Circulating dyeing machine for garments

A technology for dyeing machines and garments, which is applied to textile processing machine accessories, liquid/gas/steam finished product treatment, textiles and papermaking, etc. It can solve problems such as uneven dyeing, too light local color, and unsuitable garment dyeing, etc., to achieve Efficient dyeing and uniform dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

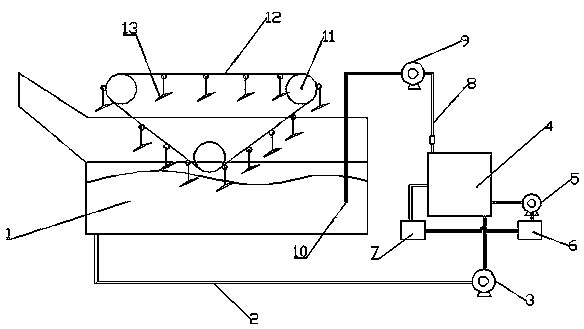

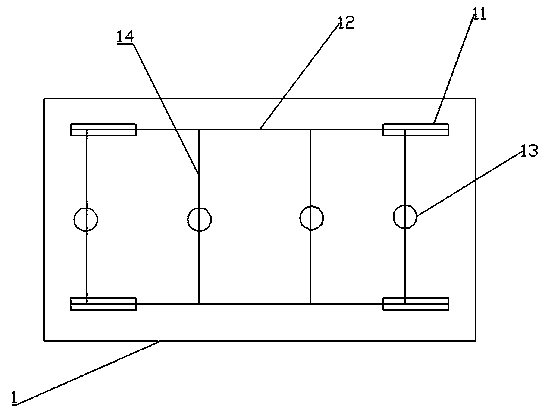

[0010] figure 1 and figure 2 In the schematic diagram of the garment cycle dyeing machine shown, the garment cycle dyeing machine is composed of a dyeing tank 1, a garment suspension device and a color liquid adjustment device. The garment suspension device includes at least two sets of rotating shafts 11, on which a conveyor belt 12 is equipped, and on the conveyor belt 12 A number of hangers 13 for fixing ready-made garments are set; the color liquid adjustment device includes a color mixing tank 4, a color liquid box 6 and a detection device 7, the color mixing tank 4 is connected to the color liquid box 6 through the A pump 5, and the color liquid box 6 enters the pipeline connection detection device 7 Connect the detection device 7 again; the lower end of the color mixing tank 4 is connected to the B pump 3, and the B pump 3 is connected to the lower end of the dyeing pool 1 through the B pipeline 2; the upper end of the color mixing tank 4 is connected to the C pump 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com