Supercritical carbon dioxide printing and dyeing technology and system

A technology of carbon dioxide and printing and dyeing process, applied in the field of printing and dyeing, can solve the problems of redundant equipment, substandard product uniformity, heat loss, etc., reduce equipment cost and heating cost, speed up the diffusion and adsorption process, and improve printing and dyeing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

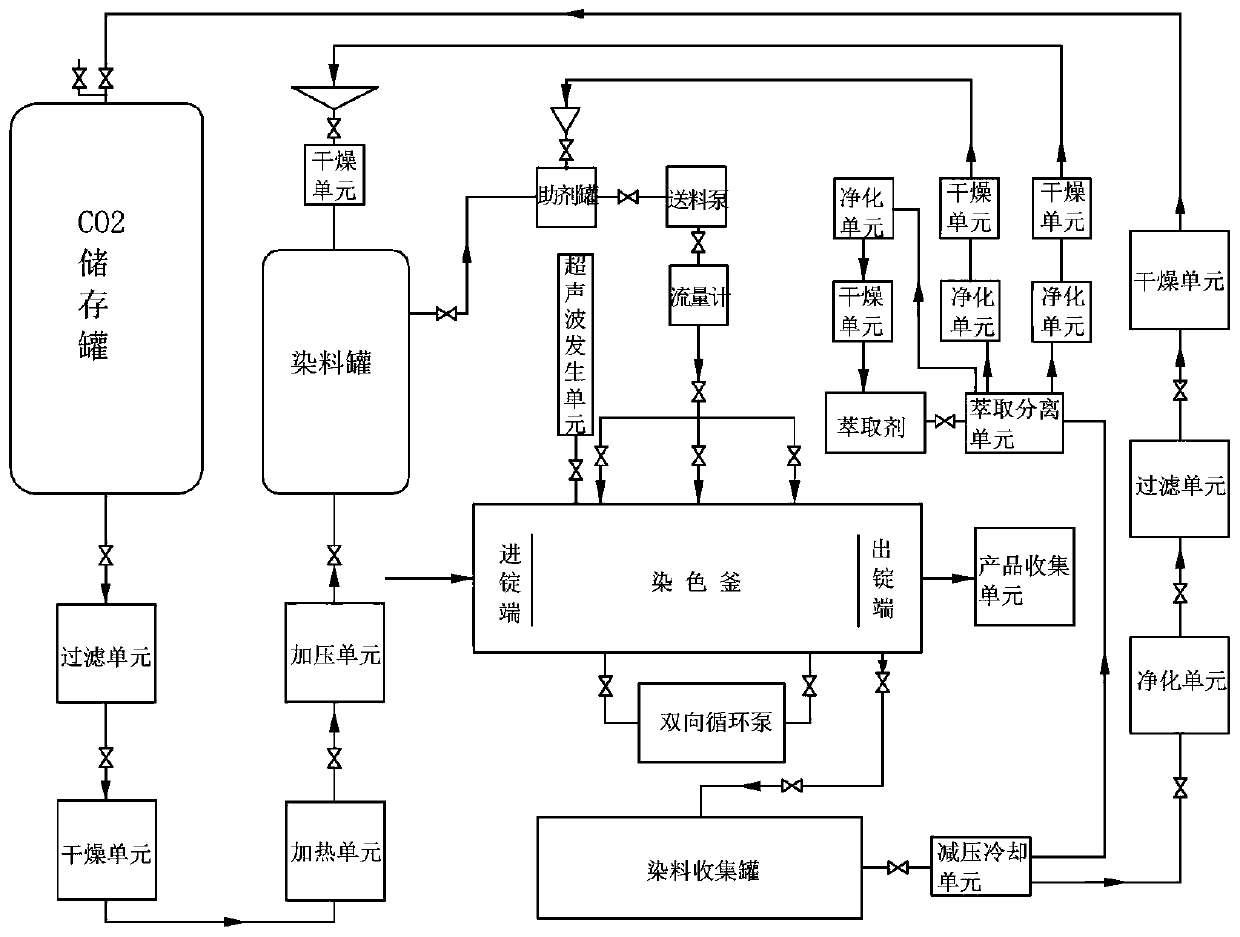

[0037] please participate figure 1 As shown, a kind of supercritical carbon dioxide printing and dyeing process is provided, comprising the steps:

[0038] (1) Convert liquid carbon dioxide into supercritical carbon dioxide after pressurization and heat treatment;

[0039] (2) mixing supercritical carbon dioxide and dyestuff to form a dye liquor;

[0040] (3) Pass the dyeing solution into the dyeing kettle, and dye the spindles from the spindle inlet end under the action of ultrasonic waves and bidirectional circulation. After the spindles are dyed mature, the spindles are sent out from the spindle outlet end to enter the next process;

[0041] (4) Collect the remaining dye liquor after dyeing and carry out decompression and separation treatment, and the separated dye and supercritical carbon dioxide are respectively purified and dried as the liquid carbon dioxide raw material of step (1) and the liquid carbon dioxide raw material of step (3). The above-mentioned dye raw mat...

