High-temperature pulse flow yarn dyeing machine with ultra low bath ratio and control method thereof

A control method and ultra-low bath technology, applied in the direction of final product manufacturing, textile processing machine accessories, sustainable manufacturing/processing, etc., can solve problems such as time-consuming 3-4 times, large pollution, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

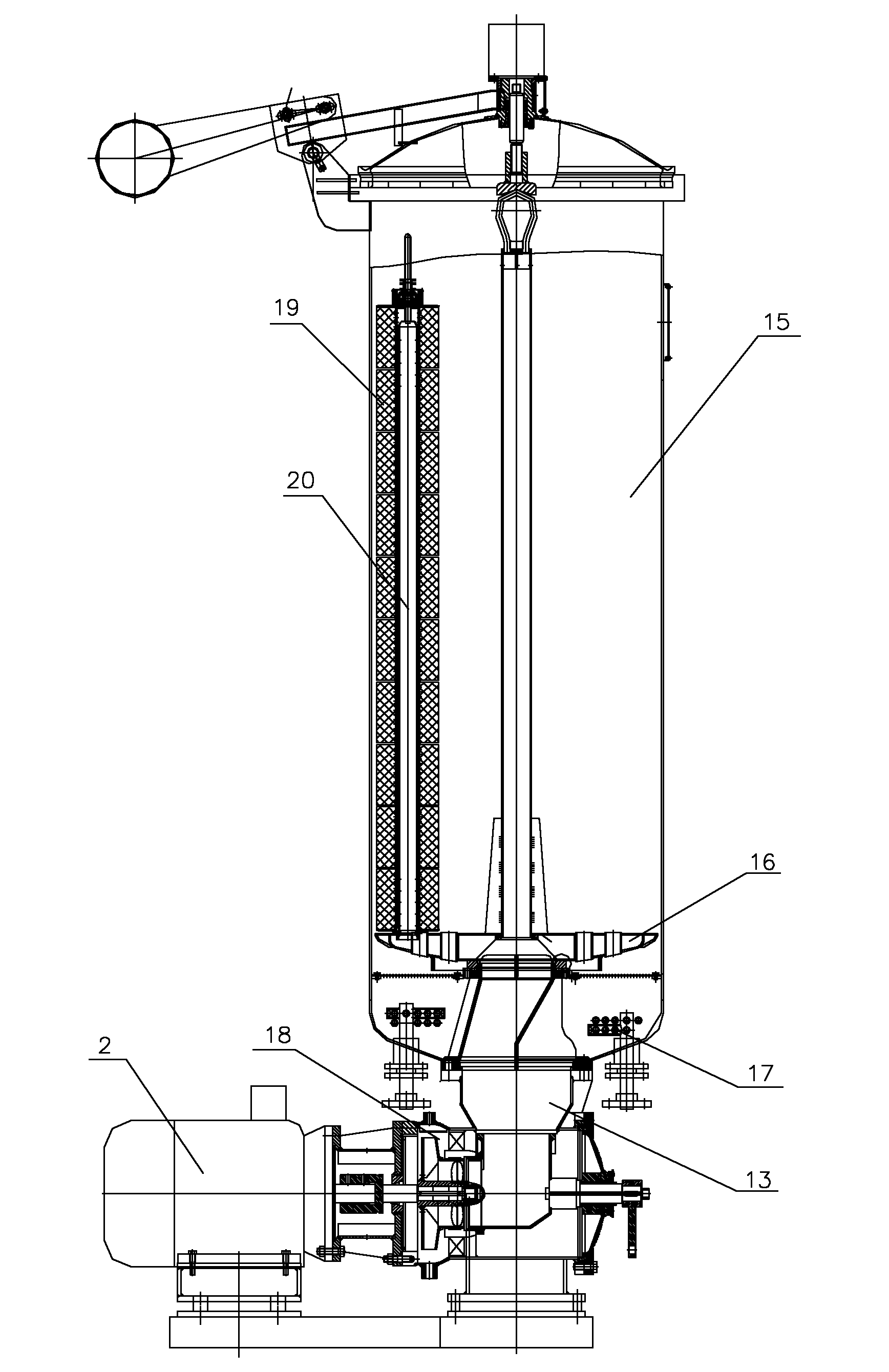

[0114] The main view of "high temperature yarn dyeing machine" is as follows: figure 1 As shown, the yarn dyeing machine consists of the following components:

[0115] (1) The basic configuration includes: main cylinder body, cylinder head, cylinder head counterweight, creel axis, creel disc, spindle, yarn lifting device, cylinder washing device, frequency conversion motor, gas filter, high temperature discharge mixed flow device , Soda mixer.

