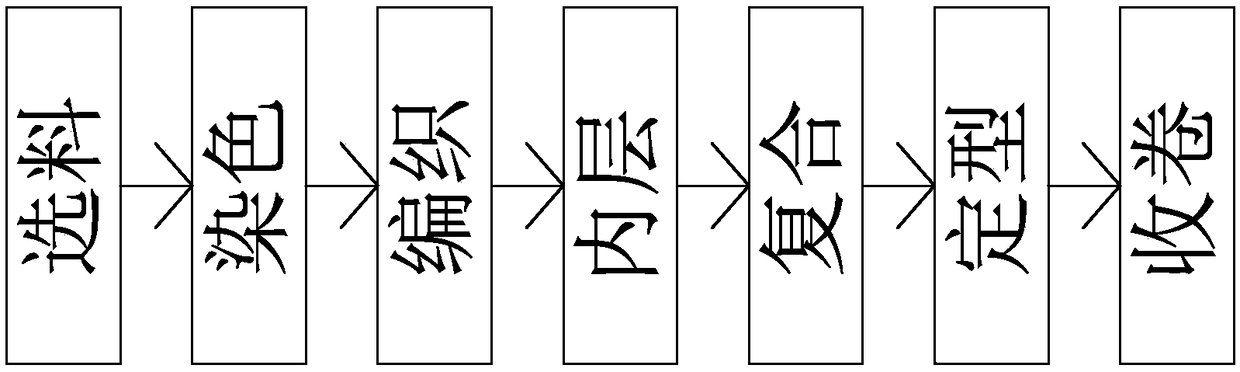

[0027] Such as Figure 1-3 Shown, a kind of manufacturing process of antibacterial environment-friendly denim composite fabric, this manufacturing process comprises the following steps:

[0028] a. Material selection: the blended yarn of spandex fiber and cotton fiber is used as warp, and the blended yarn of hemp fiber and recycled fiber is used as weft;

[0029] b, dyeing: the warp thread and the weft thread are all dyed by a dyeing vat device for yarn dyeing, and the dyeing time is 30-40 minutes;

[0030] c, weaving: the warp and weft in step b are woven into the base cloth by a textile machine, the linear density of the warp is 10.0-13.0tex, and the linear density of the weft is 10.0-13.0tex;

[0031] d. Inner layer: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com