Ultralow liquor ratio zipper dyeing machine and dyeing process thereof

An ultra-low bath and dyeing machine technology, applied in the field of zipper dyeing machines, can solve the problems of small lift, long process cycle, large pollution, etc., and achieve the effect of reducing hollow volume, uniform contact area, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

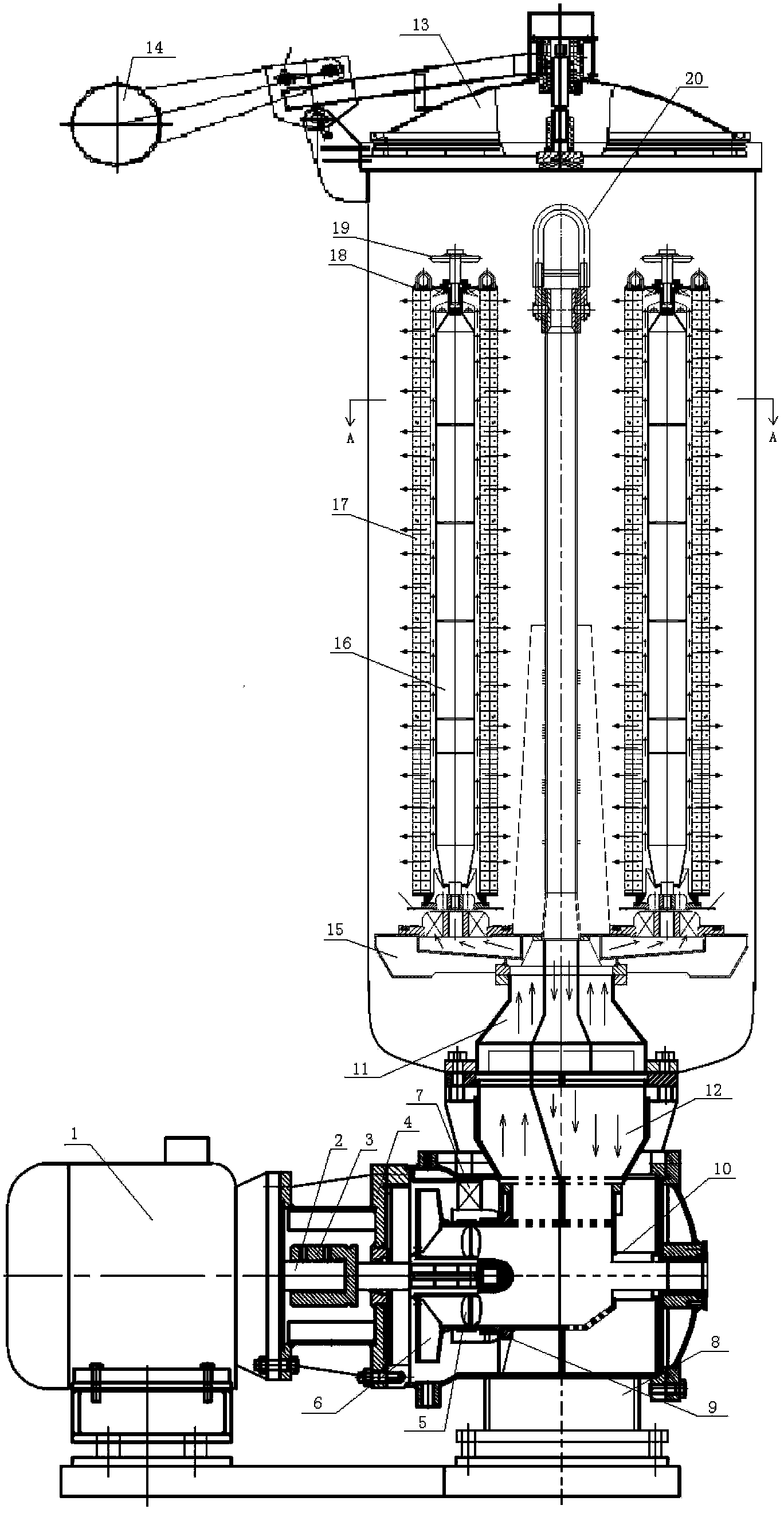

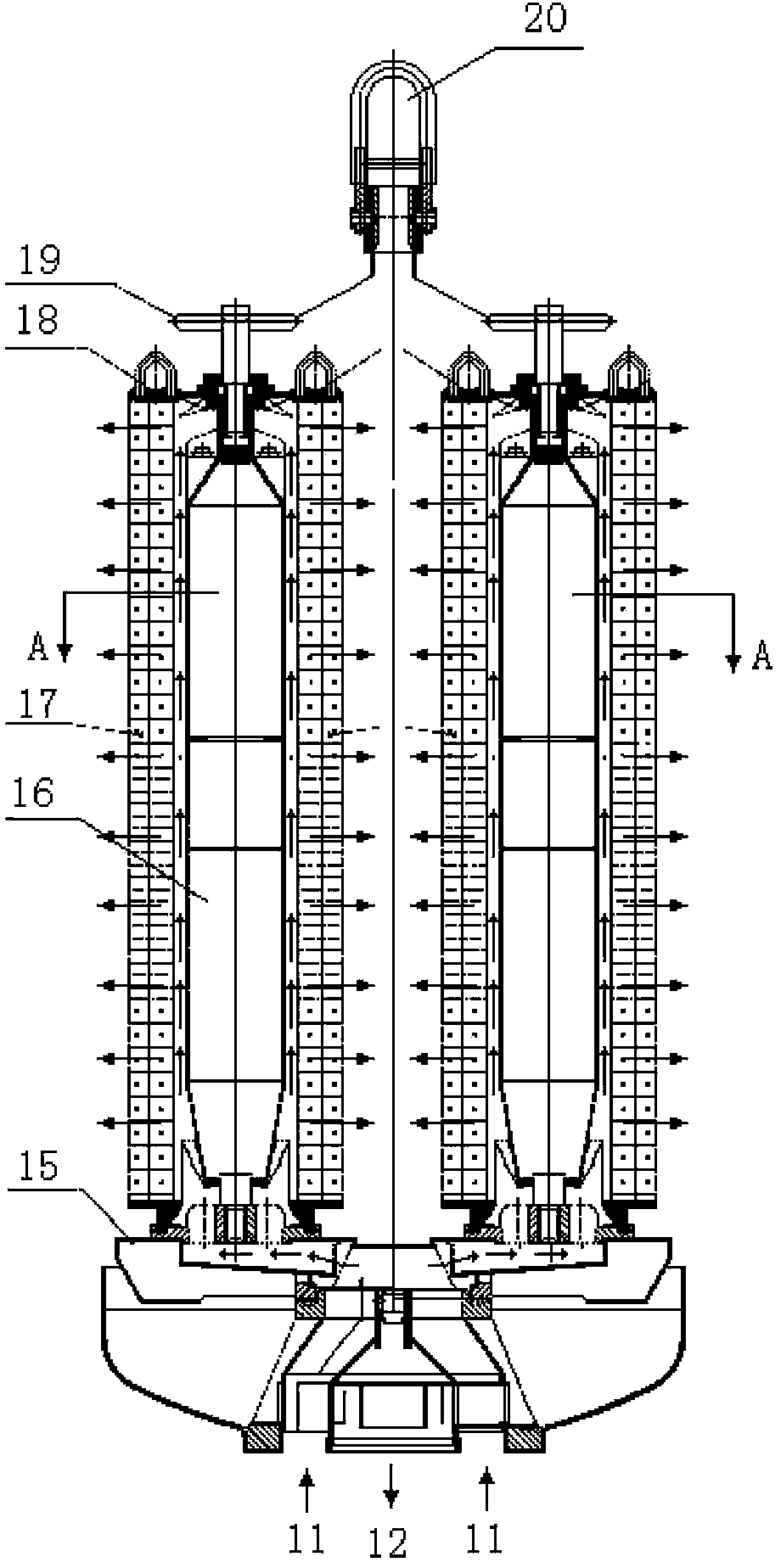

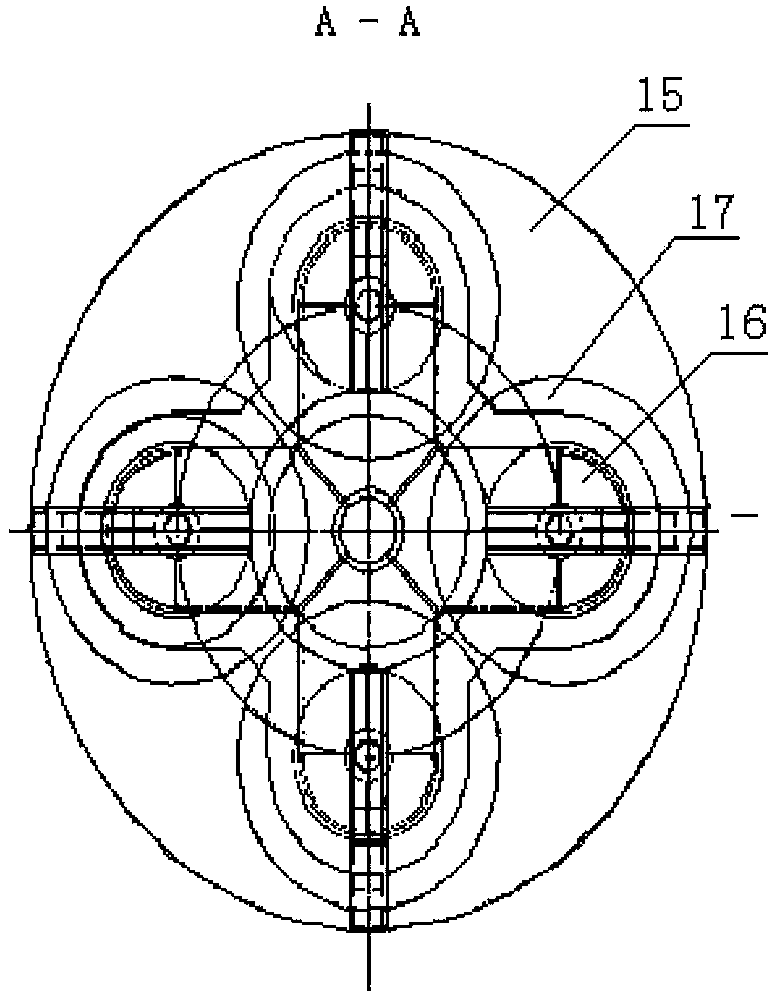

[0037] Such as figure 1 As shown, the ultra-low liquor ratio zipper dyeing machine includes frequency conversion motor 1; motor bearing 2; coupling 3; bearing seat 4; impeller pump blade 5; centrifugal pump blade 6; guide vane 7; ;Impeller housing 10; diversion inlet 11; diversion outlet 12; cylinder head 13; parallel hammer 14; zipper disc seat 15; hollow water drum 16; zipper webbing 17; Rings 20. The zipper beam frame includes diversion inlet 11; diversion outlet 12; zipper tray seat 15; hollow water drum 16; zipper webbing 17; zipper pipe sleeve 18; locking bolt 19; The bobbin cylinder and the circulating pump are connected by a trumpet pipe sleeve, the zipper warp beam frame is connected on the trumpet pipe sleeve, and the circulation pump and its motor are conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com