Paper product printing machine with good heat dissipation performance

A heat dissipation performance and printing machine technology, which is applied to printing machines, rotary printing machines, general parts of printing machinery, etc., can solve the problems of high load of printing machines, different mechanical forms, and inconvenient printing work, etc., and achieve heat dissipation performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

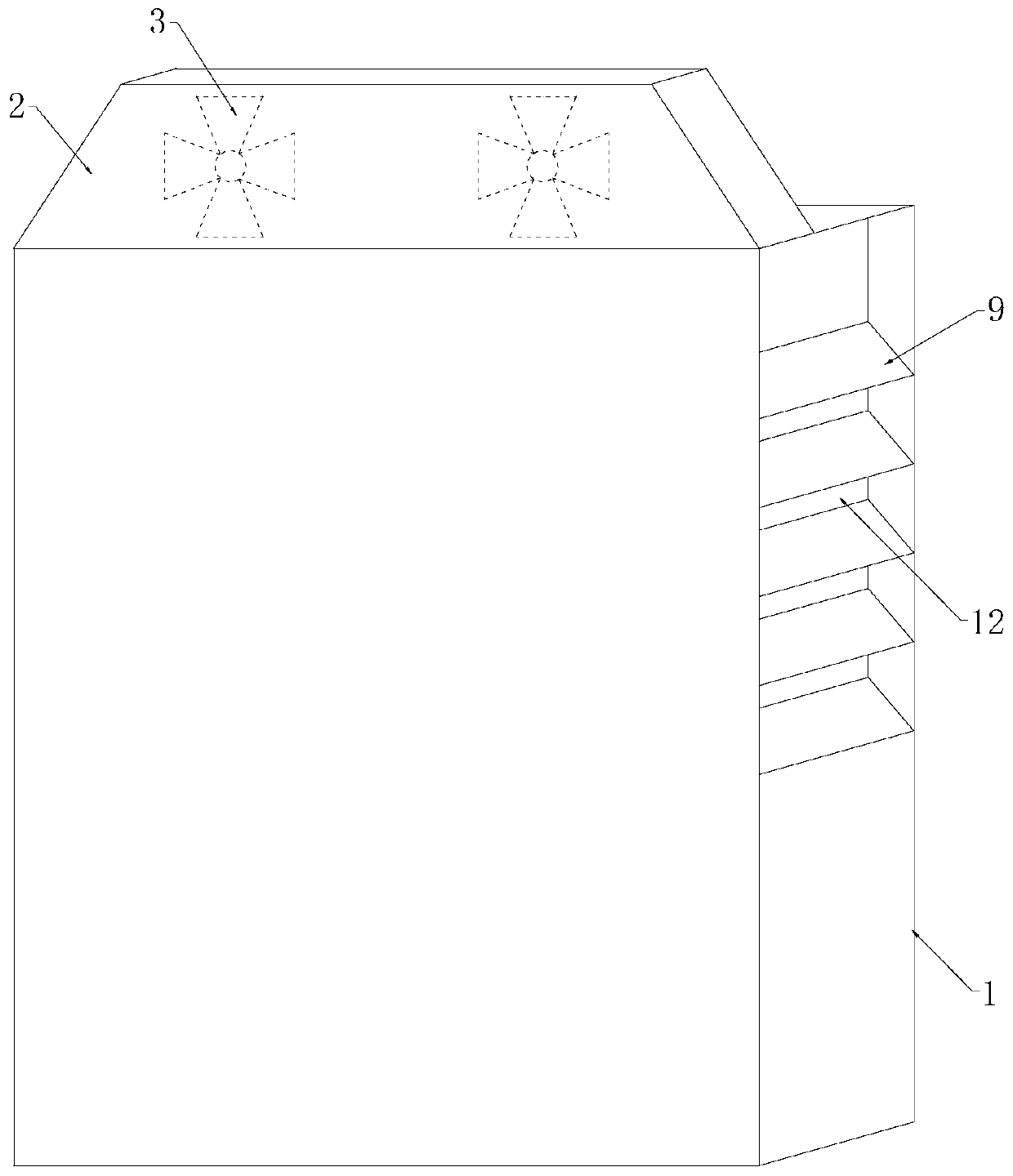

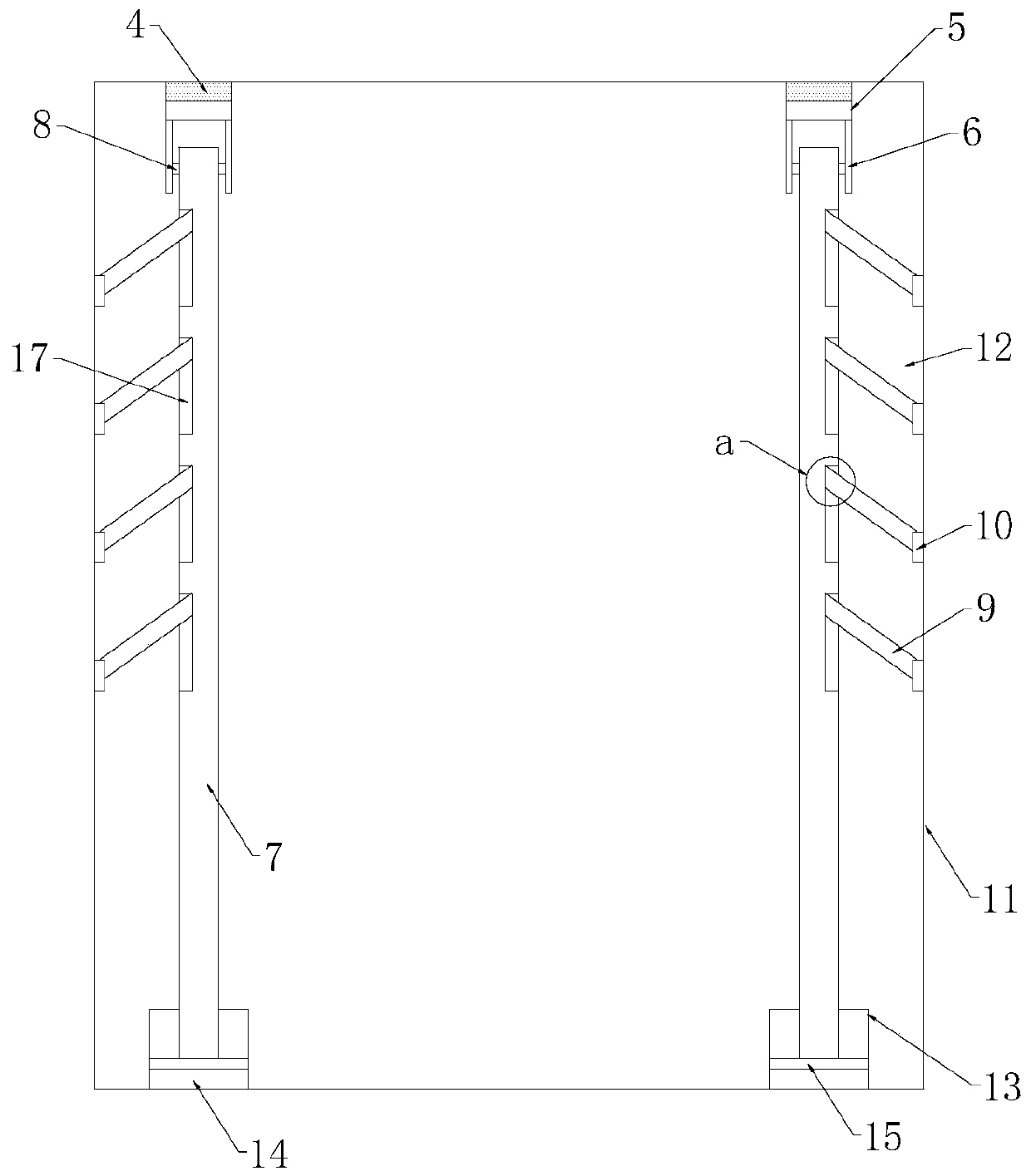

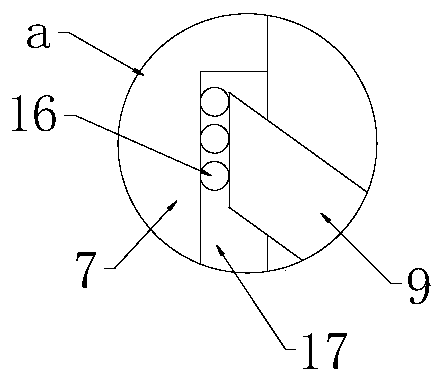

[0022] Example: such as Figure 1-3 As shown, a paper printing machine with good heat dissipation performance includes a printing machine body 1, a heat dissipation mounting plate 2 is installed on the printing machine body 1, a plurality of heat dissipation fans 3 are installed in the heat dissipation installation plate 2, and a plurality of heat dissipation fans 3 pass through the circuit The wire is connected to the contact switch 4 arranged on both sides of the printing machine body 1. The contact switch 4 is installed in the inner cavity of the guide cylinder 5. The guide plate 6 is fixed on both sides of the bottom of the guide cylinder 5, and the upper end of the temperature displacement roller 7 is covered. The set guide shaft 8 is slidingly connected to the chute embedded in the middle of the guide plate 6, and the temperature displacement roller 7 is provided with a number of adjustment chambers 17, one end of the cooling plate 9 is movably clamped in the adjustment c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com