Viscose fiber and leecy fiber blended yarn and spinning technology thereof

A kind of color fiber, viscose fiber technology, applied in the direction of fiber mixing, fiber processing, yarn, etc., can solve the problem of the antibacterial effect cannot be effectively guaranteed, increase the process procedures, time-consuming and laborious, etc., to achieve a rich sense of hierarchy, simplification technology, the effect of ensuring the antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Raw material: 70% viscose fiber and 30% Li Cai fiber with fiber content blending ratio. The specification of viscose fiber is 1.33dtex*38mm, the specification of Licai fiber is 1.33dtex*38mm, and the two are mixed.

[0030] 2. Spinning process: FA002 automatic cotton grabbing machine—FA035 mixed opener—FA106C carding opener—SFA161A vibrating cotton feeder—FA076F single beater lap machine—FA226A carding machine—FA318A draw frame—FA472 Roving frame—ZJ1298 spinning frame.

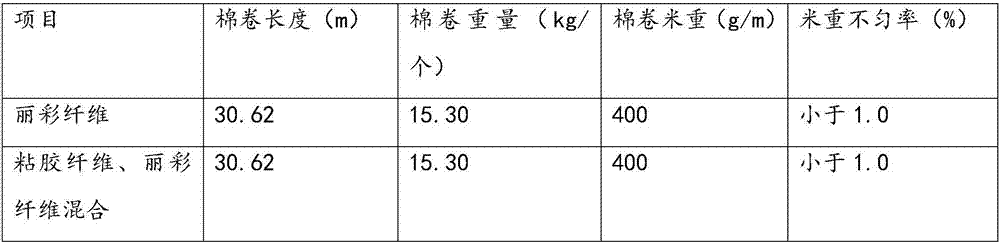

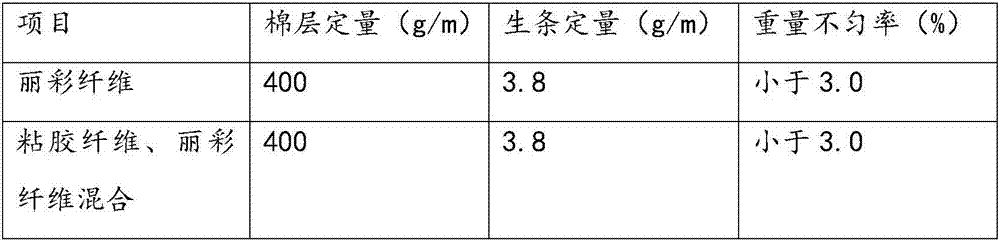

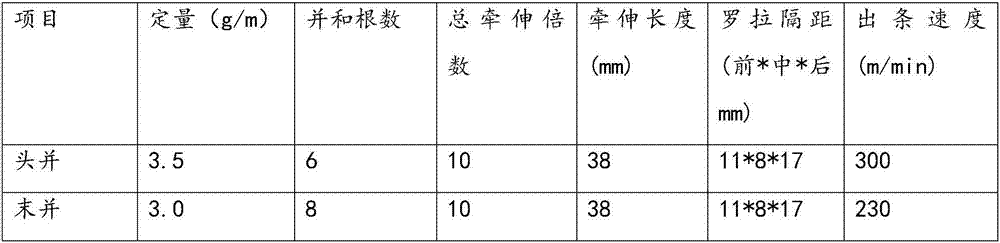

[0031] 3. The specific process of a viscose fiber and Li Cai fiber blended yarn is as follows:

[0032] (1) The Licai fiber is mixed with the viscose fiber after the opening and cleaning process and the carding process through the FA025 multi-bin cotton blender, the air volume of the blender is 5200m 3 / h, the pressure is 100pa, combined with the three methods of air mixing, laminated mixing and intensive mixing, it can ensure the uniform mixing of Li Cai fiber and viscose fiber;

[0033] (2) The mixed Lica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com