Dyeing method for improving dyeing performance of polyimide fibers

A polyimide fiber, dyeing performance technology, applied in the direction of dyeing, textiles and papermaking, etc., can solve the problems of low dyeing rate, low color fastness, etc., to achieve simple operation, low requirements for equipment and steps, and good protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

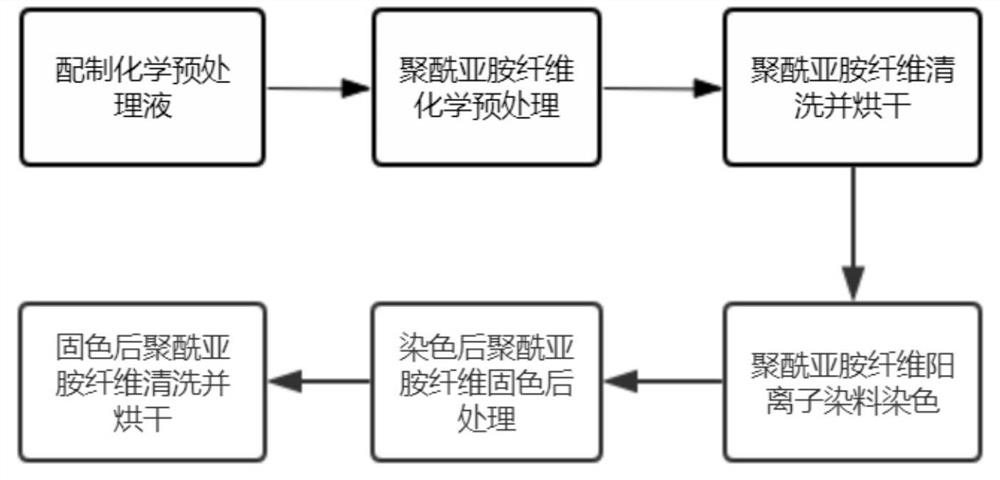

Method used

Image

Examples

Embodiment 1

[0027] A dyeing method for improving the dyeing performance of polyimide fibers. The specific steps are: before the polyimide fibers are dyed with cationic dyes, the polyimide fibers are immersed in an alkaline solution at a bath ratio of 15:1. Heat the dyeing solution to 80°C, keep the solution for 70 minutes, then cool the dyeing solution to room temperature, take out the fiber and rinse it in a 0.3mol / L weak acidic solution, then wash it with deionized water, and then dry it to obtain lye pretreatment The finished polyimide fiber; the pretreated fiber, according to the bath ratio of 15:1, immerse the chemically pretreated polyimide fiber in the dyeing solution, heat the dyeing solution to 70 ° C, and keep the solution for 70 minutes, and then Let the dyeing solution cool down to room temperature, take out the fibers, and then wash them with water, soap them, wash them with water, and dry them in order to obtain the dyed polyimide fibers; immerse the above-mentioned dyed poly...

Embodiment 2

[0029]Before the polyimide fiber is dyed with cationic dyes, immerse the polyimide fiber in the alkaline solution according to the bath ratio of 10:1, heat the dyeing solution to 60°C, keep the solution for 30 minutes, and then cool the dyeing solution to At room temperature, after taking out the fiber, rinse it with 0.1mol / L weak acidic solution, then wash it with deionized water, and then dry it to obtain the polyimide fiber after pretreatment with alkali solution; : 1. Immerse the chemically pretreated polyimide fibers in the dyeing solution, heat the dyeing solution to 60°C, and keep the solution for 40 minutes, then cool the dyeing solution to room temperature, take out the fibers and wash them with water and soap in turn. Washing, washing, and drying to obtain dyed polyimide fibers; immerse the above-mentioned dyed polyimide fibers in a preheated color-fixing solution for color-fixing treatment, and the color-fixing solution contains 50% (o.w.f) Color agent, color fixing...

Embodiment 3

[0031] Before the polyimide fiber is dyed with cationic dyes, the polyimide fiber is immersed in the alkaline solution according to the bath ratio of 12:1, the dyeing solution is heated to 70°C, and the solution is kept for 40 minutes, and then the temperature of the dyeing solution is cooled to At room temperature, take out the fiber and rinse it with 0.2mol / L weak acidic solution, then wash it with deionized water, and then dry it to obtain the polyimide fiber pretreated by alkali solution; : 1. Immerse the chemically pretreated polyimide fibers in the dyeing solution, heat the dyeing solution to 80°C, and keep the solution for 50 minutes, then cool the dyeing solution to room temperature, take out the fibers and wash them with water and soap in turn. Washing, washing with water, and drying to obtain dyed polyimide fibers; immersing the above-mentioned dyed polyimide fibers in a preheated color-fixing solution for color-fixing treatment, the color-fixing solution contains 60%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com