Embodiment 2

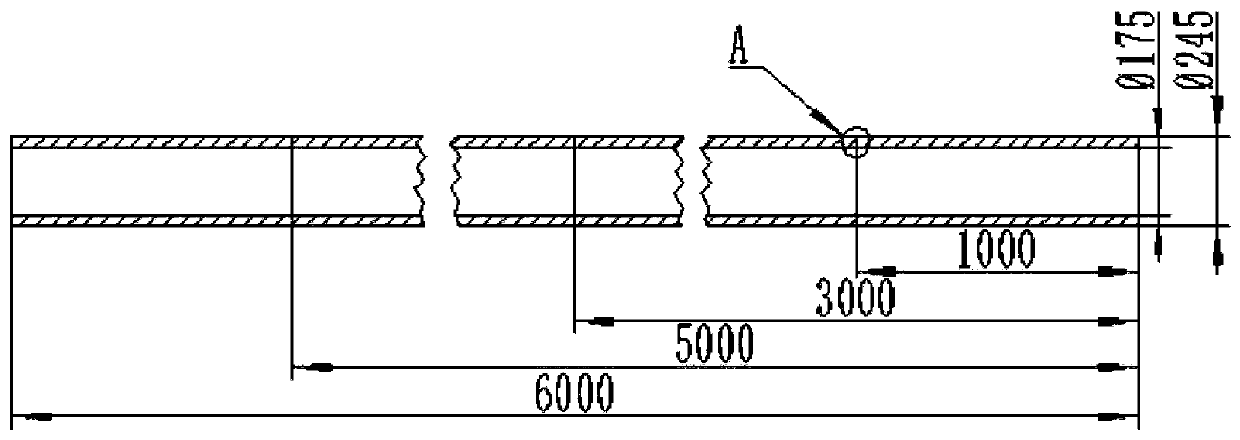

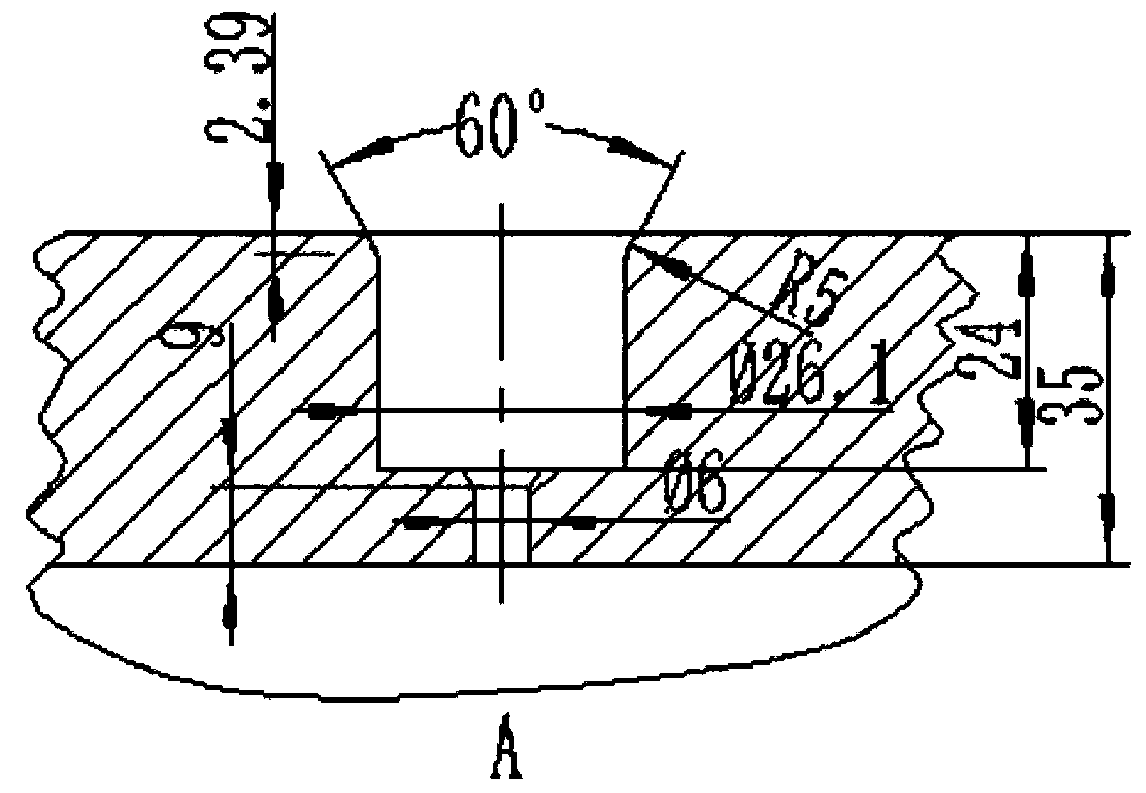

[0047] see figure 1 Shown, provide a kind of supercritical carbon dioxide printing and dyeing system as described technology, this supercritical carbon dioxide printing and dyeing system comprises: CO 2 Storage tanks, dye tanks, dyeing tanks, dye collection tanks, decompression cooling units and extraction separation units, of which:

[0048] The CO 2 The storage tank is sequentially connected to the dye tank through a pipeline through a filter unit, a drying unit, a heating unit and a pressurizing unit, so that the CO 2 The carbon dioxide in the storage tank is converted into supercritical carbon dioxide after being pressurized and heated, and the supercritical carbon dioxide is passed into the dye tank and mixed with the dye to form a dye liquor;

[0049] The dye tank is connected to the dyeing kettle through the auxiliary tank and the flowmeter in turn through the pipeline, and is used to send the dye solution into the dyeing kettle to dye the spindles from the spindle in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com