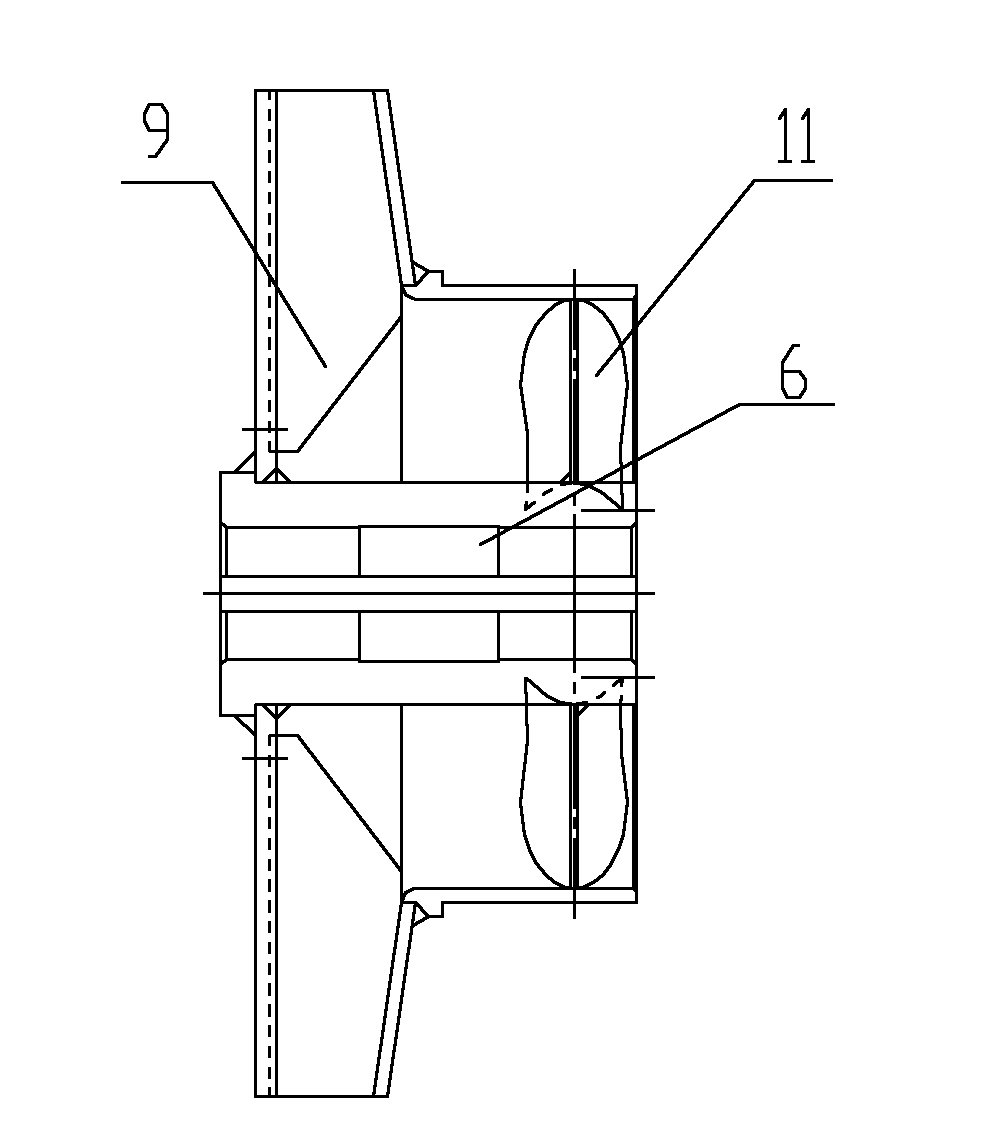

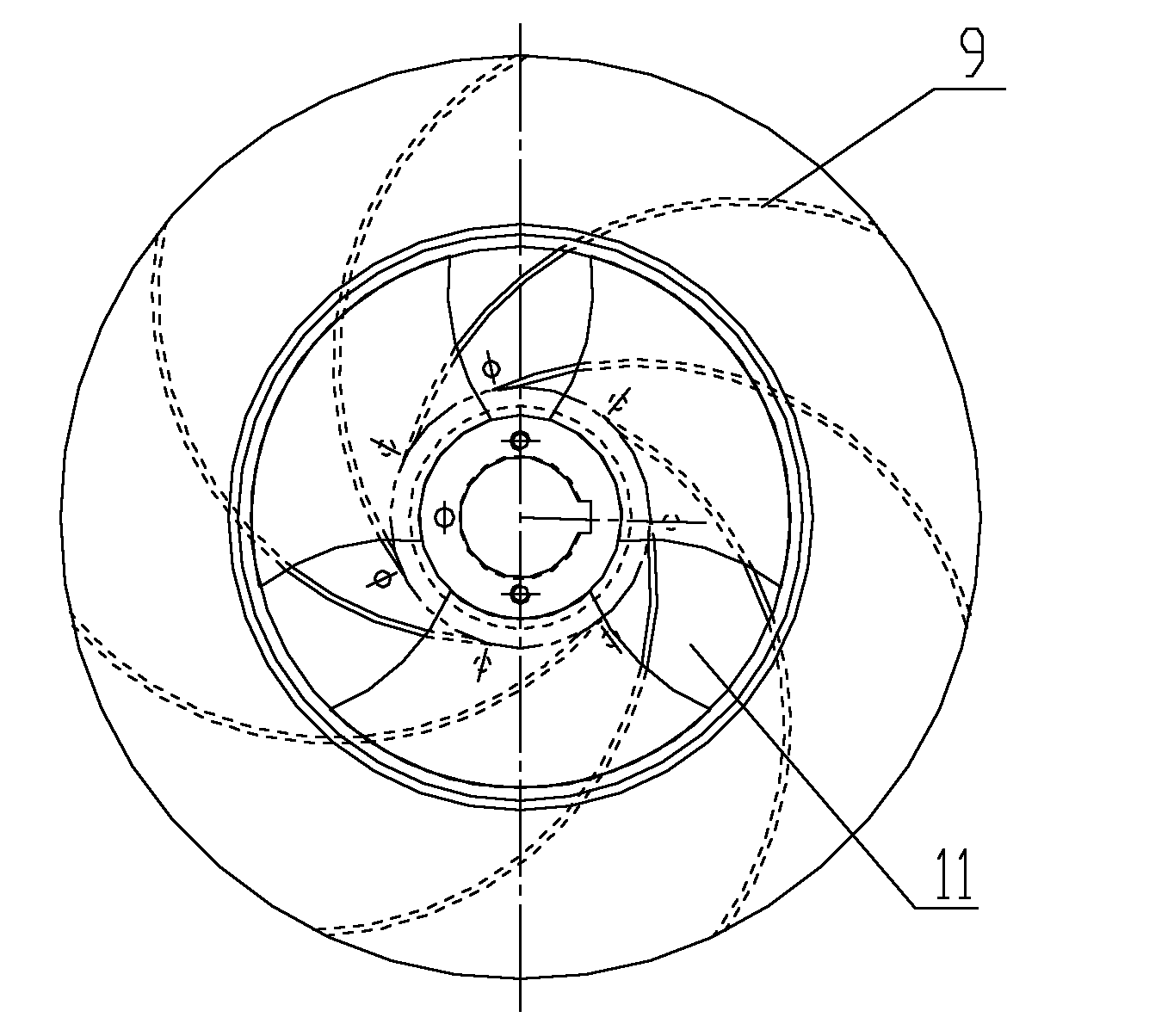

[0116] (2) Pumps and valves: axial flow vane, centrifugal pump vane, main circulation pump, guide vane, guide housing, volume sensor water inlet valve, high temperature discharge cooling valve, high temperature mixed flow discharge valve, master cylinder drain valve 2, Master vat drain valve 1, master vat steam inlet valve, master vat water inlet valve 2, master vat water inlet valve 1.

[0117] (3) Instrument sensors: thermometers, temperature probes, water level measuring devices, zero pressure switches, double needle pressure gaug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com